Depressurizing diffusion furnace and carrier plate bearing device

A technology of a carrying device and a diffusion furnace, which is applied to furnaces, furnace types, electrical components, etc., can solve the problems of difficulty in preparing shallow surface PN junctions, high sheet resistance, and poor control of doping uniformity of silicon wafers, and achieves tightness. Good, large partial pressure ratio, reducing the effect of surface recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

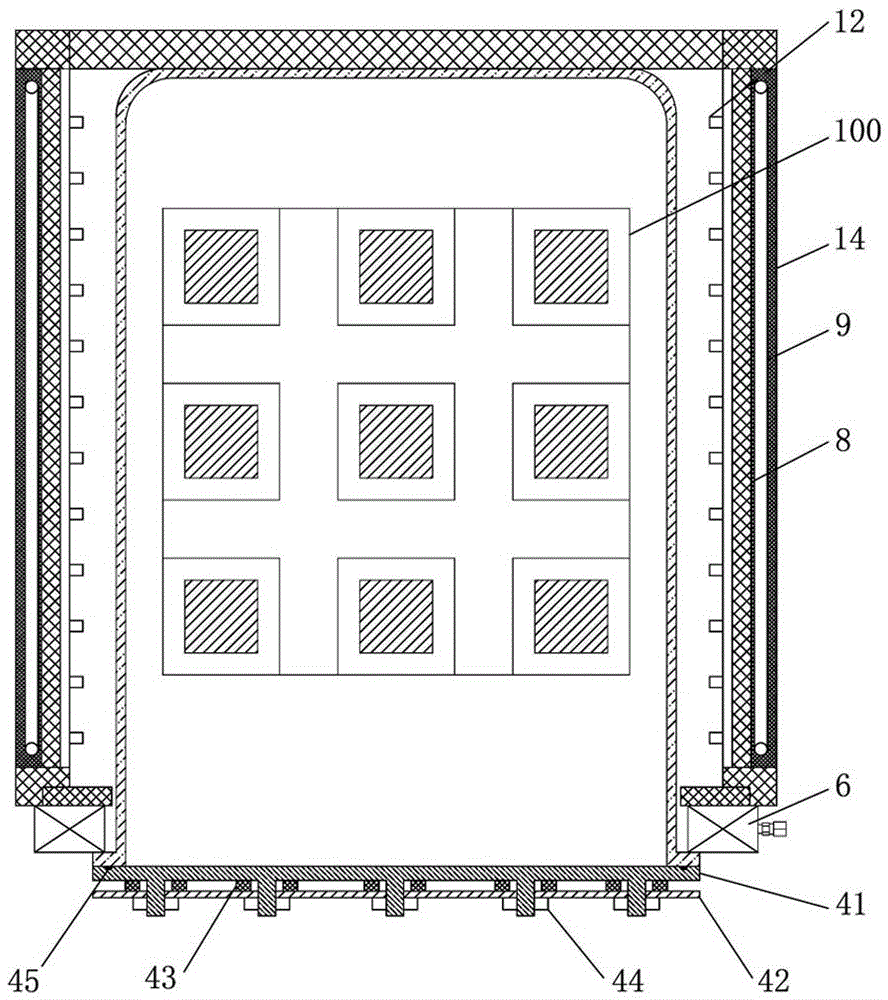

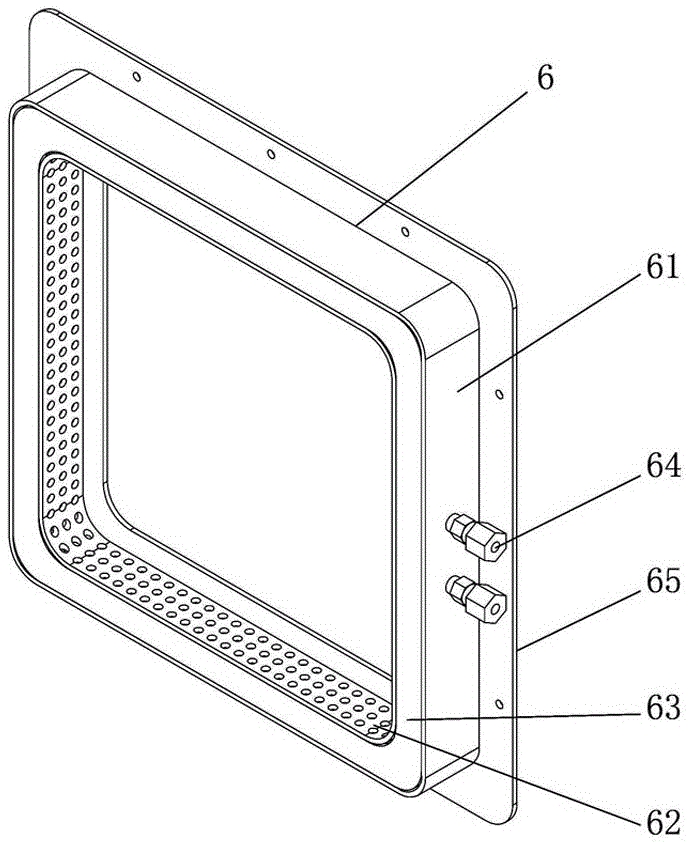

[0031] Figure 1 to Figure 4 A decompression diffusion furnace of the present invention is shown, which includes a box-type resistance furnace body 3, a furnace door assembly 4 and a quartz reaction chamber 5. The quartz reaction chamber 5 is placed in the box-type resistance furnace body 3, and through the furnace door Component 4 is sealed, and the inner side of the furnace door component 4 is provided with an annular sealing ring 45 that closely fits the end face of the quartz reaction chamber 5. The cooling device 6 can be used to cool the annular sealing ring 45 to avoid overheating failure and improve the sealing performance of the decompression diffusion furnace. The silicon wafer to be processed is placed in the quartz reaction chamber 5 . In the decompression diffusion furnace of the present invention, the silicon wafer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com