Method for subjecting red light semiconductor laser device to Zn diffusion operation

A laser and semiconductor technology, used in semiconductor lasers, lasers, laser parts, etc., can solve the problems of inability to precisely control process parameters and inability to achieve mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Utilize MOCVD to carry out the method for Zn diffusion of red light semiconductor laser, the steps are as follows:

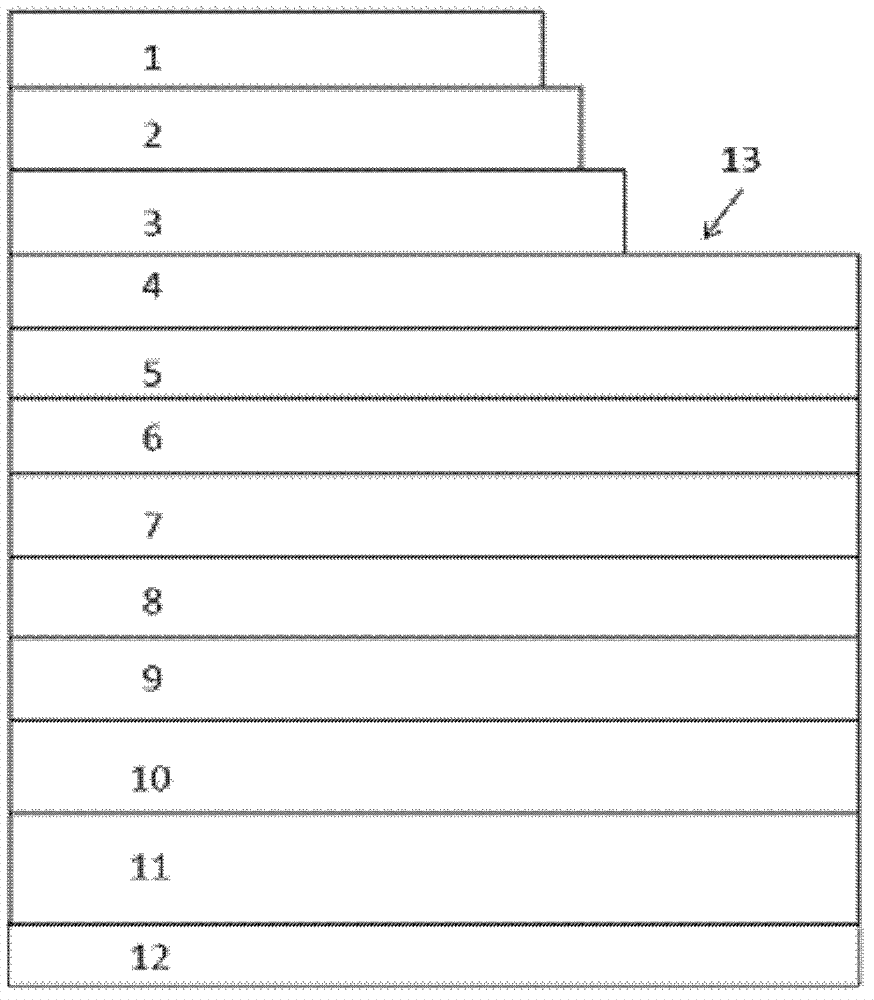

[0051] Step 1. Deposit an epitaxial layer on the semiconductor substrate by MOCVD, and the epitaxial layer includes: a buffer layer, an n-type confinement layer, an N-region intrinsic waveguide layer, an intrinsic compressive strain multi-quantum well active region, and a P-region intrinsic waveguide layer. Sign waveguide layer, p-type confinement layer, GaInP and ohmic contact layer.

[0052] The buffer layer 10 is made of Si-doped GaAs material, and the concentration of doped atoms is 1E18 atoms / cm 3 , with a thickness of 0.5 microns; the n-type confinement layer 9 is made of Al 0.5 In 0.5 P(AlInP) material, the concentration of doped atoms is 1E18 atoms / cm 3 , with a thickness of 11 microns; the N-region intrinsic waveguide layer 8 adopts (AlxGal-x) 0.5 In 0.5 P(AlGaInP) material with a thickness of 0.2 microns; the intrinsic compressive strain mu...

Embodiment 2

[0060] Embodiment 2: The difference from Embodiment 1 is the difference in the structure of the epitaxial layer of the laser and the change of the process conditions for Zn expansion

[0061] Another epitaxial structure adopted is mainly to add a GaInP layer between the buffer layer and the n-type confinement layer to ensure the stability of the lattice transition, and the thickness of each layer is also different.

[0062] Step 1, using MOCVD to deposit an epitaxial layer on the semiconductor substrate, the epitaxial layer includes: buffer layer, GaInP, n-type confinement layer, intrinsic waveguide layer, intrinsic compressive strain multi-quantum well active region, p-type confinement layer, GaInP and ohmic contact layer.

[0063] The buffer layer 10 is made of silicon-doped GaAs material, and the concentration of doped atoms is 1E18 atoms / cm 3 , with a thickness of 0.5 microns; the GaInP layer 4 has a thickness of 0.02 microns; the n-type confinement layer 9 adopts (AlxGal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com