Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Improve wire performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

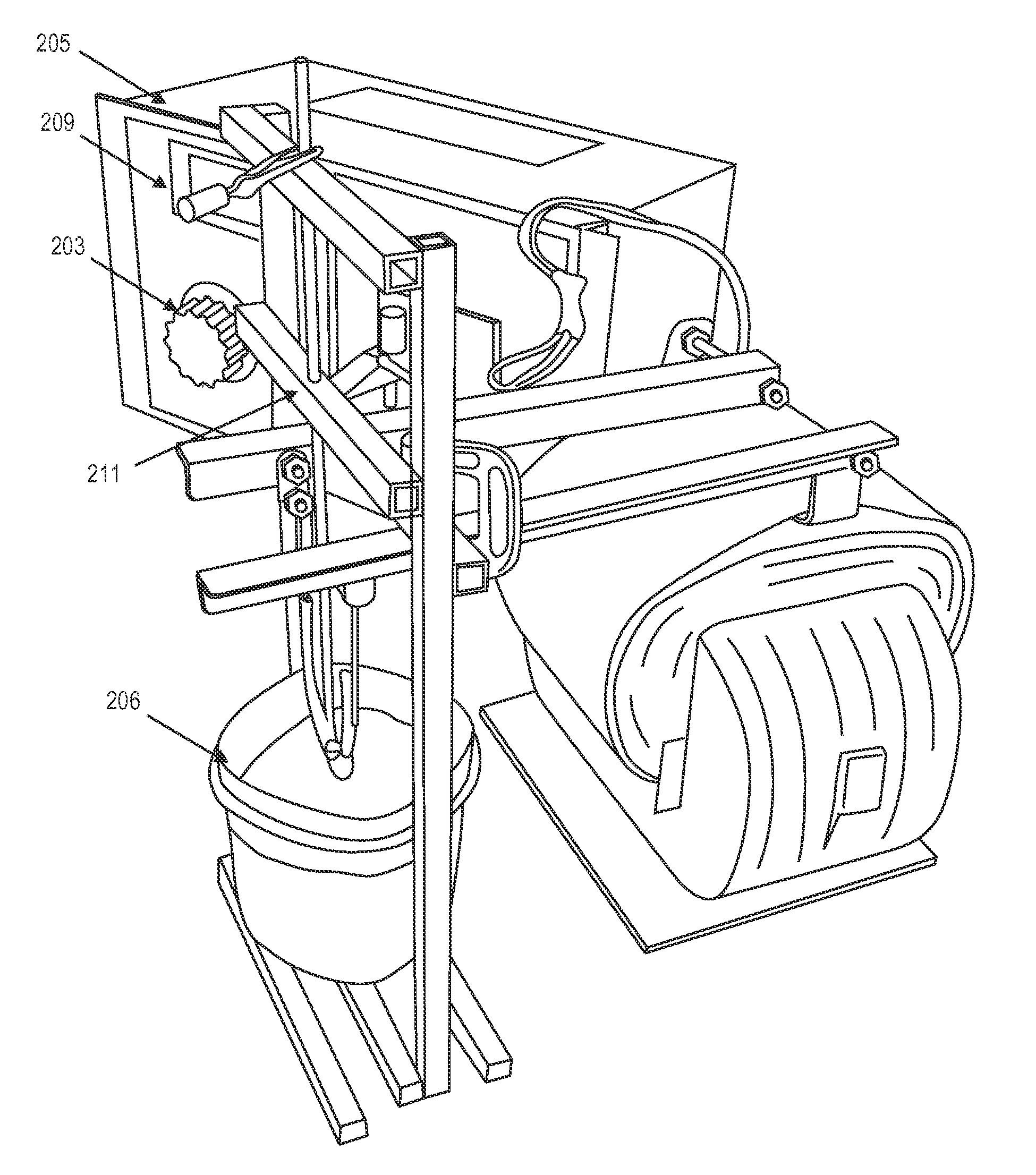

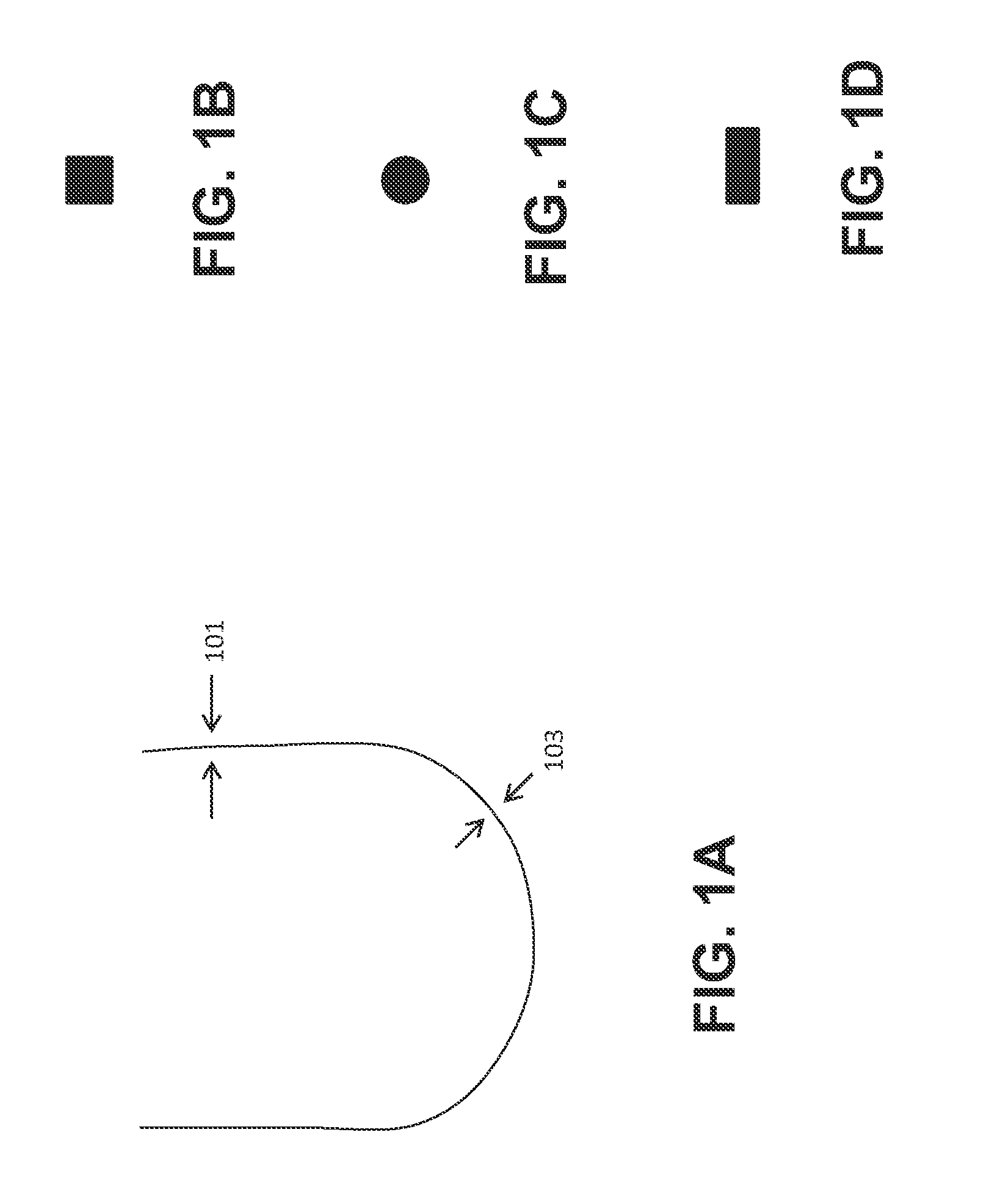

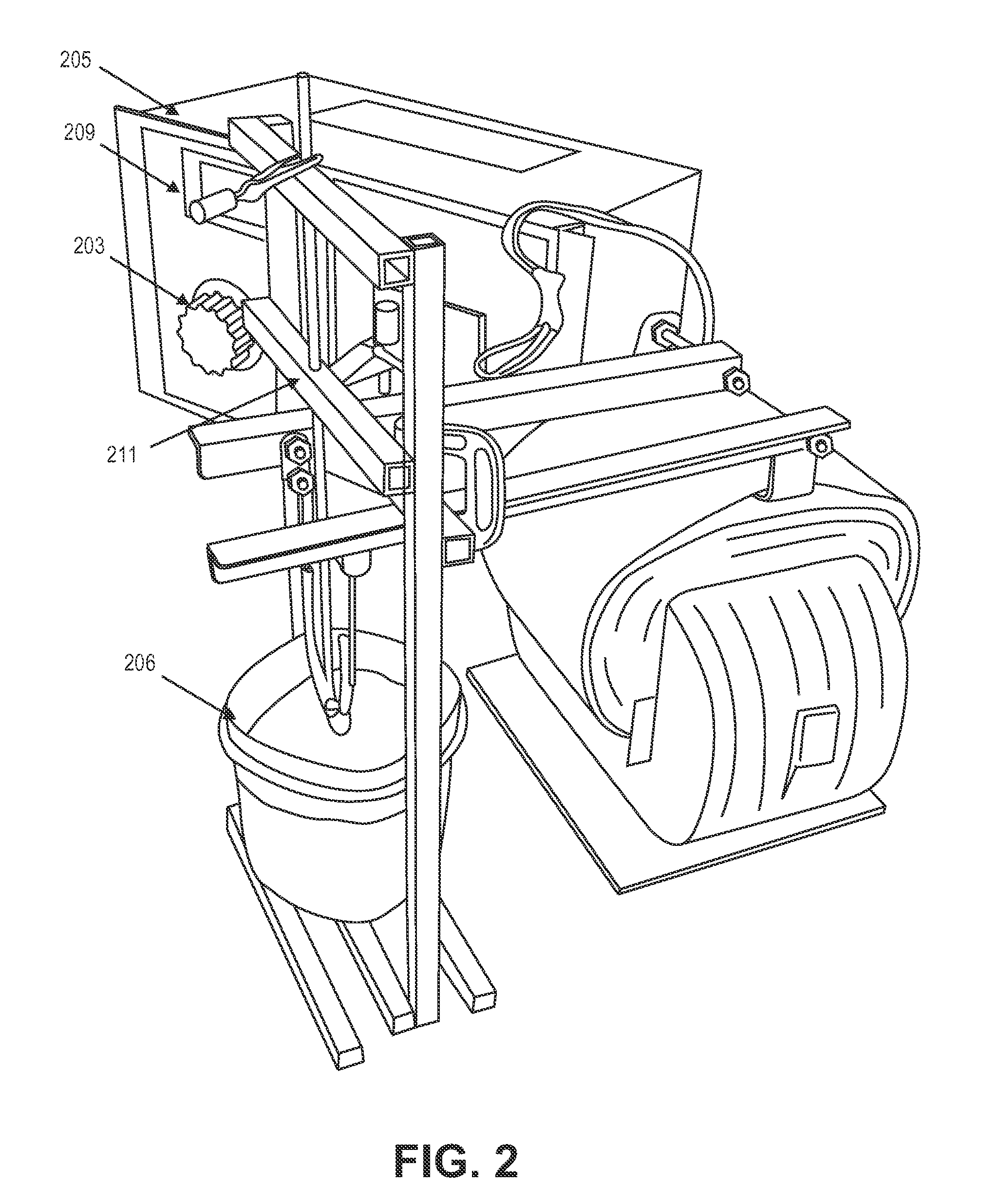

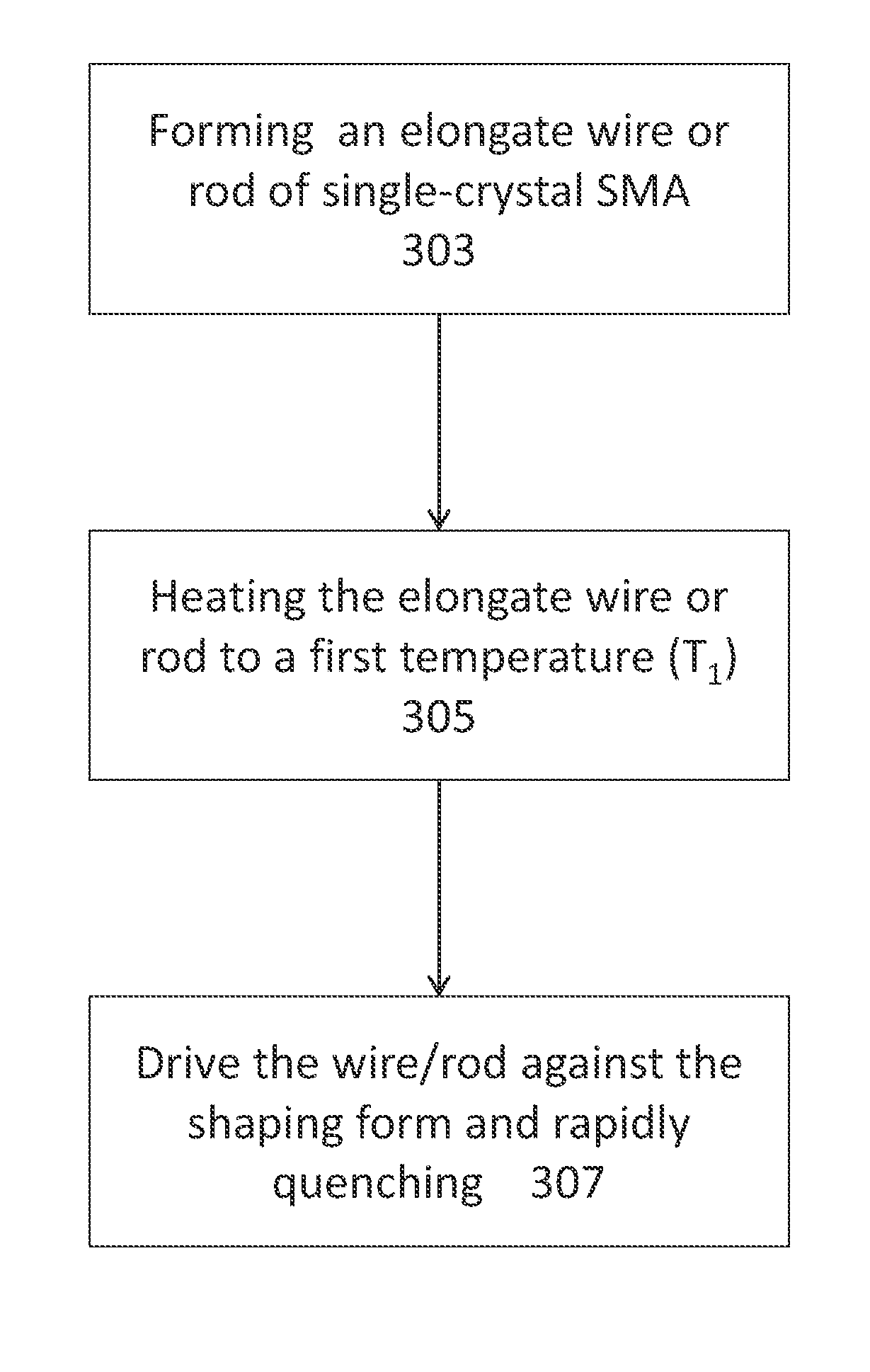

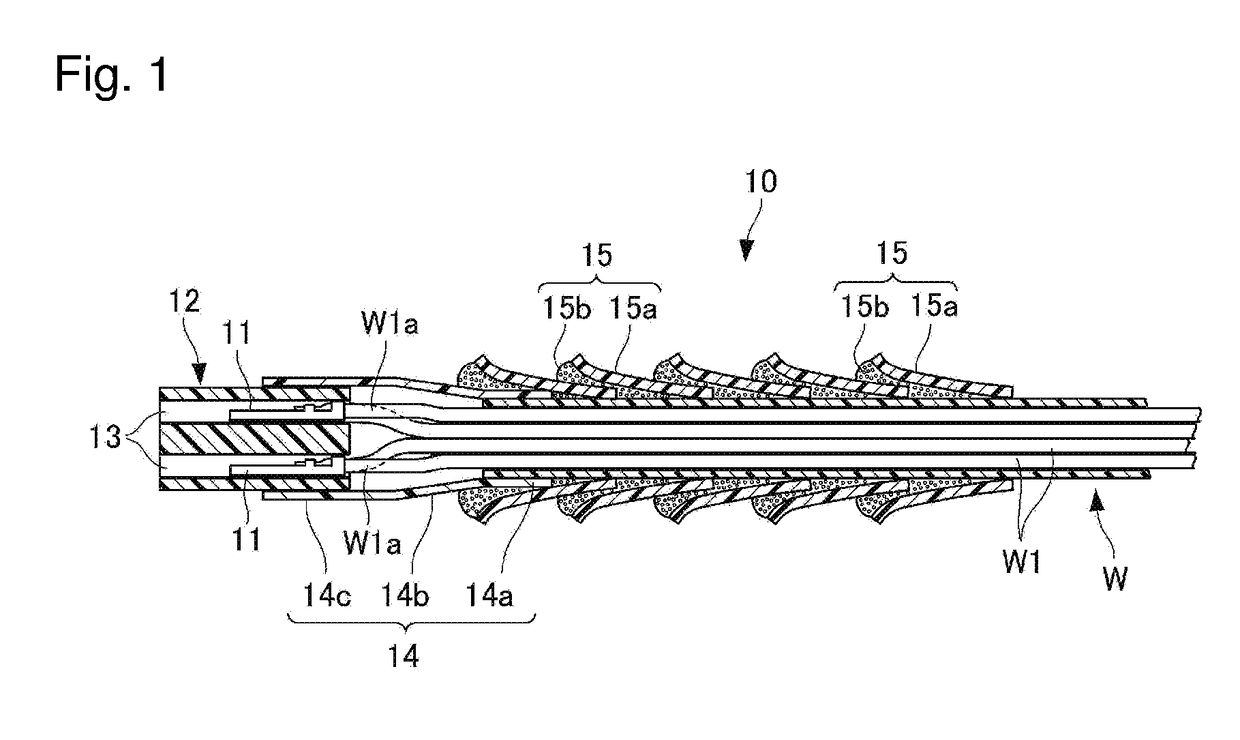

Shape setting a shape memory alloy dental arch

ActiveUS20120048432A1Reduce timeSimplify treatmentArch wiresMetal layered productsSingle crystalDental arch

Described herein are methods, systems, and apparatus for shape-setting hyperelastic, single-crystal shape memory alloy (SMA) material while preserving the hyperelastic properties of the material. Also described are hyperelastic, single-crystal SMA devices that have been shape set by these methods. In particular, described herein are hyperelastic, single crystal SMA dental archwires and methods of forming them while preserving the hyperelastic properties, e.g., without significant grain boundaries in the crystal structure.

Owner:ORMCO CORP

Shape setting a shape memory alloy dental arch

Described herein are methods, systems, and apparatus for shape-setting hyperelastic, single-crystal shape memory alloy (SMA) material while preserving the hyperelastic properties of the material. Also described are hyperelastic, single-crystal SMA devices that have been shape set by these methods. In particular, described herein are hyperelastic, single crystal SMA dental archwires and methods of forming them while preserving the hyperelastic properties, e.g., without significant grain boundaries in the crystal structure.

Owner:ORMCO CORP

Preparation method for high-conductivity heat-resistant aluminium alloy conductor

ActiveCN105671374AIncrease productionQuality improvementConductive materialMetal/alloy conductorsFilter systemIngot

The invention discloses a preparation method for a high-conductivity heat-resistant aluminium alloy conductor, and relates to a preparation method for an alloy conductor. The method comprises the following processes: step 1, heating and melting commercially pure aluminium (containing Wt, not greater than 0.13% of Fe and not greater than 0.08% of Si) with a purity of greater than 99.7% in a heating furnace, and then adding Al-Zr intermediate alloy and Al-Er intermediate alloy in the melted pure aluminium melt; step 2, carrying out degassing, impurity removal, slagging-off, covering and other evolution treatments on the melt; step 3, discharging the melt subjected to heat insulation and standing from a heat-insulation furnace by virtue of a flow groove, and enabling the aluminium melt to sequentially flow through an online degassing system and a ceramic filtering system which are connected to the rear through the flow groove; step 4, carrying out 4-6 passes of continuous ECAE forming on an aluminium wire ingot obtained through continuous casting forming; and step 5, taking the aluminium alloy rod formed through the 4-6 passes of ECAE forming and with a diameter of 8.5-12mm as a raw material, and automatically rolling the aluminium alloy rod into a coil on a wire drawing machine. The method is a method for preparation of a high-strength high-conductivity heat-resistant aluminium alloy conductive wire, and continuous ECAE dynamic age forming, for obtaining a high-performance aluminium alloy conductive wire.

Owner:江苏和拓铝线有限公司

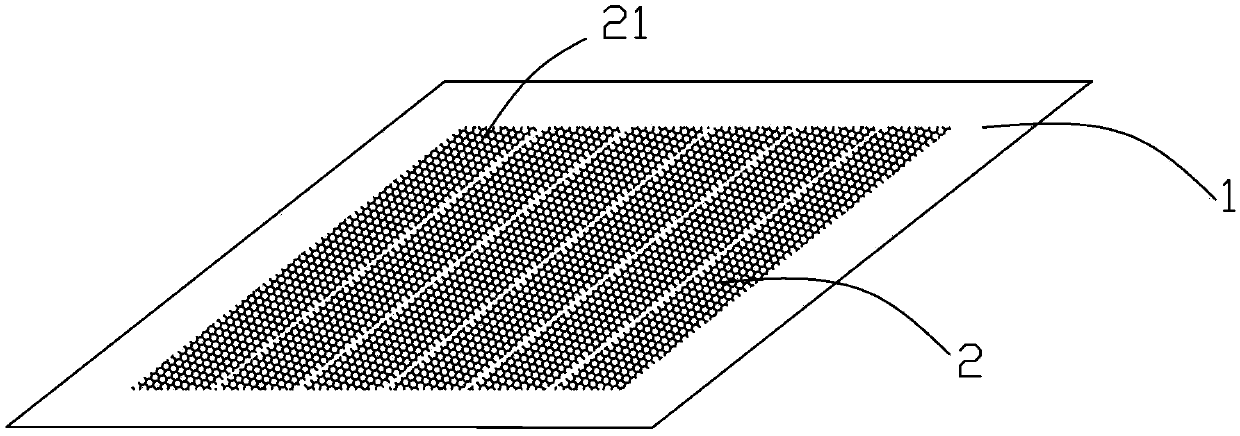

Transparent electric conductor and manufacturing method

ActiveCN103425349ALow resistivityImprove wire performanceInput/output processes for data processingManufacturing technologyTouch Senses

The invention provides a transparent electric conductor and a manufacturing method. The transparent electric conductor comprises a transparent base material and a touch sensing conducting layer arranged on the surface of the transparent base material, the touch sensing conducting layer comprises at least two electric conducting units which are in latticed patterns formed by electric conducting materials, and a preset clearance is formed between two adjacent electric conducting units. According to the transparent electric conductor, the latticed touch sensing conducting layer formed by the electric conducting materials is arranged on the transparent base material and replaces an ITO conducting film in the prior art, the electrical resistivity of the conducting layer can be effectively lowered, the electric conducting performance of the electric conductor is improved, and the transparent electric conductor is suitable for being used in a large-size touch screen. In addition, the manufacturing method of the transparent electric conductor is simple in manufacturing technology, and large-scale production can be achieved.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

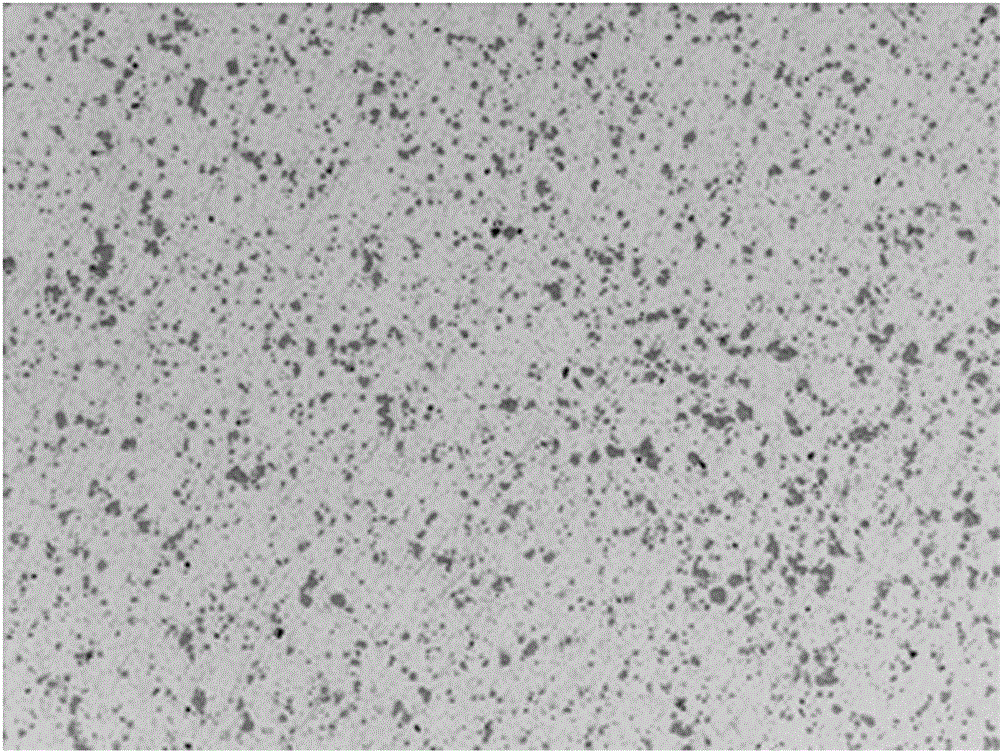

High-strength and heat-resistant aluminum alloy wire and preparation method thereof

ActiveCN104894437AThe technical difficulty of adding tungsten evenly plays a rolePlay a role in diffusion strengtheningMetal/alloy conductorsHeat resistanceRoom temperature

The invention discloses a high-strength and heat-resistant aluminum alloy wire and a preparation method thereof. The aluminum alloy wire comprises the composition by the mass percentage: 0.6-1.2% of Mg, 0.4-0.8% of Si, 3.0-7.0% of W, and the balance Al. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy liquid, atomizing the aluminum alloy liquid into a powder, screening the aluminum alloy powder, mixing a tungsten powder with the particle size of not more than 3 microns with the aluminum alloy powder, carrying out cold isostatic pressing on the mixed powder into a prefabricated blank, carrying out vacuum degassing, heating, hot-extruding into an aluminum alloy round rod, drawing into an aluminum alloy wire, and carrying out solid solution and aging treatment to obtain the high-strength and heat-resistant aluminum alloy wire. Tungsten is uniformly added into the aluminum alloy wire by adopting a powder hot extrusion method, the strength of the aluminum alloy wire is strengthened, the aluminum alloy wire has excellent room-temperature tensile mechanical properties, electrical conductivity and heat resistance, the room-temperature tensile strength is more than 320 MPa, the elongation rate is more than 9%, the electrical conductivity is more than 56%IACS, and after heat preservation for 1 h at the temperature of 250 DEG C, the tensile strength is more than 290 MPa and the tensile strength survival rate is more than 91%.

Owner:GUANGDONG SHINE CABLES

Cable aluminum alloy material

InactiveCN104593648AImprove corrosion resistanceImprove wire performanceConductive materialImpurityOverhead line

The invention discloses a cable aluminum alloy material, comprising the following elements in parts by weight: 1-3 parts of Cu, 0.8-2 parts of Fe, 0.6-1.8 parts of Cr, 1.2-2.5 parts of Mg, 5-10 parts of Zn, 0.1-0.5 part of Ag, 0.8-1.5 parts of Ni, and the balance of Al and inevitable impurities. The invention has the following beneficial effects: proper amounts of Ag and Fe are added into the aluminum alloy, so that the electrical conductivity of materials is improved, the resistance is reduced, meanwhile, the tension strength of the materials is enhanced, the diameter of a steel core can be reduced in a manufacturing process of an overhead line, consequently, the mass of the overhead line is reduced, and the energy is saved; Ni is added, so that the resistance to corrosion of the alloy is improved greatly, and the alloy is easy to popularize.

Owner:KUNSHAN SHUOCI METAL MATERIAL PROD

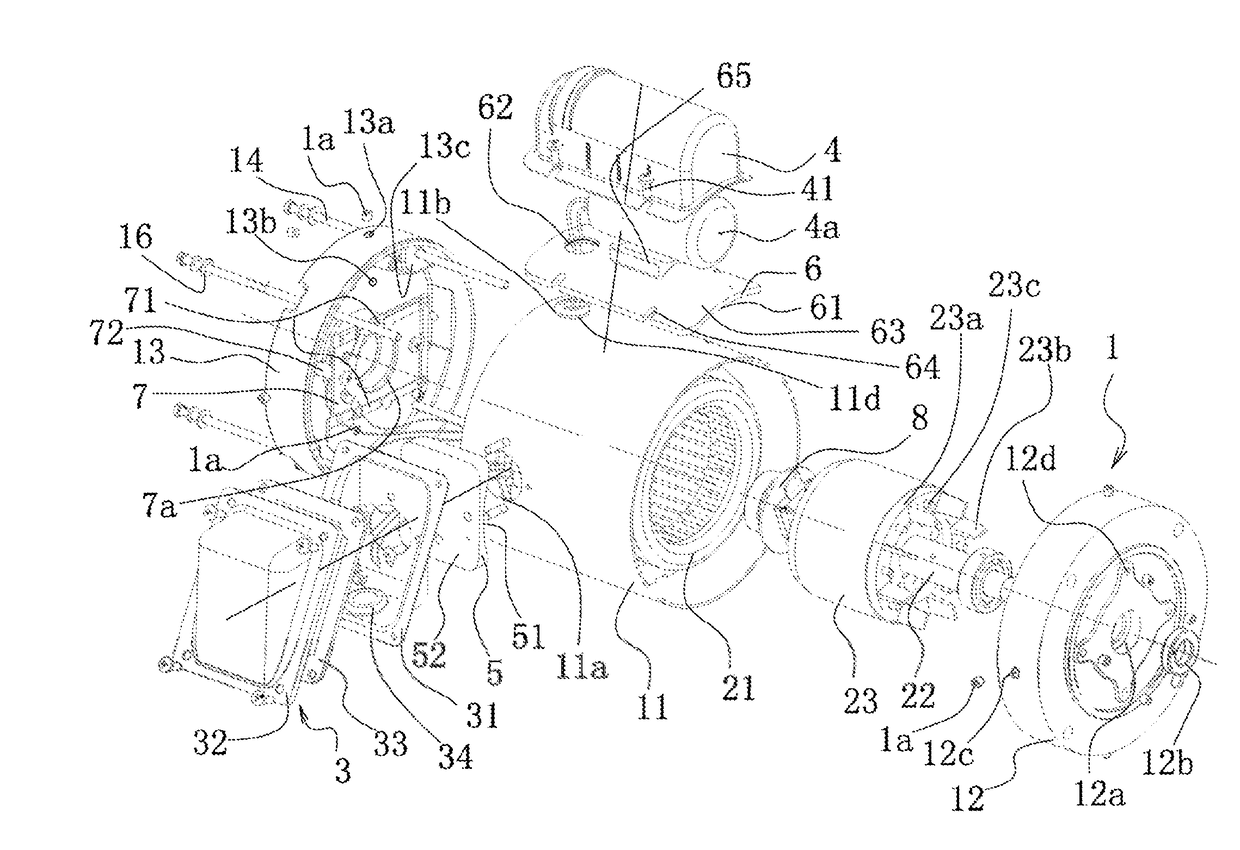

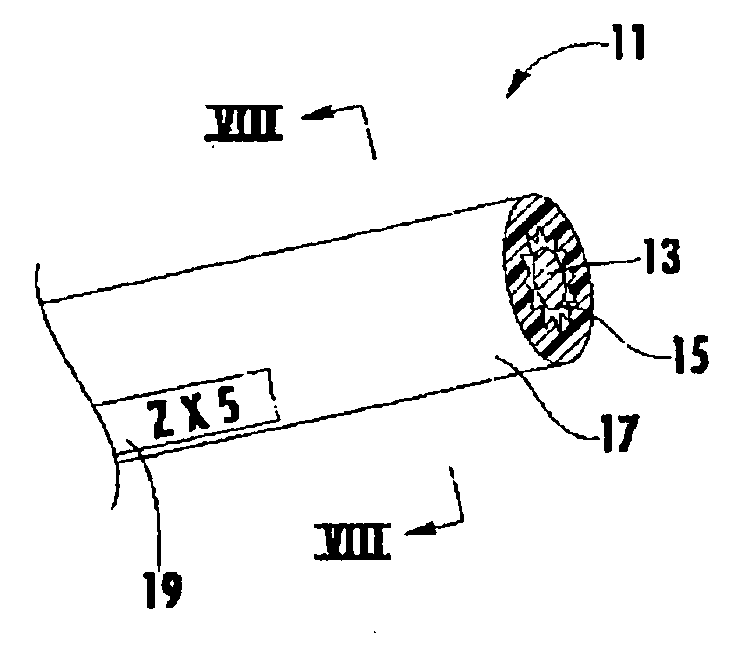

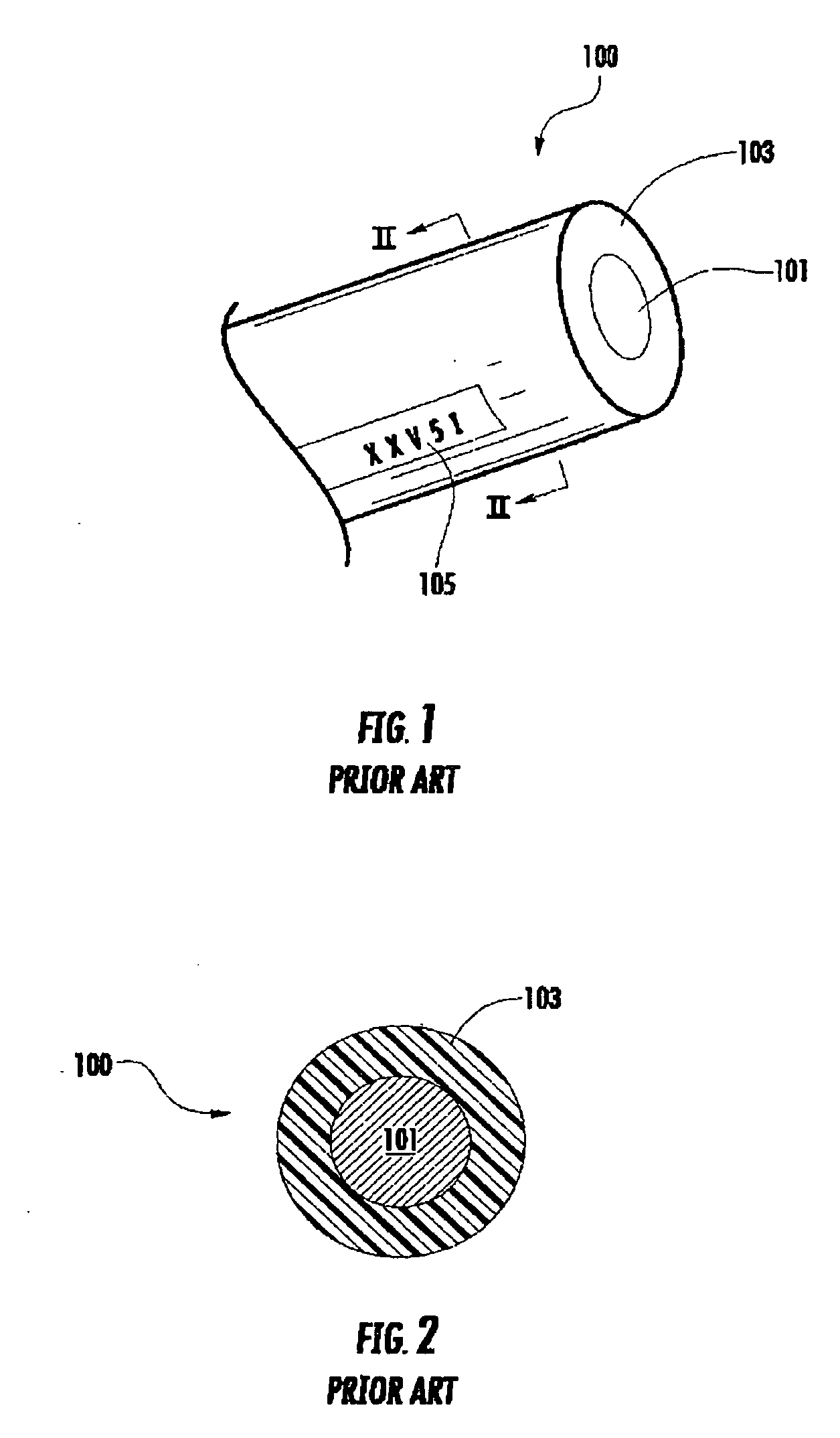

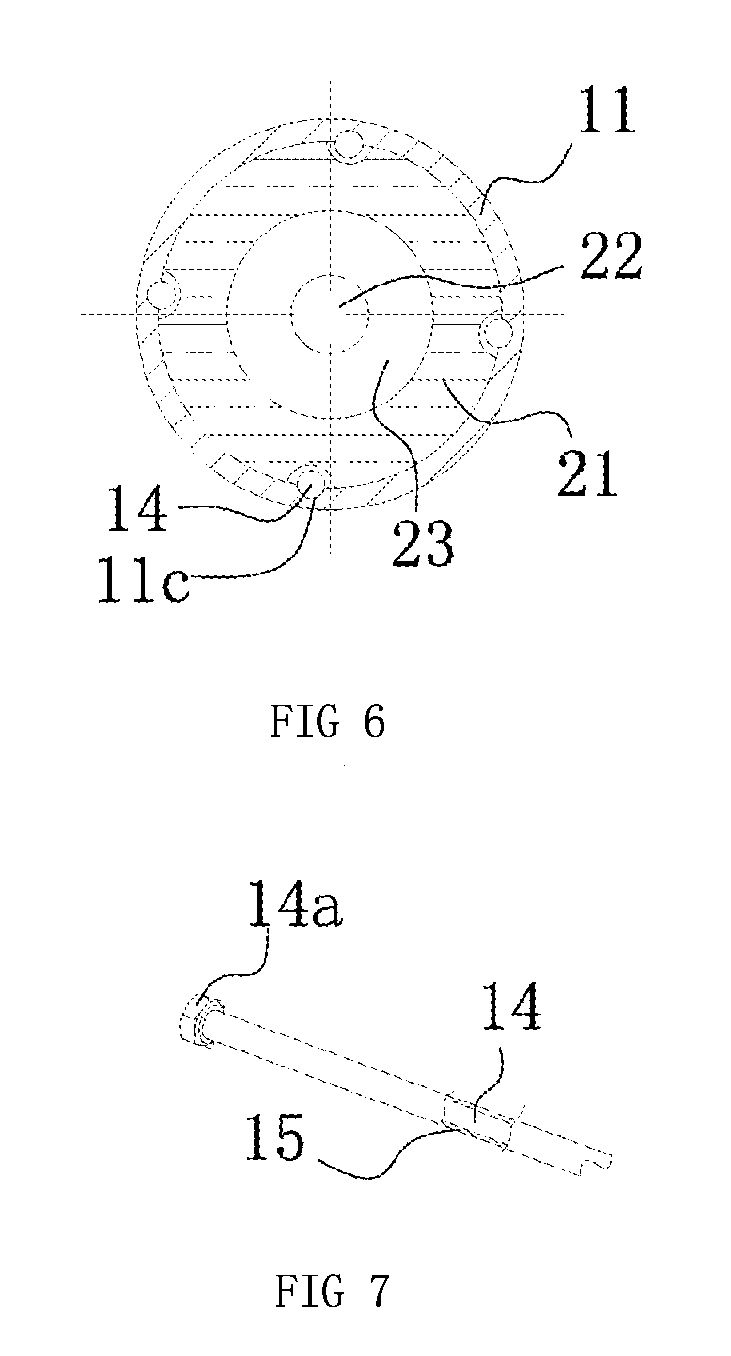

Stainless steel motor with high weather resistance and high sealing performance

ActiveUS20170117770A1Improve sealingExtended service lifeSupports/enclosures/casingsWeather resistanceEngineering

A stainless steel motor with high weather resistance and high sealing performance comprises a cylindrical housing (11) made of a stainless steel material. A front end cover (12) is arranged at one end of the cylindrical housing, and a rear end cover (13) is arranged at the other end of the cylindrical housing. A rotary shaft hole (12a) is provided in the front end cover. A rotary shaft sealing sleeve (12b) is arranged in the rotary shaft hole, and a rotor shaft (12) is sleeved in the rotary shaft sealing sleeve (12b). A first drainage structure is arranged on the front end cover, and a second drainage structure is arranged on the rear end cover. A first wire penetrating hole (11a) and a second wire penetrating hole (11b) are provided in the cylindrical housing. A junction box (3) located on the outside of the first wire penetrating hole and a capacitor box (4) provided with a capacitor (4a) and located on the outside of the second wire penetrating hole are arranged on the outer wall of the cylindrical housing. A first sealing structure is arranged between the cylindrical housing and the junction box, and a second sealing structure is arranged between the cylindrical housing and the capacitor box. The motor has the advantages of easy draining and good sealing effect.

Owner:ZHEJIANG DONGXIN ITECH CO LTD

Pre-electroplated lead frame and preparation method thereof

PendingCN111863764AShorten the production cycleImprove solderabilitySemiconductor/solid-state device detailsSolid-state devicesEtchingDevice material

The invention belongs to the technical field of semiconductor devices, and particularly relates to a pre-electroplated lead frame and a preparation method thereof. The lead frame comprises a lead frame unit and a non-functional area, a silver plating layer is formed in a local area of the upper surface of the lead frame unit, a nickel-palladium-gold plating layer is formed in all exposed areas ofthe lower surface of the lead frame unit, and the side wall of the lead frame unit and the non-functional area on a frame body are free of electroplating layers. The lead frame is prepared through film pasting, silver plating, nickel-palladium-gold plating, etching and film stripping in sequence. According to the invention, a method of selective electroplating and etching in sequence is adopted, the upper surface is subjected to medium-low-speed, low-cyanide and low-temperature electroplating, and the obtained silver coating is high in compactness, uniform in thickness, smooth in surface and good in routing performance; the nickel-plated palladium-gold layer on the lower surface is resistant to high temperature and high humidity, has excellent storage time and good weldability, can providehigh air tightness and reliability for packaged products, and meets the production requirements of environmental protection and energy conservation.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Textile yarn guide device for textile machine

InactiveCN107130323ASimple structureEasy to manufacture and installWeft knittingLoomsBobbinTextile yarn

The invention discloses a textile yarn guiding device for a textile machine, comprising an upper horizontal support plate, a lower horizontal support plate, a front support frame, a rear support frame, a first yarn guide, a second yarn guide and a middle pulling yarn guide Cylinder mechanism, the middle pulling yarn guiding tube mechanism includes the middle yarn guiding tube, the upper telescopic mechanism, the support rod, the upper pulling wheel, the lower pulling wheel and the driving motor, and the upper telescopic mechanism is connected and fixed between the middle yarn guiding tube and the upper horizontal support plate , the lower traction wheel is placed under the upper traction wheel and is connected and fixed with the upper end of the support rod, the support rod is vertically fixed on the lower horizontal support plate, and the first yarn guide and the second yarn guide are symmetrically arranged on the middle yarn guide On both sides, the first yarn guide and the second yarn guide are connected and fixed on the upper horizontal support plate through elastic expansion and contraction parts. The initial lead wire of the textile yarn wire device for a textile machine is quick and convenient, effectively achieves the wire effect, can better protect the yarn, avoid its wear and tear, and has high practicability.

Owner:SUZHOU XUNXIAN TEXTILE TECH CO LTD

Preparation method for magnesium alloy welding wire

InactiveCN106180624AEliminate hot extrusion processSimple processWelding/cutting media/materialsSoldering mediaWater flowMagnesium alloy

The invention discloses a preparation method for a magnesium alloy welding wire. The preparation method is characterized by comprising the following steps: under the conditions with the cooling water flow rate being 500-1500L / h, the cooling water temperature being 20-30 DEG C and the vacuum degree being 0.1-1Pa, treating fused magnesium alloy in a heated casting mould with the billet drawing speed being 1-100mm / min to prepare a wire billet with the diameter being 4.0-8.0mm; and carrying out 3-15 pass pulling processing on the magnesium alloy wire billet to finally obtain the magnesium alloy welding wire with the diameter being 1.0-3.0mm, wherein the pulling pass elongation coefficient is 1.1-1.5. The preparation method for the magnesium alloy welding wire is simple in process and high in efficiency and is capable of preparing the magnesium alloy welding wire with the diameter size being 2.0mm or below.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

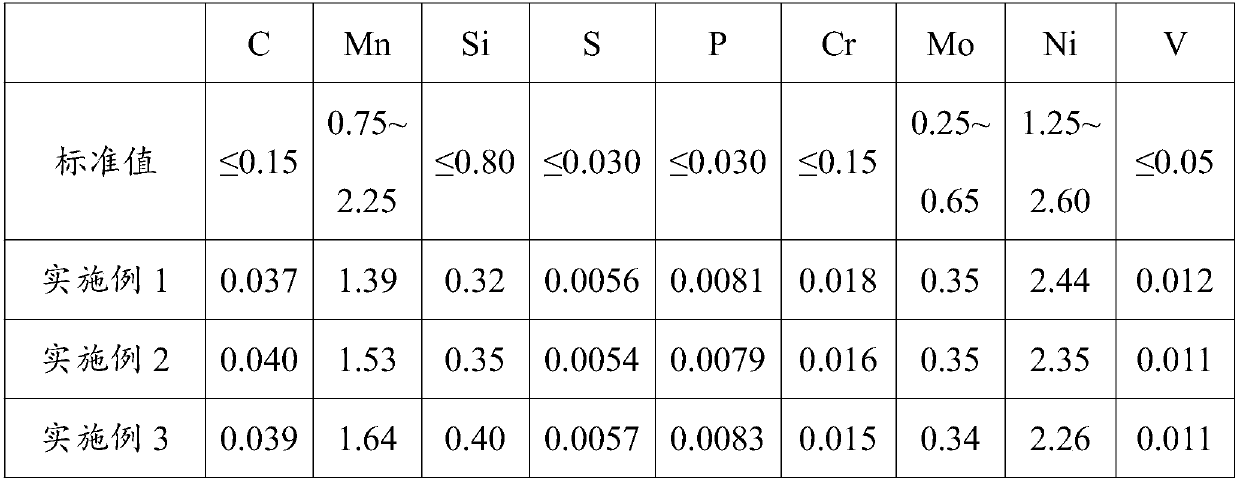

Rutile flux-cored wire with tensile strength of 800 MPa grade and preparation method thereof

ActiveCN107914099AExcellent drawing performanceReduce temper brittlenessWelding/cutting media/materialsSoldering mediaIron powderManganese

The invention discloses a rutile flux-cored wire with tensile strength of 800 MPa grade and a preparation method thereof. The flux-cored wire comprises a cover and a core; and the core comprises the following components: 20-40 weight parts of rutile, 2-10 weight parts of silicate minerals, 2-10 weight parts of magnesium powder, 0.2-4 weight parts of fluoride, 2-8 weight parts of titanium powder, 2-8 weight parts of molybdenum iron, 10-20 weight parts of nickel powder, 10-20 weight parts of electrolytic manganese, 2-8 weight parts of 75 silicon iron, 2-8 weight parts of wollastonite, and 12-17weight parts of iron powder. Compared with the prior art, the flux-cored wire is excellent in welding process performance and physical and chemical property, achieves such purposes as excellent welding process performance, stable arc, low splashing, beautiful molding of welding lines and capability of welding in all positions on process, and achieves the purpose of excellent mechanical performanceon performance.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Aluminum alloy material for cables

The invention relates to an aluminum alloy material for cables. The aluminum alloy material for cables comprises the following elements in parts by weight: Cu: 1-3 parts, Fe: 0.8-2 parts, B: 0.6-1.8 parts, Mg: 1. 2-2.5 parts, Zn: 5-10 parts, Ag: 0.1-0.5 part, the balance being Al and unavoidable impurities, aluminum ingots and an alloy comprising the corresponding composition in ratio are added to a shaft furnace, and the alloy elements are added in a form of an intermediate alloy and are stirred, refined, deslagged and extruded into bars, and finally the bars are quenched by cold water. The aluminum alloy material provided by the invention has the beneficial effects that appropriate amounts of Ag and iron are added to the aluminum alloy, so that the conductor characteristic of the material is improved, and the resistance is reduced; meanwhile, the tensile strength of the material is enhanced, and the diameter of a steel core can be reduced in the manufacturing process of overhead lines, so that the mass of the overhead lines is reduced, the energy is saved, and the material is easy to popularize.

Owner:KUNSHAN ZELA METAL PROD

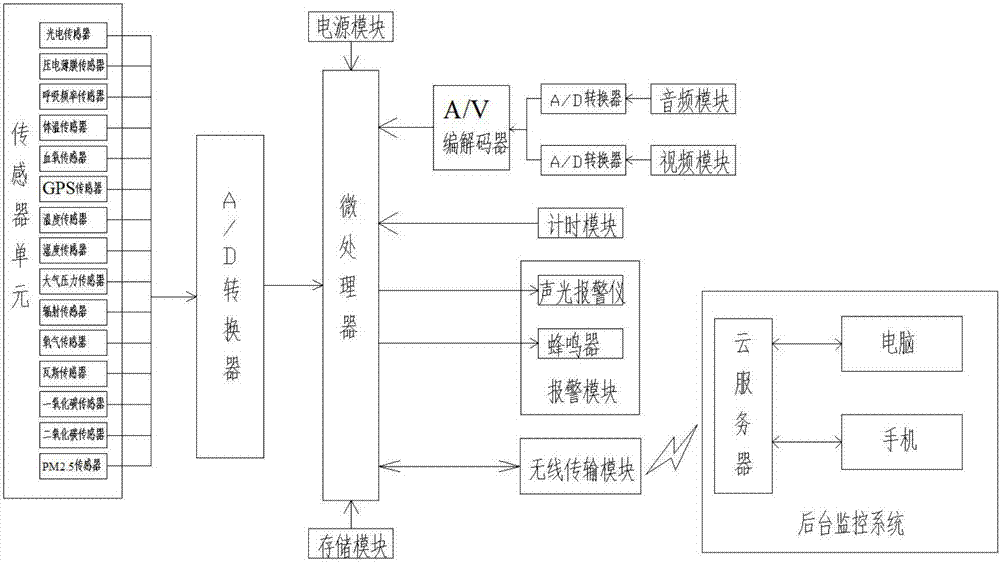

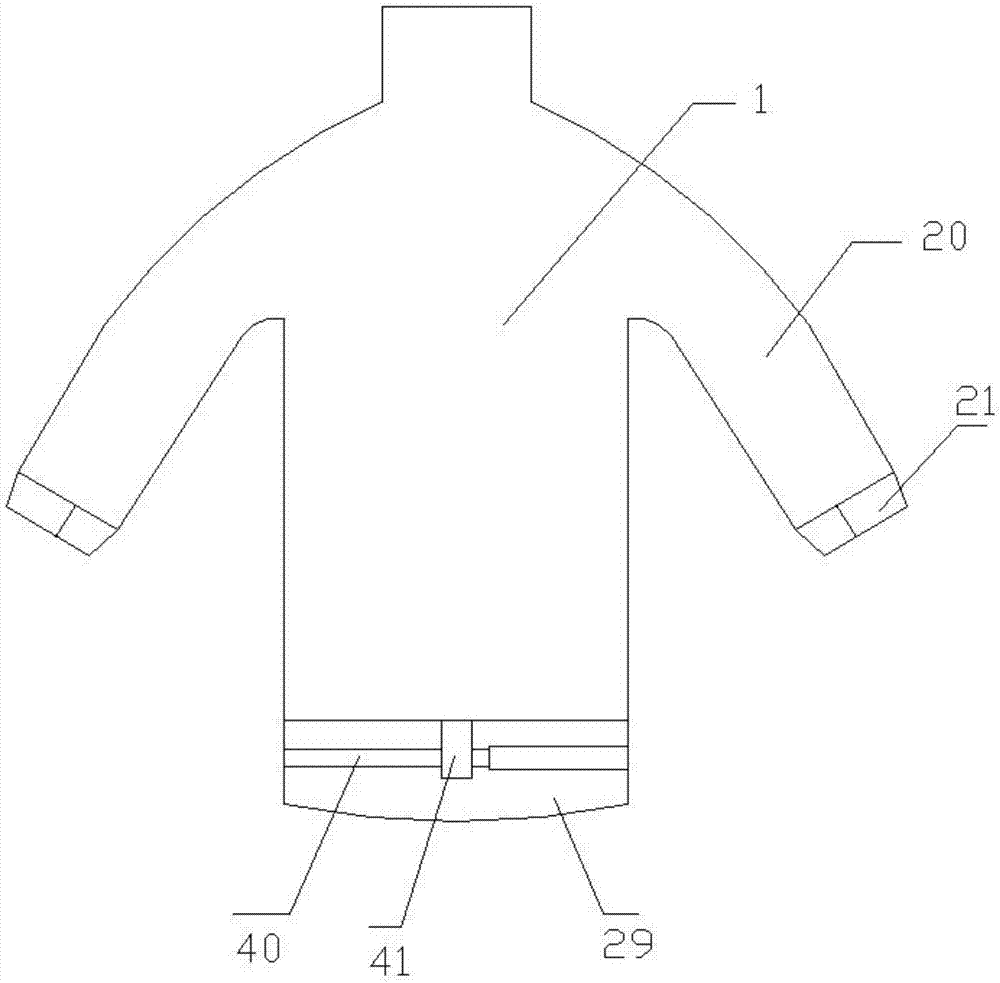

High-safety-performance special protection system based on internet of things

PendingCN107281665APlay the role of "black box"Guaranteed validityChemical protectionHeat protectionThe InternetProtection system

The invention relates to a high-safety-performance special protection system based on the internet of things. The high-safety-performance special protection system comprises a protective suit, a personal terminal system and a background monitoring system. The personal terminal system comprises a control terminal shell which is internally provided with a sensor unit, a power module, an audio module, a video module, a timing module, a storage module, a microprocessor, an A / D converter, an A / V coder and decoder, an alarm module and a wireless transmission module. The background monitoring system comprises a cloud server, a computer and a mobile phone, the cloud server is in wireless connection with the wireless transmission module, and the computer or the mobile phone is connected with the cloud server. The high-safety-performance special protection system has an omnibearing multi-angle information collection function and an information storage function and is high in adaptability, good in safety and wide in application field.

Owner:晶至科技制衣(江苏)有限公司

Electroplating method of smart card package frame

The invention provides an electroplating method of a smart card package frame and belongs to the technical field of electronic information. The electroplating method is characterized by comprising the following steps of: electroplating a nickel layer which is 1.8-2.2 microns thick on the contact layer of the frame after performing pretreatment on the molded frame, and then electroplating a phosphorus-nickel alloy layer which is 0.4-0.8 microns thick on the basis of the nickel layer, and further electroplating a gold layer which is 0.009-0.05 microns thick outside the phosphorus-nickel alloy layer of the contact surface of the frame. The electroplating method provided by the invention can be used for improving the wearability and corrosion resistance of the contact surface of the product. Besides, the electroplating method is also capable of reducing the thickness of the hard metal, omitting the application of posttreatment and greatly saving the cost.

Owner:新恒汇电子股份有限公司

Foam skin insulation with support members

InactiveUS20090119901A1Electrical performance be enhanceLow dielectric constantWave amplification devicesInsulated cablesEngineeringElectrical conductor

A wire includes a conductor. A foam insulation surrounds an outer surface of the conductor. A jacket surrounds the foam insulation and presents a plurality of projections on an inner surface thereof, which extend toward the conductor, yet do not purposefully contact the conductor. With the foam insulation having a lower dielectric constant than the jacket material, the electrical performance of the wire is improved, while maintaining a good crush resistance.

Owner:COMMSCOPE INC

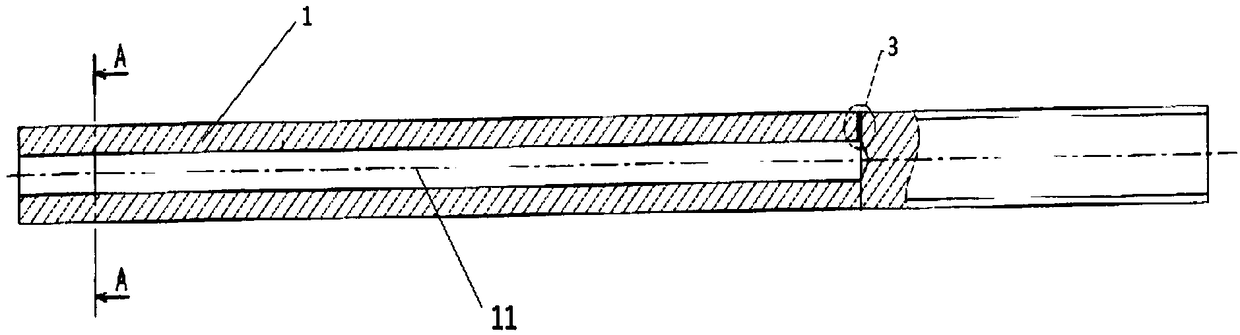

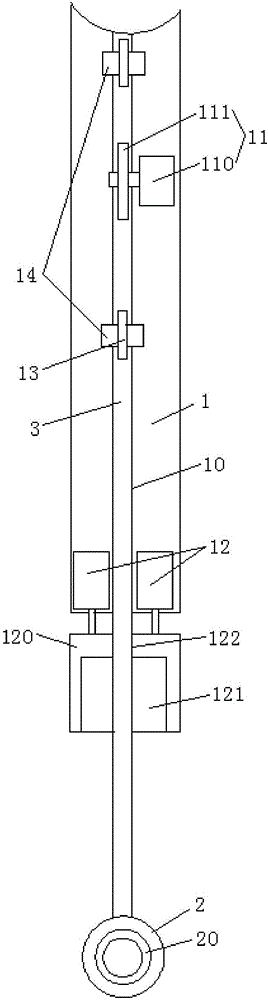

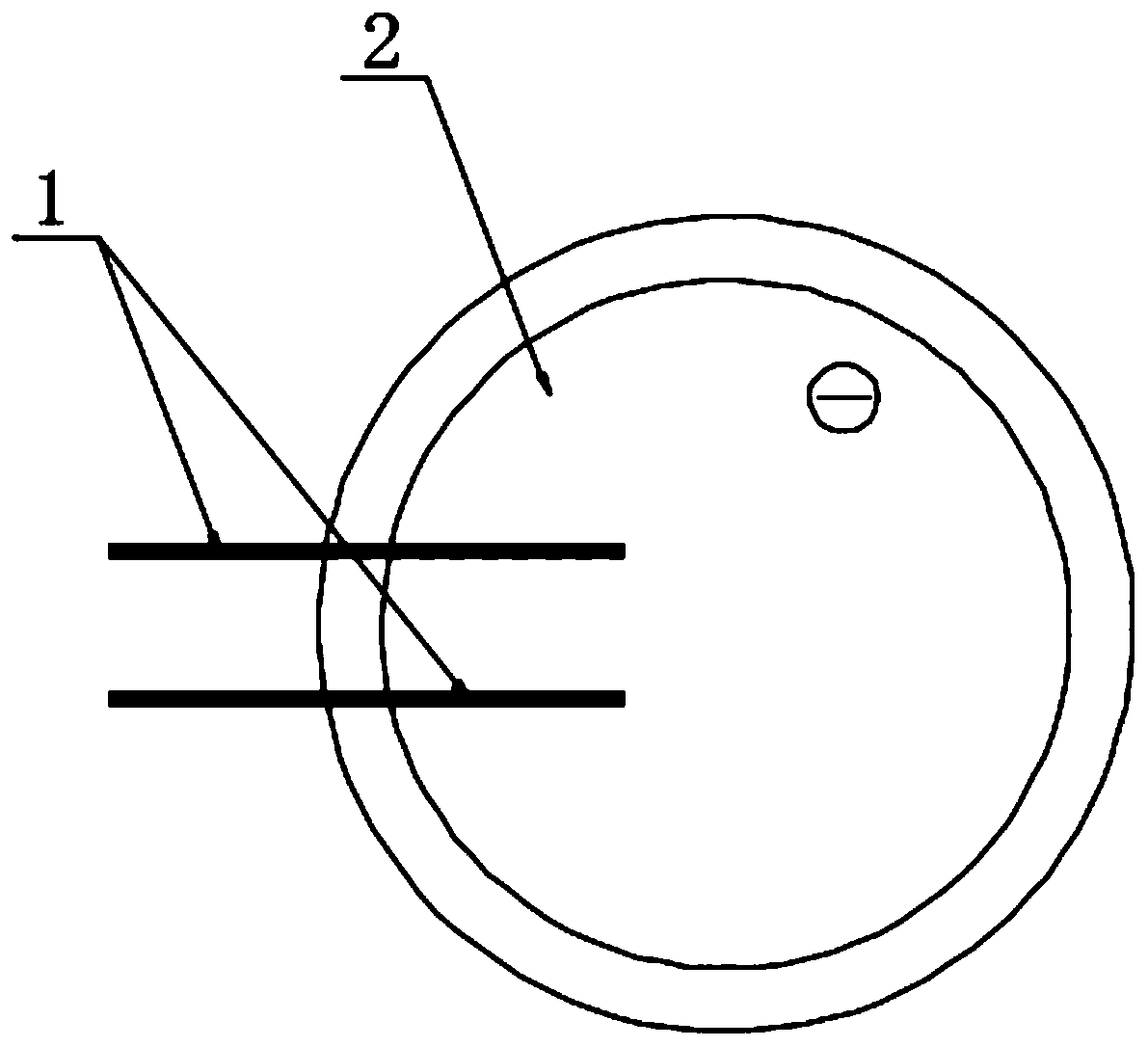

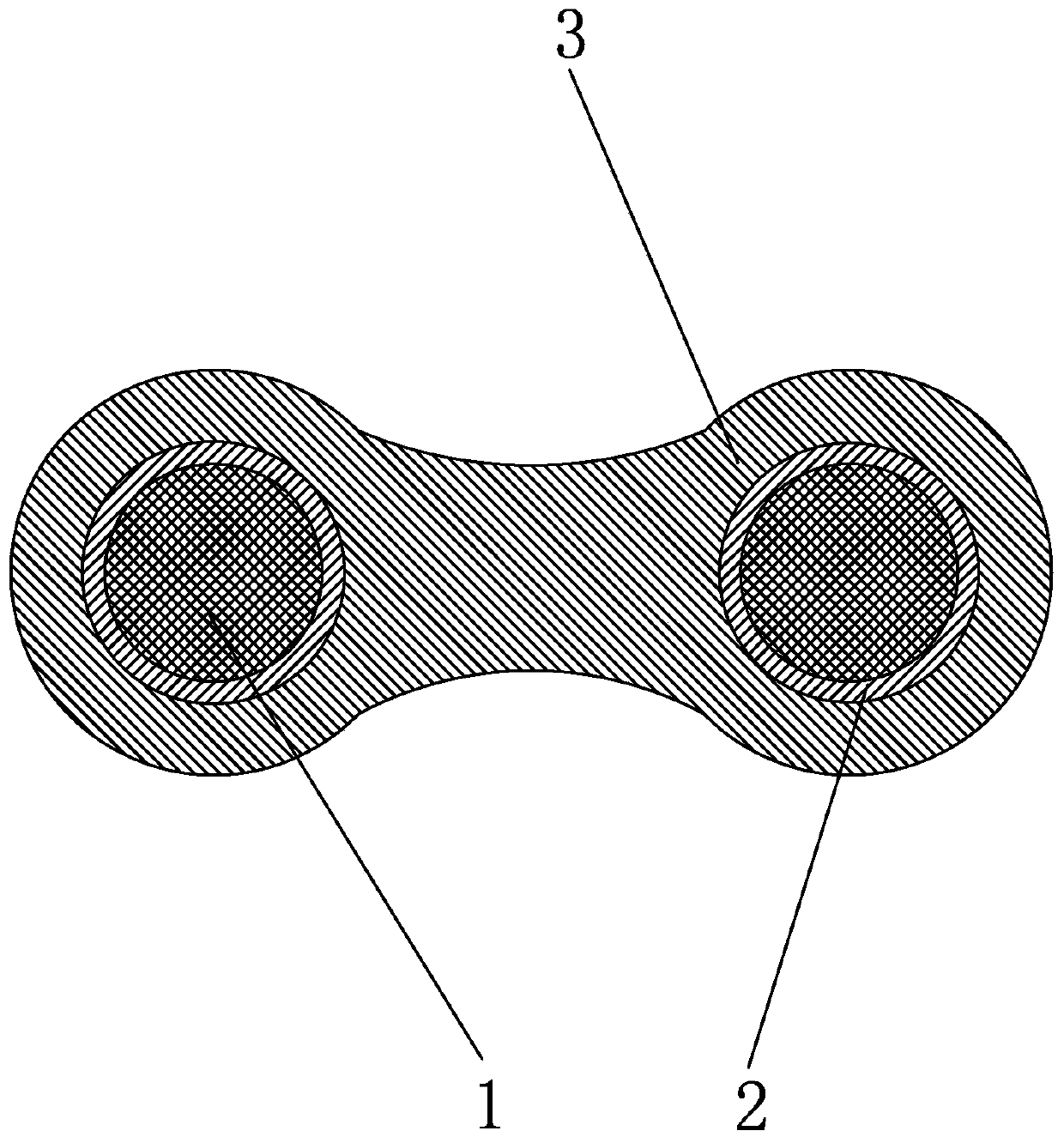

Cathode steel bar for effectively restraining horizontal current and manufacturing method of cathode steel bar

The invention provides a cathode steel bar for effectively restraining horizontal current. Copper is adopted for improving the electric conductivity of the cathode steel bar. The center of the cathodesteel bar (1) is provided with a drill hole (11) in the axial direction; a copper core (2) which has the same diameter with the drill hole (11) is placed inside the drill hole (11); the copper core (2) makes close electric contact with the cathode steel bar (1); the length of the copper core (2) is 1 / 2 to 4 / 5, preferably 3 / 4 of the length of the cathode steel bar (1); a baffle (4) is arranged atan open end of the cathode steel bar (1); and the baffle (4) is welded on the cathode steel bar and is a little sunk in the end face of the cathode steel bar. In use, the cathode steel bar is not prone to fall off, being separated or being damaged and can effectively strain the horizontal current.

Owner:郑州久达科技有限公司

Preparation technology for high-strength high-conductivity copper alloy guide lines

The invention discloses a preparation technology for high-strength high-conductivity copper alloy guide lines, and relates to the technical field of guide line production and processing. The preparation method is characterized by comprising the following steps of (1) fully mixing 16-18 parts by weight of nanometer refined copper powder of which the grain diameter is 0.4-0.8 mum and 2-4 parts by weight of nanometer refined copper powder of which the grain diameter is 0.2-0.3 mum with 84-86 parts by weight of nanometer refined tungsten powder of which the grain diameter is 0.2-0.6 mum, and putting the mixture in a ball grinding mill to carry out ball milling; (2) protecting, distinguishing and drying by filling a vacuum glove box with argon after the ball milling is completed; (3) carrying out extrusion forming, wherein dried powder raw materials can be extruded into guide lines under the action of a press machine, and the pressure of the press machine is set to be 500-600MPa; (4) sintering, wherein sintering forming is carried out on the guide lines which are formed by extrusion forming, and the sintering temperature is controlled to be 900-1000 DEG C. The preparation technology is convenient for large-scale production, is low in price and has very high strength, high conductivity and high temperature-resisting capacity.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

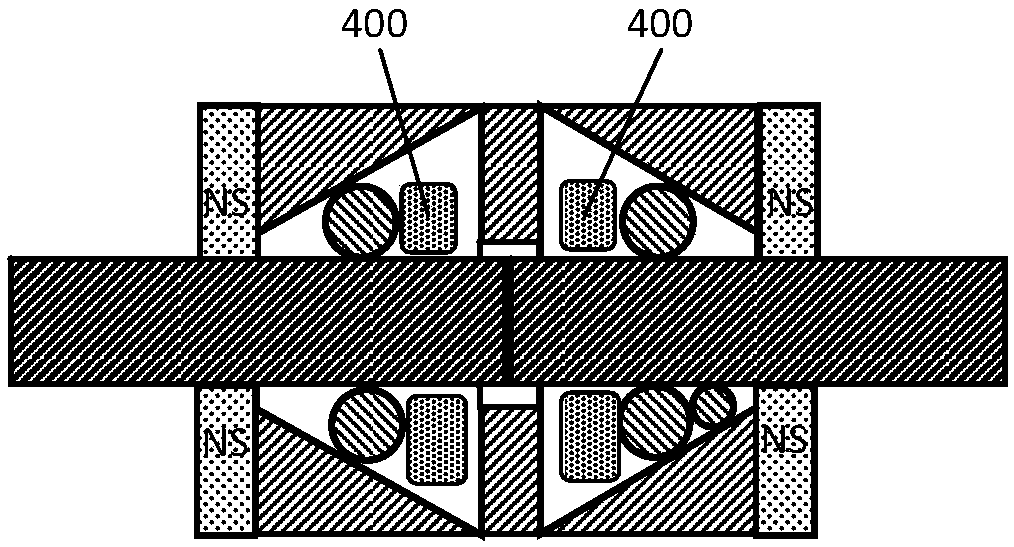

Manufacturing method of two-in-one structure inductor with air gap formed in side surface

ActiveCN111724980AEasy to installPlay efficientlyTransformers/inductances coolingTransformers/inductances coils/windings/connectionsStructural engineeringInductor

The invention discloses a manufacturing method of a two-in-one structure inductor with an air gap formed in the side surface. A base of the inductor is provided with four electrode grooves, so electrodes can be conveniently installed without using an additional positioning device for positioning. A tail end of the coil is close to a Z-shaped extension sheet of the electrode, so the extension sheetwraps the tail end of the coil and is pressed by a jig, the extension sheet of the electrode is Z-shaped, the extension sheet can just wrap the tail end of the coil, wrapping and welding of the extension sheet and the coil achieve a better conductive effect, and loss is effectively reduced. Compared with an inductor with an air gap formed in the front face, the inductor of the two-in-one structure with the air gap formed in the side surface and manufactured through the manufacturing method is compact in overall structure, small in size and good in performance. The preparation method disclosedby the invention is simple to operate and convenient to assemble, an air gap is formed in the formed independent complete side surface during production, and working efficiency is high.

Owner:GUANGZHOU DELOOP ELECTRONICS DEVICES

Hot-pressing buffer sheet and preparation method thereof

InactiveCN107471783AImprove heat resistanceImprove wire performanceSynthetic resin layered productsUltrasonic/sonic fibre treatmentLiquid temperaturePolymer science

The invention discloses a hot-pressed buffer sheet and a preparation method thereof. The hot-pressed buffer sheet and the preparation method thereof comprise a Teflon glass fiber cloth, an adhesive and a heat-conducting silica gel layer, and the surface of the Teflon glass fiber cloth is coated with an adhesive , the adhesive forms an adhesive layer, and the adhesive is made of the following materials in mass fraction: 30-40% of organosilicon-modified silicon resin, 30-40% of silane coupling agent, 10-20% of organic solvent and liquid resistant 10-20% warming agent, and a heat-conducting silica gel layer is arranged on the adhesive layer, and the heat-conducting silica gel layer is composed of heat-conducting silica gel with a mass fraction of 100%, 0.2-3% A / B platinum vulcanizing agent or 1-5% bis Four or 1-5% double 25, 5-30% conductive adhesive or 5-30% conductive powder, 2-5% carbon nanotubes, nano-titanium oxide and silica gel wetting agent. Through the above method, the present invention has good heat resistance, conductivity and release property, is not easy to delaminate, and has a long service life.

Owner:苏州中垒新材料科技有限公司

Conductor contact connector

PendingCN109586057AAchieve connectionReliable contactCoupling contact membersMultiple conductors connectorElectrical conductorMechanical engineering

Owner:杨斌堂

Preparation method of magnesium alloy welding wire

InactiveCN112091475APure welding wireLow oxide impurity contentWelding/cutting media/materialsSoldering mediaLiquid metalIngot

The invention discloses a preparation method of a magnesium alloy welding wire, and belongs to the technical field of welding. The method includes the following steps that a mother alloy cast ingot isheated and melted through an induction coil under protection of high-purity argon, then liquid metal is sprayed to the surface of a copper roller rotating at a high speed, a welding wire is obtainedafter the liquid metal is rapidly cooled, and the multi-strand stranded magnesium alloy welding wire is obtained after stranding. The welding wire produced with the method has the stirring effect on molten pool metal, the electric arc is stable, the components are consistent with those of base metal, the welding wire has the good surface quality, the surface is free of cracks, and the strength ofa post-welding joint is high.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Wire harness

InactiveUS20170117071A1Easy to implementEffective waterblockingVehicle connectorsPlastic/resin/waxes insulatorsFoaming agentPolyolefin

A wire harness includes a group of wires having a plurality of covered electrical wires; a terminal provided to each lead wire end portion; a connector having a plurality of cavities which house and hold each terminal; a connector cover that is a resin mold body having a small opening tubular portion, a trumpet-shaped tubular portion, and a large opening tubular portion covering the connector; and a sheet fixating portion having a belt-like sheet wound over an area from the small opening tubular portion of the connector cover to a predetermined length of the covered electrical wires in a spiral form. The sheet fixating portion has a two-layer structure having a belt-like polyolefin sheet and a foaming agent layer, and is heated in a wound state with the foaming agent layer facing inward, the foaming agent layer foaming so as to fill gaps between the connector cover.

Owner:SUMITOMO WIRING SYST LTD

Stainless steel motor with high weather resistance and high sealing performance

ActiveUS10361602B2Improve sealingExtended service lifeSupports/enclosures/casingsWeather resistanceEngineering

A stainless steel motor with high weather resistance and high sealing performance comprises a cylindrical housing (11) made of a stainless steel material. A front end cover (12) is arranged at one end of the cylindrical housing, and a rear end cover (13) is arranged at the other end of the cylindrical housing. A rotary shaft hole (12a) is provided in the front end cover. A rotary shaft sealing sleeve (12b) is arranged in the rotary shaft hole, and a rotor shaft (12) is sleeved in the rotary shaft sealing sleeve (12b). A first drainage structure is arranged on the front end cover, and a second drainage structure is arranged on the rear end cover. A first wire penetrating hole (11a) and a second wire penetrating hole (11b) are provided in the cylindrical housing. A junction box (3) located on the outside of the first wire penetrating hole and a capacitor box (4) provided with a capacitor (4a) and located on the outside of the second wire penetrating hole are arranged on the outer wall of the cylindrical housing. A first sealing structure is arranged between the cylindrical housing and the junction box, and a second sealing structure is arranged between the cylindrical housing and the capacitor box. The motor has the advantages of easy draining and good sealing effect.

Owner:ZHEJIANG DONGXIN ITECH CO LTD

Lithium battery with protection function

InactiveCN111525052AWith protective functionReduce vibrationSmall-sized cells cases/jacketsBattery isolationStructural engineeringMechanical engineering

The invention relates to the technical field of battery equipment and discloses a lithium battery with a protection function. The lithium battery comprises a lithium battery body, wherein a buffer sleeve is fixedly mounted on an outer surface of the lithium battery body, protective pads are fixedly mounted on the left sides and the right sides of the top and the bottom of the buffer sleeve, buffersprings are fixedly mounted in gaps formed by the protective pads and the lithium battery body and located in the buffer sleeve, and a battery interface seat is fixedly mounted at the top of the lithium battery body. The lithium battery with the protection function is advantaged in that through a protective pad, protection performance of the equipment can be effectively improved, problems that the equipment is damaged and the service life is short when the equipment is used in a frequent vibration environment are avoided, the effect of effectively reducing vibration borne by the lithium battery body is achieved through the arrangement of the buffer spring, the service life of the equipment is prolonged, and the sealing performance of the equipment can be effectively improved through the arrangement of the sealing limiting ring which is a soft rubber ring.

Owner:YANGZHOU GOLDEN JOY POWER SUPPLY CO LTD

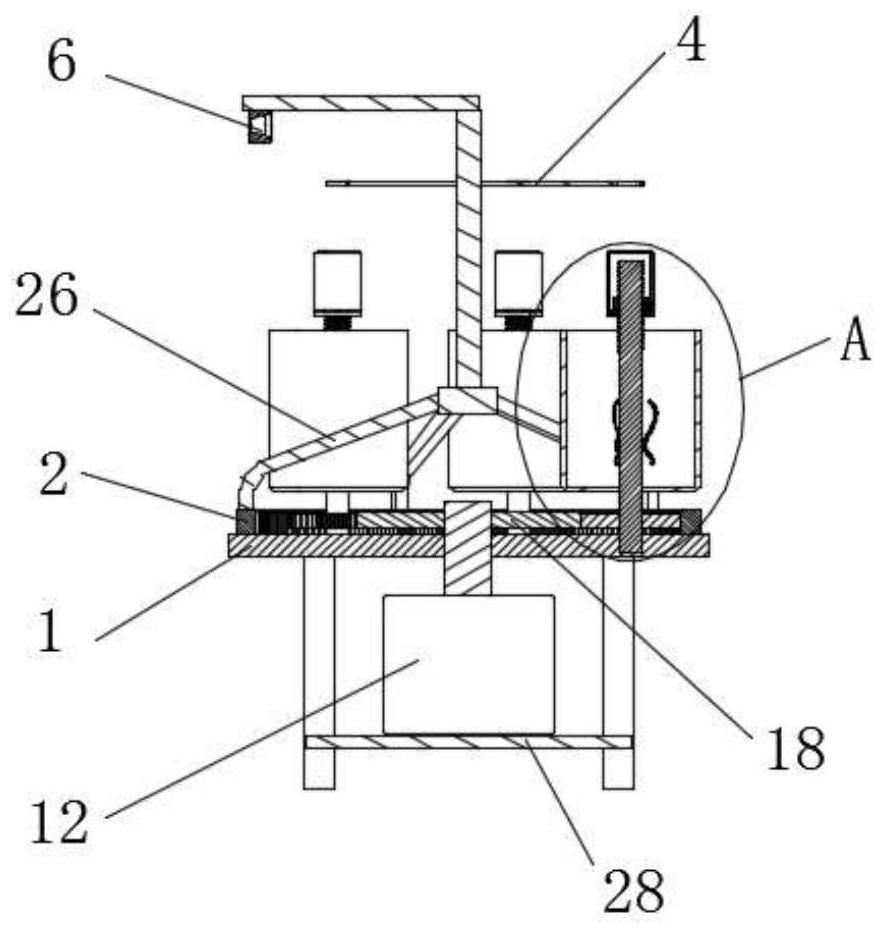

Stator winding machine lead cutting device and method

The invention relates to a stator winding machine lead cutting device which comprises a longitudinal installing plate, a lead ring and an elongated fixed supporting rod fixedly connected with the lead ring. A sliding groove corresponding to the fixed supporting rod is formed in the installing plate. An adjusting and fixing mechanism for adjusting and fixing the height of the fixed supporting rod is arranged on the installing plate. A lead cutting air cylinder is arranged on the installing plate, and a lead cutting head is arranged at the movable end of the lead cutting air cylinder. A groove corresponding to the lead ring is formed in the lower end face of the lead cutting head, and a via hole corresponding to the fixed supporting rod is formed in the upper end face. The inner wall of the groove is provided with a knife edge. During lead winding, a copper line penetrates through the lead ring to be guided by the lead ring, and the height of the fixed supporting rod is adjusted through the adjusting and fixing mechanism to adjust the height of the lead ring. When lead cutting is needed, the relative distance between the lead cutting head and the lead ring is changed by adjusting a fixing mechanism and / or the lead cutting air cylinder, lead cutting is completed at the knife edge, a lead guiding effect is good, adjustment is easy, the lead cutting speed is high, and the stator winding machine lead cutting device is simple and compact in whole structure, low in cost and small in occupied space.

Owner:SHENZHEN LUTRON MECHANICAL & ELECTRICAL EQUIP CO LTD

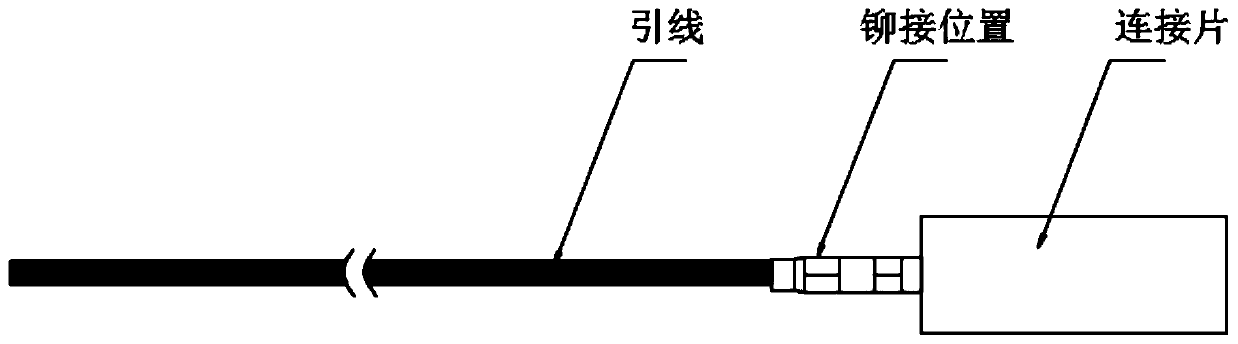

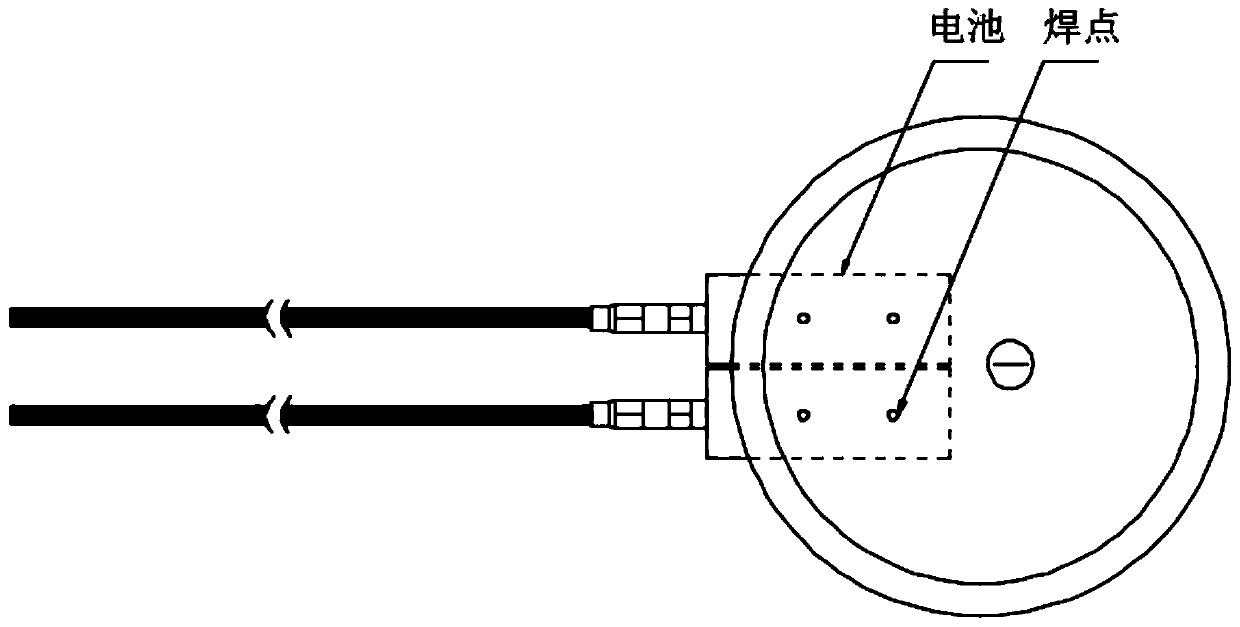

Button cell pin and welding method thereof

ActiveCN111200098ANot easy to break offReduce volumeSmall-sized cells cases/jacketsButton batteryElectrical battery

The invention discloses a button cell pin and a welding method thereof, and particularly relates to the field of button cells. The pin comprises a wire, wherein the wire is specifically a single-corewire, the wire is made of a single metal or alloy material with a melting point close to that of a cell steel shell, and the wire is welded with the cell steel shell through a welding pin. The weldingmethod comprises the steps of starting welding after a lead is machined; preparing a hole sealing coating by adopting asphalt-based aluminum paste, mineral alcohol and hydrotalcite, coating the welding part of the battery steel shell with the hole sealing coating, welding the wire and the battery steel shell through an electric welding machine, and coating the welding part with the hole sealing coating again after the welding is completed and the temperature is reduced to a certain degree. According to the invention, the lead is set as the single-core wire, and the adopted raw material is themetal or alloy material with the melting point being consistent to that of the battery steel shell, so that the lead can be directly welded on the battery steel shell, the welding process is simple,the welding strength is high, the lead is not easy to break and fall off, the size is small, and the space is saved.

Owner:SHENZHEN LIDEA BATTERY

Yarn twisting device and efficient twisting machine

InactiveCN112680836AReasonable structureThe twist is exactly the sameContinuous wound-up machinesYarnGear wheel

The invention discloses a yarn twisting device and an efficient twisting machine. The yarn twisting device comprises a base frame; the top side of the base frame is of a circular structure; a first gear is arranged at the center position of the base frame; a plurality of rotating shaft holes are evenly formed in the edge position of the top side of the base frame; center rotating shafts are rotationally installed in the multiple rotating shaft holes correspondingly; the multiple center rotating shafts are sleeved with second gears and rotating cylinders correspondingly; and a first yarn guiding ring is arranged on the top side of the base frame. The invention further discloses the efficient twisting machine. The yarn twisting device is reasonable in structure and easy to operate; through the arrangement of a gear mechanism, the multiple rotating cylinders synchronously rotate along the multiple center rotating shafts at the same speed, different strands of yarn are fixedly installed in the multiple rotating cylinders correspondingly to be rotated and twisted, and the yarn is converged into one strand of yarn through the first yarn guiding ring, so that the effects that multiple strands of the yarn can be twisted at the same time, the twist degree is completely consistent are achieved, and the occupied space of equipment is effectively reduced.

Owner:史继林

Nanometer titanium nitride-flake graphite filling-modified PA6/ABS composite thermal conductive plastic for LEDs and preparation method thereof

InactiveCN105255170AImprove wire performanceGood mechanical propertiesMelt spinning methodsArtifical filament manufactureFilling materialsTitanium nitride

The invention discloses a nanometer titanium nitride-flake graphite filling-modified PA6 / ABS composite thermal conductive plastic for LEDs and a preparation method thereof. The thermal conductive plastic employs a mixture of PA6 and ABS plastics and has excellent plasticity, durability and electric insulation performance; and after filling modification by flake graphite and nanometer titanium nitride, the PA6 and ABS plastics have better thermal conductivity, and composite short fibers with high thermal conductivity prepared from the composite materials through melt spinning are more uniformly dispersed and bonded in later mixing and can form a uniform and stable heat transfer network, so the phenomenon of nonuniform heat transfer of plastics in traditional production methods can be improved and the utilization rate of the thermal conductive filling materials can be enhanced. Test results show that the composite thermal conductive plastic has excellent thermal conductivity, resistance to UV ageing and durability, is rarely prone to yellowing and embrittlement, and can be widely used in the field of heat dissipation of the LEDs.

Owner:ANHUI HEHAN OPTOELECTRONICS TECH

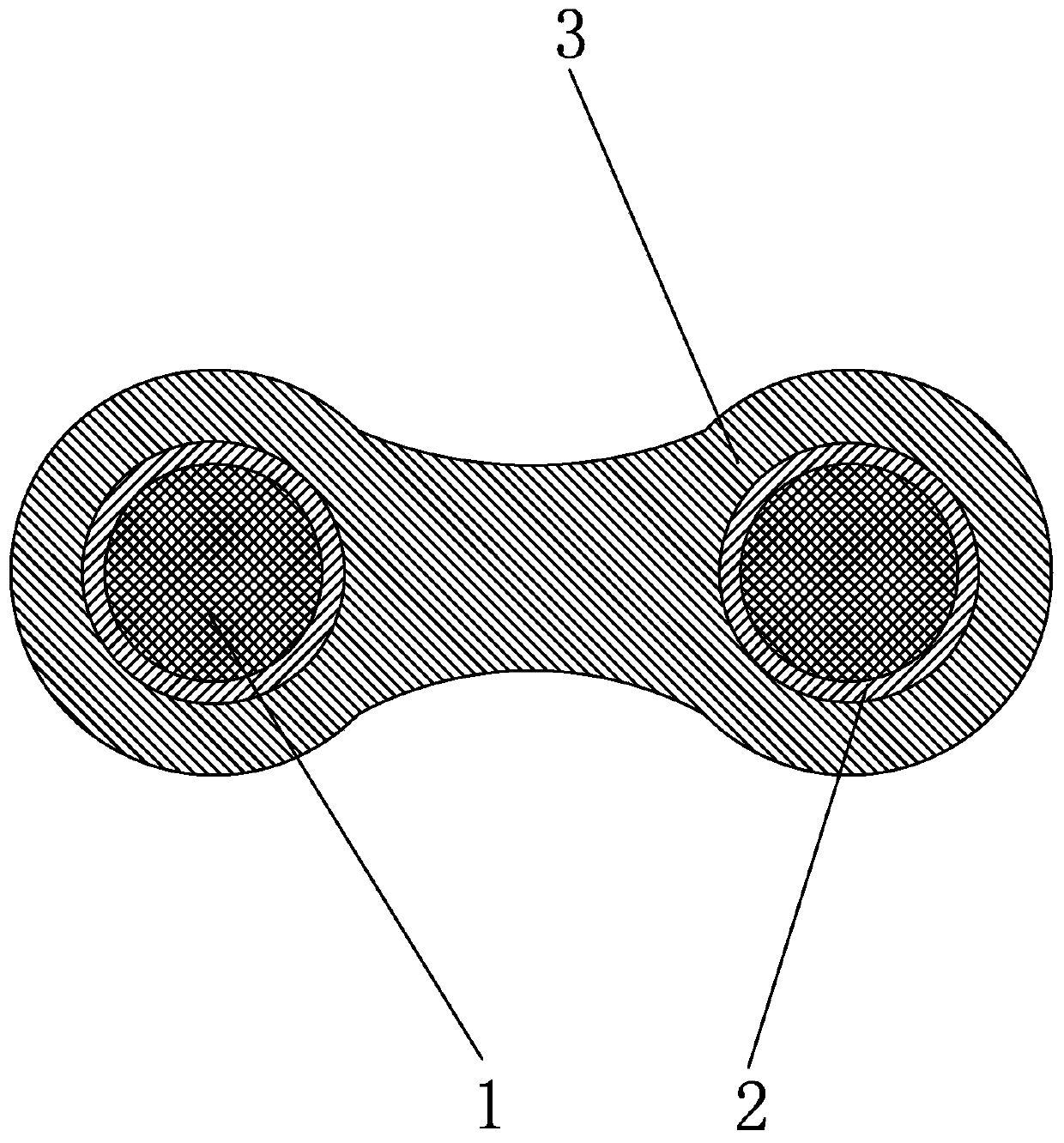

Sports instrument wire harness

InactiveCN109712745APrevent creepAvoid mutual interferencePlastic/resin/waxes insulatorsFlat/ribbon cablesCarbon fibersCompressive strength

The invention discloses a sports instrument wire harness. The sports instrument wire harness comprises a wire harness body. The wire harness body is of a flat structure and comprises two core wires, an aramid fiber wrapping layer and an insulating outer layer. The core wires are formed by stranding and twisting aluminum alloy conductive wires and carbon fiber conductive wires. The diameter of aluminum alloy conductive wires is 0.25-0.85mm. The diameter of the carbon fiber conductives is 0.15-0.65mm. The two core wires are arranged side by side in parallel at intervals. Each core wire comprisesat least three carbon fiber conductive wires and at least six aluminum alloy conductive wires. The aramid fiber wrapping layer is arranged around the core wire. The thickness of the aramid fiber wrapping layer is 0.5-1.2mm. The insulating outer layer is coated outside the aramid fiber wrapping layer. The wire harness is low in manufacturing cost, good in wire performance, good in tensile breakingstrength and compressive strength, good in connection stability, capable of effectively preventing the wire harness from being twisted and convenient to wire and tidy.

Owner:苏州昱艺鑫电子有限公司

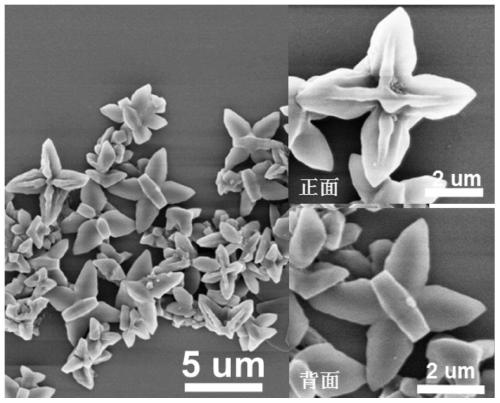

Azafluorene-based small molecule butterfly-shaped organic nanocrystal material and its preparation method and application

ActiveCN109678893BEasy to operateLow costOrganic chemistry methodsSolid-state devicesConductive atomic force microscopyOrganic semiconductor

The invention discloses an azafluorene-based small molecule butterfly-shaped organic nanocrystal material and its preparation method and application. The azafluorene-based small-molecule butterfly-shaped organic nanocrystal material has an asymmetric double-sided butterfly-shaped multi-dimensional micron structure , one side is plum-shaped and the other is butterfly-shaped. The invention realizes the controllable preparation of pure organic small molecule nanometer material in the field of multi-dimensional structure. Through the corresponding dynamic growth process and single crystal analysis and other characterization methods, the growth mechanism of this organic nanomaterial and the deep relationship between the morphology and molecular structure were confirmed. In addition, the excellent wire performance of the structure was verified based on the conductive atomic force microscopy platform. The application potential of such organic semiconductor materials in future optoelectronic devices is demonstrated.

Owner:NANJING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com