Yarn twisting device and efficient twisting machine

A technology of twisting device and twisting machine, applied in spinning machine, continuous winding spinning machine, textile and papermaking, etc., can solve the problems of uneven fineness, unguaranteed twist, and uneven distribution of twist. , to achieve the effect of reducing the floor space, reasonable structure and completely consistent twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

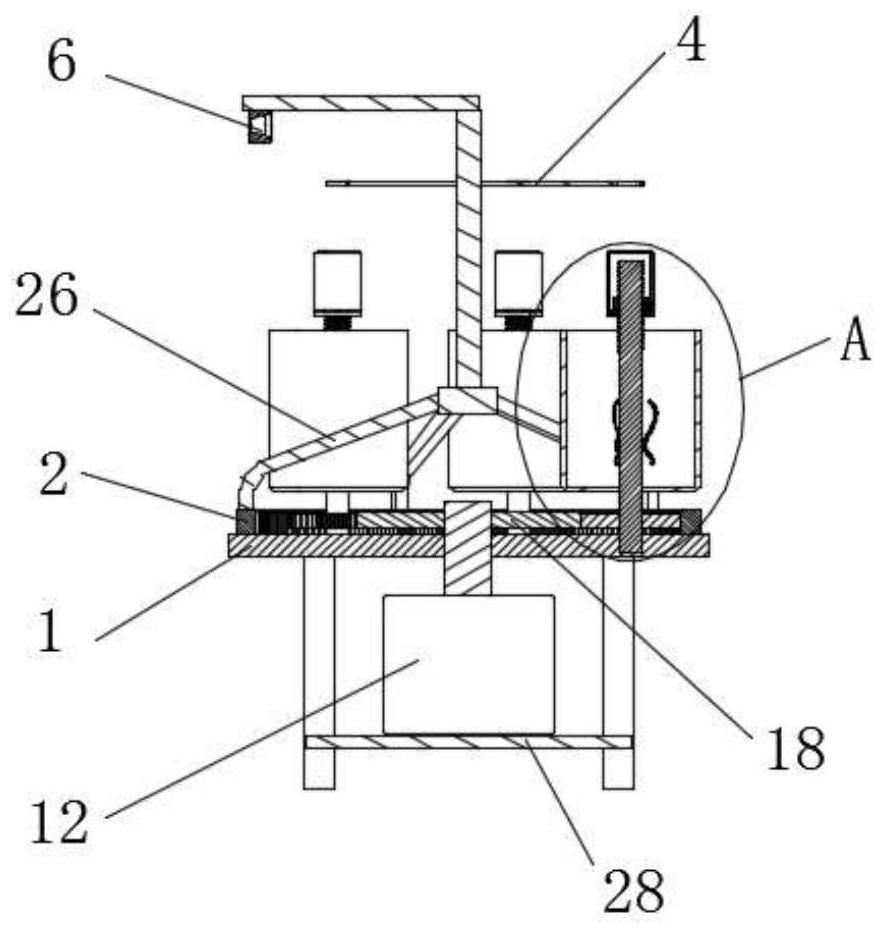

[0042] Example: Reference Figure 1-8 A kind of yarn twisting device shown, comprises base frame 1, and base frame 1 is welded by the hard material in the prior art such as round steel plate and angle steel frame.

[0043] The motor 12 is fixedly installed on the bottom side of the base frame 1 through the supporting plate 28, and the top side of the base frame 1 is in a circular structure with a avoidance hole at its center. The output shaft of the motor 12 passes through the avoidance hole and extends to the base frame 1, and the first gear 18 is sleeved and installed, and the top side of the base frame 1 is located at its edge position to evenly open a plurality of rotating shaft holes, and a central rotating shaft 13 is installed in the plurality of rotating shaft holes. Second gears 14 and rotating drums 3 are sleeved on each central rotating shaft 13, and a plurality of rotating drums 3 are respectively positioned at the top side positions of a plurality of second gears ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com