Transparent electric conductor and manufacturing method

A technology of transparent conductors and conductive layers, which is applied in the direction of electrical digital data processing, instruments, and data processing input/output processes. It can solve the problems of poor conductivity and high resistivity of ITO conductive films, and achieve mass production. Improved conductivity and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

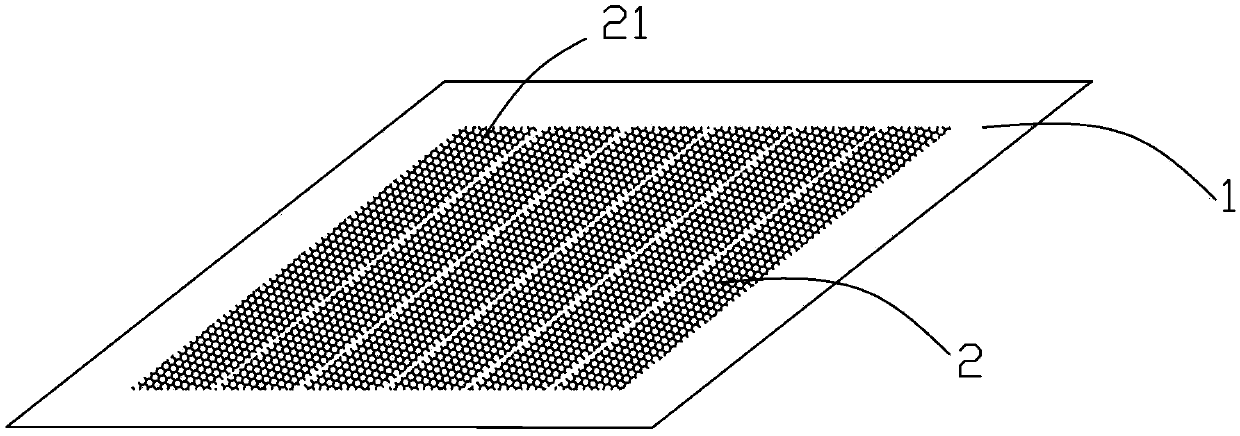

[0047] Such as figure 1 and figure 2 Shown is a schematic structural diagram of the transparent conductor provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the transparent conductor described in the first embodiment includes: a transparent substrate 1 and a touch-sensitive conductive layer 2 disposed on the surface of the transparent substrate 1 . Such as figure 2 As shown, the touch-sensitive conductive layer 2 includes at least two conductive units 21 . The conductive unit 21 is a grid pattern formed of conductive material, and there is a preset gap between two adjacent conductive units 21 .

[0048] This embodiment replaces the ITO conductive film in the prior art by setting a grid-shaped touch-sensitive conductive layer formed of conductive material on the transparent substrate, which can effectively reduce the resistivity of the touch-sensitive conductive layer and improve the transparent conductor. The lead wire is suitable for use in l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com