Cathode steel bar for effectively restraining horizontal current and manufacturing method of cathode steel bar

A cathode steel rod and horizontal current technology, which is applied in the field of cathode steel rods, can solve the problems of insignificant effect of suppressing horizontal current, reduced mechanical strength of cathode steel rods, easy falling off, separation or damage, etc., so as to improve electrolysis efficiency and reduce production difficulty. , the effect of fast manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

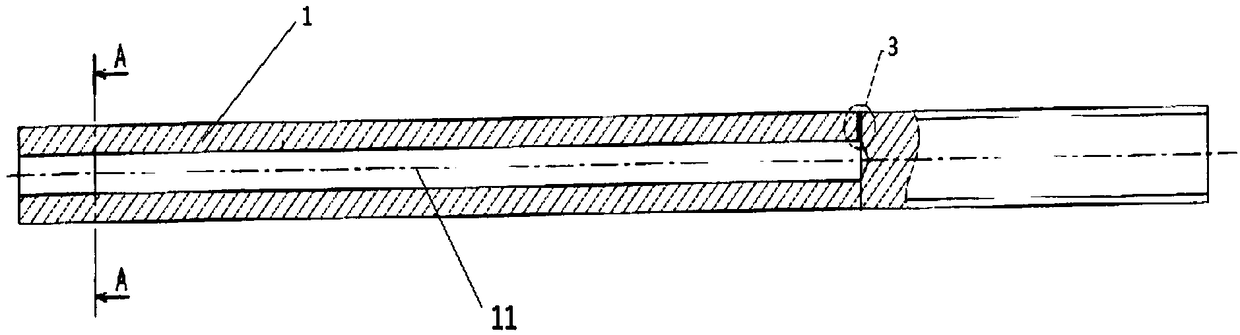

[0033] In the production equipment of electrolytic aluminum, etc., the cathode steel rod is a metal conductive part arranged in the steel rod groove at the bottom of the cathode carbon block of the aluminum electrolytic cell. It is arranged along the length direction of the cathode carbon block. The material of the cathode steel rod is low carbon steel. The cross-sectional shape in the direction is an equal-area rectangle. Its design purpose is to conduct the overcurrent of the cathode aluminum liquid of the aluminum electrolytic cell to the cathode busbar, and to reduce and suppress the aluminum electrolytic cell while completing the carbon-metal conductive transition. Generation of horizontal current in molten aluminum. However, since the cathode steel rod installed in the steel rod groove at the bottom of the cathode carbon block of the aluminum electrolytic cell is in a high temperature zone, the material resistivity of the cathode steel rod made of metal steel material wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com