Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about How to "Improve the level of environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

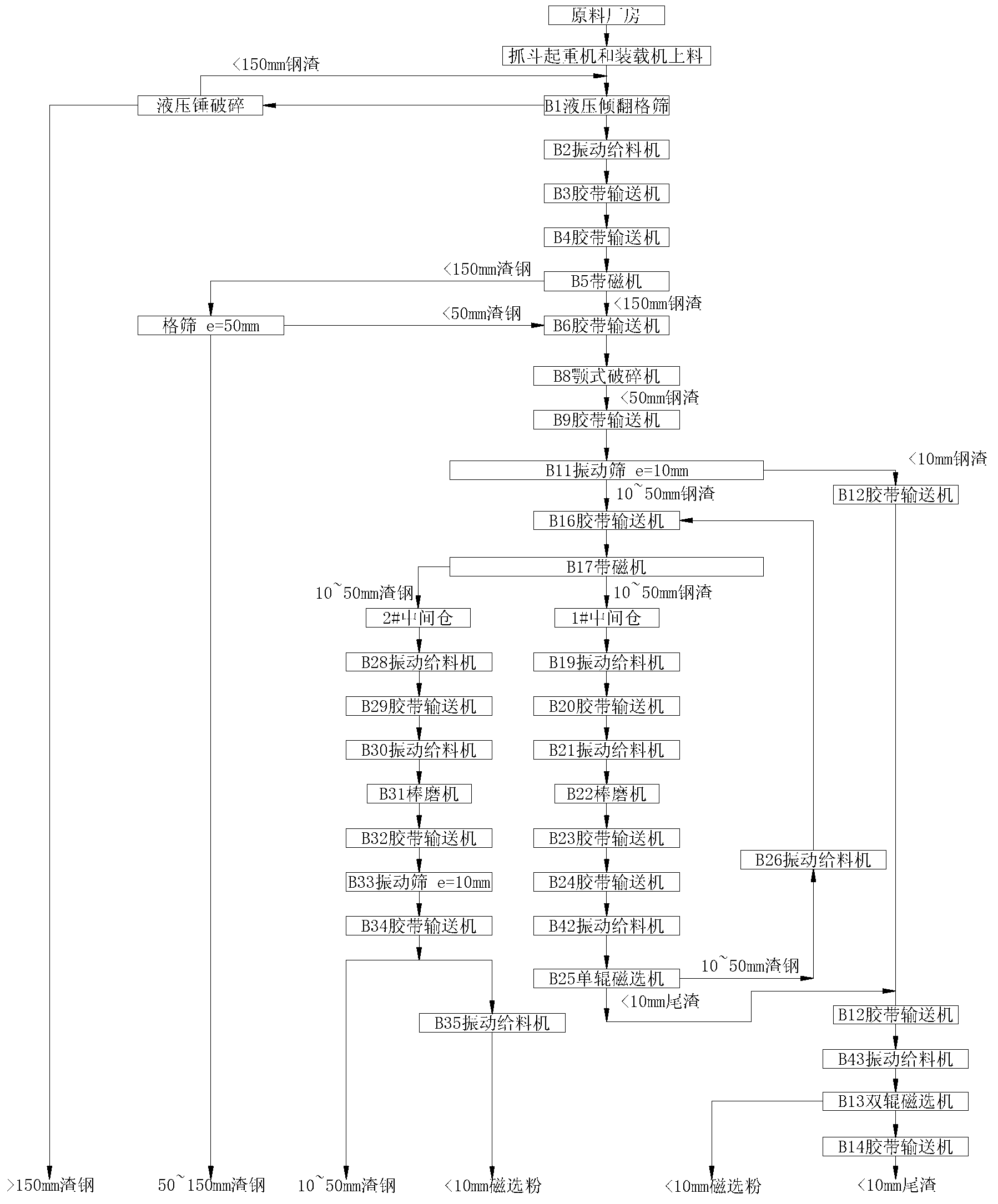

Steel slag treating technology

ActiveCN103290153AIncrease added valueFor subsequent useRecycling and recovery technologiesSteelmakingClosed loop

The invention relates to a steel slag treating technology which can be used for treating steel slag after which is stabilized by adopting a hot and stuffy method. According to the technology, the steel slag is treated by the procedures of screening, crushing, magnetic separation, purification and the like through utilizing the mode of combining an open loop and a closed loop circulation to obtain five high-value-added high-quality products, namely first-type bulk slag steel with the grade of more than or equal to 80% and particle size of 150mm, a second-type bulk slag steel with the grade of more than or equal to 80% and particle size of 50-150mm, slag steel with grade of more than or equal to 85% and particle size of 10-50mm, magnetic separation powder with grade of more than or equal to 42% and particle size of 10mm, and metal iron content (2% of tailings with the particle size of 10mm), wherein the first-type bulk slag steel and the second-type bulk slag steel and the slag steel with the grade of more than or equal to 85% can be returned for steelmaking, the magnetic separation powder can be used for sintering, and the tailings can be used for producing steel slag micropowder as high-activity admixture of cement and concrete and the like. Through the technology, the zero emission of the steel slag can be realized, the defects that the steel slag stored occupies a large area and pollutes the environment can be solved, and the economic benefits of a steel mill can be increased.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

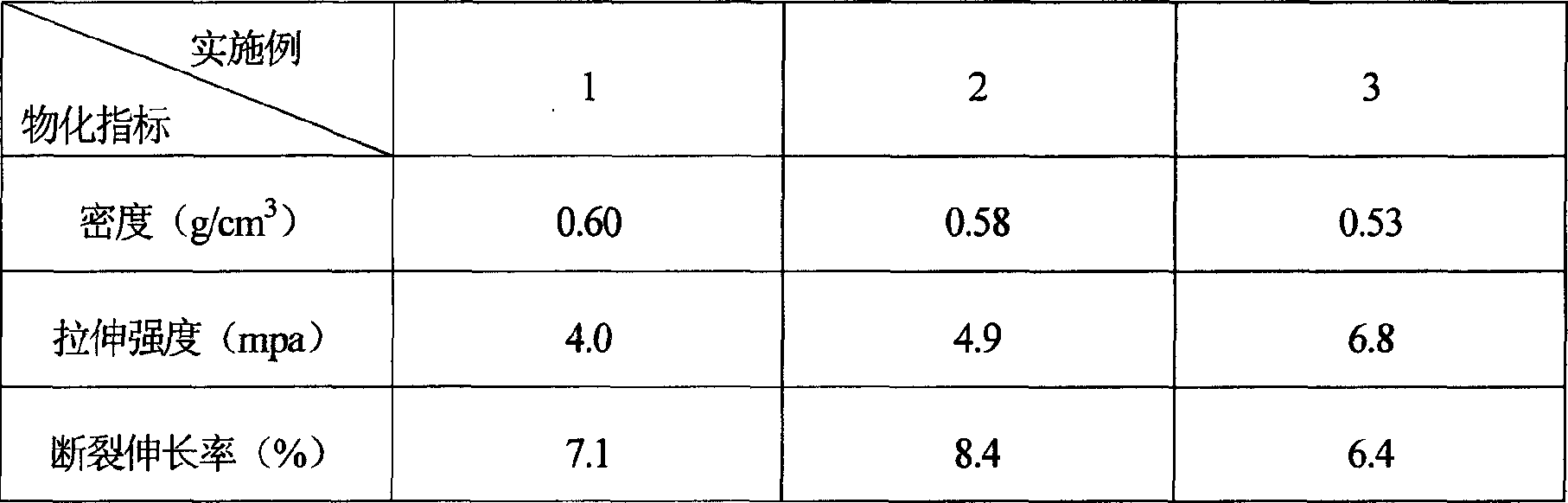

Polycomponent combined degradable foamed plastic and its preparation method

InactiveCN1786072AImprove the level of environmental protectionImprove the value-added ability of conversionPolymer scienceFoaming agent

The present invention relates to a multicomponent combined degradable foamed plastic material and its preparation method. Its composition includes (by weight portion) 70-100 portions of modified polylactic acid mother granules, 1-20 portions of carbon dioxide resin and / or fatty polycaprolactone, 0.5-1.5 portions of lubricant demoulding agent, 1-5 portions of foaming agent and foaming adjuvant and 1-5 portions of cross-linking agent. Its preparation method includes the following steps: (1). inorganic powder body modification; (2). starch modification; (3). polylactic acid modification; and (4). plasticization foaming so as to obtain the degradable foamed plastic sheet material.

Owner:朱家牧

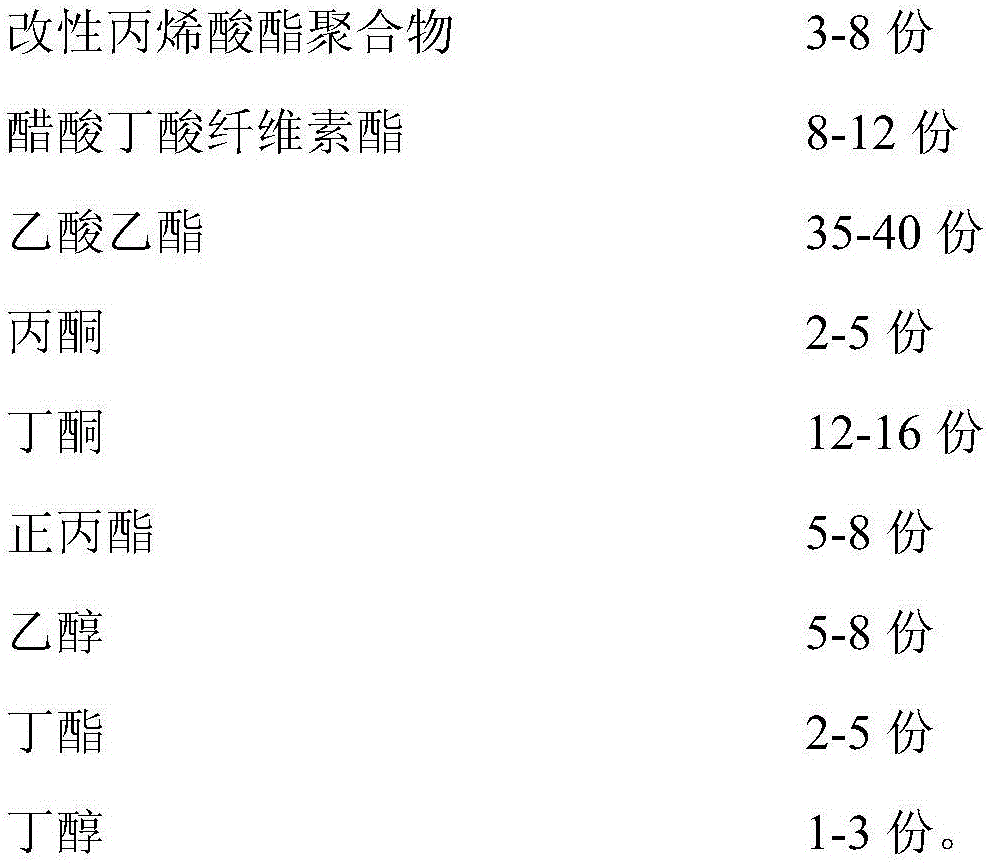

Green environment protection adhesion agent and production method

InactiveCN101220249AImprove the level of environmental protectionMonocarboxylic acid ester polymer adhesivesGreen environmentBenzene

The invention relates to an environment-friendly adhesive and a preparation method and belongs to the technical field of fine chemical industry. The invention provides a novel recipe and the preparation method for preparing the environment-friendly adhesive. The technical key of the invention is to polymerize different polymerization monomers, coupling agents, evocating agents, emulsifying agents and negative ion dispersing mediums into crosslinkable and curing high molecular polymer in a certain temperature by a certain method. The environment-friendly adhesive is suitable for woodworks, such as industries of hard board, furniture and composite floor board. The physical mechanical performance and the environmental protection index of the various woodworks produced by using the novel environment-friendly adhesive meet and even surpass the national standard requirement of various woodworks. The invention can effectively remove the pollution and danger of benzene and formaldehyde.

Owner:柏晓东 +3

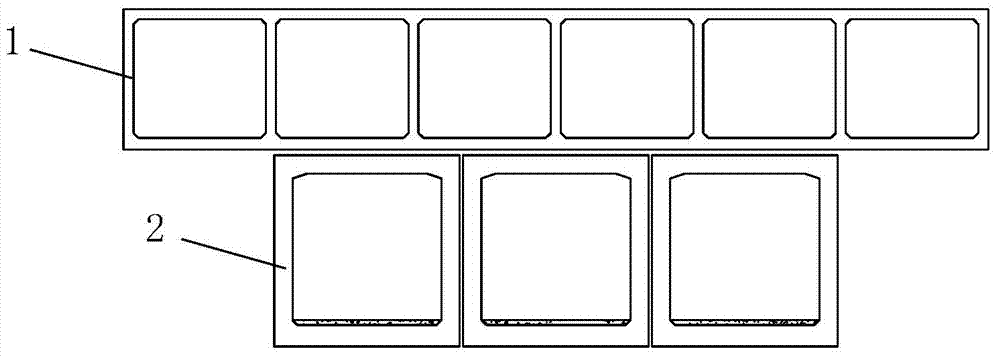

Construction process of double-layer jacking culvert penetrating through existing railway lines

ActiveCN103485288AThe method steps are simpleReasonable designGround-workTunnelsSupporting systemCulvert

The invention discloses a construction process of a double-layer jacking culvert penetrating through existing railway lines. The construction process includes the following steps: (1) precasting of an upper-layer bridge culvert body, (2) construction of a back and a back beam used for jacking of the upper-layer bridge culvert body, (3) reinforcement of the existing railway lines, wherein the existing railway lines are reinforced through a line overhead reinforcing structure, (4) digging of a jacking pit of the upper-layer bridge culvert body, (5) jacking of the upper-layer bridge culvert body, (6) construction of a bottom supporting system of the upper-layer bridge culvert body, (7) detachment of the line overhead reinforcing structure, (8) precasting of a lower-layer bridge culvert body, (9) construction of a back and a back beam used for jacking of the lower-layer bridge culvert body, (10) digging of a jacking pit of the lower-layer bridge culver body, (11) jacking of the lower-layer bridge culvert body, and (12) concrete pouring, wherein after the lower-layer bridge culvert body is jacked properly, concrete is poured between the upper-layer bridge culvert body and the lower-layer bridge culvert body. The method is simple, reasonable in design, low in investment construction cost and good in using effect, the construction process of the double-layer jacking culvert can be easily, conveniently and quickly finished and is high in quality, and the construction process is safe and reliable.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Natural polymer composite-base formaldehyde remover and preparation method thereof

InactiveCN101607174AImprove the level of environmental protectionFlexible usageDispersed particle separationAdhesiveNational standard

The invention discloses a formula of a formaldehyde remover made from a natural plant extract and a preparation method thereof. The raw material of the formaldehyde remover is the natural plant extract which can react with formaldehyde with high efficiency. After being prepared, the solution of the formaldehyde remover is added into adhesives, or sprayed on the surfaces of furniture or plates or sprayed into the air to make formaldehyde content of a post-processed products or space meet the requirements of national standards.

Owner:上海复爱绿色化学技术有限公司 +1

Adhesive

InactiveCN102604574ASimple production processEasy to operateAldehyde/ketone condensation polymer adhesivesControl measureUrea

The invention discloses an adhesive. The adhesive is characterized in that the adhesive is prepared from raw materials including 12,666 to 12,726kg of aqueous formaldehyde solution, 9,972 to 10,237.2kg of urea, 55 to 65kg of polyvinyl alcohol, 1,176 to 1,224kg of melamine and 11 to 13kg of aqueous sodium hydroxide solution. In the aqueous formaldehyde solution, the mass percent of formaldehyde is36.5 to 37.5; in the urea, the mass percent of nitrogen is 46.0 to 46.4; and in the aqueous sodium hydroxide solution, the mass percent of sodium hydroxide is 25 to 35. The adhesive has the advantages that the productive technology is simple, the solid content is high, the free formaldehyde content is low, formaldehyde catcher or modifying agent is not required to be added during adhesive mixing process when the adhesive is used for manufacturing particle boards, the curing time of the mixed adhesive is short, and the formaldehyde emission of the particle boards manufactured through the adhesive is stable, and can meet the standard of E0F4 level of Japan and the standard on formaldehyde emission in the second stage according to Composite Wood Products Airborne Toxic Control Measure (ATCM)of California, USA.

Owner:上海美连商务信息咨询服务有限公司

Environment-friendly ecological board and production process thereof

InactiveCN105291207AHigh glossImprove flatnessWood veneer joiningWood layered productsWater basedEnvironmental resistance

The invention provides an environment-friendly ecological board and a production process thereof. The production process comprises: performing hot-press gluing on one side of an artificial board and impregnated bond paper into an impregnated bond paper decorative artificial board, and cooling the impregnated bond paper decorative artificial board till a room temperature for later use, wherein hot pressing is performed for 5-15 minutes at a temperature ranging from 100 to 150 DEG C and under a pressure ranging from 0.3 to 1.5MPa; coating both sides of a substrate with a cold-pressing glue and performing cold pressing on the substrate and the obtained impregnated bond paper decorative artificial board, wherein the cold-pressing glue is a water-based isocyanate adhesive; cold pressing is performed for over 30 minutes under a pressure ranging from 0.1 to 1Mpa; relieving the pressure, and aging for 5 or more hours followed by cutting edges, thereby obtaining the finished environment-friendly ecological board. The invention provides the environment-friendly ecological board that is few in production steps and high in finished product yield and grade rate, and the production process thereof.

Owner:张建明

Composite additive

ActiveCN105567375AHigh activityIncrease the effective areaSolid fuelsFuel additivesInorganic compoundOrganic compound

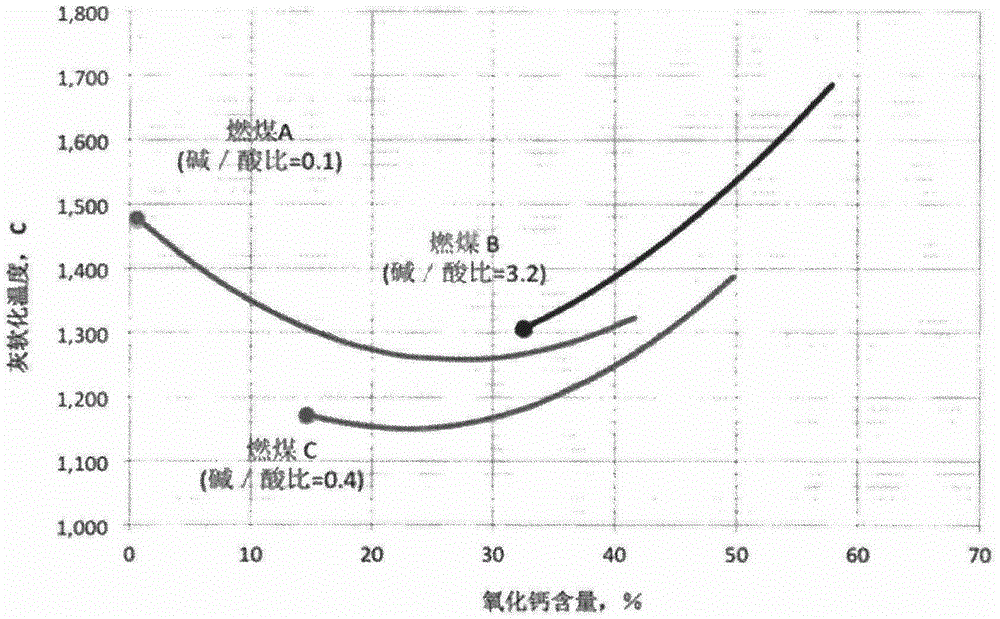

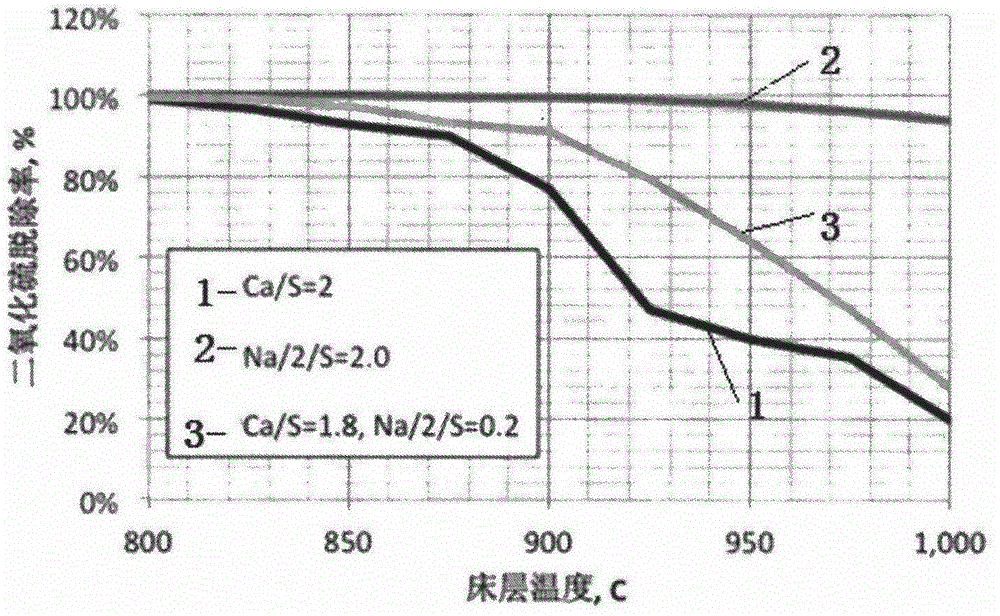

Embodiments of the invention provide a composite additive, which comprises a calcium-based additive and a sodium-based additive, wherein the calcium-based additive comprises an inorganic calcium compound, an organic calcium compound or a combination of an inorganic calcium compound and an organic calcium compound, and the sodium-based additive comprises at least one selected from baking soda powder (NaHCO3), at least soda ash (Na2CO3) and caustic soda (NaOH). According to the present invention, the composite additive provided by the embodiments and coal are doped, and the obtained mixture is burned, such that SO2, HCL, HF, NOx and other toxic and harmful gases produced during the coal burning can be reduced, and the environmental pollution can be reduced.

Owner:YANKUANG GRP CO LTD +1

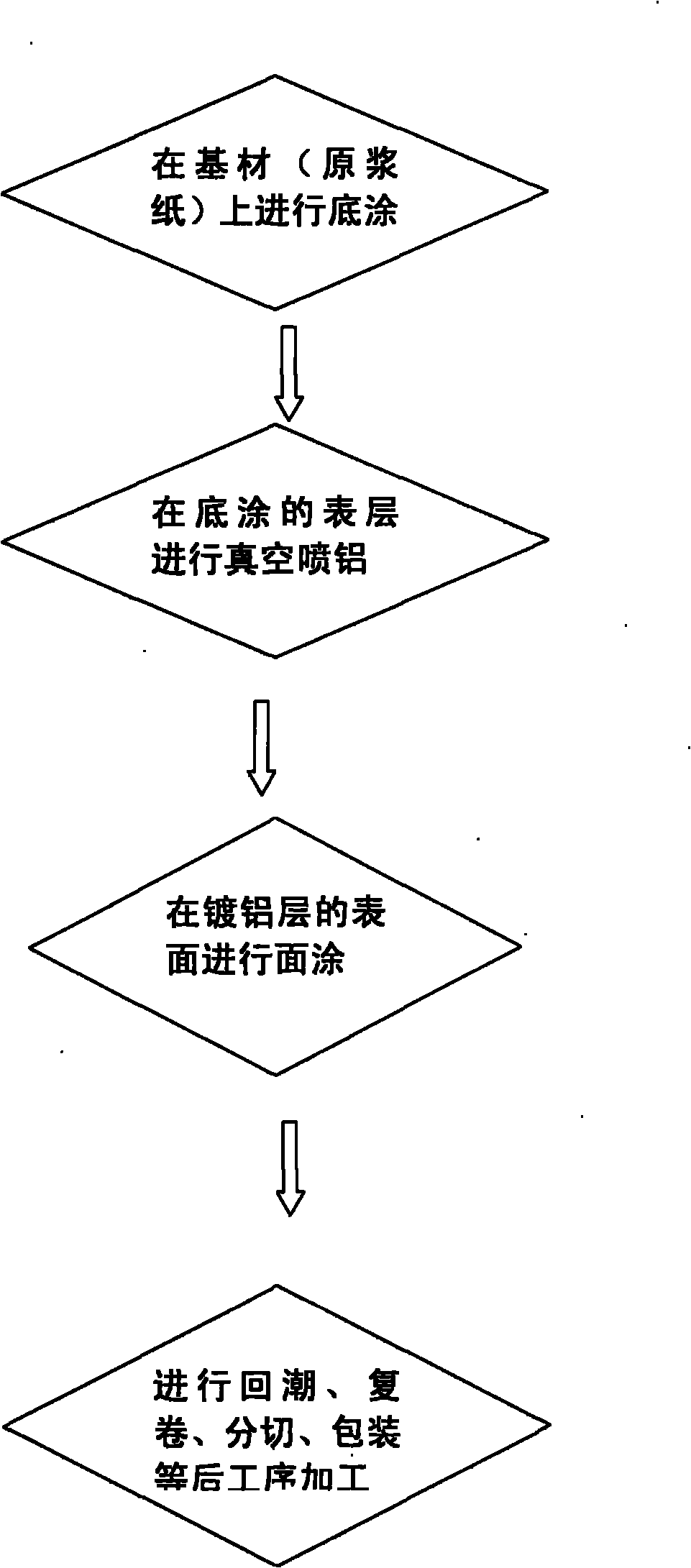

Packing paper with effect of halo in many colors and production technology thereof

The invention discloses a production technology of packing paper with the effect of halo in many colors. The production technology comprises the following steps: (1) preparing a transfer coating by using modified acrylate polymer as base resin; (2) coating a PET film with the transfer coating to prepare a transfer film; (3) vacuum-aluminizing the transfer film by a vacuum-aluminizing machine; (4) coating the aluminized transfer film with aqueous composite glue by a wet coating machine to be compounded with backing paper, coating the backing paper with a back glue material, and drying; (5) separating an aluminized coating of the compounded and cured product with the base PET film so as to prepare aluminized packing paper; and (6) printing the surface of the packing paper obtained after stripping with printing ink. The packing paper with the effect of halo in many colors has advantages of good luster effect, high tensile strength, low cost, strong alkaline hydrolysis resistance, strong adhesive force, low shrinkage and good anti-adhesion and wear-resisting properties.

Owner:上海睿途新材料科技有限公司

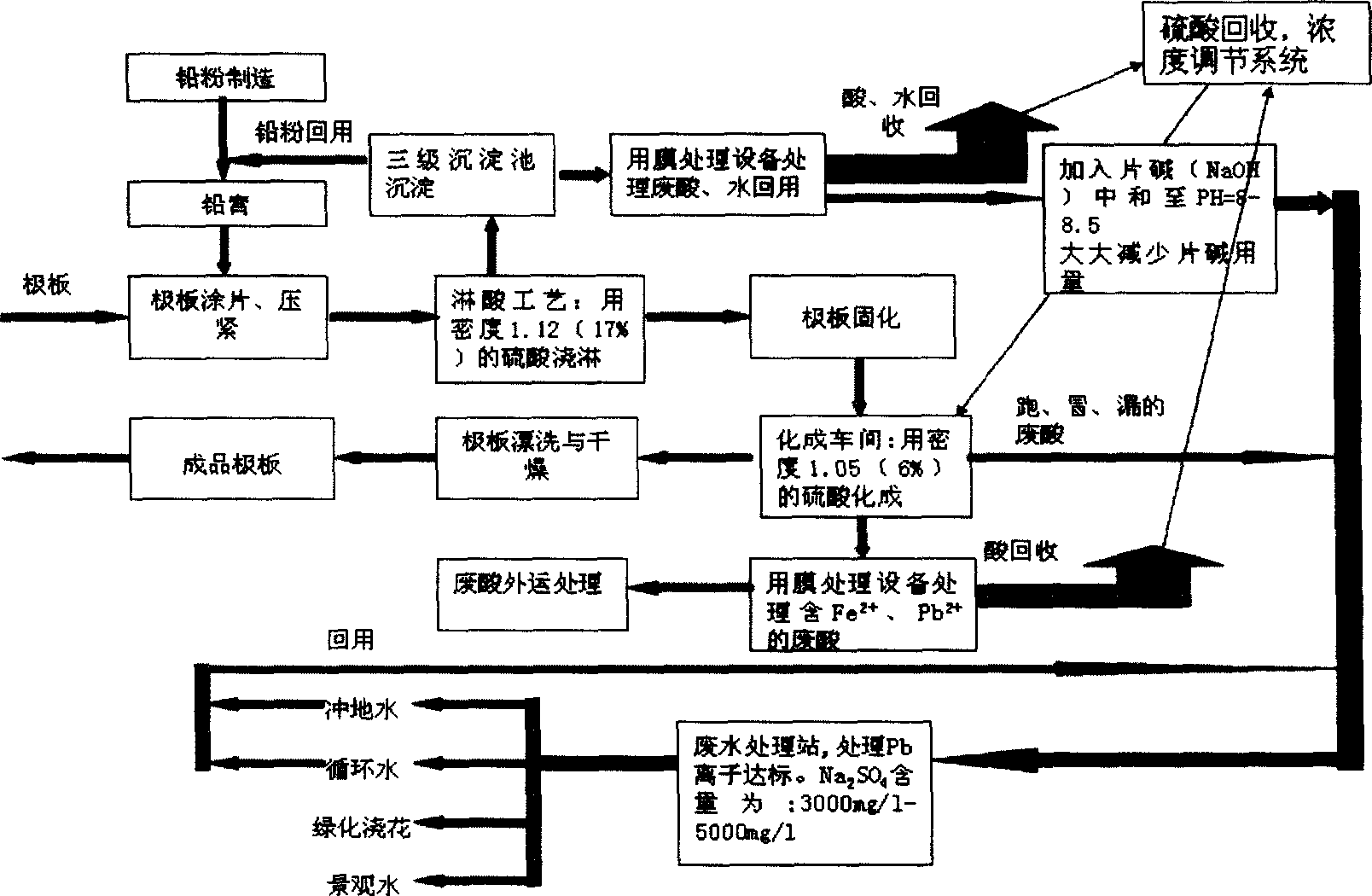

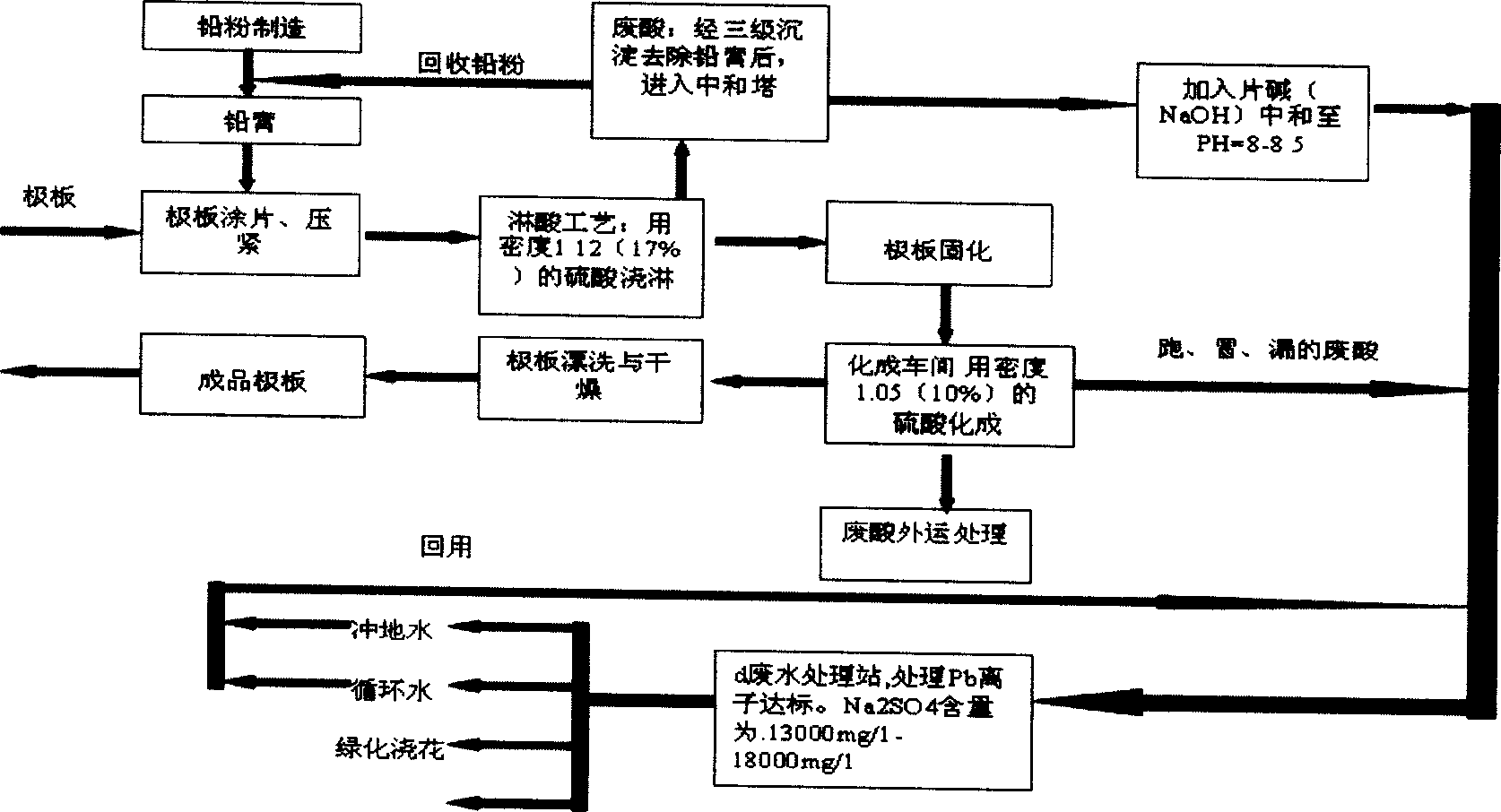

Waste vitriol re-use technics and apparatus for accumulator plate product

InactiveCN1722511APromote environmental protectionImprove efficiencyLead-acid accumulator electrodesWaste accumulators reclaimingFractional PrecipitationChemical reaction

This invention relates to a process for recycling waste sulphuric acid in course of making accumulator pole plate and its device, comprising recycling lead by adding acid and fractional precipitation, alkali neutralization, chemical reaction and waste sulphuric acid transmission, and using the first and second films separating method to comprehensively treat waste sulphuric acid brought from drenching acid and chemical reaction. The invention has the advantages of lower production cost, saving water in maximum extent and improving the condition of water usage in factory district, improving environment protection level and economical benefit.

Owner:郝华

Oriented strand board composite decorative board and manufacturing method

InactiveCN105966143ASimple processImprove internal bond strengthSpecial ornamental structuresWood working apparatusWood shavingsRoom temperature

The invention provides an oriented strand board composite decorative board which comprises a substrate layer and an overlaying layer or overlaying layers, wherein the overlaying layer or overlaying layers is / are glued at the single side or double sides of the substrate layer through a formaldehyde-free adhesive, and the substrate layer is an oriented strand board taking wood or wheat straw shavings as the raw material and taking isocyanate resin and / or phenolic resin as the adhesives or the adhesive. A manufacturing method of the oriented strand board composite decorative board comprises the following steps that by taking the wood or wheat straw shavings as the raw material and taking isocyanate resin and / or phenolic resin as the adhesives or the adhesive, the oriented strand board is manufactured according to directional pavement and hot-pressing technologies; the both sides of the oriented strand board are sanded and puttied; one side or both sides of the substrate layer is / are coated with the formaldehyde-free adhesive, and is / are bonded with the overlaying layer or the overlaying layers; and room temperature cold pressing treatment is carried out to allow the adhesive(s) to be solidified, wherein the pressing temperature is 20-35 degrees, the pressing pressure is 0.5-1.5MPa, and the pressing time is 0.5-4h. According to the oriented strand board composite decorative board, the problems that the conventional decorative board is high in formaldehyde content, complicated in technology, and high in cost are solved.

Owner:NINGBO ZHONGJIA LOW CARBON NEW TECH RES INST

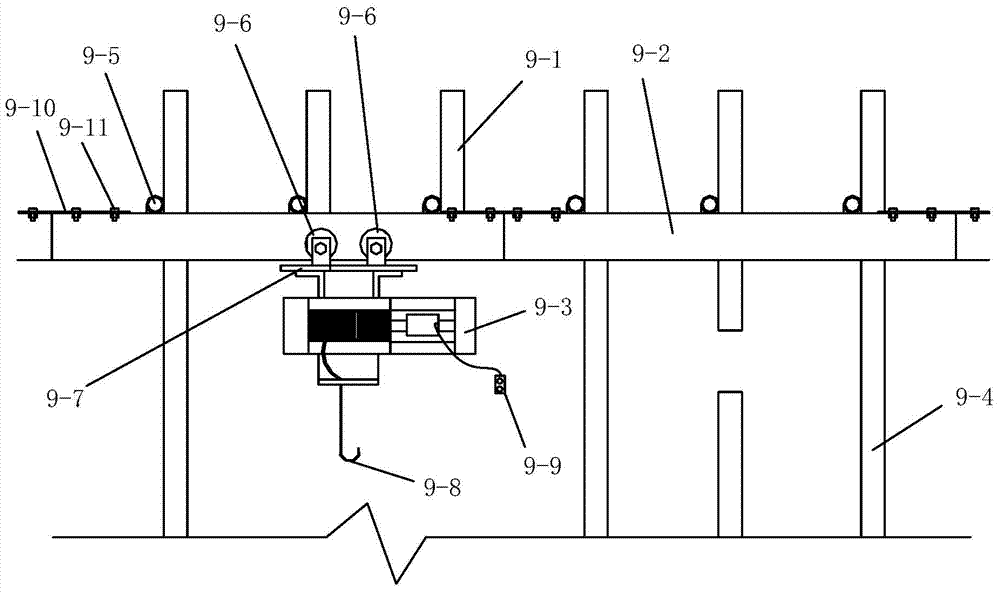

Flow line magnesium electrolysis production method

The invention discloses a flow line magnesium electrolysis production method. In the method, a head cell (1), a melt pipeline (2), an electrolysis cell (3) and a tail cell (6) are utilized; and the head cell (1), the electrolysis cell (3) and the tail cell (6) are connected in series through the melt pipeline (2) to form a closed cycle magnesium electrolysis production method. By adopting the method, the defect that the conventional magnesium electrolysis cell can only be operated independently is overcome, and centralized charging and centralized magnesium production of a magnesium electrolysis process are realized. The labor intensity of workers is reduced, and the frequency of conveying high-temperature melt through a crown block in a workshop is greatly reduced, so that the safety production level is improved.

Owner:GUIYANG AL-MG DESIGN & RES INST

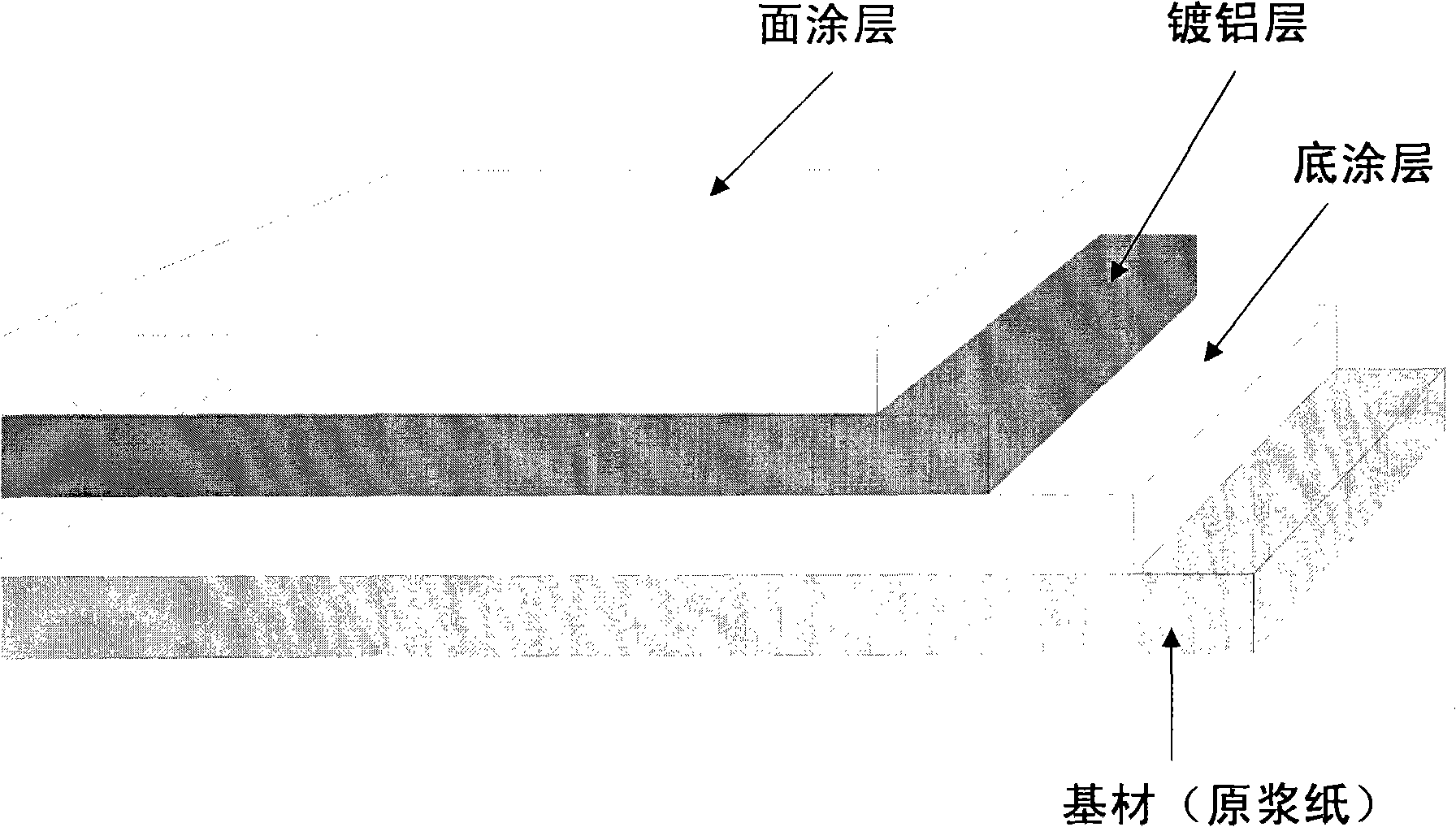

Method for preparing ink holdout type metallized paper

ActiveCN101864692AWith toner performanceEasy to filter and recycleEpoxy resin coatingsMetal coatingsPlatinumPaper production

The invention discloses a method for preparing metallized paper used for label printing and other aspects and having ink holdout function, and in particular relates to innovation of a priming coat and a top coat used for vacuum metallized paper production. (The coating referred below comprises the priming coat and the top coat.) The ink holdout type coating is mainly characterized in that: water borne epoxy resin is taken as a main component and is dissolved in solvents of water and ethanol to form the two-component ink holdout coating, wherein the epoxy resin is high molecular weight bisphenol A water borne epoxy resin meeting the following standards: 1) the epoxy equivalent weight (g / eq) is 1,600 to 2,000; 2) the viscosity (cps, 150DEG C) is 1,300 to 10,000 (5.8); 3) the softening point (DEG C) is 125 to 142; and 4) the color (platinum-cobalt method) is 100 to 250Max. The metallized paper solves the problem that an aluminum layer and an ink layer fall off when a metallized paper label is soaked in aqueous alkali (NaOH); and the metallized paper produced and metallized paper beer labels printed by the invention have strong alkaline hydrolysis resistance and good permeability, and the aluminum layer and the ink layer do not fall off when the metallized paper and the metallized paper beer labels are soaked in the aqueous alkali (NaOH). The metallized paper has important environmental protection application value, and also has significance for reducing the production cost of beer producers and recycling waste.

Owner:GUANGDONG MANCHEONG KEYI MATERIAL +2

Aluminum-wood heterogeneous composite engineered wood

ActiveCN110861372AWith glossy decorative effectImprove rigidity and toughnessNon-macromolecular adhesive additivesDomestic upholsteryAdhesive cementSingle plate

The invention relates to engineered wood, and in particular, relates to aluminum-wood heterogeneous composite engineered wood. The aluminum-wood heterogeneous composite engineered wood sequentially comprises an Ayous veneer layer, more than one group of second blank plate layers and an Ayous veneer layer; the second blank plate layers are each formed by compounding, pressurizing and gluing a firstblank plate layer, an aluminum plate and a second blank plate layer, and the first blank plate layer is formed by recombining more than one Ayous veneer. A preparation method comprises the followingsteps: (1) recombining more than one Ayous veneer by coating a first adhesive to prepare the first blank plate layer; (2) coating the single surface of each of two blank plates A with a second adhesive, and compounding, pressurizing and gluing with a pretreated aluminum plate to obtain the second blank plate layer; (3) compounding, recombining, pressurizing and curing the second blank plate layersand the Ayous veneer coated with a third adhesive, and thus obtaining the aluminum-wood heterogeneous composite engineered wood batten; and (4) slicing. The aluminum-wood heterogeneous composite engineered wood is not prone to cracking and good in stability and has the metallic luster decoration effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Production technology of nano-self cleaning architechtural aluminium curtain wall board

InactiveCN1824394ALess investmentReduce manufacturing costWallsPretreated surfacesProduction lineSpray coating

The present invention discloses a production process of nano self-cleaning building aluminium curtain wall plate. Said production process includes the following steps: (1). spray-coating face paint; (2). leveling; (3). spray-coating nano self-cleaning solution; (4). heating and curing; and (5) photocuring.

Owner:蒋建新

Method of directly melting and molding scrap copper to extract copper by electrolysis

InactiveCN104278291AHigh recovery rateShort processPhotography auxillary processesProcess efficiency improvementCopper sulfateTin

The invention provides a method of directly melting and molding scrap copper to extract copper by electrolysis. The method comprises the following steps: 1) directly melting and molding scrap copper with copper content of over 60% into an anode and taking a pure copper thin sheet as a cathode; 2) using copper sulfate, sulfuric acid and hydrochloric acid to prepare electrolyte adding the electrolyte into an electrolytic cell, wherein the electrolyte comprises the following components: 45-60g / L copper sulfate, 160-200g / L sulfuric acid, 0.04-0.08g / L hydrochloric acid and the balance of water; 3) switching on direct current for the electrolytic cell to perform electrolysis, wherein the process conditions for electrolysis are as follows: electrolyte temperature of 55-65 DEG C and cathode current density of 150-260A / m<2>. The scrap copper applicable to the method comprises the following components in percentage by weight: 60-99.5% of copper, 0-10% of lead, 0-5% of nickel, 0-3% of iron, 0-3% of iron, 0-3% of tin and 0-10% of zinc. The method disclosed by the invention can be used for solving the problem that the existing production process is long in process flow, low in recovery rate, high in energy consumption and low in utilization level and causes serious environmental pollution. The method abandons smelting processes such as oxidizing and reducing used in the existing process and has the advantages of a high recovery rate, low cost, a short production period, capacity of relieving environmental pollution, and the like.

Owner:天津中色再生金属工程技术研究院

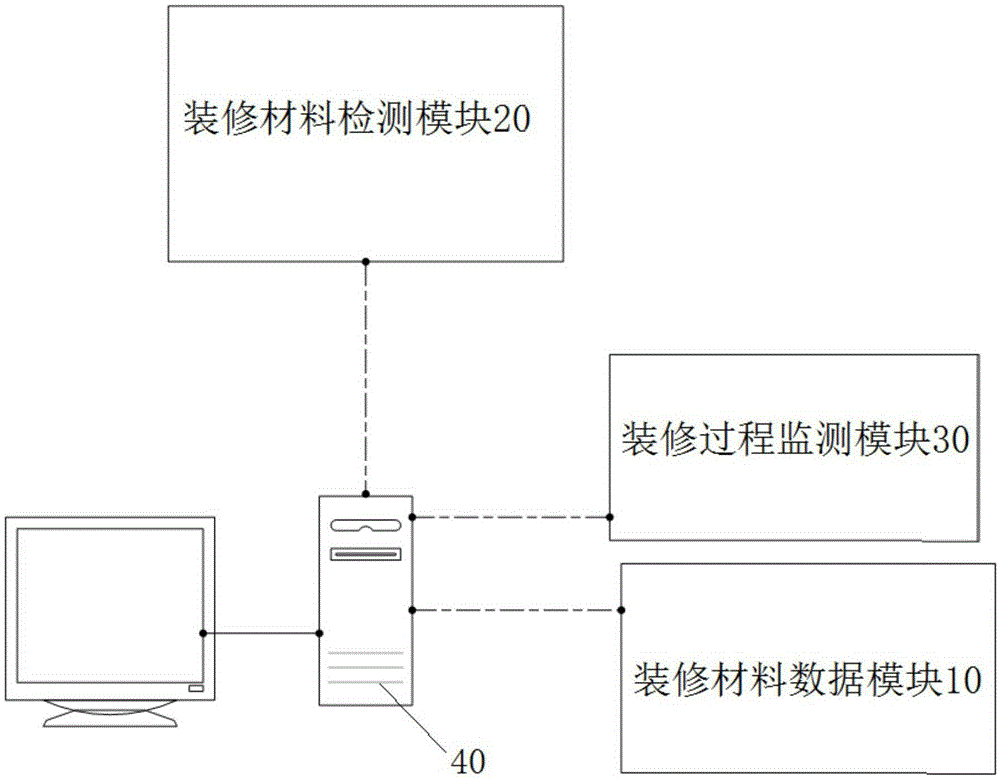

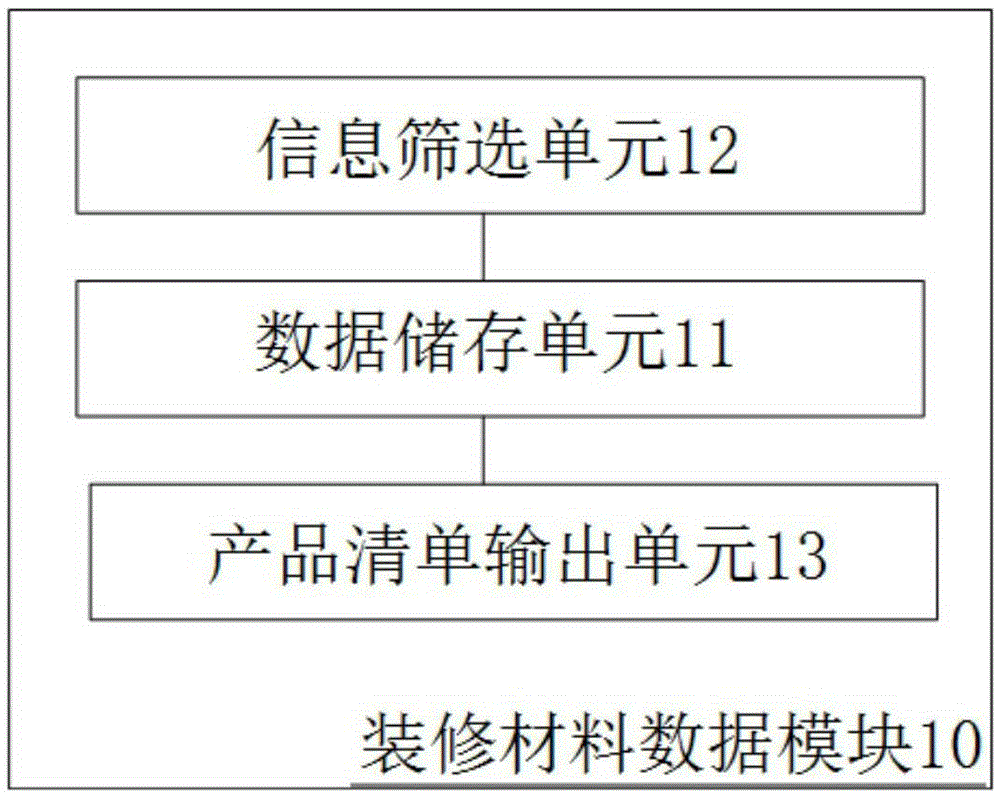

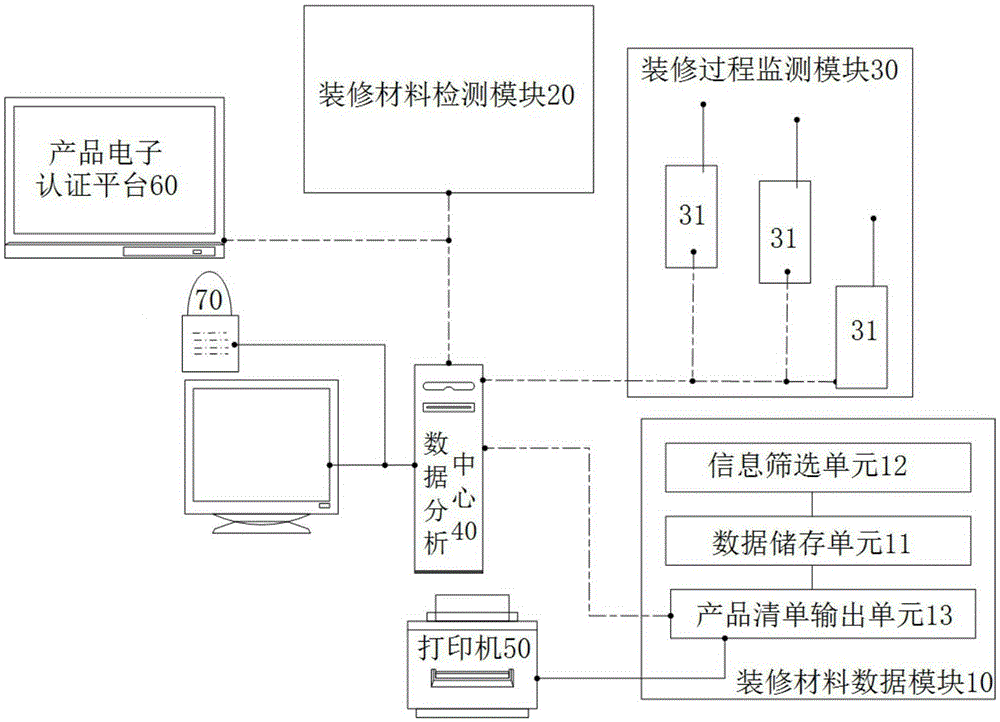

Integrated control system and control method of formaldehyde-free decoration

InactiveCN105279712AEffective monitoringGuaranteed pollutionData processing applicationsMaterial analysisControl systemData information

The invention discloses an integrated control system and control method of formaldehyde-free decoration. The system is composed of a decoration material data module, a decoration material detection module, a decoration process monitoring module, and a data analysis center. The decoration material data module is used for storing formaldehyde content data of a decoration material; the decoration material detection module is used for carrying out formaldehyde content detection on the decoration material; the decoration process monitoring module is used for monitoring a formaldehyde content in air at a decoration scene; and the data analysis center is used for receiving data information transmitted by all modules and analyzing whether a formaldehyde content exceeding phenomenon occurs. The data analysis center carrying out signal connection with the decoration material data module, the decoration material detection module, and the decoration process monitoring module is used for analyzing whether a phenomenon of exceeding a standard by the formaldehyde content exists in the data information transmitted by all modules by the data analysis center. Therefore, selection control of decoration materials before decoration as well as formaldehyde monitoring during the decoration process and after decoration can be realized.

Owner:SHANGHAI LANDLEAF BUILDING TECH CO LTD

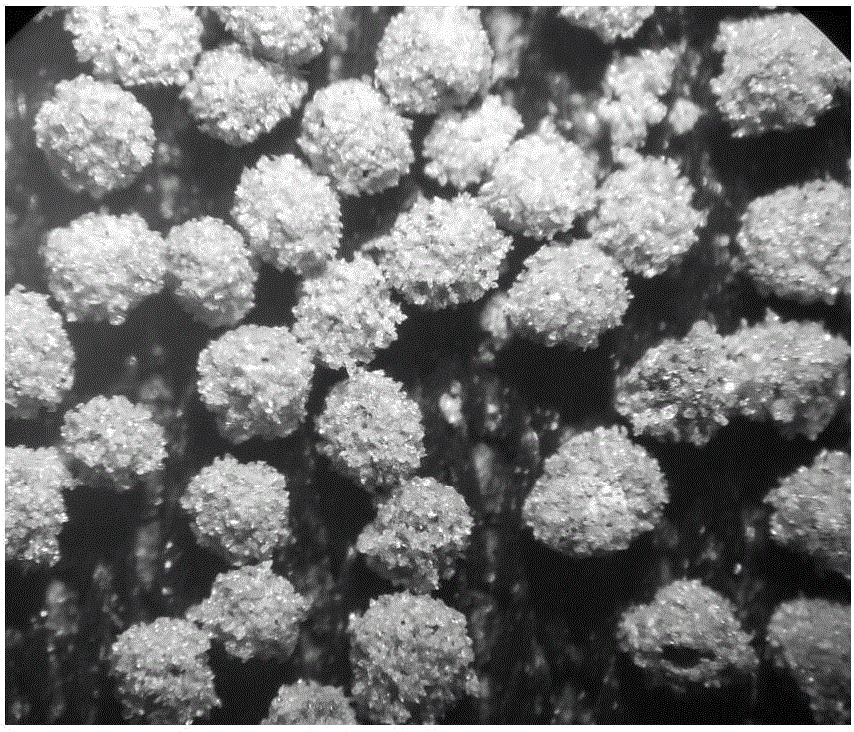

Diamond micro-powder aggregate preparation method using magnesia as binder

ActiveCN106244109AExtended service lifeImprove efficiencyOther chemical processesWater ChestnutsPolymer chemistry

The present invention relates to a diamond micro-powder aggregate preparation method using magnesia as a binder. According to the present invention, calcined magnesia is adopted as a main binder component, diamond micro-powder, a curing agent A and a curing agent B are added, and a water chestnut type sugar coating machine is used to complete the diamond micro-powder aggregate preparation, wherein the aggregate has a particle size of 0.8-3.0 mm and contains 25-75% (Wt.) of diamond micro-particles, and the particle size of the diamond micro-particles is 0.1-55 [mu]m; the problems of non-uniform mixing and easy shedding of the diamond micro-powder abrasive material in the magnesia grinding device, the resin fine grinding, super fine grinding and polishing grinding device due to the small particle size and the large specific surface area are solved, the service life and the efficiency of the grinding device are improved, the emission of the non-degradable grinding waste is reduced, the environmental protection level is increased, and the currently-used SiC abrasive material grinding block is replaced; and the method has characteristics of simple operation and low cost, and is suitable for industrial production.

Owner:YANSHAN UNIV

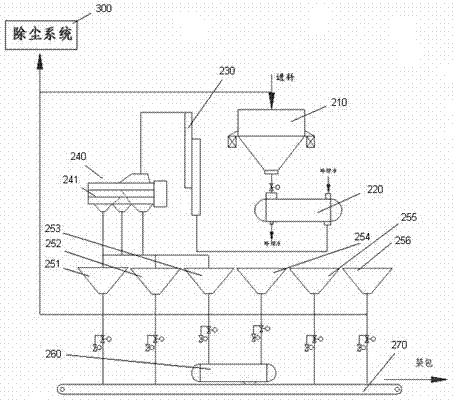

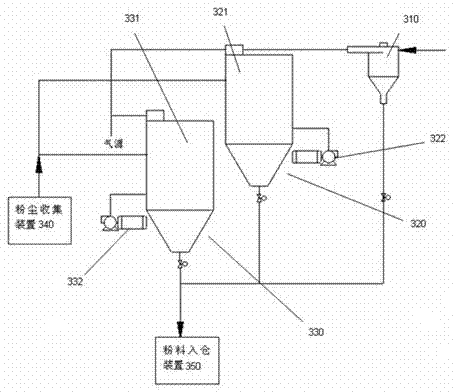

Efficiently environment-friendly graphitization furnace cooling technology

ActiveCN102963889ASmart and friendly operabilityProcess stabilityCarbon compoundsEnvironmental resistanceMetallurgy

The invention provides an efficiently environment-friendly graphitization furnace cooling technology. The efficiently environment-friendly graphitization furnace cooling technology comprises the following specific steps of: step 1. increasing a material absorbing depth and a material absorbing frequency step by step by using a multifunctional traveling crane and taking time as a moving direction, and controlling the temperature reduction range of a product to be less than 30 DEGC / h, when the product is exposed, the surface temperature of the product is less than 400 DEG C; step2. screening a heat preservation material in a main storage bin of the multifunctional traveling crane; and step 3. carrying out dedusting on the screened granules. The multifunctional traveling crane provided by the invention is used for the graphitization furnace cooling technology and can independently complete the cooling process. Due to the adoption of the multifunctional traveling crane, the cooling time of the graphitization furnace is shortened, the working efficiency is improved, the production cost is reduced, and the environmental protection level of the graphitization furnace in the cooling process is increased.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

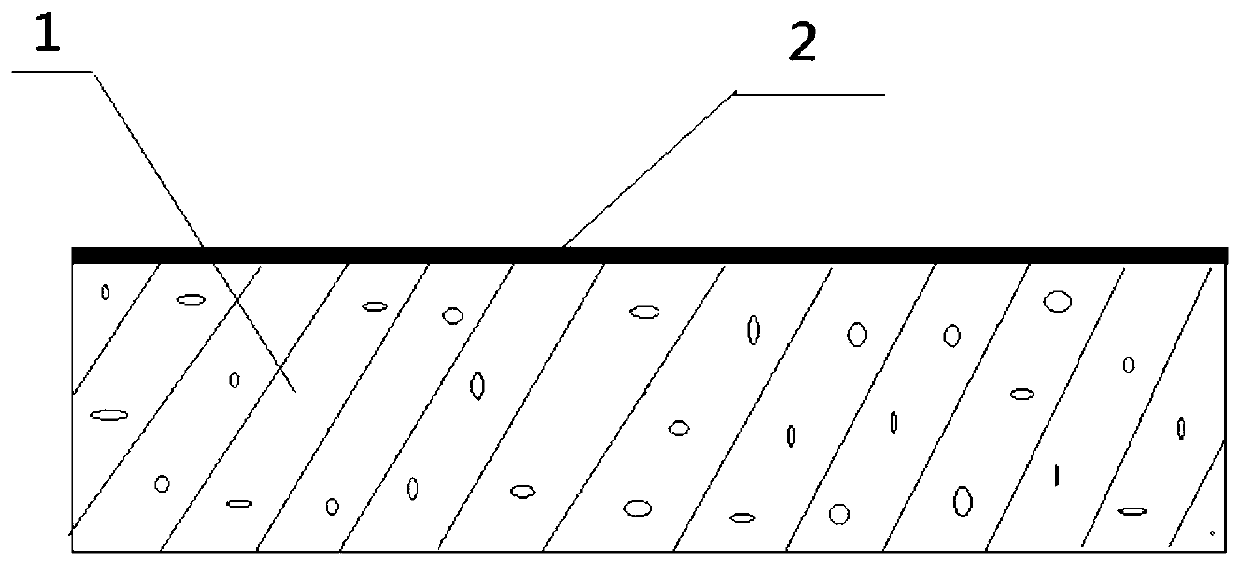

Aldehyde-free composite artificial board and manufacturing method thereof

InactiveCN105966004AImprove the level of environmental protectionSimple processLamination ancillary operationsLaminationWood veneerResin adhesive

The invention provides a formaldehyde-free composite wood-based panel, comprising a substrate layer and a veneer layer, the veneer layer is bonded to one or both sides of the base material layer by an formaldehyde-free adhesive, the base The material layer is formaldehyde-free plywood with wood veneer as raw material and thermoplastic resin film as adhesive. The method for manufacturing the formaldehyde-free composite wood-based panel comprises the following steps: using wood veneer as a raw material, using a thermoplastic resin film as an adhesive, first hot-pressing and then cold-pressing to form formaldehyde-free plywood; using formaldehyde-free plywood as a base material, Repair and scrape putty on both sides of the base material; after sanding the above base material, apply formaldehyde-free adhesive on one or both sides of the base material, and glue the veneer layer; cold press the above board at room temperature to make the adhesive solidify. The invention solves the problems of high formaldehyde content, complex process and high cost of the existing decorative boards, and has the advantages of many kinds of patterns, beautiful styles, paint-free and environmental protection, convenient processing and use, and low cost.

Owner:NINGBO ZHONGJIA LOW CARBON NEW TECH RES INST

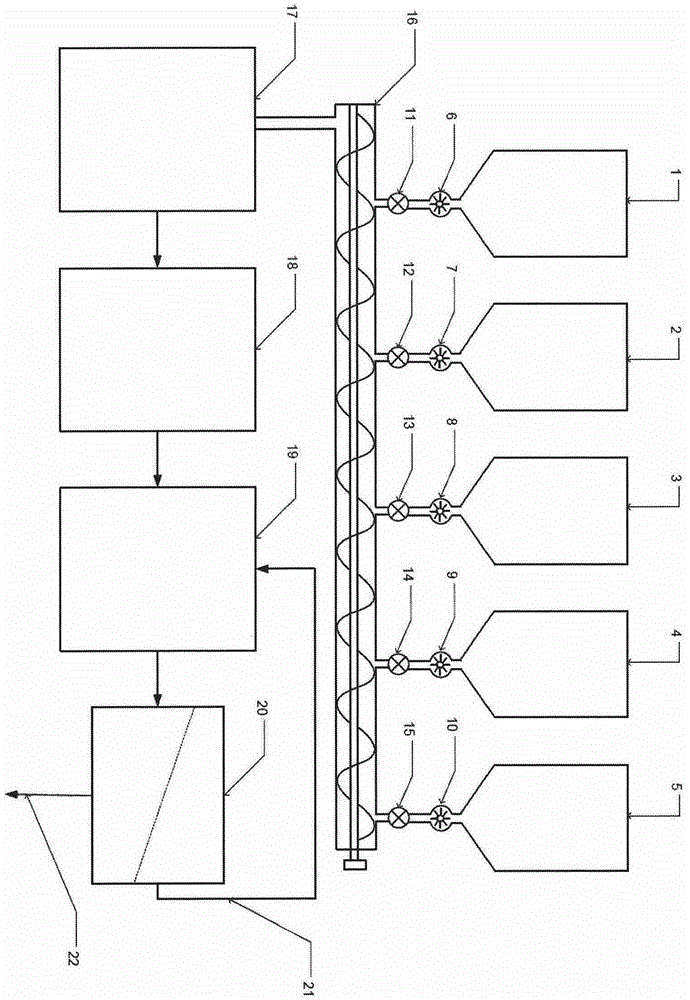

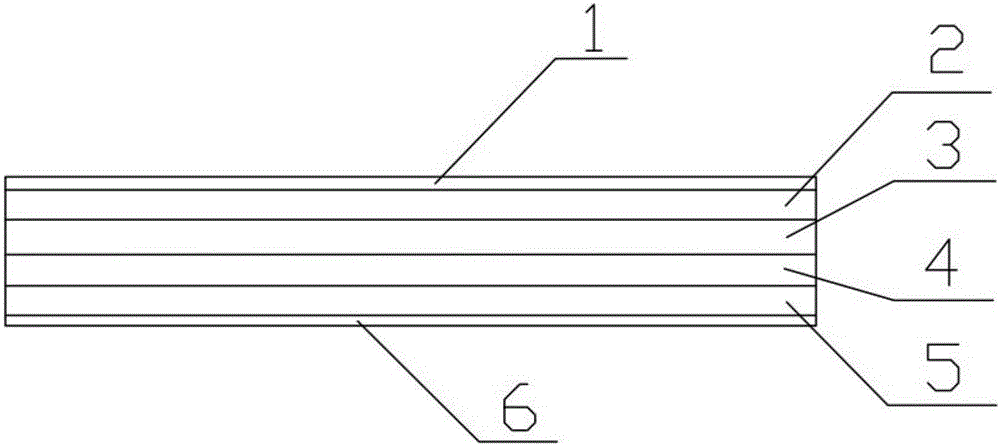

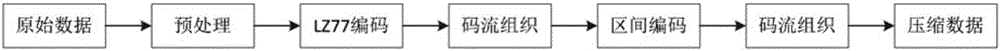

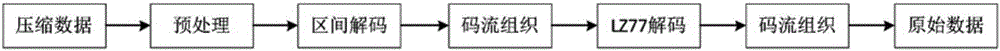

Online monitoring and management system for ultra low emission unit

InactiveCN106651171AStrengthen enthusiasm for operationImprove the level of environmental protectionOffice automationResourcesProcess configurationData compression

The invention discloses an online monitoring and management system for an ultra low emission unit, which comprises a data processing module, a technological process configuration processing module and an evaluation index online calculation module, wherein the data processing module is composed of a data acquisition module, a data compression transmission module and a data storage module; the technological process configuration processing module uses PI Processbook to carry out full replication on a field DCS monitoring scene, an SVG technology is used for carrying out processing and display on a monitoring platform, and full replication of the field technological process can be realized; and the evaluation index online calculation module captures measurement point hour data from a PI real-time database for calculation to thus judge whether ultra low emission desulfurization, denitration and dust removal facilities are put to operation according to the configuration information. Real-time online management on the operation condition of the ultra low emission facility of a coal-fired unit can be realized, the power environmental protection supervision range is expanded, and the power environmental protection supervision level is enhanced.

Owner:JIANGSU FRONTIER ELECTRIC TECH +2

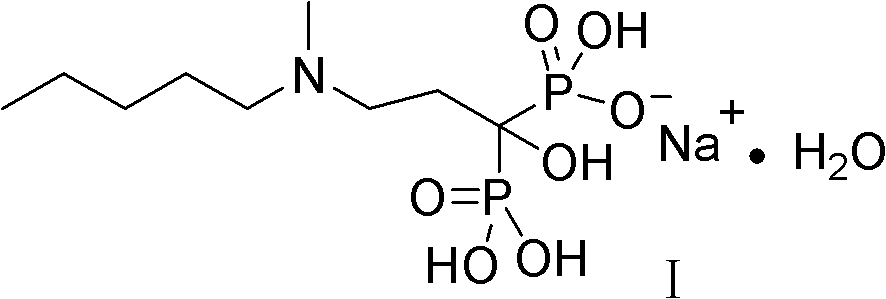

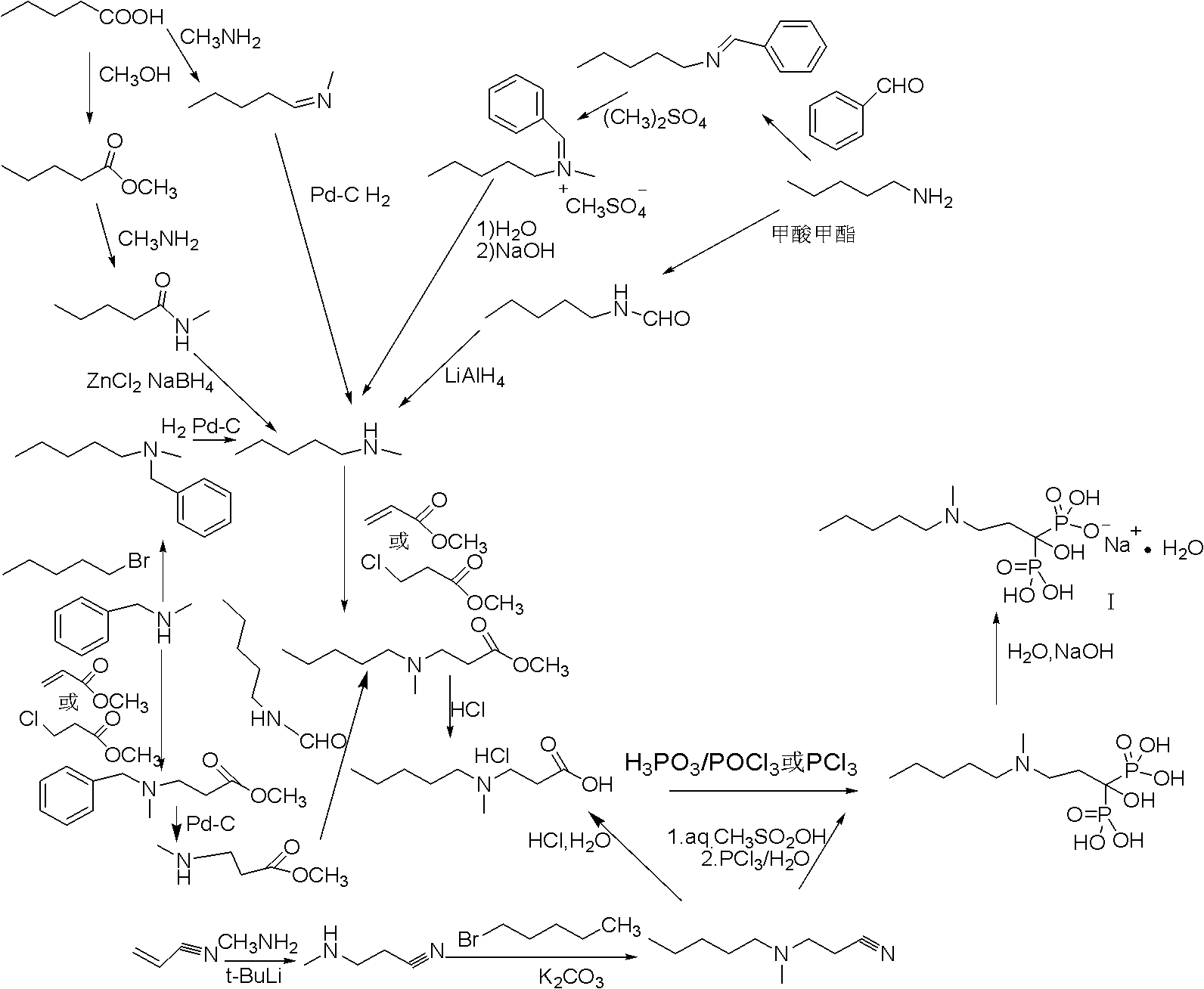

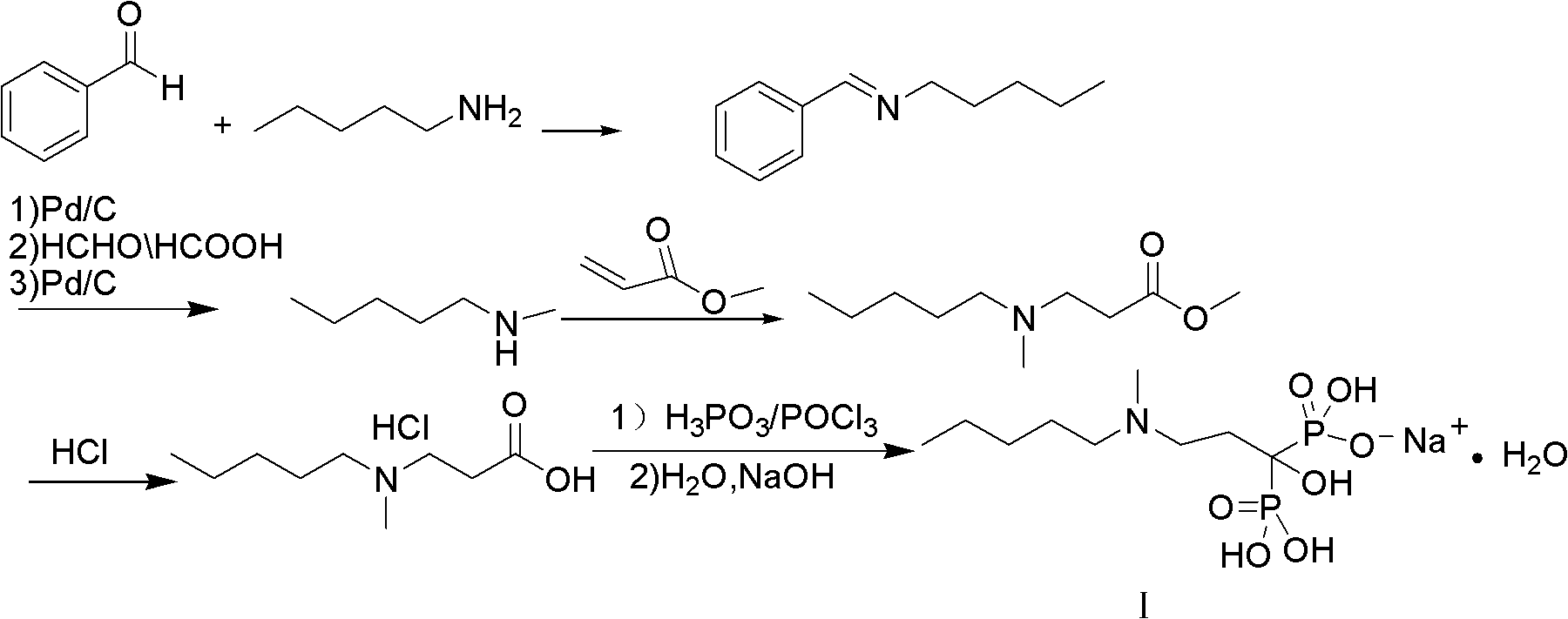

Method for synthesizing sodium ibandronate

ActiveCN102093416AFew stepsEasy to operateGroup 5/15 element organic compoundsIbandronate SodiumReaction step

The invention discloses a method for synthesizing sodium ibandronate. The sodium ibandronate is prepared by the following steps: reacting an intermediate compound (III) with halogenated n-pentane; and then hydrolyzing and acidifying so as to obtain the sodium ibandronate, wherein in the formula (III), R1 is C1-4 alkyl. The method has the characteristics that the reaction steps are less, the used reagent is small in toxicity, the safety is good, and the like.

Owner:南京恒生制药有限公司 +1

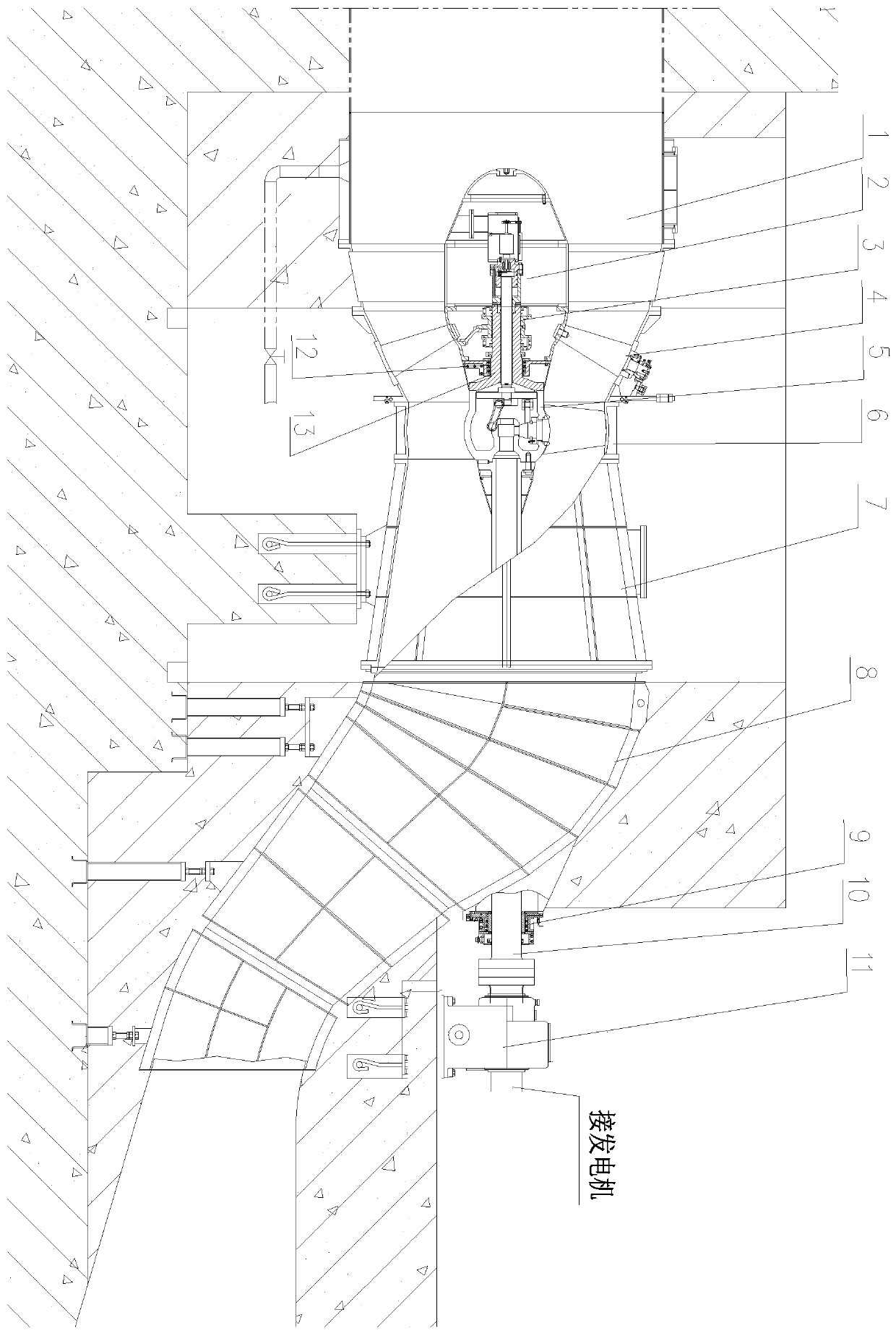

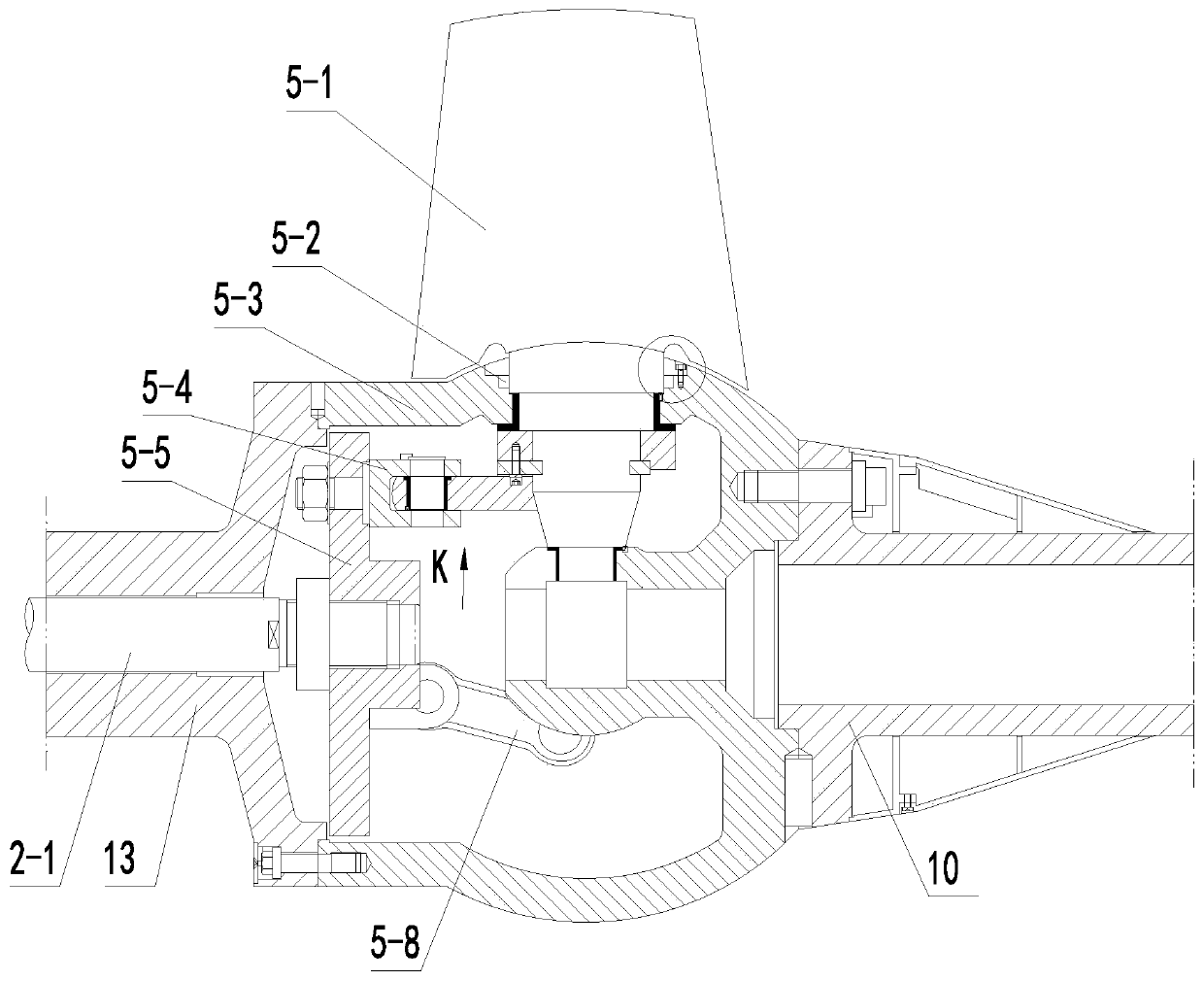

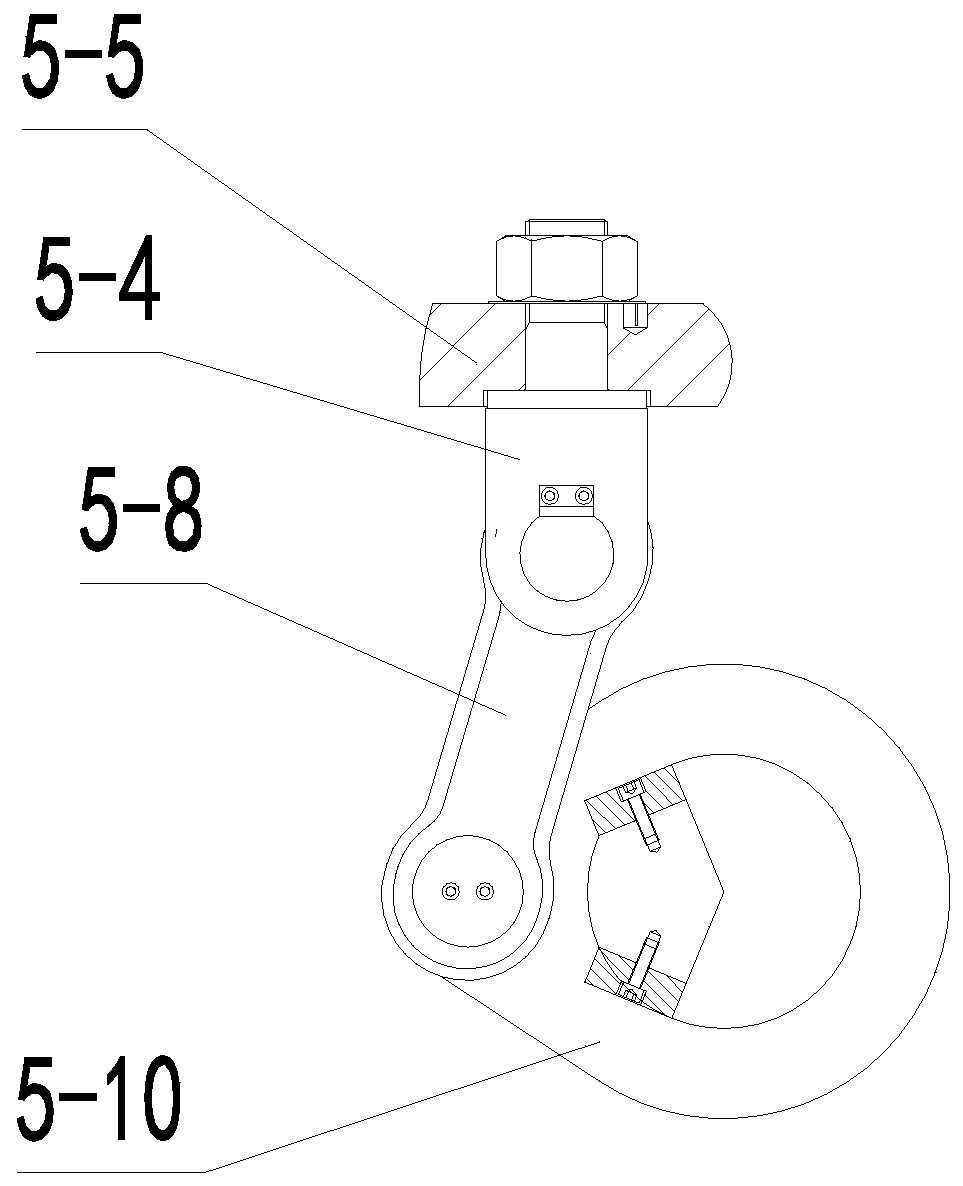

Shaft-extending cross-flow propeller type water turbine

InactiveCN110671253ASimple structureEasy to processHydro energy generationReaction enginesWater turbinePropeller

The invention relates to a shaft-extending cross-flow propeller type water turbine. The shaft-extending cross-flow propeller type water turbine comprises a water inlet part, a water guide mechanism, aleading bearing mechanism, a front spindle, a front spindle seal, a runner mechanism, a runner chamber, a tail water conical pipe, an S-shaped tail water elbow pipe, a rear spindle, a rear spindle sealing mechanism and a thrust combination bearing, wherein the inner diameter of the runner chamber is of a spherical shape, the runner blade of the runner mechanism is a rotatable runner blade, the outer edge of the runner blade of the runner mechanism is spherical, the fixed propeller runner of the water turbine is designed into the rotating propeller runner structure for the first time in China,the shaft-extending cross-flow water turbine blade can be kept in a co-linkage manner along with the change of the water head and the load, the operating range of the water turbine is expanded, the efficiency of the water turbine is improved, and the stability of the unit is improved.

Owner:湖南云箭集团有限公司

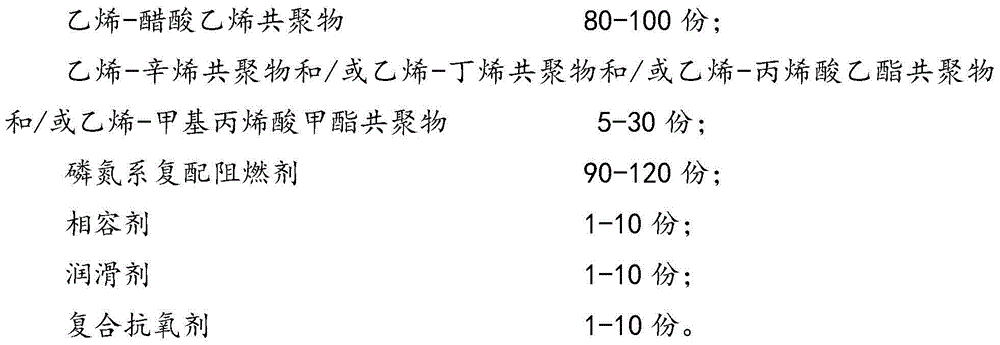

Halogen-free red phosphorus-free high-flame retardation heat-shrinkable bush and preparation method thereof

ActiveCN105801990AImprove environmental protection levelProtect personal healthChemistryHuman health

The invention relates to a halogen-free red phosphorus-free eco-friendly material and a use thereof and especially relates to a halogen-free red phosphorus-free high-flame retardation heat-shrinkable bush and a preparation method thereof. The halogen-free red phosphorus-free high-flame retardation heat-shrinkable bush comprises, by weight, 80-100 parts of an ethene-vinyl acetate copolymer, 5-30 parts of an ethene-octylene copolymer and / or an ethene-butene copolymer and / or an ethene-ethyl acrylate copolymer and / or an ethene-methyl methacrylate copolymer, 90-120 parts of a phosphor-nitrogen composite fire retardant, 1-10 parts of a compatilizer, 1-10 parts of a lubricant and 1-10 parts of a composite anti-oxidant. In halogen-free red phosphorus-free high-flame retardation heat-shrinkable bush production, an inorganic material is used as a raw material and does not contain red phosphorus and halogens so that an environmental protection level is high, poisonous and harmful gas produced through red phosphorus and halogens is avoided, human health is protected and environmental friendliness is obtained. The halogen-free red phosphorus-free high-flame retardation heat-shrinkable bush has low contraction temperature responsiveness, can completely shrink at a temperature of less than or equal to 95 DEG C and has a low shrinkage temperature.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL +1

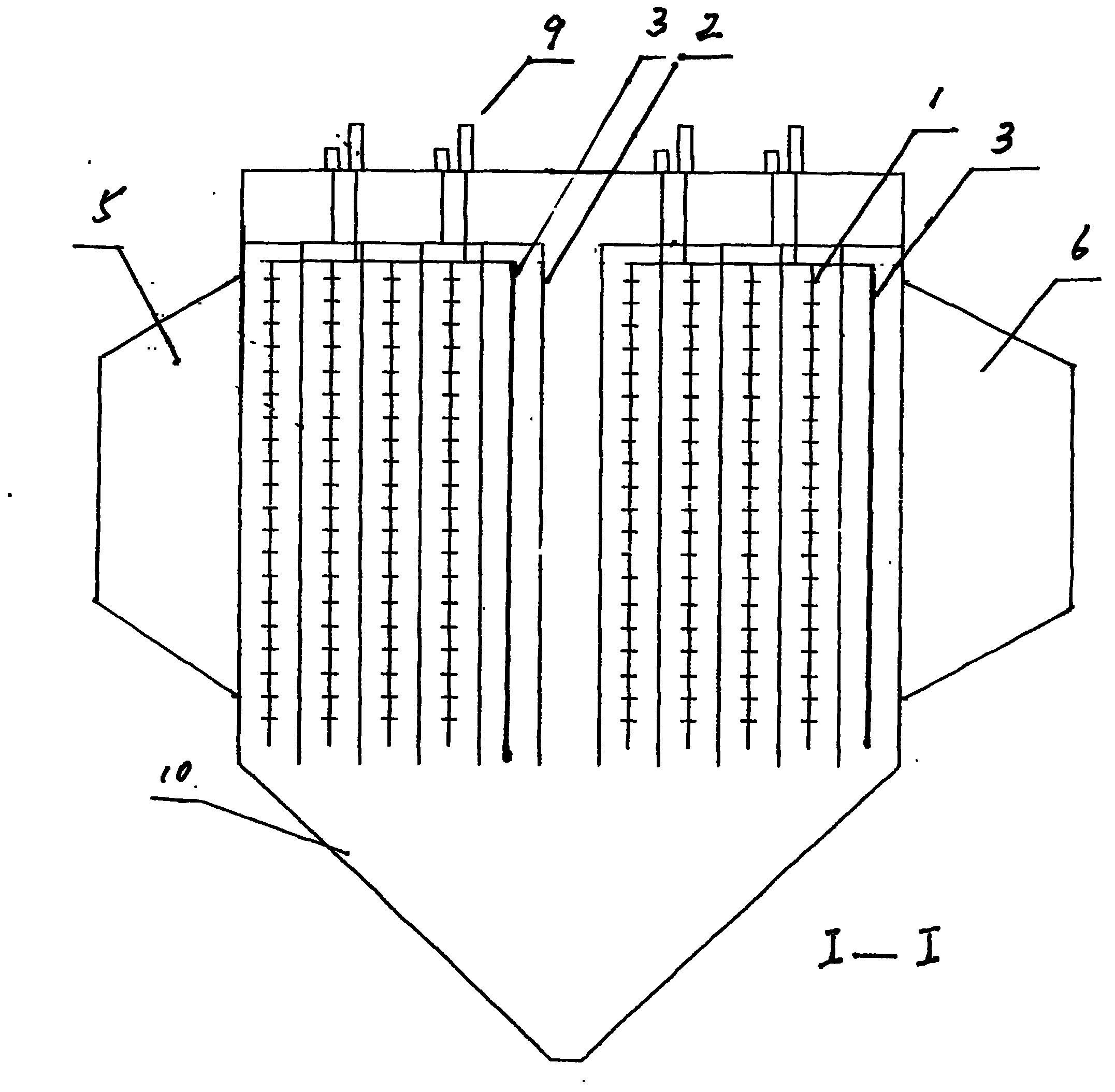

Electric dust collector with ultra- low concentration discharge

InactiveCN101130180BSimple structureLower internal resistanceExternal electric electrostatic seperatorElectrode constructionsElectricityCorona discharge

The invention discloses a hyperlow density discharge electric dedusting device of industrial smoke, which comprises the following parts: box body, intake box and ventilating box at two ends of box, ash bucket at lower part of the box, permeability dust collection block and corona discharge wire in the box body, absorbent electric field with multiple transverse dust collection grids in perpendicular to flow moving direction with equal distance and paralleling alternatively, deashing beating device on the corona discharge wire and dust collection board separately, wherein the dust collection board has multiple ventilation holes; one or more block grid net is set in each block grid of absorbent electric field with damper to seal air-out end at air-out position. The invention eliminates sub-micron graded smoke particle effectively to avoid secondary dust to reduce bulk and cost.

Owner:SHENYANG LONGDA ENVIRONMENTAL PROTECTION

Lightweight concrete as well as preparation method and application thereof

InactiveCN110078453ALow costImprove economyForms/shuttering/falseworksBuilding material handlingFiberSuspending Agents

The invention discloses lightweight concrete as well as a preparation method and an application thereof. The lightweight concrete is prepared from raw materials as follows: cement, building wastes, calcium oxide, fiber, a water reducing agent, a foam stabilizer, an air entraining agent, cellulose ether, a foaming agent, hydrogen peroxide, an expanding agent, a suspending agent, a thickening agent,calcium hydroxide, fly ash and water. Meanwhile, the invention also discloses a preparation method of the lightweight concrete. The invention also discloses a construction method of nonbearing wall casting in situ by using the lightweight concrete. The construction method comprises the steps as follows: 1) mounting constructional columns in a preset nonbearing wall position; 2) embedding water pipes and electric wires; 3) mounting nonbearing wall formworks; 4) casting the lightweight concrete into the formworks; 5) 24 h after casting, removing the formworks; 6) curing and arranging the wall.The lightweight concrete has the characteristics of lightweight, high strength and low cost and has good economical, social and environmental protection benefits.

Owner:广东中正环保建材有限公司

Five-in-one functional facing shaving board and preparing method thereof

InactiveCN111168804AImprove pollutionIdeal 5-in-1 functional veneer particleboard with pollutionWood veneer joiningDomestic articlesMechanical engineeringPollution

The invention provides a five-in-one functional facing shaving board and a preparing method thereof, and belongs to the technical field of shaving board production. The shaving board can have the functions that left formaldehyde pollution is avoided, negative ions can be released, sterilization is effective, radiation is prevented, damp and wet are prevented, and fire preventing and inflaming retarding are achieved at the same time, and tested indexes are stable. The five-in-one functional facing shaving board is composed of a three-in-one functional shaving board and a composite nano decoration film layer, and the composite nano decoration film layer is attached to one or two sides of the functional shaving board. The preparing method can be applied to manufacturing of the five-in-one functional facing shaving board, and the market requirements can be effectively met.

Owner:木德(上海)新材料科技有限公司

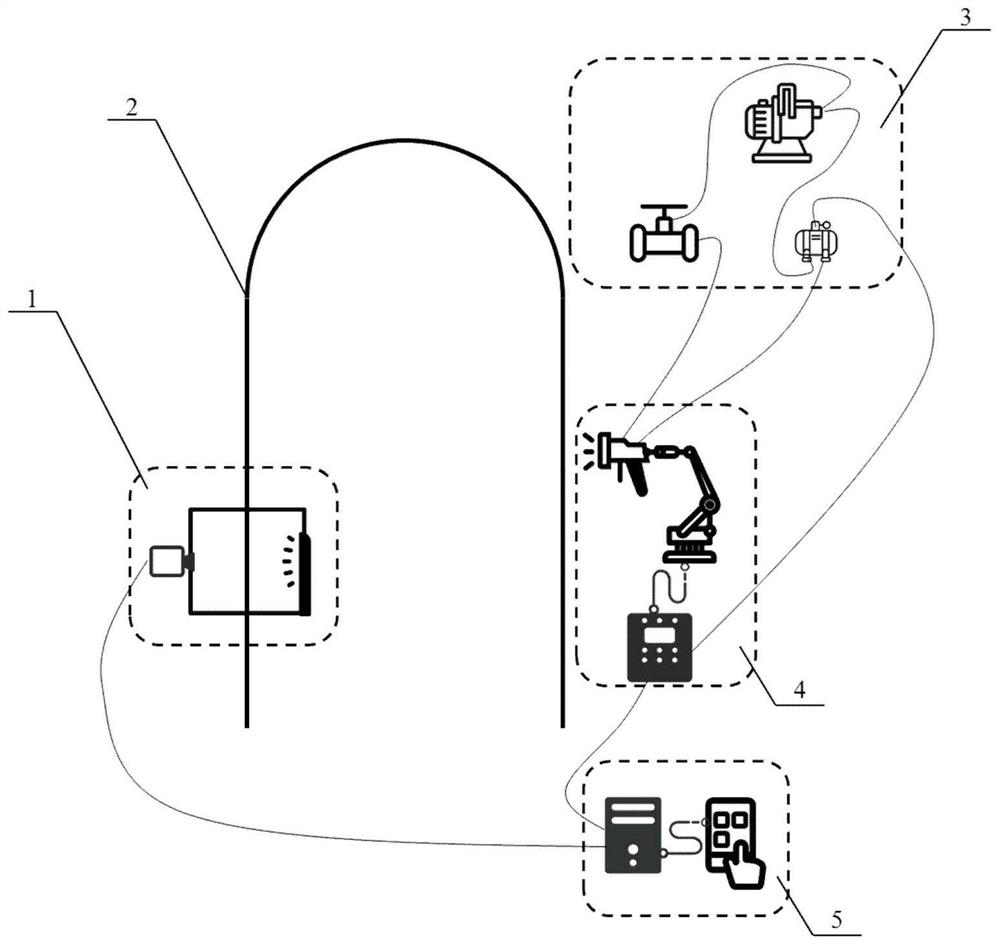

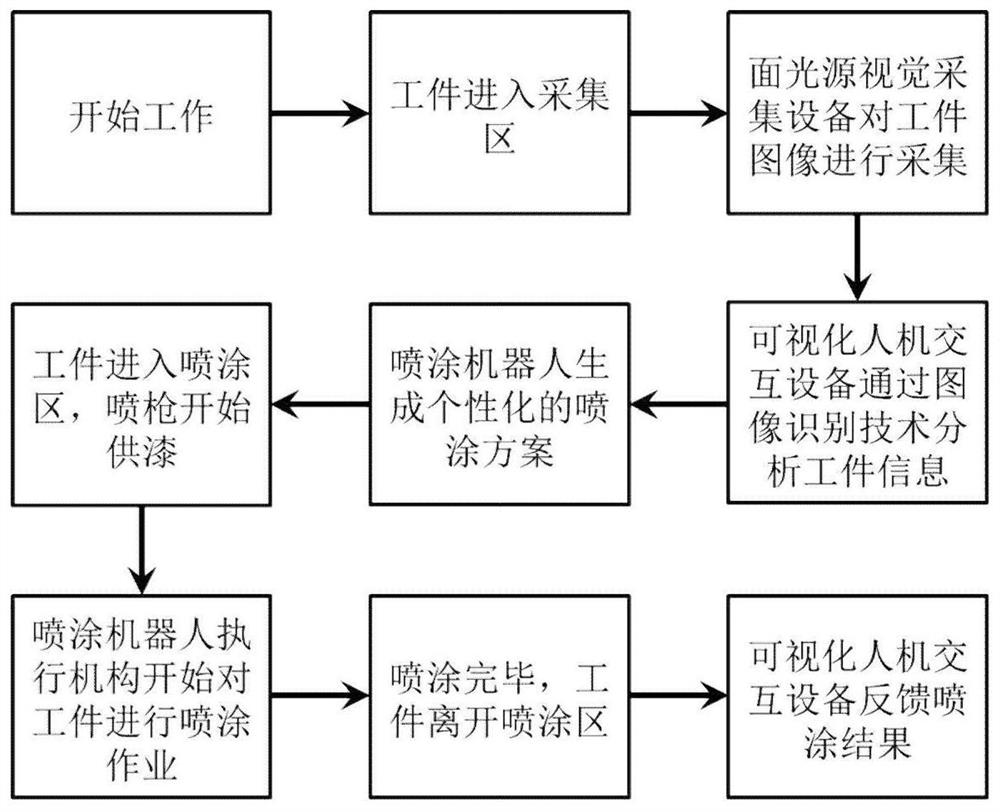

Moving workpiece automatic spraying robot system based on machine vision and working method

InactiveCN112452581AHarm reductionReduce human resource costsSpraying apparatusManipulatorInteraction deviceAcquisition apparatus

The invention discloses a moving workpiece automatic spraying robot system based on machine vision. The moving workpiece automatic spraying robot system comprises an area source vision acquisition device for acquiring feature information such as shape, size, position and posture of a to-be-sprayed workpiece through a vision image, an autorotation type hook guide rail capable of conveying the to-be-sprayed workpiece to a spraying working area and enabling the workpiece to autorotate at a constant speed after the workpiece enters the working area, a parameter-controllable air pressure type paintsupply system for spraying paint and providing dynamic spraying control parameters, a spraying robot used for executing a specific spraying action on the workpiece, and visual man-machine interactionequipment for providing a man-machine interaction interface to control the working mode and the working state of the spraying robot system and displaying the real-time working state and the working condition parameters of the system. The automatic spraying robot system is controlled through interactive interface input, a customized spraying scheme is generated for different workpieces through themachine vision technology, misoperation of manual control is avoided, operation is convenient, action is sensitive, and control is accurate.

Owner:JIANGSU SANLI HYDRAULIC MACHINERY

Plasma-facilitated photocatalytic purification device and purification method

PendingCN106823791ASimple structureReduce use costGas treatmentDispersed particle separationExhaust fumesPollutant

The invention discloses a plasma-synergized photocatalytic purification device and a plasma-synergized photocatalytic purification method. The plasma-synergized photocatalytic purification device comprises a box body, a filter layer, a plasma layer and a photochemical layer, wherein a passage communicated with the two ends of the box body is formed inside the box body; the filter layer, the plasma layer and the photochemical layer are sequentially fixed into the passage; the photochemical layer comprises an UV optical layer and a catalyst layer; the UV optical layer is positioned on one side, facing the filter layer, of the photochemical layer; the catalyst layer is positioned on one side, back from the filter layer, of the photochemical layer. The plasma-synergized photocatalytic purification device has the advantages and beneficial effects as follows: the plasma-synergized photocatalytic purification device is simple in structure and low in using cost, and can greatly reduce or even completely eliminate organic pollutants in waste gas emitted in a factory and discharge water and carbon dioxide which are harmless to the environment, so that the environmental protection level of the factory is improved, the environment around the factory is avoided from being damaged by the organic pollutants, and the body health of residents around the factory is protected.

Owner:上海巨浪环保科技发展有限公司

Sack dust adding method for blast furnace coal injection

InactiveCN1743465AIncrease burn rateImprove the level of environmental protectionDust arrestersBurn rateCoal

This invention relates to a method for adding bag-ash to blast sprayed coal characterizing in adding 2-8% weight percentage of bag-ash into the sprayed coal powder, and the volume keeps at 4% when the oxygen enrichment rate is less than 3% and increase along with the increase of the wind temperature is over 1150deg.C, 2% bag-ash is increased and the oxygen enrichment rate should increase 1%. The carbon in the ash can be used circularly in the oven and the iron oxide in the ash can increase the burning rate of coal powder, in addition to that, the ash can increase the gas permeability during sintering and reduce the circulation of fine dust in the sintering.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com