Halogen-free red phosphorus-free high-flame retardation heat-shrinkable bush and preparation method thereof

A heat-shrinkable sleeve, high flame-retardant technology, applied in the field of halogen-free, red phosphorus-free, high-flame-retardant heat-shrinkable sleeve and its preparation, can solve the problem of carcinogenicity of toxic and harmful gases, high shrinkage response temperature, personal and environmental damage, etc. problems, to achieve the effects of excellent comprehensive product performance, low shrinkage temperature response, and rapid industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

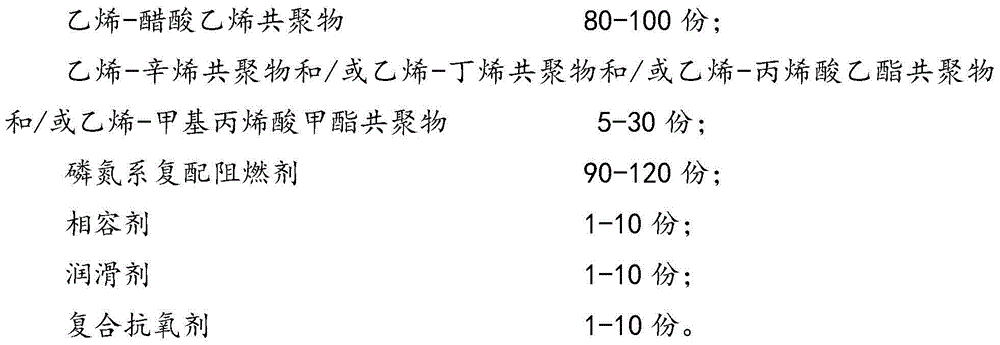

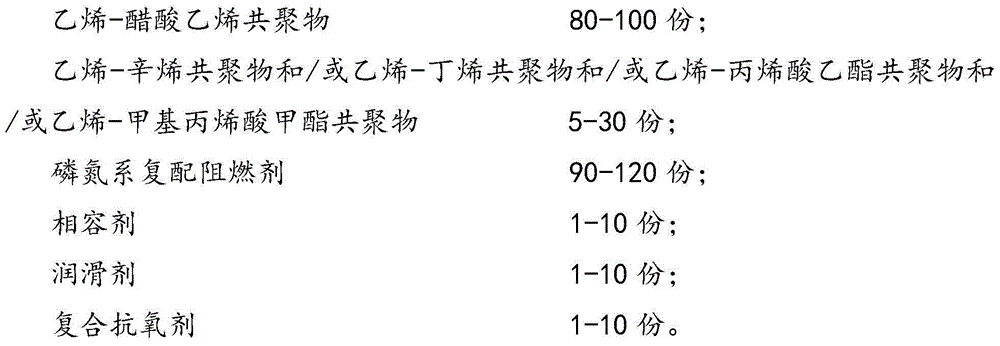

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a halogen-free, red-phosphorus-free, high-flame-retardant heat-shrinkable sleeve, which is applied to the above-mentioned halogen-free, red-phosphorus-free, high-flame-retardant heat-shrinkable sleeve, specifically includes the following steps:

[0040] S110 Prepare the raw materials according to the above formula ratio;

[0041] S120 Put the phosphorus-nitrogen compound flame retardant in the raw material in a high-speed mixer and stir for 5 minutes to compound;

[0042] S130 Put the raw materials into an internal mixer in turn and mix them for 10-20min in a temperature environment of 80-150°C;

[0043] In S140, pass the agglomerate mixture through a screw granulator to form masterbatch;

[0044] In S150, the masterbatch is placed in a single screw, extruded at an ambient temperature of 80-150°C, cooled and shaped into a pipe;

[0045] S160 Radiation cross-linking of the pipe through cobalt 60 or an electron accelerator with an irradiation dose...

specific Embodiment 1

[0048]Prepare materials according to the following formula: melt index is 40Kg (equivalent to 80 parts) of ethylene-vinyl acetate copolymer of 3-5g / 10min, wherein, the percentage of vinyl acetate content is 28%; Melt index is 2-4g / 10min Ethylene-methyl methacrylate copolymer 5Kg (corresponding to 10 parts), wherein, the percentage of the content of methyl acrylate is 8%-40%; Melt index is the ethylene-octene copolymer 5Kg of 0.5-2g / 10min ( Equivalent to 10 parts), wherein the content of octene is 20-30%; particle size d 99 Phosphorus nitrogen compound flame retardant ≦10μm 45Kg (equivalent to 90 parts), particle size d 99 Melamine cyanurate ≦10μm 10Kg (equivalent to 20 parts); compatibilizer (maleic anhydride grafted ethylene-vinyl acetate copolymer) 2Kg (equivalent to 4 parts) with a grafting rate of 0.6-2.0%; lubrication agent zinc stearate 2Kg (equivalent to 4 parts); composite antioxidant 1.5Kg (equivalent to 3 parts); carbon black 2Kg (equivalent to 4 parts).

[0049] S...

specific Embodiment 2

[0052] Prepare materials according to the following formula: melt index is 40Kg (equivalent to 80 parts) of ethylene-vinyl acetate copolymer of 3-5g / 10min, wherein, the percentage of the content of vinyl acetate is 28%; Melt index is 0.5-2g / 10min 15Kg (equivalent to 30 parts) of ethylene-octene copolymer, wherein, the percentage composition of octene content is 20-30%; Particle diameter d 99 Phosphorus nitrogen compound flame retardant ≦10μm 40Kg (equivalent to 80 parts), particle size d 99 15Kg (equivalent to 30 parts) of melamine cyanurate ≦10μm; 2Kg (equivalent to 4 parts) of compatibilizer (maleic anhydride grafted ethylene-vinyl acetate copolymer) with a grafting rate of 0.6-2.0%; lubrication The agent is 2Kg (equivalent to 4 parts) of silicon masterbatch containing 30-60% organic silicon compound; 1.5Kg (equivalent to 3 parts) of composite antioxidant.

[0053] Specifically, the preparation method applied to the above-mentioned specific examples is: stir the phosphorus-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com