Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Improve resistance to salt spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet curing anti-drag paint in steel pipes

ActiveCN102079937AGood adhesionGood mechanical properties and chemical resistancePolyurea/polyurethane coatingsEpoxy resin coatingsPrepolymerSteel quality

The invention relates to an ultraviolet curing anti-drag paint in steel pipes. Epoxy acrylate and polyester acrylate are combinedly used as prepolymers, and phosphate-modified acrylate resin is used as an adhesion promotor, thereby greatly increasing the adhesion; a mixture of two or three of tripropylene glycol diacrylate, isobornyl acrylate and ethoxylated trimethylolpropane triacrylate is selected as an active monomer, and multiple functional group monomers are selectively added for compounding, thereby simultaneously satisfying curing speed, hardness, adhesion, flexibility and other requirements; multiple initiator compounding systems are adopted so as to simultaneously implement curing on the surface layer and deep layer; the paint provided by the invention has favorable mechanical properties and chemical resistance on a steel substrate; after coating, the surface is very smooth, has favorable anti-drag effect, can effectively enhance the salt fog resistance and corrosion resistance of the coating and the transmission efficiency of the pipeline, and can be widely used in anti-drag corrosion prevention in transmission pipelines in the fields of oil transmission, gas transmission, water supply and drainage, and the like.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

Synthesis method of isocyanate curing agent

InactiveCN106632947ALow viscosityImprove adhesionFireproof paintsPolyurea/polyurethane coatingsAminosilochromeSilicon oxygen

The invention belongs to the field of chemical processing, and particularly relates to a synthesis method of an isocyanate curing agent. The synthesis method comprises the following steps: (1) synthesis of an organic silicon modified polyaspartate prepolymer: taking amino siloxane, dropwise adding maleate in equal molar weight with the amino siloxane, and carrying out heat preservation treatment after dropwise adding is completed, thus obtaining the polyaspartate prepolymer; (2) synthesis of the isocyanate curing agent: dropwise adding the polyaspartate prepolymer into an isocyanate tripolymer which is equivalently in equal molar weight with the polyaspartate prepolymer, and carrying out heat preservation after the dropwise adding is completed, thus obtaining the organic silicon modified isocyanate curing agent. In the technology, the rising of reaction temperature is not vigorous, the speed is controllable, and synthetic isocyanate is low in viscosity and can be directly applied to the industry of two-component polyurethane coating; silicon oxygen bonds and aspartate structures are introduced to polyurethane, so that the adhesion of a polyurethane coating film can be effectively increased, and the properties of high temperature resistance, aging resistance, salt fog resistance and the like are increased; the market prospect and the economic value are huge.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

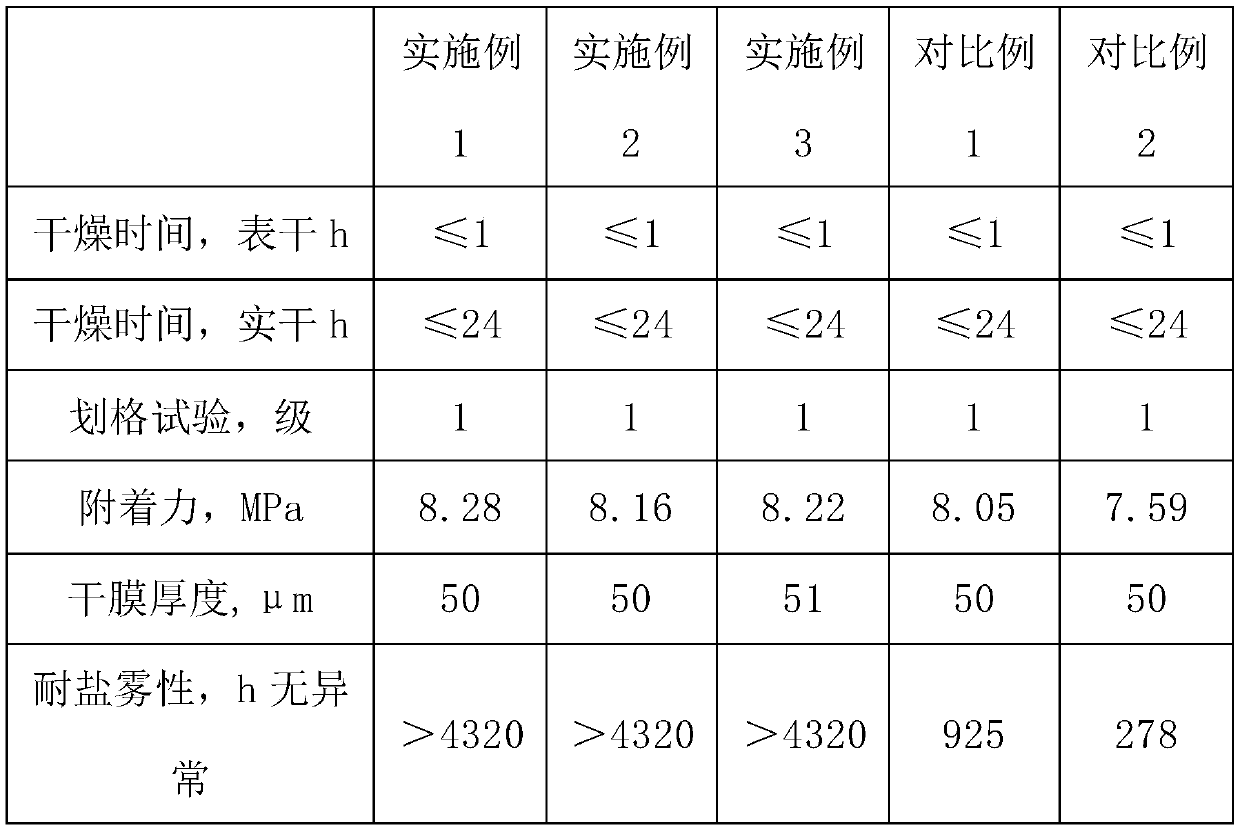

Environment-friendly single-component industrial anti-corrosion coating and preparation method thereof

The invention relates to a waste-based coating, in particular to a water-based industrial anti-corrosion coating. The invention discloses the water-based industrial anti-corrosion coating and a preparation method thereof. The anti-corrosion coating is prepared from the following components in percentage by weight: 10 to 50 percent of modified water-based acrylic resin, 5 to 20 percent of anti-rust pigments, 0.5 to 20 percent of a filler, 10 to 40 percent of a solvent, 2 to 20 percent of an auxiliary, 0.1 to 4 percent of a water-based dryer, 0.1 to 4 percent of a diluent and 0.5 to 2 percent of a water-based thickener. The water-based industrial anti-corrosion coating does not have the problems of blistering, whitening, fracturing, delaminating and the like, can be firmly attached to the surface of a metal, and is high in flexibility and bonding strength; the salt fog resistance and the corrosion resistance of the water-based industrial anti-corrosion coating can be improved, and the drying performance of the coating is improved; the water-based industrial anti-corrosion coating is excellent in corrosion resistance; furthermore, the raw materials are highly available; the production process is simple, and the construction is convenient.

Owner:广东珠江化工涂料有限公司

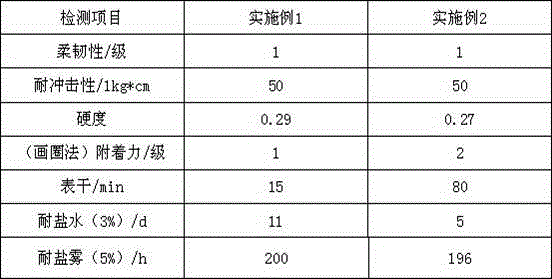

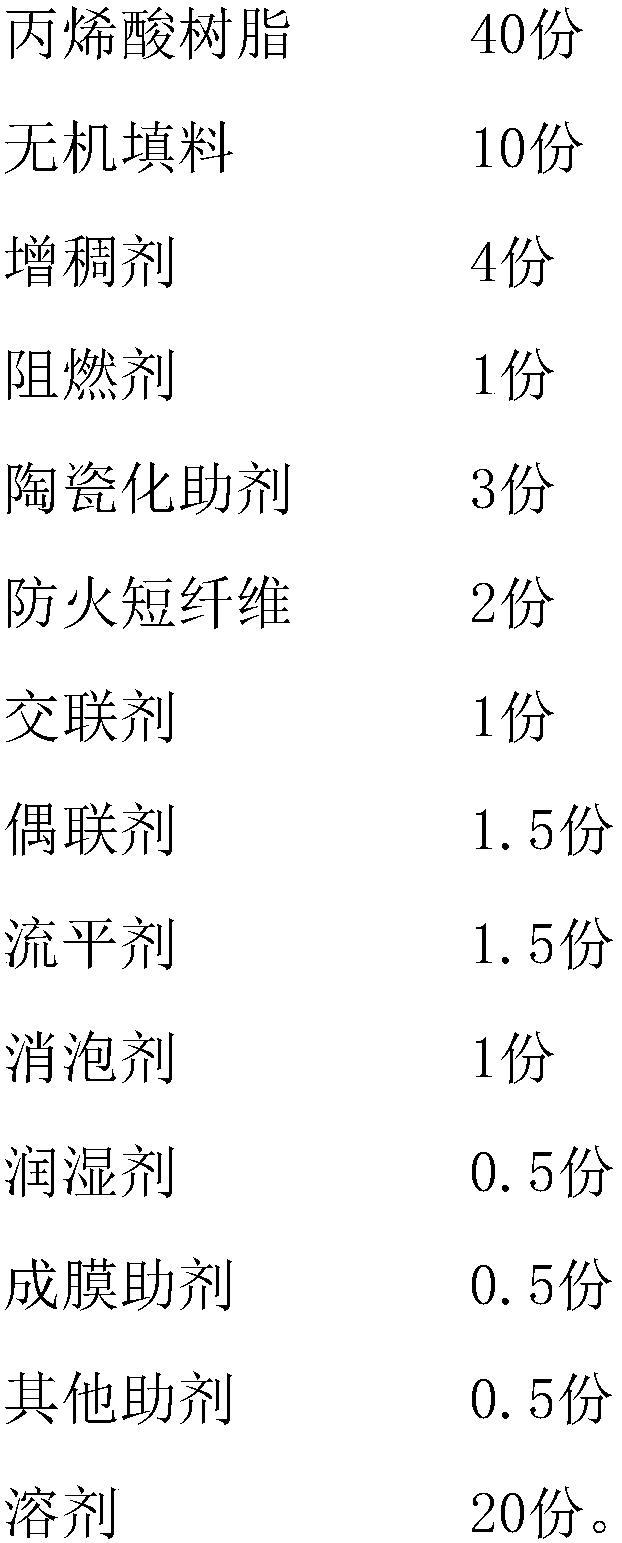

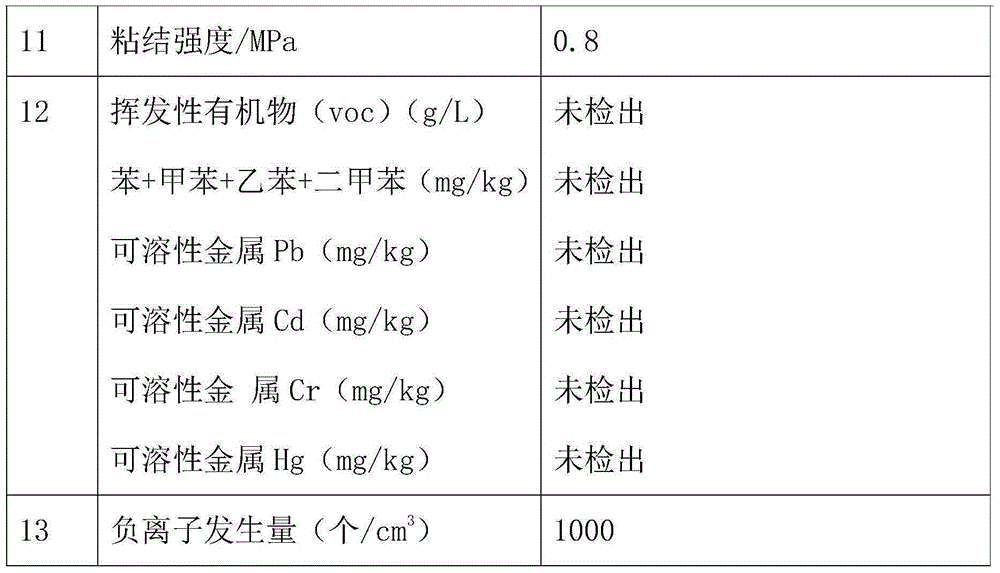

High temperature-resistant fireproof coating and preparation method thereof

ActiveCN108504257AGood weather resistanceImprove performance such as salt spray resistanceFireproof paintsEpoxy resin coatingsFiberAcrylic resin

The invention relates to the technical field of coatings, in particular to a high temperature-resistant fireproof coating and a preparation method thereof. The high temperature-resistant fireproof coating is prepared from the following raw materials in parts by weight: acrylic resin, inorganic filler, a thickener, a flame-retardant agent, a ceramic additive, fireproof short fibers, a crosslinkingagent, a coupling agent, a flatting agent, a defoaming agent, a wetting agent, a film forming additive, other additives and solvents. The high temperature-resistant fireproof coating has the advantages that high temperature can be endured, the flame-retardant property is good, the propagation of fire condition is well blocked, and the fireproof property is excellent; the effect of resisting long-time impact by 1100 DEG C hydrocarbon high-temperature fire hazard is realized; the weather-resistant property and waterproof property are realized, the shrinkage is avoided, the coating strength is high, and the surface is flat.

Owner:GUANGDONG ZHICHENG CHEM +1

Alkyd paint for ship cabin and its production process

InactiveCN1810902AImprove temperature resistanceImprove moisture and water resistanceAntifouling/underwater paintsPaints with biocidesSolventResin modified

The present invention discloses one kind of paint for steel structure surface of ship and its production process. The paint has the main components including organic silicon resin modified alkyd resin, phenolic resin modified alkyd resin, pigment, nanometer zinc oxide, superfine aluminum hydroxide, superfine barium sulfate, nanometer silica, paint drier, No. 200 solvent gasoline and methyl ethyl ketoxime. The production process includes dispersing all the materials except paint drier and methyl ethyl ketoxime in a cylinder for 15 min, sand grinding to fineness superior to 40 microns, regulating with resin and paint drier to acid value not greater than 11 mgKOH / g and viscosity of 200-400 sec at 25 deg.c, filtering, packing while adding methyl ethyl ketoxime. The present invention solves the problem of paint film to release fume and toxic matter and has high safety performance and heat resistance.

Owner:梁新方

Chromium-free passivation solution and preparation method thereof

InactiveCN103866304AImprove corrosion resistanceImprove stabilityMetallic material coating processesEpoxyChromium free

The invention discloses a chromium-free passivation solution comprising 15-60% of modified waterborne epoxy resin, 2-5% of silica sol and additives. The chromium-free passivation solution has the beneficial effects that 1, embossed aluminum plates having required high corrosion, acid and alkali resistance and hardness can be produced by directly applying the chromium-free passivation solution onto the embossed aluminum plate in a roller coating manner; 2, the chromium-free passivation solution has strong stability and good self-crosslinking properties, so that the coating having excellent overall performance can be obtained; 3, water-based modification of epoxy can be achieved, and good self-crosslinking properties are realized by introducing a variety of functional groups into grafting monomers of the modified waterborne epoxy resin, so that corrosion resistance is improved and the salt spray resistance can be improved by more than 100 hours; 4, the amino modified silane is used for chain extension of the grafted epoxy resin in the chromium-free passivation solution instead of the anodizing solution disclosed by the invention, and the adhesion between the coating and embossed aluminum plate is greatly improved by introducing siloxane groups; 5, the hardness of the film is greatly improved by adding silica sol in the formula, and the hardness of the coated embossed aluminum plate reaches 6H above.

Owner:WENZHOU WANZHONG SURFACE TREATMENT TECH CO LTD

Scrubbing-resistant anti-microbial inner wall emulsion paint

InactiveCN105131672AHigh strengthImprove wear resistanceAntifouling/underwater paintsPaints with biocidesEmulsionPolyphosphate

The invention discloses a scrubbing-resistant anti-microbial inner wall emulsion paint. The emulsion paint comprises raw materials: modified PVA, methyl methacrylate, polymethyl methacrylate, light calcium carbonate, talcum powder, lithopone, calcined kaolin, hydroxyethyl cellulose, a dispersant SN-5040, a dispersant SN-5027, a multifunctional auxiliary agent AMP-95, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, an antifoaming agent NXZ, negative ion-anti-microbial additives, sodium polyphosphate, a flatting agent, a nano stain-resistant agent NZM-1, propylene glycol, 5-chloro-2-methyl-4- isothiazolin-3-ketone and deionized water. The inner wall emulsion paint is not easy to generate powder, has good scrubbing resistance and stain resistance, is safe and environmentally friendly, and has a long anti-microbial validity period.

Owner:TIANCHANG YINHU PAINT

Water-soluble epoxy silicone acrylic resin and preparation method thereof

The invention provides water-soluble epoxy silicone acrylic resin and a preparation method thereof. The preparation method includes following steps: 1), weighing, by weight, 63-92 parts of acrylate, 8-15 parts of acrylic acid and 5-7 parts of initiator, and well stirring to obtain mixed liquid a; 2), weighing 8-12 parts of epoxy resin, 3-5 parts of initiator and 39-62 parts of organic solvent for mixing, and well stirring and dissolving at 100-130 DEG C to obtain mixed liquid b; 3), at 100-110 DEG C, dropwise adding the mixed liquid a obtained in the step 1) at a constant speed into the mixed liquid b, holding temperature for 0.8-1.2 h after dropwise adding is finished, adding 2-4 parts of silane coupling agent, and holding temperature for 0.8-1.2 h; 4), sampling, adding a neutralizing agent water solution to detect water solubility until the sample is completely dissolved in water, and stopping reaction for cooling. When water-soluble resin is used to prepare various coatings, tap water is directly used for blending, no solvent is needed for blending, and environment protection is realized.

Owner:广东顺德大地缘新材料有限公司

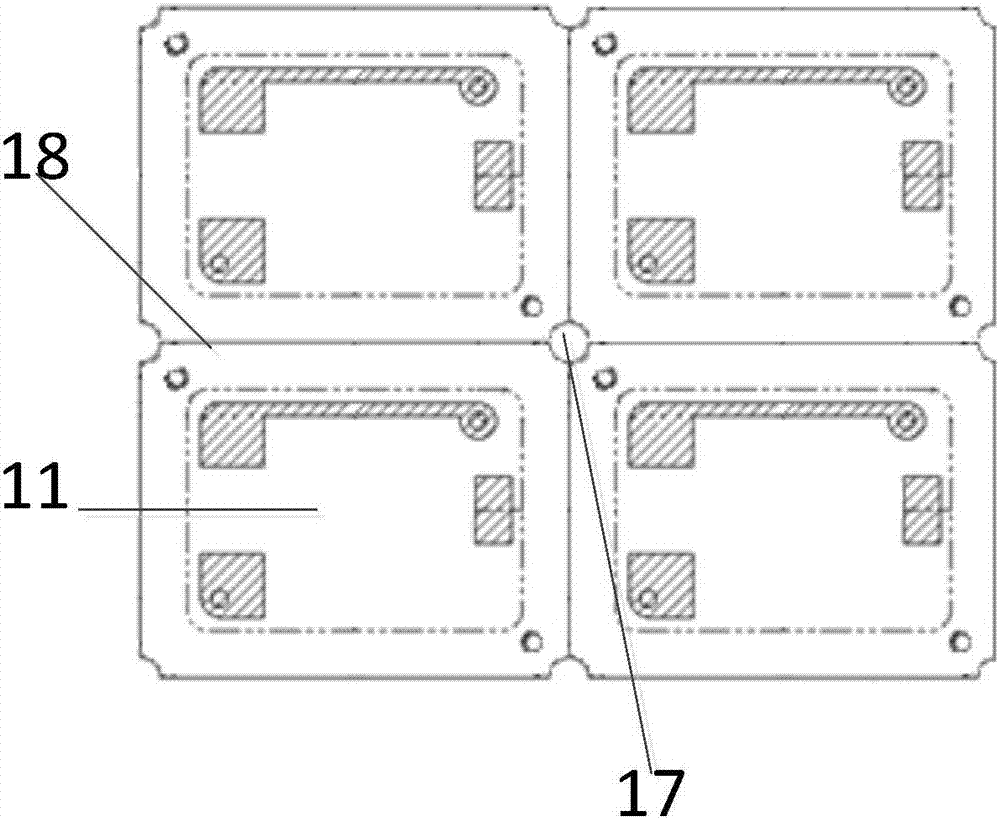

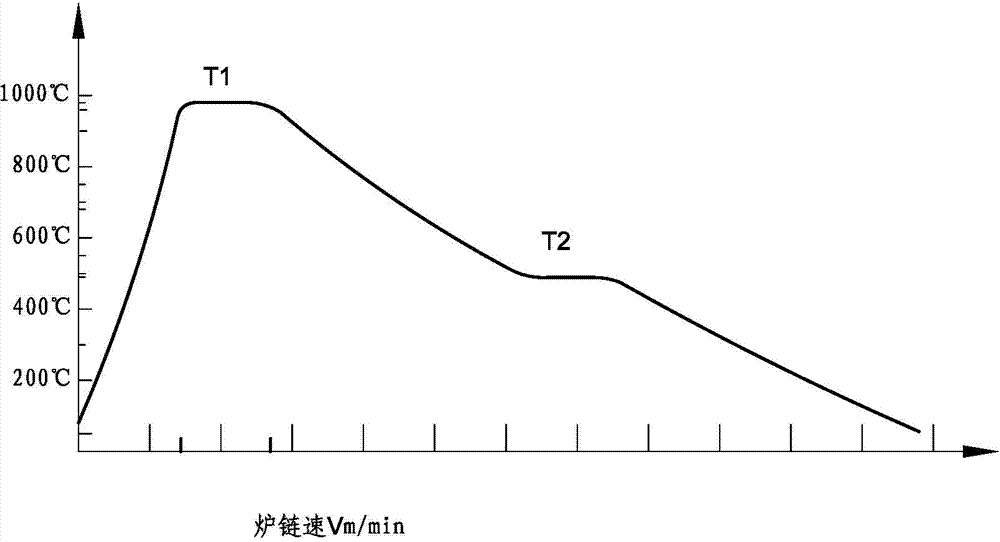

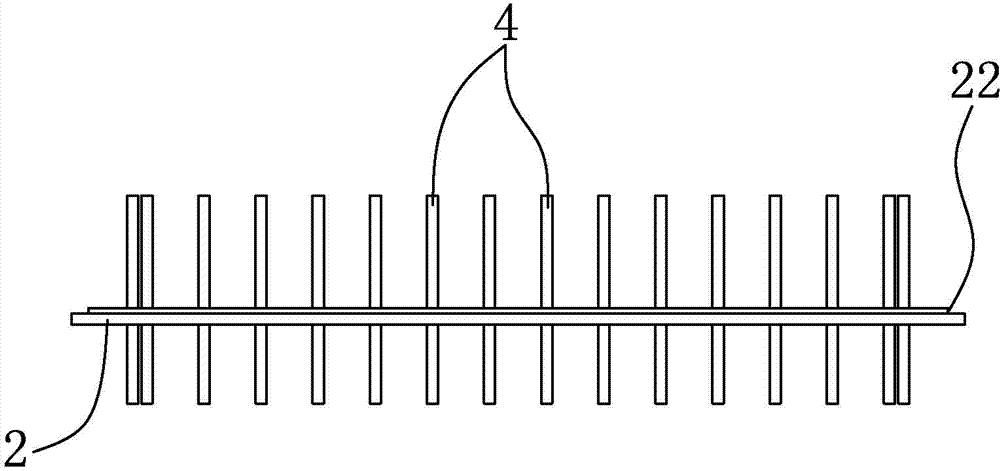

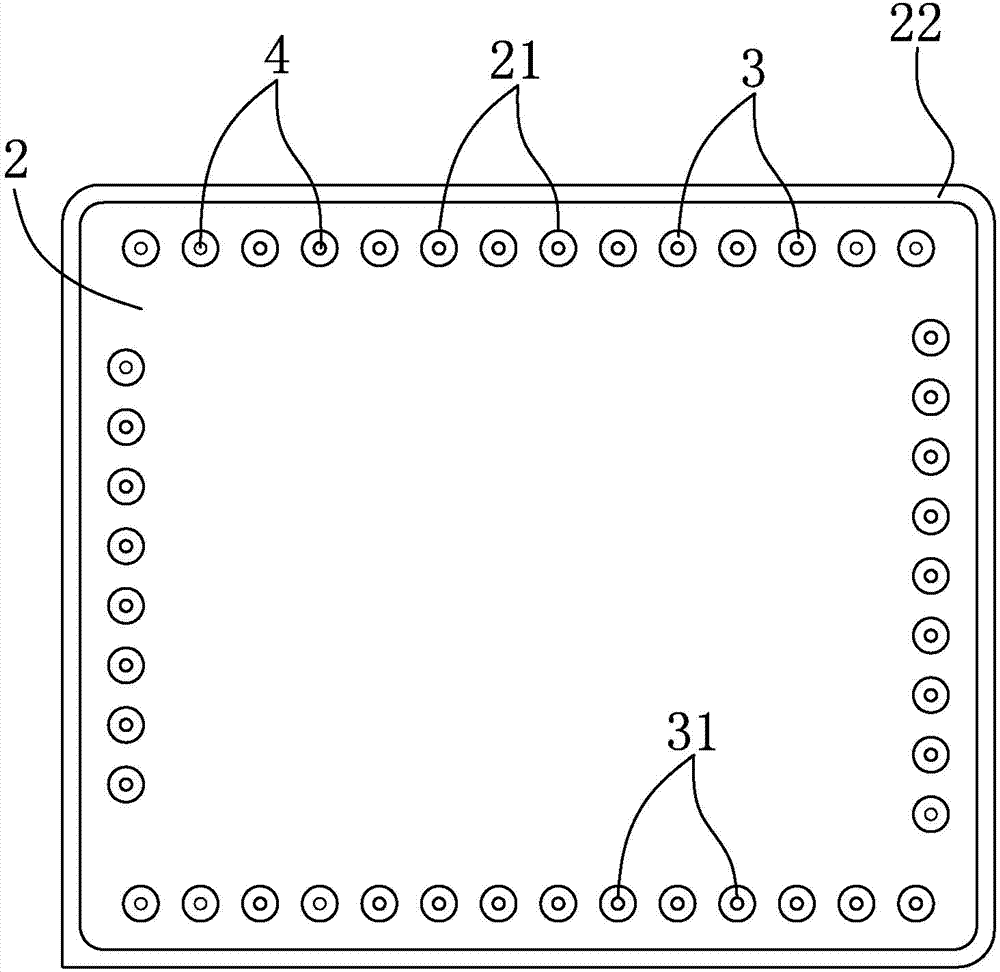

SMD quartz crystal resonator processing method and resonator thereof

The invention relates to a processing method of a SMD quartz crystal resonator. The processing method comprises the following steps: firstly providing a complete board resonator semi-finished product, wherein the complete board resonator semi-finished product comprises a base complete board and a cover complete board covered on the base complete board; and then cutting the cover complete board on the complete board resonator to form single base cover boards, and spraying and coating protective layers on the upper surface and sections of each cover board, wherein the method for spraying and coating the protective layer comprises pretreatment process and spraying and coating process; the pretreatment process comprises cleaning, washing, air showering and drying; the spraying and coating process comprises the following steps: firstly spraying and coating the spraying and coating material on the upper surface and section of each base cover board of the resonator complete board by using an electrostatic spraying and coating process to form the coatings, and then performing curing treatment on the coatings to form the protective layers on the upper surface and the section of each base cover board. The processing method disclosed by the invention aims at improving the salt mist resistance and high temperature and high humidity resistance of the SMD quartz crystal resonator under the severe environment. The invention further relates to a resonator prepared by adopting the above-mentioned method.

Owner:SICHUAN MDH TECH CO LTD

Ceramic sol modified polyether-ether-ketone paint and preparation method thereof

The invention discloses ceramic sol modified polyether-ether-ketone paint and a preparation method thereof. The invention aims at providing safe, environment-friendly, oleophobic and hydrophobic water-based paint and manufacturing and spray coating methods thereof. The ceramic sol modified polyether-ether-ketone paint is prepared from prime coat paint, floating coat paint and surface coat paint, wherein the prime coat paint is prepared from all the following ingredients in mass fraction: 5 to 30 parts of ceramic sol, 5 to 15 parts of alkoxy silane, 5 to 30 parts of polyether-ether-ketone matter, 2 to 20 parts of fluroresin, 5 to 20 parts of powder filler, 1 to 15 parts of pigment filler and 10 to 40 parts of solvent; the floating coat paint is prepared from all the following ingredients inmass fraction: 5 to 30 parts of ceramic sol, 5 to 15 parts of alkoxy silane, 10 to 40 parts of fluroresin, 2 to 15 parts of powder filler, 1 to 15 parts of pigment filler and 20 to 50 parts of solvent; the surface coat paint is prepared from all the following ingredients in mass fraction: 40 to 60 parts of fluroresin, 30 to 50 parts of solvent, 0.2 to 2 parts of pearl powder and 1 to 5 parts of aid. The ceramic sol modified polyether-ether-ketone paint disclosed by the invention is mainly applied to paint production.

Owner:GUANGDONG FRUTO NEW MATERIALS CO LTD

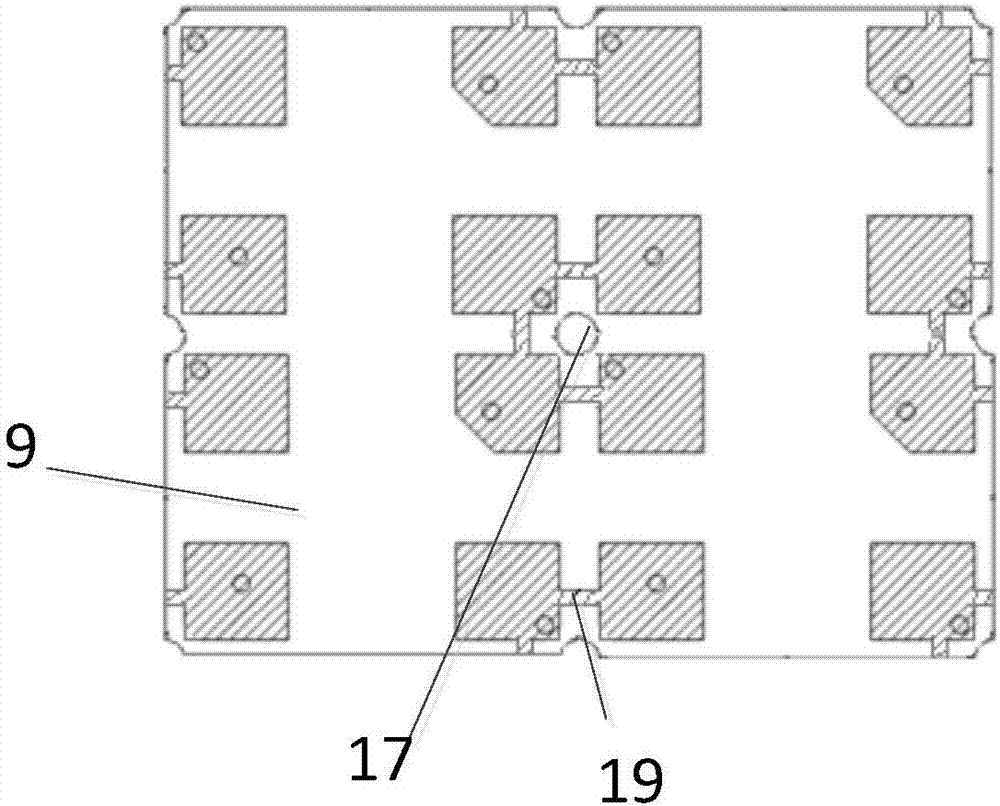

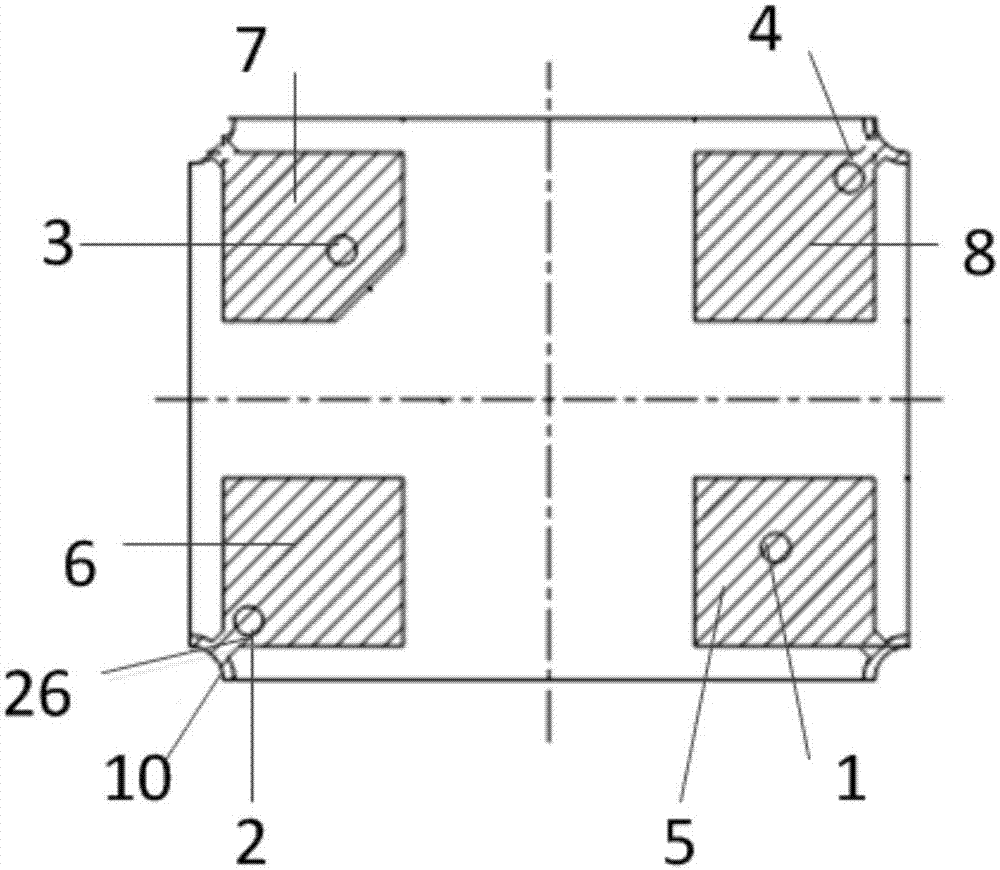

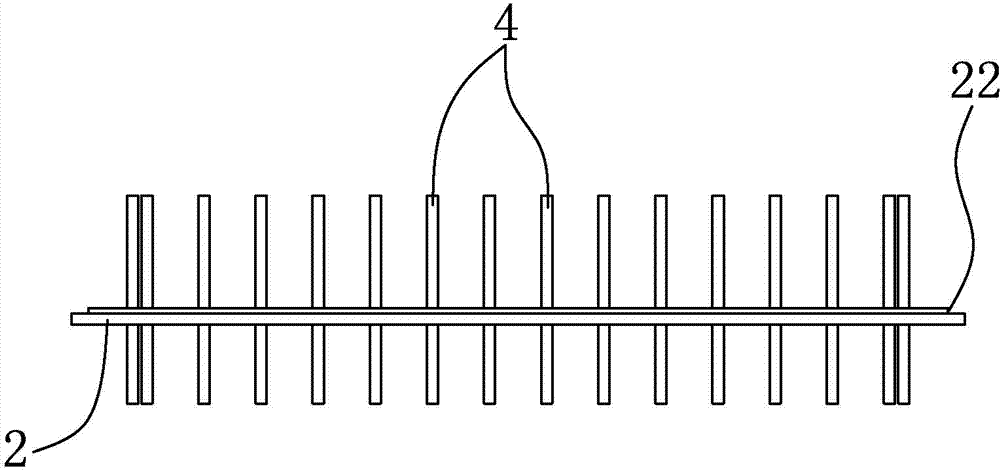

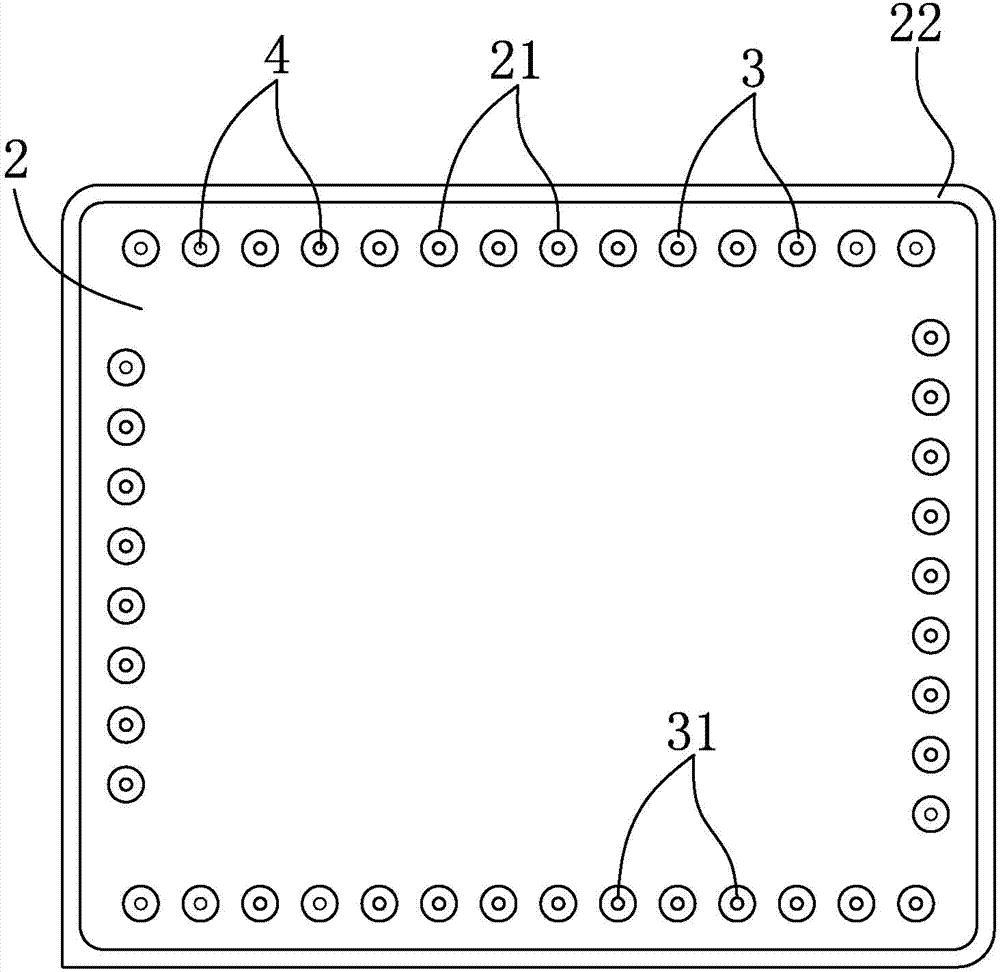

Machining method of metal packaging shell of large-scale and large-power integrated circuit

ActiveCN102832140AImprove air tightnessHigh withstand voltageSemiconductor/solid-state device manufacturingComputer moduleEngineering

The invention relates to a machining method of a metal packaging shell of a large-scale and large-power integrated circuit. The shell comprises a base and an outer cover, wherein the base is composed of a base plate, a plurality of glass blanks and a plurality of terminal pins; a plurality of first through holes for holding the terminal pins and the glass blanks are formed on the base plate; and the terminal pins are arranged inside the first through holes on the base plate through the glass blanks. When the base and the outer cover are machined well, required elements such as integrated circuits and modules are installed on the base; and the outer cover is welded with the base; the integrated circuits, the modules and the like are fixed on the base of the metal shell, and are connected with external tested devices through leading-out terminals of the terminal pins, thereby accomplishing the output, input and detection and control functions of system signals. The outer cover is welded with the base; the integrated circuits and the modules are sealed inside the metal shell, so that both the functions of signal output, detection and control are achieved, and the internal circuit is prevented from being influenced by various external severe environments.

Owner:中国电子科技集团公司第四十研究所

Weather-proof FEVE (Fluoroethylene Vinyl Ether) ambient temperature curing fluorocarbon coating and preparation method thereof

InactiveCN105385255AHigh electronegativityStrong carbon-fluorine bondAnti-corrosive paintsEpoxy resin coatingsVinyl etherDefoaming Agents

The invention discloses weather-proof FEVE (Fluoroethylene Vinyl Ether) ambient temperature curing fluorocarbon coating and a preparation method thereof. The weather-proof FEVE ambient temperature curing fluorocarbon coating comprises a component A and a component B according to a weight ratio of 1 to (0.2 to 0.5); the component A comprises the following raw materials in parts by weight: 30 to 45 parts of FEVE fluorocarbon resin, 5 to 10 parts of alicyclic epoxy resin, 15 to 35 parts of butyl acetate, 10 to 18 parts of propylene glycol methyl ether acetate, 20 to 40 parts of pigments and fillers, 1 to 2 parts of modified organic bentonite, 1 to 2 parts of calcined kaolin, 1 to 2 parts of sodium sulfonate, 1 to 2 parts of flatting agent, 0.1 to 0.3 part of polyether modified polydimethylsiloxane, 1 to 3 parts of dispersing agent, 1 to 2 parts of anti-fungus agent and 0.2 to 0.5 part of defoaming agent; the component B comprises the following raw materials in parts by weight: 10 to 20 parts of trimer prepolymer of aliphatic isocyanate, 2 to 5 parts of boron trifluoride diethyl etherate and 15 to 20 parts of butyl acetate. The weather-proof FEVE ambient temperature curing fluorocarbon coating disclosed by the invention has good corrosion protection and weather resistance properties, and the preparation method is simple and convenient for actual operation.

Owner:ANHUI JINDUN PAINT

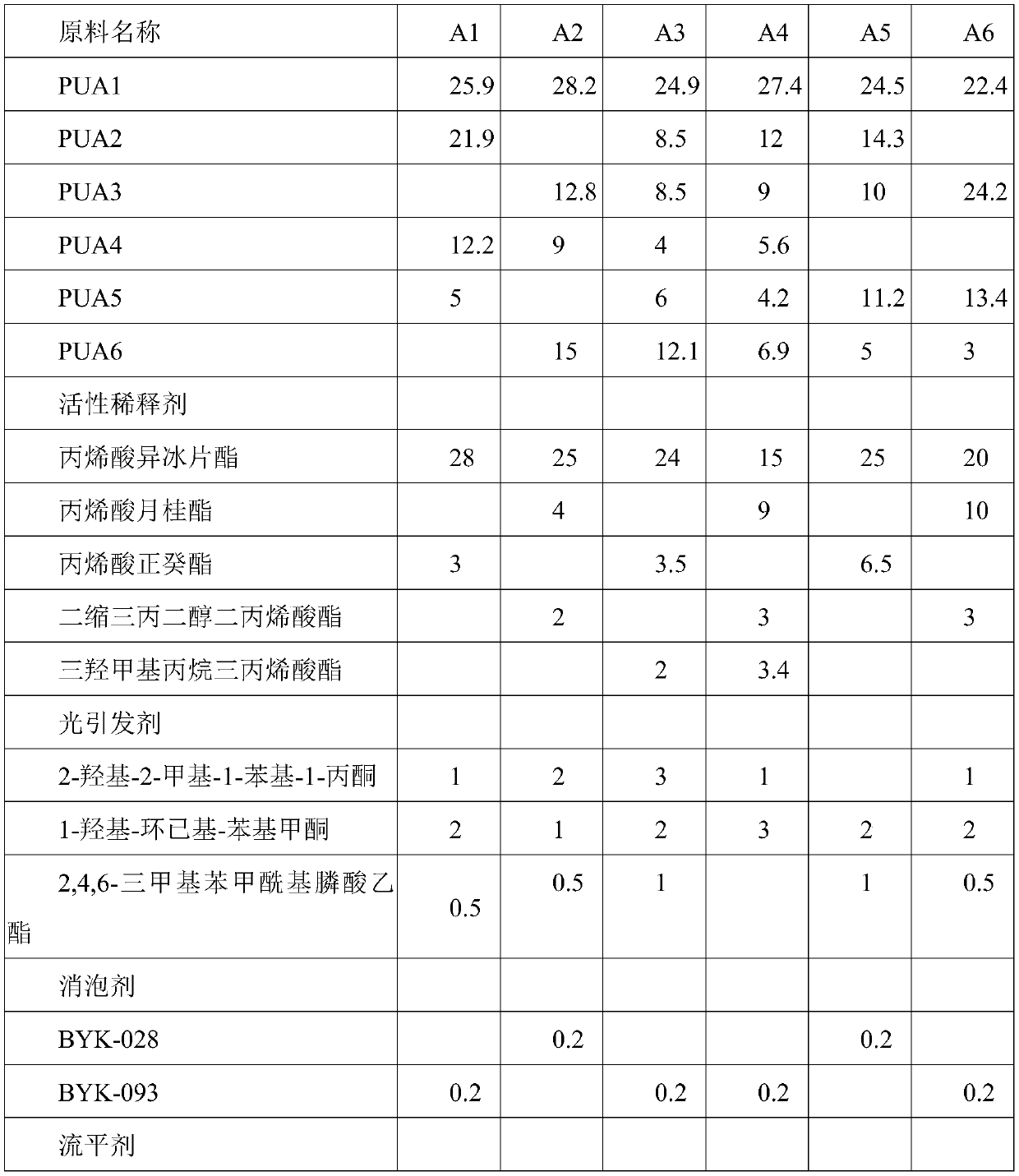

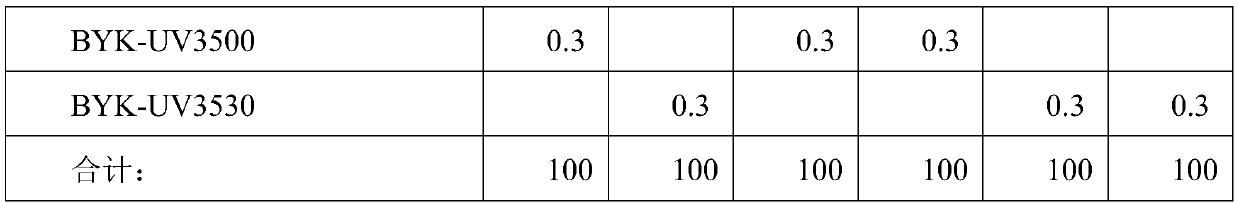

Preparation method of flame-retardant UV-moisture dual-curing polyurethane acrylate conformal coating

ActiveCN110885625AImprove wear resistanceImprove resistance to salt sprayFireproof paintsAnti-corrosive paintsPhosphoric Acid EstersPolymer science

The invention discloses a preparation method of flame-retardant UV-moisture dual-curing polyurethane acrylate conformal coating. The method comprises the steps of: taking UV-moisture dual-curing polyurethane acrylate resin containing a phosphate ester compound as a base material, and adopting a low-odor and low-irritation reactive diluents matched with a photoinitiator to prepare a flame-retardantUV-moisture dual-curing polyurethane acrylate conformal coating. The flame-retardant UV-moisture dual-curing polyurethane acrylate conformal coating does not contain a volatile organic solvent, has aflash point higher than 61 DEG C, has low odor, is a non-hazardous chemical three-proofing paint, and can be stored and transported according to conventional chemicals; a UV and moisture dual-curingmechanism is adopted, so that the curing speed is high, and the efficiency is high; and the coating film of the flame-retardant UV-moisture dual-curing polyurethane acrylate conformal coating has highwear resistance, high salt spray resistance, high damp-heat resistance, high acid and alkali resistance and an excellent electrical insulation performance, and can be widely applied to the high-corrosion-resistance fields of power supply frequency conversion, automotive electronics, industrial control, communication, household appliances, military industry and the like.

Owner:SHENZHEN NEWOLL NEW MATERIAL CO LTD

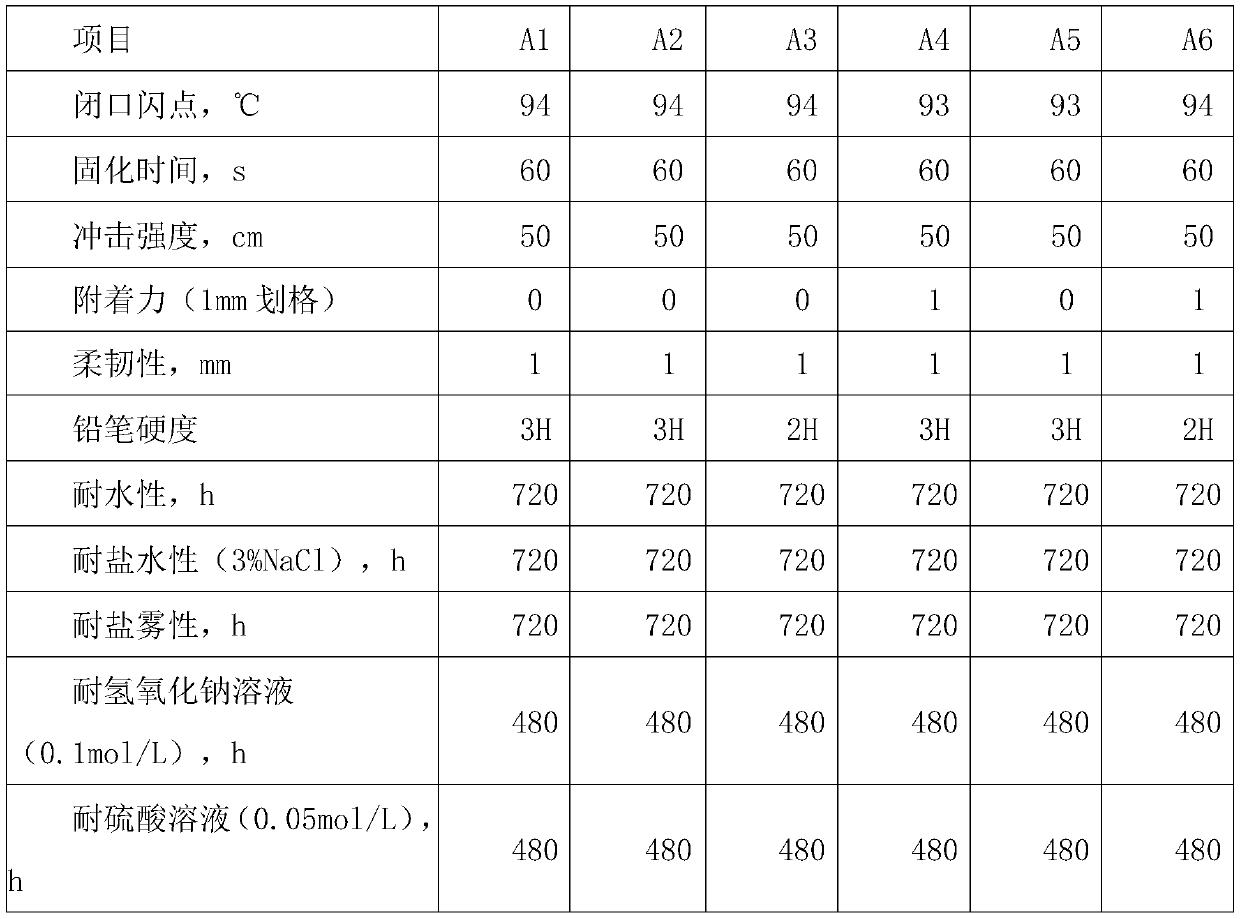

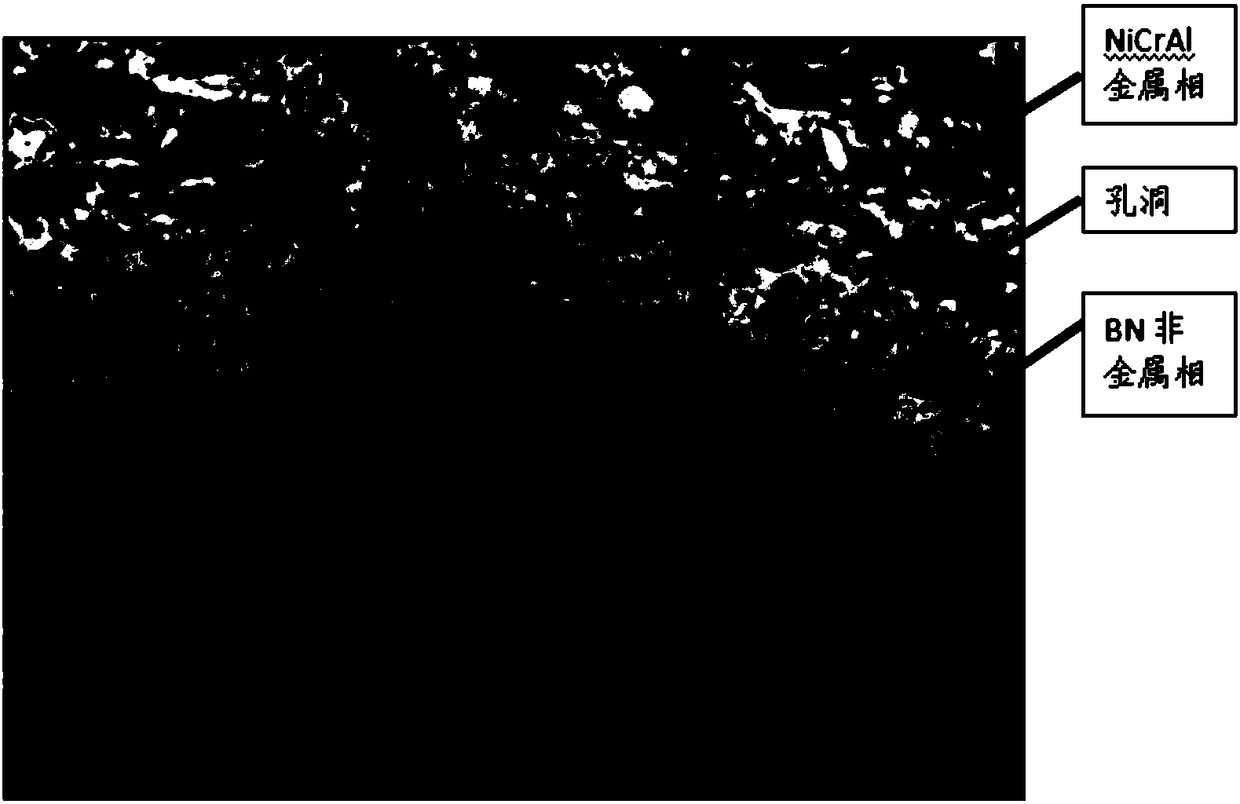

Marine corrosion-resistant thermal spraying abradable seal coating and preparation method thereof

ActiveCN108203799AImprove resistance to salt sprayImprove overall service performanceHot-dipping/immersion processesMolten spray coatingCorrosion resistantBonding strength

The invention belongs to the gas path seal coating technology of components such as the inner wall of an aero-engine compressor case, and particularly relates to a marine corrosion-resistant thermal spraying abradable seal coating and a preparation method thereof. The method comprises the following steps that (1), a bottom layer is prepared, and a NiAl bottom layer on the surface of a high-temperature alloy substrate is prepared by adopting an atmospheric plasma spraying method; and (2), an abradable surface layer is prepared, and a NiCrAl / BN surface layer is prepared on the NiAl bottom layerby adopting the atmospheric plasma spraying method, wherein NiCrAl / BN surface layer phases are composed of a NiCrAl alloy phase and a non-metal phase h-BN, and the prepared NiCrAl / BN surface layer isof a typical porous multi-phase structure. The corrosion-resistant seal coating has good marine environmental corrosion resistance, and decrement of the coating hardness, the bonding strength and thelike of the coating is low after the coating is subjected to marine environment corrosion, so that the use requirements of aero-engine gas path sealing are met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Seedling cultivating method for improving salt mist resisting ability of cerbera manghas

ActiveCN105210756AImprove soil salinity and alkali resistanceImprove resistance to salt spraySeed and root treatmentCultivating equipmentsNutrientGermination

The invention discloses a seedling cultivating method for improving salt mist resisting ability of cerbera manghas, wherein the method comprises following steps: select the seeds that are produced by nursery stocks locally growing on seaside, and perform initial-stage salt-resisting exercise beginning from the soaking period of the seeds; adopt salt solution with low concentration to synchronously perform soil salinity resistance training and salt mist resistance training to the nursery stocks beginning from the seedlings producing with 5-10 leaves to the seedlings with height of 1m; change large size nutrient bags after the height of the seedlings arrive at 1m, and enhance the intensity of synchronously performing soil salinity resistance training and the salt mist resistance training to the nursery stocks within a year of planting with the large size nutrient bags and four months before finishing the nursery stage. Through the above three stages of training, the survival rate and the growth vigor of the cerbera manghas planted along the coastal areas are as good as the cerbera manghas planted in inland areas. In the seed soaking stage, the germination rate of the seeds, the survival rate of the nursery stocks during the seedling planting period, and the survival rate of the nursery stocks during the big seedlings planting period are all within the range of 90-95%; and the survival rate of the big seedlings planted along the coastal areas after the big seedlings come out of the nursery stage is more than 95%.

Owner:FUJIAN SPRING ECOLOGICAL TECH CO LTD +1

Preparation method of epoxy resin modified waterborne acrylic emulsion

The invention discloses a preparation method of an epoxy resin modified waterborne acrylic emulsion. The preparation method comprises the following steps: putting epoxy resin, styrene, methyl methacrylate, butyl ester and acrylic acid in a stirrer, stirring for 30 minutes, and mixing evenly to obtain a first component; adding water and a first emulsifying agent in a pre-emulsification tank, mixing evenly, adding the well mixed first component into the pre-emulsification tank, and stirring and pre-emulsifying for 0.5-1 hour to obtain a second component; adding water and a second emulsifying agent in a reaction kettle, and stirring and heating to 80 DEG C; adding an initiator in the reaction kettle, starting to add the pre-emulsified second component dropwise, adding dropwise for 3.5 hours, thermally insulating for 1.5 hours after adding dropwise, and regulating the ph to 7. Through the mode, the preparation method of the epoxy resin modified waterborne acrylic emulsion greatly improves the adhesive force on base materials like metal and glass, improves the properties of water tolerance, salt spray resistance and the like, and is more environmentally friendly.

Owner:CHANGSHU LINRUN FLUORINE & SILICONE MATERIAL

Preparation method of degree-of-functionality-adjustable ultraviolet light cured waterborne resin

The invention provides a preparation method of degree-of-functionality-adjustable ultraviolet light cured waterborne resin. The method comprises the following steps that a polyacrylate chain segment with a side chain containing a hydroxide radical is synthesized; a polyurethane acrylate chain segment with a -NCO group at one end is synthesized, and the polyurethane acrylate chain segment containsa waterborne carboxylic acid group; the polyacrylate chain segment with the side chain containing the hydroxide radical and the polyurethane acrylate chain segment with the -NCO group at one end are subjected to a reaction, waterborne polyurethane acrylate modified polyacrylate is obtained, an alkali solution is added for neutralizing, and the anionic ultraviolet light cured waterborne resin. According to the technical scheme, by means of the resin, mutual balance of various properties is achieved, the viscosity is low, the water solubility is achieved, diluent is not needed, and environmentalfriendliness is better achieved; the obtained resin side chain has polyfunctionality, and the resin correlation degree is greatly improved in the curing process, and all the properties of a curing film are improved.

Owner:SHENZHEN POLYTECHNIC

Acid-rain-resistant waterborne anticorrosive coating for steel structures and preparation method thereof

The invention discloses acid-rain-resistant waterborne anticorrosive coating for steel structures. The coating comprises the following main components: 25 to 35 percent of acrylic emulsion, 0.2 to 0.5percent of a pH regulator, 20 to 30 percent of self-made slurry, 4 to 8 percent of a coalescing agent, 0.1 to 0.2 percent of a defoaming agent, 0.5 to 1 percent of a flash rust prevention additive, and 0.1 to 0.15 percent of a thickening agent, with the balance being water. Through the interaction of the components, a solid complex is formed on the metal surface, so that a layer of compound filmwhich is compactly bonded by chemical bonds and physics is generated on the steel surface, and the acid rain resistance and the salt mist resistance are lasting; the anticorrosive coating provided bythe invention is refined by adopting an advanced process, has the advantages of low price, good coating film hardness, no bubbling, no gloss loss and the like under the condition of acid rain, good adhesion to steel and good adhesion to various primers, and can also be used as primer-topcoat coating.

Owner:湖州市南浔联谊喷涂厂

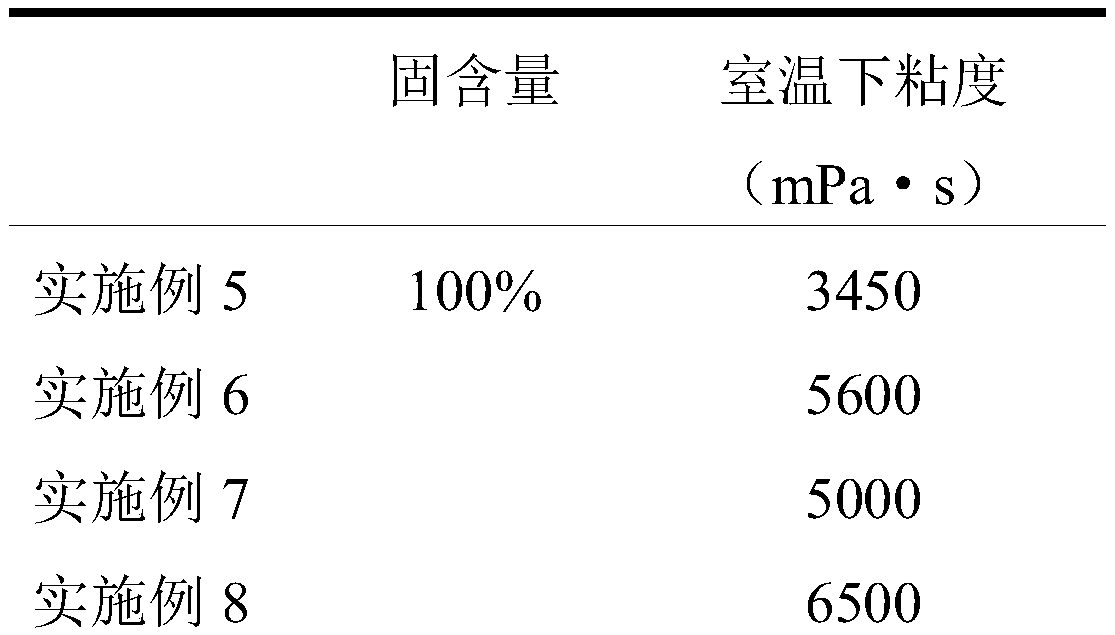

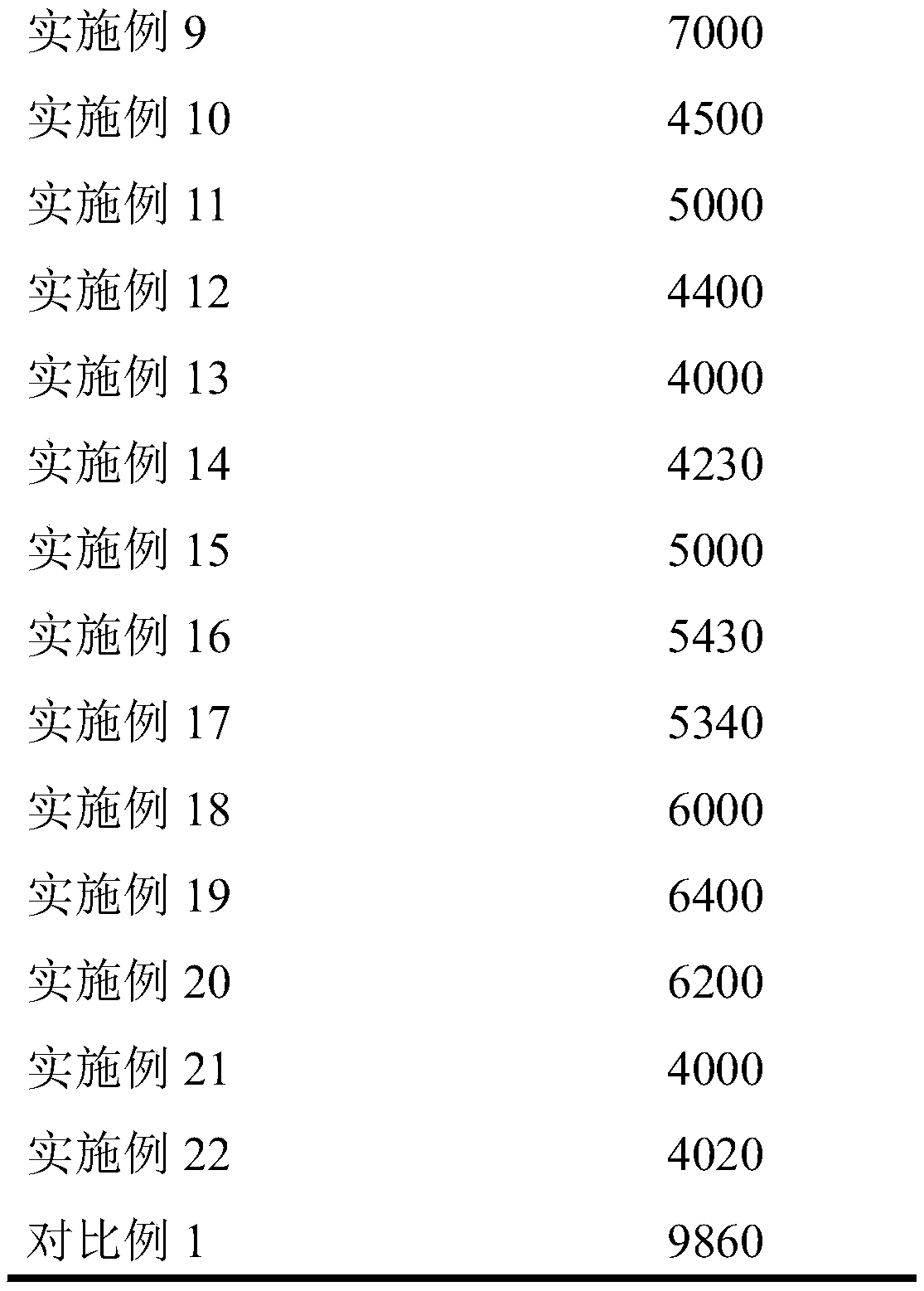

Solvent-free closed colored polyisocyanate curing agent as well as preparation method and application thereof

InactiveCN111349214AImprove physical and chemical propertiesImprove water resistancePolyurea/polyurethane coatingsIsocyanateChemistry

The invention discloses a solvent-free closed colored polyisocyanate curing agent as well as a preparation method and application thereof, and belongs to the technical field of coatings, wherein the polyisocyanate curing agent is prepared by modifying polyisocyanate with enol or acrylate, then carrying out copolymerization of unsaturated double bonds under the action of an initiator and blocking the remaining NCO with a blocking agent; the curing agent solves the problems of high pollution, strong smell, high toxicity and the like of a traditional solvent type polyisocyanate curing agent.

Owner:武汉仕全兴聚氨酯科技有限公司

Wire enamel with high temperature classification and preparation method

InactiveCN103725191AImprove scratch resistanceHigh hardnessPolyamide coatingsEpoxy resin coatingsTripropylene glycolEpoxy

The invention discloses wire enamel with high temperature classification. The wire enamel is characterized by being prepared by raw materials in parts by weight (kilogram) as follows: 30-35 parts of nylon 12, 10-12 parts of E-12 epoxy resin, 1-2 parts of magnesium hydrate, 8-10 parts of aluminum triphosphate, 12-15 parts of ethylene glycol, 6-9 parts of dimethyl terephthalate, 4-6 parts of trimethyl trimellitate, 2-3 parts of 3-methylphenol, 8-10 parts of nano bentonite, 10-12 parts of tripropylene glycol diacrylate, 1-2 parts of nano emery powder, 2-3 parts of dicumyl peroxide DCP, 8-12 parts of potassium hexatitanate whiskers, 7-9 parts of an auxiliary, 120-130 parts of cresol and 110-120 parts of xylene. With the adoption of the wire enamel with high temperature classification, forming of a paint film with uniform, dense and smooth surface can be facilitated during coating in the follow-up process, micropores are greatly reduced, and scratch resistance, harness, salt mist resistance and severe environment resistance of the paint film are remarkably improved.

Owner:铜陵天河特种电磁线有限公司

Waterborne weather-resisting anticorrosive coating and preparation method thereof

ActiveCN109762455AAvoid pollutionThe preparation process is easy to operateAnti-corrosive paintsPolyurea/polyurethane coatingsWeather resistanceChemistry

The invention relates to waterborne weather-resisting anticorrosive coating and a preparation method thereof and relates to the field of waterborne anticorrosive coating. The coating is prepared by uniformly mixing and stirring a resin component and an isocyanato curing agent component, wherein the resin component contains fluorocarbon resin, and the ratio of the hydroxyl mol number of the fluorocarbon resin to the isocyanato mol number of the isocyanato curing agent component is 1 to (1.02 to 1.05); the resin component also contains graphene powder which accounts for 0.1 to 5.0 percent of thetotal weight of the coating; the coating can be used for effectively improving the water resistance, acid resistance, alkali resistance, temperature and heat resistance, salt mist resistance and weather resistance of a whole body, so that the safe, green, environment-friendly and pollution-free utilization requirements on the coating in the market can be effectively met.

Owner:赵娜

PVDF fluorocarbon powder coating and preparation method thereof

The invention discloses a PVDF fluorocarbon powder coating and a preparation method thereof. The PVDF fluorocarbon powder coating comprises the following materials: ultra-fine PVDF resin, auxiliary solid resin, a pigment and an auxiliary agent; the PVDF fluorocarbon powder coating is characterized in that the weight ratio of the ultra-fine PVDF resin to the auxiliary solid resin is 70:30, the auxiliary solid resin comprises acrylic resin and alicyclic epoxy resin, wherein the weight ratio of the acrylic resin to the alicyclic epoxy resin in the auxiliary solid resin is (5:25)-(25:5); and the preparation method comprises the following steps: (1) dispersing and mixing the auxiliary solid resin and the pigment at a high speed and performing rubbing to generate heat; (2) adding the ultra-finePVDF resin, performing high-speed dispersion and mixing continuously, and performing rubbing to generate heat; (3) performing melt extrusion, performing cooling, performing drying, and performing pressure-roller cutting; (4) spraying liquid nitrogen and performing freezing; (5) performing crushing, and in the crushing process, performing freezing by using liquid nitrogen; (6) classifying powder; (7) collecting qualified powder, adding an adhesion accelerator and a nano modifier auxiliary agent, and performing spheroidization and loosening treatment; and (8) screening powder which meets a standard. According to the technical scheme, a problem that the PVDF resin is plasticized is avoided, and therefore the PVDF resin and the acrylic resin are mixed uniformly.

Owner:广东依斯特新材料有限公司

Pure water-base cold spray lacquer as well as preparation method and application thereof

InactiveCN106833202AImprove surface propertiesIncrease brightnessSlide fastenersClothes buttonsBenzeneWater based

The invention relates to a pure water-base cold spray lacquer as well as a preparation method and an application thereof. The pure water-base cold spray lacquer comprises the following components in parts by weight: 45-60 parts of modified pure water-base polyhydric alcohol resin, 2-4 parts of diethanol amine, 12-25 parts of water-base amino resin and 15-26 parts of water. The preparation method comprises the following steps: adding diethanol amine into the modified pure water-base polyhydric alcohol resin; uniformly mixing and then adding water; uniformly mixing again, and then adding the water-base amino resin; uniformly dispersing and then de-foaming and filtering; and collecting filtrate, thereby acquiring the pure water-base cold spray lacquer. In the pure water-base cold spray lacquer provided by the invention, water is adopted for replacing a thinning agent in oil paint; after the completing of the paint spraying, water is used for washing, so that the effect of cold paint spraying surface is promoted; the use method is simplified; the production cost is lowered; the harmful matters, such as, benzene, added into the oil paint can be prevented; the pure water-base cold spray lacquer is environment-friendly and nontoxic; the prepared pure water-base cold spray lacquer has the qualified flexibility, adhesive force, salt mist resistance and water washing resistance.

Owner:珠海富邦新材料科技有限公司

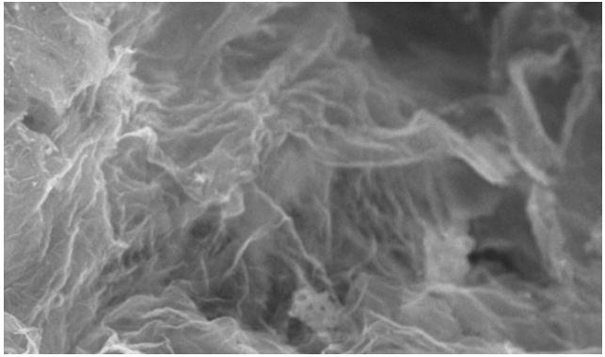

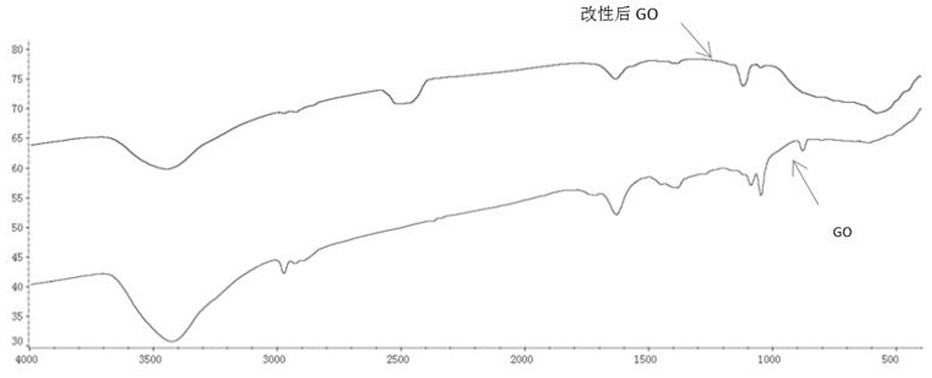

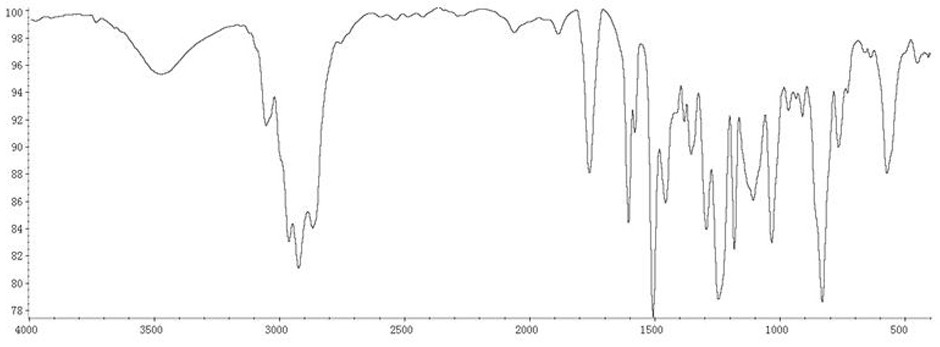

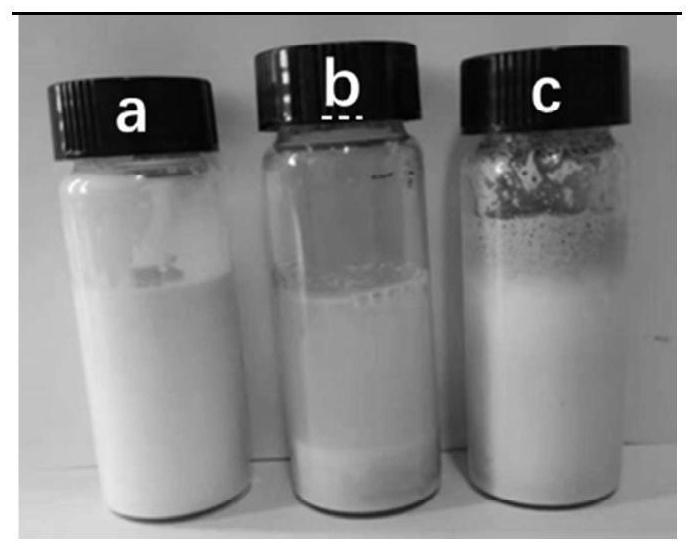

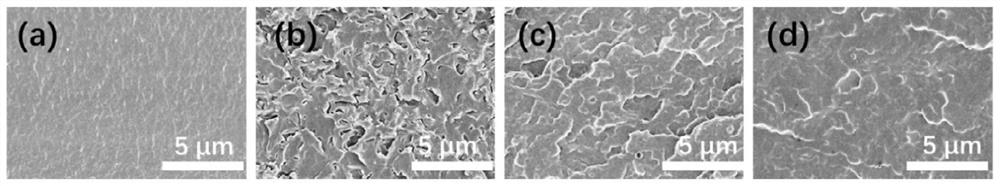

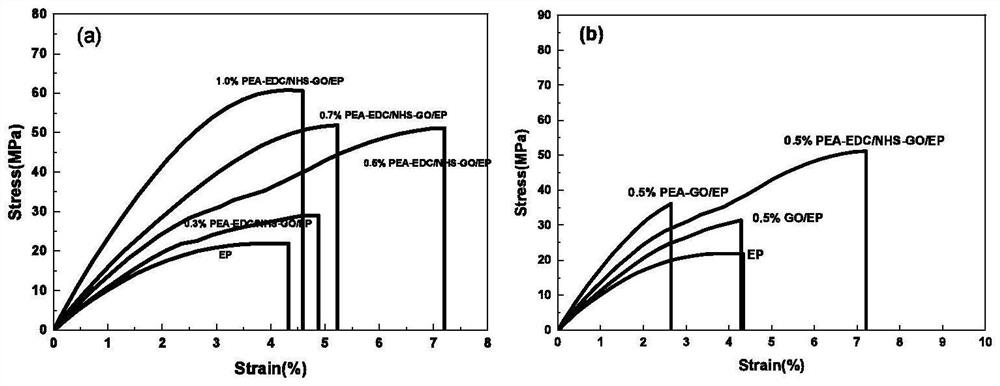

MPA/KH567/rGO enhanced waterborne epoxy amino baking varnish and preparation method thereof

The invention discloses MPA / KH567 / GO enhanced waterborne epoxy amino baking varnish and a preparation method thereof. The method comprises the following steps that: GO is prepared by using a modified Hummers method, and is modified by using a coupling agent KH567 and 3-mercaptopropionic acid, and silicon hydroxyl is introduced at the same time to leave a space for subsequent performance improvement; oo surfactant or dispersing agent is added, and the reinforcing agent modified rGO is dispersed in the waterborne epoxy emulsion by using an improved phase inversion method; a waterborne epoxy emulsifier is prepared by reacting N,N-methylene bisacrylamide, hydroxyethyl acrylate and epoxy resin E-44; the MPA / KH567 / rGO enhanced waterborne epoxy amino baking varnish is obtained by uniformly mixing epoxy equivalent in the waterborne epoxy emulsion and reactive hydrogen equivalent in an amino curing agent according to a ratio of 1: 1. The baking vanish has a certain practical application value.

Owner:FUZHOU UNIV

Polyfunctionality hybrid cured resin and preparation method thereof

ActiveCN110016143ARigidAchieving Thermal Hybrid CuringPolyurea/polyurethane coatingsSide chainUltraviolet lights

The invention provides polyfunctionality hybrid cured resin and a preparation method thereof. The molecular chain of the polyfunctionality hybrid cured resin is of a comb-type structure, and includesa polyacrylate main chain and urethane acrylate side chains, wherein a plurality of acrylate double bonds and epoxy groups are contained in the side chains of the polyfunctionality hybrid cured resinseparately. The resin of the technical scheme has low viscosity and multiple functionality, the use amount of a diluent can be reduced in subsequent use, and the polyacrylate main chain and the urethane acrylate side chains are contained in the structure of the resin; and since a plurality of acrylate double bonds and epoxy groups are contained in the side chains, ultraviolet light-radical-heat hybrid curing or ultraviolet light-radical-cation hybrid curing can be achieved, and the degree of cross-linking of the resin obtained after hybrid curing is performed is improved greatly, so that thehardness, adhesion, wear resistance, solvent resistance, salt spray resistance and other properties of a cured film are improved effectively.

Owner:SHENZHEN POLYTECHNIC

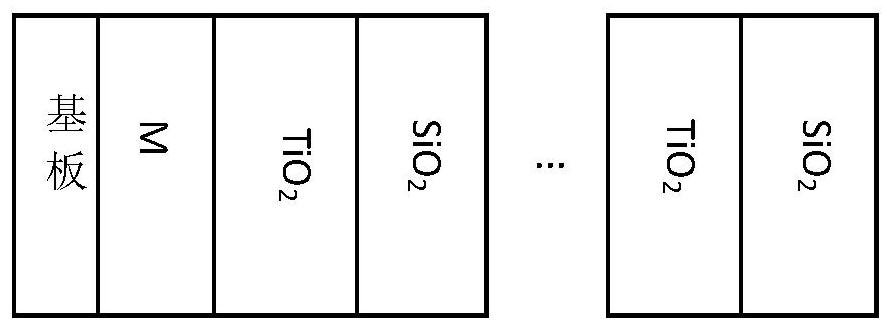

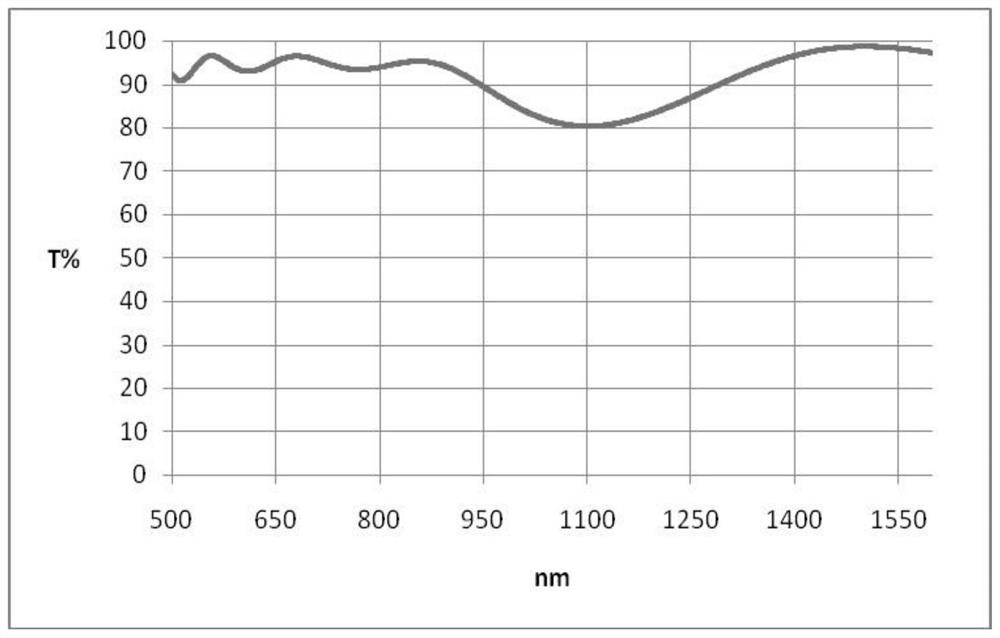

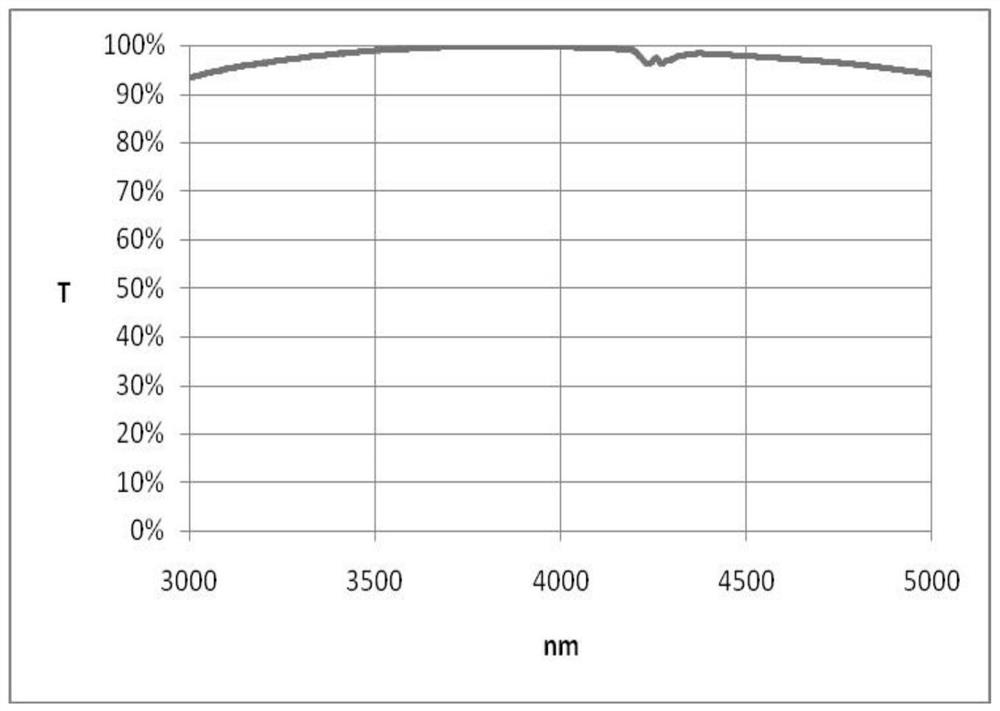

ZnS substrate-based multiband salt spray-resistant antireflection film and preparation method thereof

ActiveCN112323023AImprove firm performanceExcellent heat and humidity resistanceVacuum evaporation coatingSputtering coatingOxygen ionsOptical thin film

The invention discloses a preparation method of a ZnS substrate-based multiband salt spray resistant antireflection film, and belongs to the technical field of optical films. The design theory of a multilayer antireflection film stretching across visible light, near-infrared light and medium-wave infrared bands is utilized, the design theory of the multilayer antireflection film on a high-refractive-index substrate is combined, a matching layer design for enhancing binding force is inserted, and refractive index matching with the substrate is achieved through an asymmetric equivalent layer andan asymmetric equivalent layer by adopting an asymmetric lambda / 4 film system. High-density oxygen ions emitted by an ion source are utilized to further oxidize the film, and meanwhile, high-energy argon ions and oxygen ions are utilized to pretreat the substrate. On one hand, the mechanism characteristics at the interface of the substrate and a film layer are improved, so that the bonding forcebetween the substrate and TiO2 is increased by a bonding layer; and on the other hand, the nodule defect with poor adhesive force generated in the coating process can be effectively removed before growth, the film layer is more compact, and meanwhile, the stress influence between the TiO2 and SiO2 is reduced, and the firmness, the damp and heat resistance and the salt mist resistance of the film layer are improved.

Owner:江苏北方湖光光电有限公司

Acid-resisting epoxy resin waterborne anticorrosive coating and preparation method thereof

InactiveCN108117820AImprove acid resistanceGood oil resistanceAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention relates to acid-resisting epoxy resin waterborne anticorrosive coating and belongs to the field of application of graphene materials. The coating is prepared by mixing a component A anda component B, wherein the component A is an epoxy resin base material and is prepared from epoxy resin, an emulsifier, water, disperse medium water, an auxiliary agent and graphene pigment and filleraccording to the mass ratio of (100 to 200) to (5 to 10) to (50 to 100) to (100 to 150) to (1 to 3.0) to (100 to 250); the component B is a waterborne phenolic aldehyde amine type curing agent; a graphene component is added into the coating, so that the acid resisting performance of the epoxy resin waterborne anticorrosive coating is greatly improved; the acid-resisting epoxy resin waterborne anticorrosive coating is also environmentally friendly and has no injuries to constructors.

Owner:LUOYANG DAYU IND

Machining method of metal packaging shell of large-scale and large-power integrated circuit

ActiveCN102832140BImprove air tightnessHigh withstand voltageSemiconductor/solid-state device manufacturingComputer modulePower integrated circuits

The invention relates to a machining method of a metal packaging shell of a large-scale and large-power integrated circuit. The shell comprises a base and an outer cover, wherein the base is composed of a base plate, a plurality of glass blanks and a plurality of terminal pins; a plurality of first through holes for holding the terminal pins and the glass blanks are formed on the base plate; and the terminal pins are arranged inside the first through holes on the base plate through the glass blanks. When the base and the outer cover are machined well, required elements such as integrated circuits and modules are installed on the base; and the outer cover is welded with the base; the integrated circuits, the modules and the like are fixed on the base of the metal shell, and are connected with external tested devices through leading-out terminals of the terminal pins, thereby accomplishing the output, input and detection and control functions of system signals. The outer cover is welded with the base; the integrated circuits and the modules are sealed inside the metal shell, so that both the functions of signal output, detection and control are achieved, and the internal circuit is prevented from being influenced by various external severe environments.

Owner:中国电子科技集团公司第四十研究所

Preparation method of waterborne epoxy-modified graphene oxide nano composite coating

PendingCN114517047AGood dispersionImprove stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyCompatibilization

The invention discloses a preparation method of a waterborne epoxy-modified graphene oxide nano composite coating, and belongs to the field of high polymer material modification. According to the invention, polyether amine is utilized to modify graphene oxide, and through ring-opening reaction of polyether amine and water-borne epoxy resin, interfacial interaction between graphene oxide and water-borne epoxy resin is enhanced, and dispersibility and compatibility of graphene oxide in water-borne epoxy resin are improved; the mechanical property of the water-borne epoxy resin and the anti-corrosion and barrier properties of a coating are improved, and the water-borne epoxy resin has a very good application prospect in the heavy-duty anti-corrosion fields of automobiles, ships, pipelines, containers, storage tanks and the like.

Owner:JIANGNAN UNIV

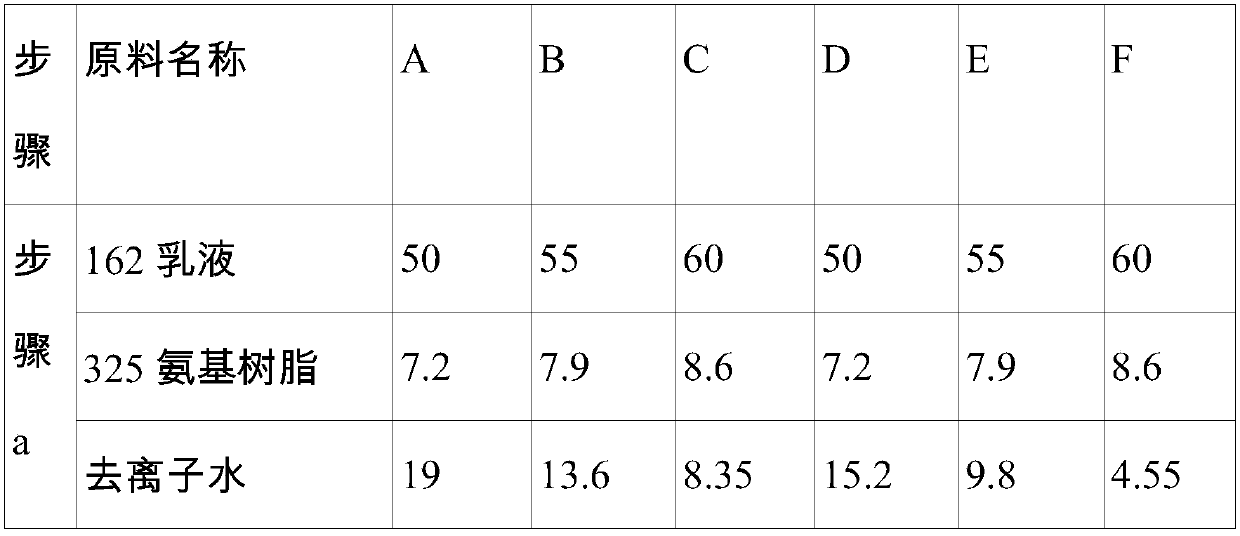

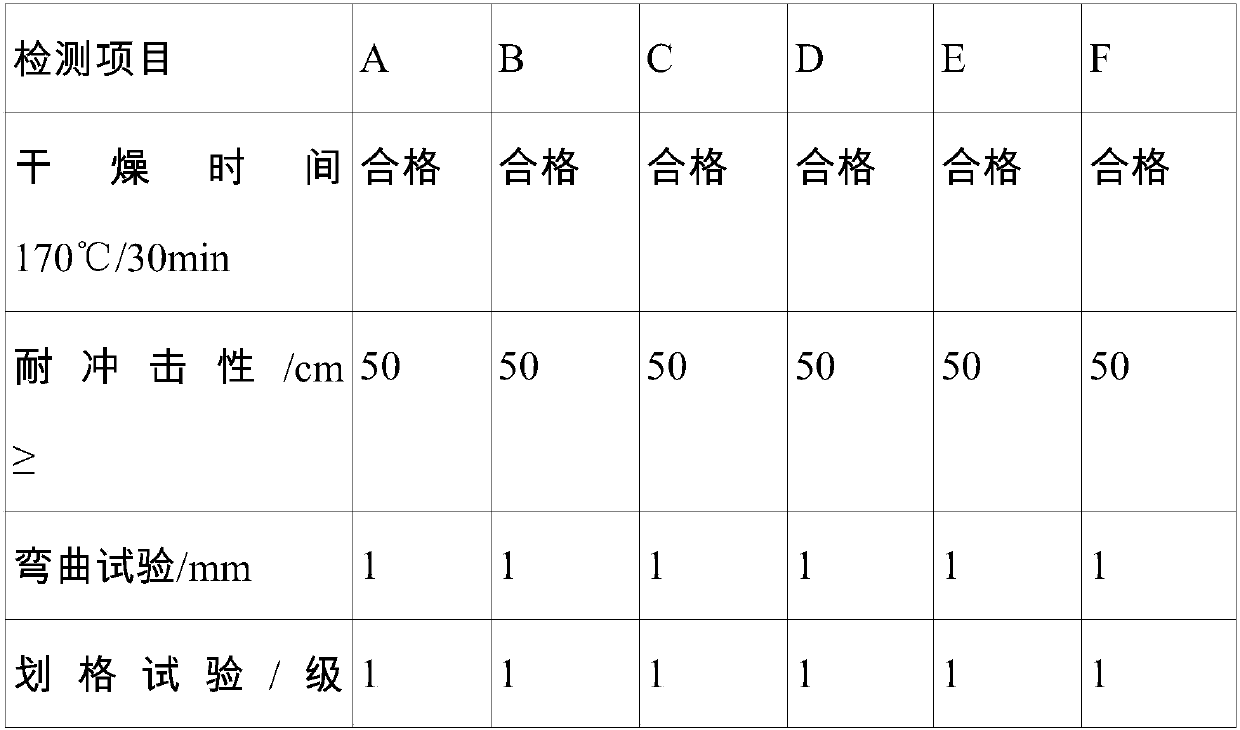

Waterborne silver powder stoving varnish for surface of hydraulic equipment

InactiveCN107641438AImprove mechanical propertiesImprove water resistanceEpoxy resin coatingsEpoxyHydraulic equipment

The invention provides a waterborne silver powder stoving varnish for the surface of hydraulic equipment. The waterborne silver powder stoving varnish is prepared from the following components by percentage: 50 to 60 percent of epoxy modified waterborne acrylic emulsion, 7.2 to 8.6 percent of amino resin, 10 to 12 percent of waterborne aluminum paste, 0.3 to 0.4 percent of dispersing agent, 0.2 to0.25 percent of defoaming agent, 0.1 to 0.15 percent of multifunction additive, 0.5 to 0.55 percent of anti-flash rust agent, 0.5 to 0.7 percent of silver powder directional arrangement agent, 0.15 to 0.2 percent of wetting agent, 0.2 to 0.25 percent of rheological additive, 0.1 to 0.15 percent of bactericide, 0.4 to 1.2 percent of thickening agent, 3.5 to 4 percent of propanediol butyl ether, 3.5 to 4 percent of isopropanol and the balance of deionized water. By using reasonable formula combination and improving a technology, the prepared waterborne silver powder stoving varnish provided bythe invention has excellent mechanical properties; in addition, water resistance, salt mist resistance and volatile oil resistance are significantly improved; besides, the waterborne silver powder stoving varnish has the advantages of high speed of overall drying rate, smooth and uniform coating film, capability of replacing oil paint for use, safety and environment friendliness.

Owner:湖州金强涂料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com