ZnS substrate-based multiband salt spray-resistant antireflection film and preparation method thereof

An anti-reflection coating, multi-band technology, used in sputtering, ion implantation, coating, etc., can solve problems such as poor environmental adaptability and poor test results, reduce the impact of stress, and improve the mechanism. characteristics, the effect of improving the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

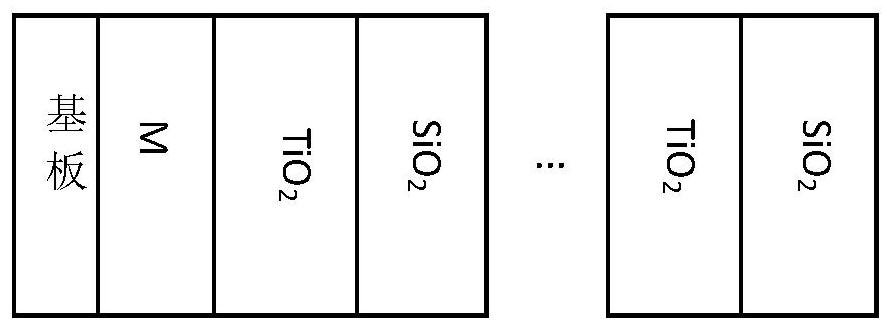

[0028] The invention provides a method for preparing a multi-band salt spray resistant anti-reflection film based on a ZnS substrate, such as figure 1 As shown, the steps are as follows:

[0029] Step 1: Place the evaporation material required for plating and load the cleaned substrate in the coating machine;

[0030] Step 2: Wait for the vacuum to reach 5×10 -3 After Pa, for M and TiO 2 The crucible where it is located is fully pre-melted;

[0031] Step 3: Heat the substrate to 120°C, hold the temperature for 1200s, and wait for the vacuum degree to drop to 1×10 -3 Start plating after Pa;

[0032] Step 4: Start the RF ion source with the magnetron sputtering coater with RF source, the parameters are: BeamV=400~500V, BeamA=400~500mA, Gas1=45~50sccm, Gas2=0sccm, Gas3=8~10sccm , ion cleaning the substrate for 3 to 5 minutes;

[0033] Step 5: After cleaning, the plating of the primer layer M(La0.5Al1.5O3) is carried out, and the evaporation rate is 0.3nm / s. The parameters of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com