Catalyst for ozone catalytic oxidation reactions, and preparation method thereof

An ozone catalytic oxidation and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as weakening catalytic performance, avoid secondary pollution, improve utilization efficiency, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

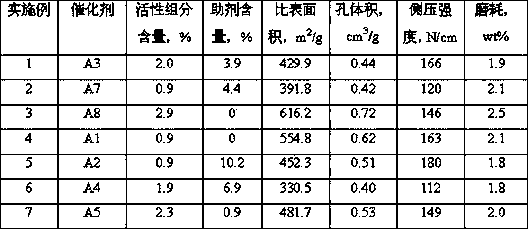

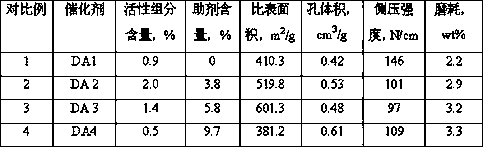

Examples

Embodiment 1

[0053] Add 50g of activated carbon powder to 200g of magnesium gluconate solution with a mass fraction of 18%, stir slowly, and soak for 4 hours; slowly add 290mL of sodium hydroxide solution with a concentration of 0.6mol / L dropwise under stirring to generate magnesium hydroxide precipitate, Stir, stand still for 2 hours, filter, dry at 80°C for 12h, and bake at 1100°C for 3 hours under nitrogen protection to obtain an activated carbon-magnesia composite. The obtained complex was added to 200 g of distilled water at a temperature of 90 ° C, and CO was introduced after 2 h. 2 Gas, pressure 0.18MPa, temperature 150°C, control the end point pH to 7.5, filter after natural cooling, dry at 70°C for 8 hours, and roast under nitrogen protection at 180°C for 4 hours to obtain a composite carrier material of activated carbon and basic magnesium carbonate. The obtained carrier material was made into a cylindrical shape with a diameter of 2.5 mm, dried at 70° C., and then calcined under...

Embodiment 2

[0055] Add 50g of activated carbon powder to 250g of L-magnesium lactate solution with a mass fraction of 19.2%, stir slowly, and soak for 4 hours; slowly add 270mL of ammonium carbonate solution with a concentration of 0.7mol / L dropwise under stirring to generate magnesium carbonate precipitation, stir, Stand still for 2 hours, filter, dry at 80°C for 12h, and bake at 1100°C for 3 hours under the protection of nitrogen to obtain the activated carbon-magnesia composite. The obtained complex was added to 200 g of distilled water at a temperature of 85 ° C, and CO was introduced after 2 h. 2 Gas, pressure 0.36MPa, temperature 90°C, control the end point pH to 8.0, filter after natural cooling, dry at 70°C for 8 hours, and roast at 200°C for 2 hours under the protection of argon to obtain a composite carrier material of activated carbon and basic magnesium carbonate. The obtained support material was made into a four-leaf clover shape with a diameter of 2.0 mm, dried at 70° C., a...

Embodiment 3

[0057] Add 100g of activated carbon powder to 300g of 10% L-magnesium aspartate solution by mass fraction, stir slowly, and soak for 4 hours; slowly add 210mL of ammonia water with a concentration of 1.0mol / L dropwise under stirring to generate magnesium carbonate precipitation, stir, Stand still for 2 hours, filter, dry at 80°C for 12h, and bake at 1100°C for 3 hours under the protection of nitrogen to obtain the activated carbon-magnesia composite. The obtained complex was added to 200 g of distilled water at a temperature of 90 ° C, and CO was introduced after 1 h. 2 Gas, pressure 0.15MPa, temperature 110°C, control the end point pH to 9.0, filter after natural cooling, dry at 70°C for 8 hours, and roast at 200°C for 2 hours under the protection of argon to obtain a composite carrier material of activated carbon and basic magnesium carbonate. The obtained support material was made into a spherical shape with a diameter of 3.0 mm, dried at 70° C., and then calcined under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com