SMD quartz crystal resonator processing method and resonator thereof

A quartz crystal and processing method technology, applied in the field of resonators, can solve problems such as resonator burrs, unusability, damage, etc., and achieve the effects of improving high temperature and high humidity resistance, good protection effect, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

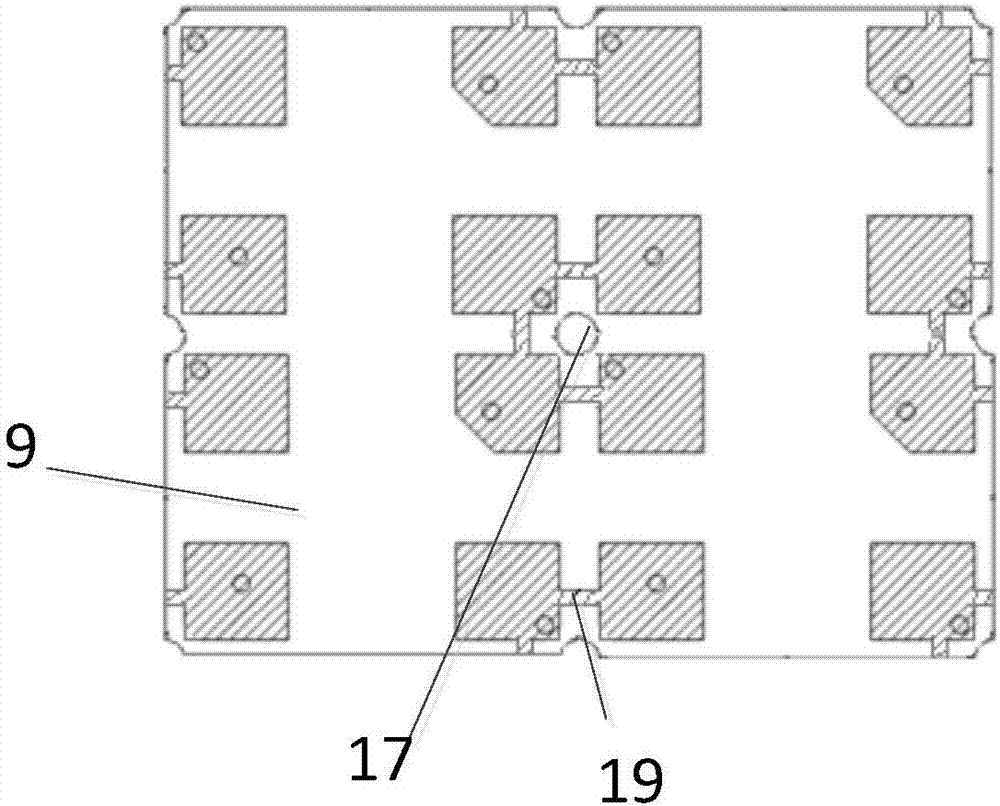

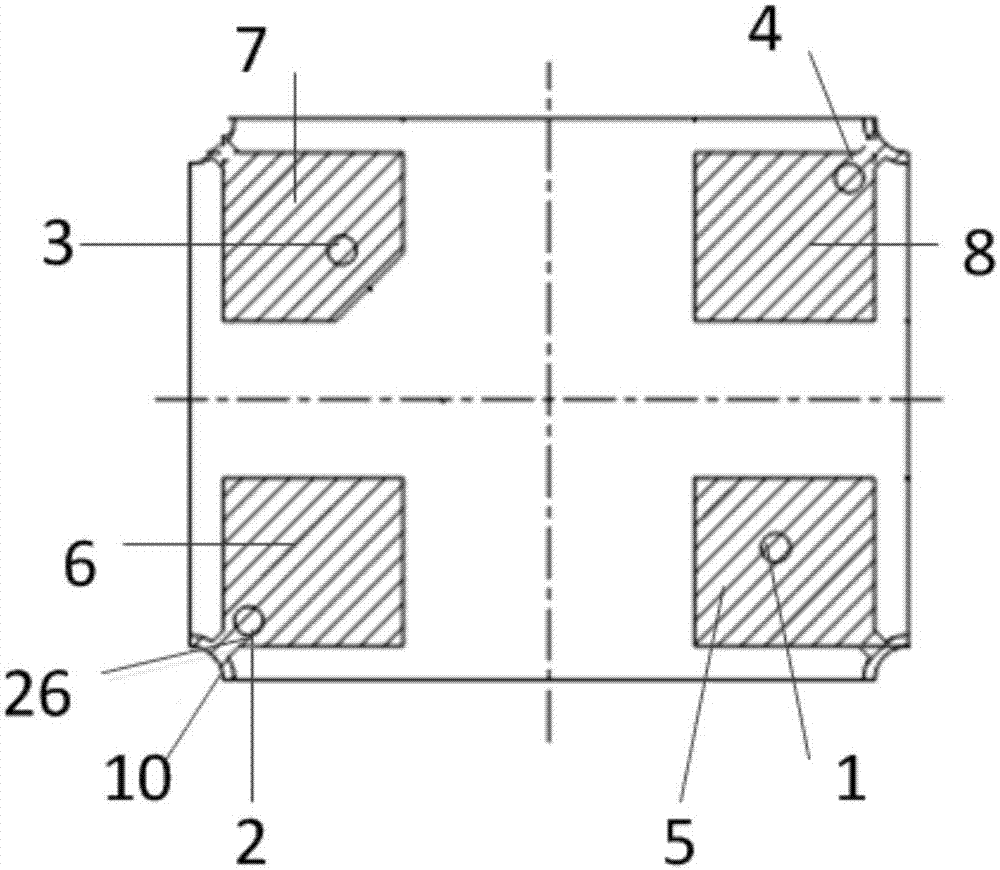

[0081] Such as Figure 3-8 Shown, a kind of processing method of SMD quartz crystal resonator, at first provide the whole board resonator semi-finished product, described whole board resonator semi-finished product comprises the base whole board, the chip that is fixed on each base and covers the base whole board The entire cover plate 20 on the top; then cut the entire cover plate 20 on the entire plate resonator to form a plurality of base cover plates 20-1, and then spray on the upper surface and cut surface of each base cover plate 20-1 Protective layer; finally, the entire board resonator is detected and divided into single SMD quartz crystal resonators, including the following steps:

[0082] The processing steps of the semi-finished product of the whole board resonator are as follows:

[0083] 1), provide or process the whole base board

[0084] A base arranged in a matrix is processed on the entire base plate, the back of the base is provided with four electrodes, ...

Embodiment 2

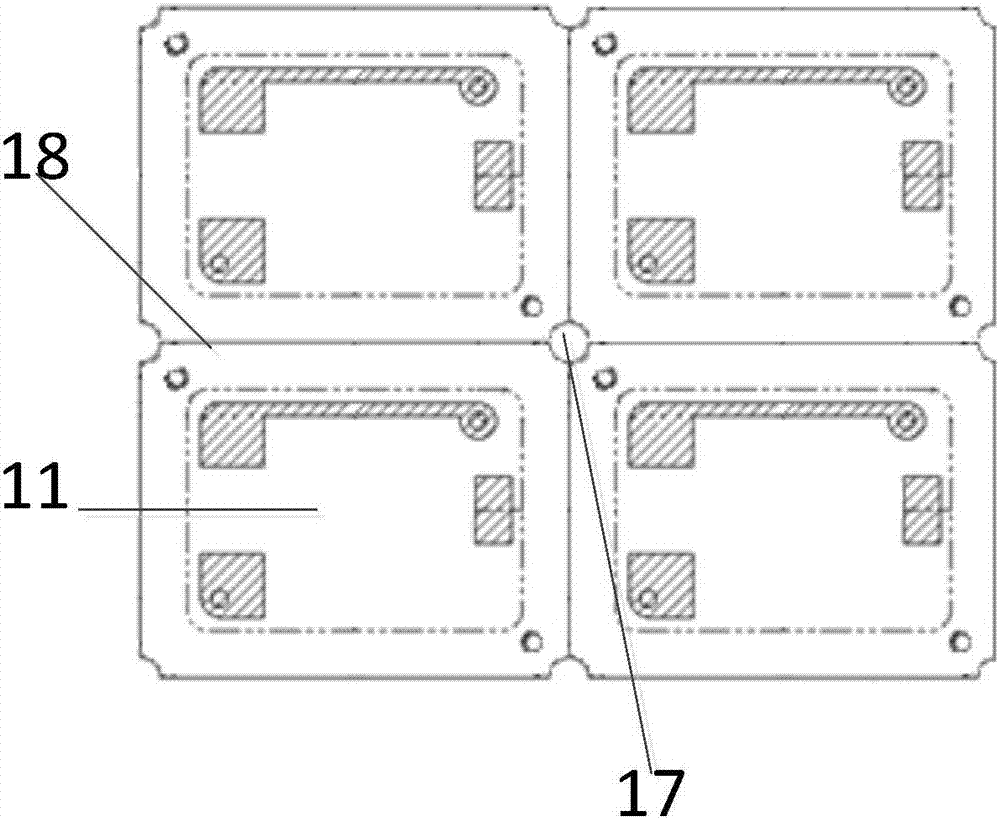

[0117] Such as Figure 1-2 As shown, the difference from Example 1 is that there is no need to carry out metallization treatment on the through hole, and there is no crack line on the back of the whole board of the base. The cracked board line on the front is the same as the base board processing technology in the prior art. Although the spraying process is used in this scheme to form a protective layer, there is no crack board line on the back of the base board. The surface effect of the latter single resonator is not good enough. Other steps are the same as those in Embodiment 1, and will not be repeated here.

[0118] The present invention also relates to an SMD quartz crystal resonator prepared by the above processing method, comprising a base and a base cover, the base is provided with a resonator chamber, and the front of the base is provided with a ring metal coating, the annular metal coating is covered with the metal cover plate, the upper surface and four sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com