Nylon copper plating film and preparation method thereof

A nylon film, nylon technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems affecting the large-scale production of nylon copper plating process, restricting the development of nylon copper plating shielding materials, and incomplete coverage of metal film. and other problems, to achieve the effect of low cost, low price, human body and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

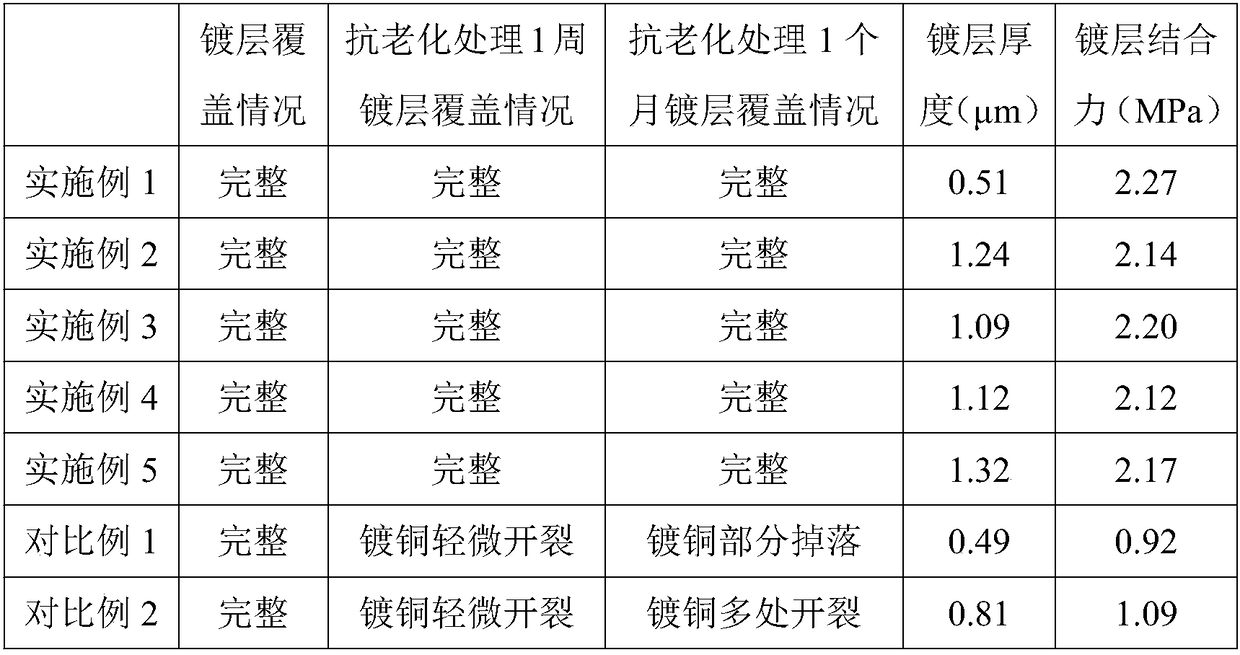

Examples

Embodiment 1

[0043] The present embodiment provides a nylon copper-plated film and a preparation method thereof, comprising the following steps:

[0044] S1. Surface treatment of nylon membrane: grind the nylon membrane in the same direction with a metallographic sample pre-grinder, and then dip it in sodium hydroxide solution;

[0045] Among them, the speed of the metallographic sample pre-grinding machine is 100r / min, the grinding time is 30s, and the specification of the sandpaper used is 800 mesh. The concentration of sodium hydroxide solution is 100g / L, the temperature is 50°C, and the soaking time is 20min.

[0046] S2. Activation and catalysis of the nylon membrane: the nylon membrane of step S1 is activated and catalyzed in silver ammonia solution and sodium hypophosphite solution respectively;

[0047] Wherein, silver ammonia solution is configured with silver nitrate, ammonia water, deionized water, and silver nitrate concentration is 2g / L, and ammonia water concentration is 5mL...

Embodiment 2

[0053] The preparation steps of this embodiment and embodiment 1 are basically the same, the difference is:

[0054] In step S1, the speed of the metallographic sample pre-grinder is 200r / min, the grinding time is 10s, and the specification of the sandpaper used is 2000 mesh. The concentration of sodium hydroxide solution is 75g / L, the immersion temperature is 65°C, and the immersion time is 30min.

[0055] In step S2, the concentration of silver nitrate is 6g / L, the concentration of ammonia water is 15mL / L; the concentration of sodium hypophosphite solution is 40g / L. The activation temperature is 25° C., and the time is 30 minutes; the catalytic temperature is 40° C., and the time is 15 minutes.

[0056] In step S3, the concentration of copper sulfate in the plating solution is 50g / L, the concentration of ethylenediaminetetraacetic acid is 90g / L, the concentration of sodium hydroxide is 15g / L, and the temperature of deionized water for configuring the solution is 40°C; the r...

Embodiment 3

[0059] The preparation steps of this embodiment and embodiment 1 are basically the same, the difference is:

[0060] In step S1, the speed of the metallographic sample pre-grinder is 150r / min, the grinding time is 20s, and the specification of the sandpaper used is 1500 mesh. The concentration of sodium hydroxide solution is 50g / L, the immersion temperature is 80°C, and the immersion time is 10min.

[0061] In step S2, the concentration of silver nitrate is 4g / L, the concentration of ammonia water is 10mL / L; the concentration of sodium hypophosphite solution is 30g / L. The activation temperature is 40° C. and the time is 20 minutes; the catalytic temperature is 30° C. and the time is 20 minutes.

[0062] In step S3, the concentration of copper sulfate in the plating solution is 30g / L, the concentration of ethylenediaminetetraacetic acid is 60g / L, the concentration of sodium hydroxide is 12g / L, and the temperature of deionized water for configuring the solution is 50°C; the red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com