Machining method of metal packaging shell of large-scale and large-power integrated circuit

An integrated circuit and metal packaging technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problem of not being able to reach industrial production, not fully satisfying the processing of large-scale high-power integrated circuit shells, and not fully satisfying the product environment Adaptability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

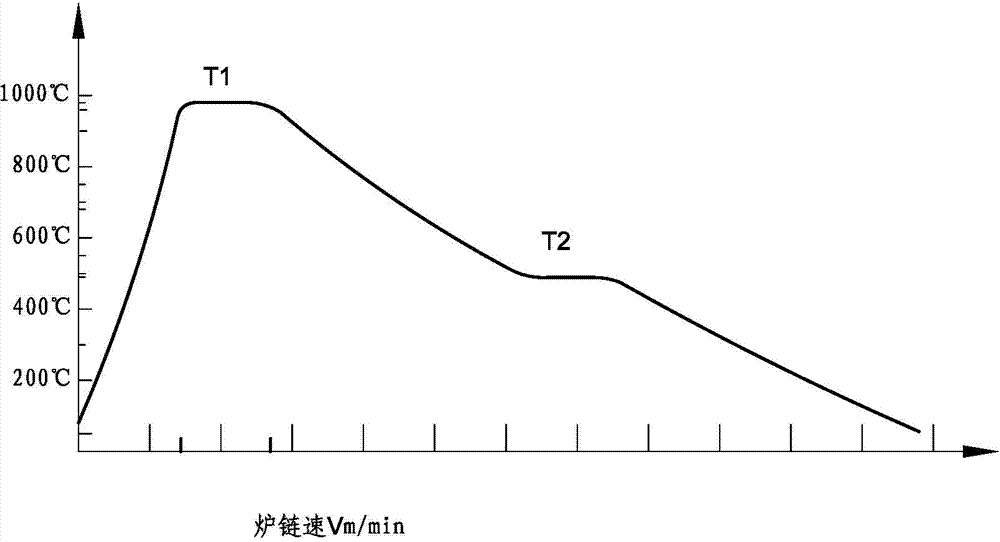

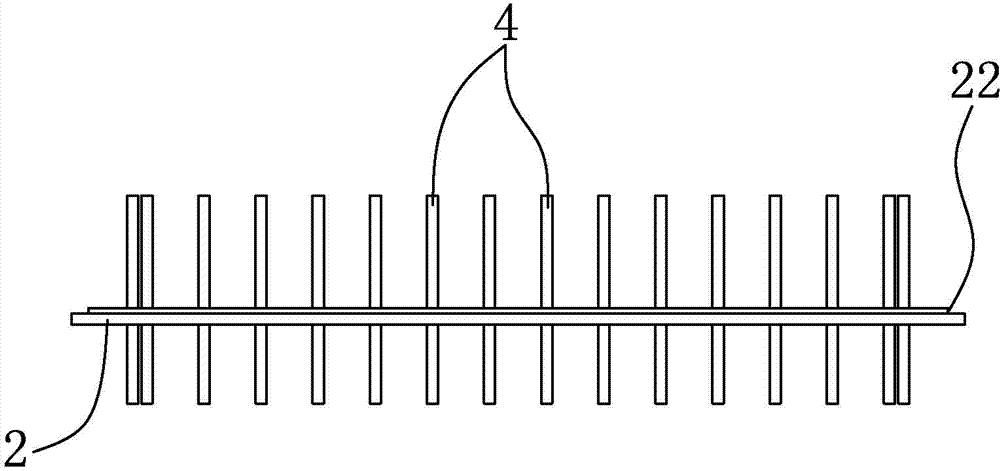

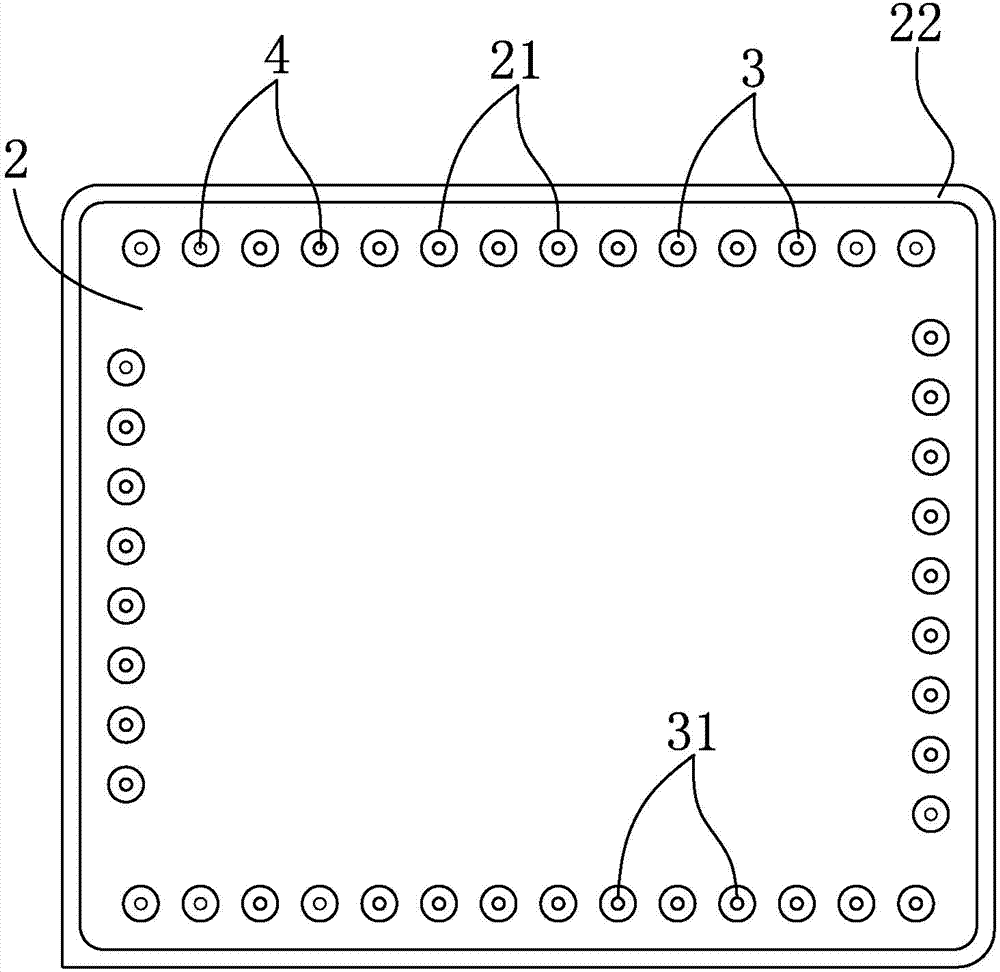

[0046] For the processing method of large-scale and high-power integrated circuit metal packaging shell, see figure 2 — Figure 5 , the shell includes a base and an outer cover 1, the base is composed of a base plate 2, forty-five glass blanks 3, and forty-five lead pins 4, and the base plate 2 is provided with forty-five pins for placing lead pins 4 and glass blanks. 3 through the first through hole 21, the lead pin 4 is placed in the first through hole 21 on the bottom plate 2 through the glass gob 3;

[0047] The processing method of the base includes the following process steps:

[0048] (1) Use the processing center LMC-1000 to process the Kovar alloy sheet material 4J29 into a rectangular bottom plate 2 with forty-five first through holes 21 for placing the lead pins 4 and the glass blank 3. The periphery of the bottom plate 2 is provided with Place the step 22 of the outer cover 1, after the machining is completed, sandblast the surface of the bottom plate 2, and then ...

Embodiment 2

[0057] For the processing method of large-scale and high-power integrated circuit metal packaging shell, see figure 2 — Figure 5 , the shell includes a base and an outer cover 1, the base is composed of a base plate 2, forty-five glass blanks 3, and forty-five lead pins 4, and the base plate 2 is provided with forty-five pins for placing lead pins 4 and glass blanks. 3 through the first through hole 21, the lead pin 4 is placed in the first through hole 21 on the bottom plate 2 through the glass gob 3;

[0058] The processing method of the base includes the following process steps:

[0059] (1) Use the processing center LMC-1000 to process the Kovar alloy sheet material 4J29 into a rectangular bottom plate 2 with forty-five first through holes 21 for placing the lead pins 4 and the glass blank 3. The periphery of the bottom plate 2 is provided with Place the step 22 of the outer cover 1, after the machining is completed, sandblast the surface of the bottom plate 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com