MPA/KH567/rGO enhanced waterborne epoxy amino baking varnish and preparation method thereof

A technology of KH567 and epoxy amino, which is applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of water resistance of the paint film, decline in corrosion resistance, small shrinkage of the paint film, and unfriendly environment. Excellent chemical corrosion resistance, small film shrinkage, good abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

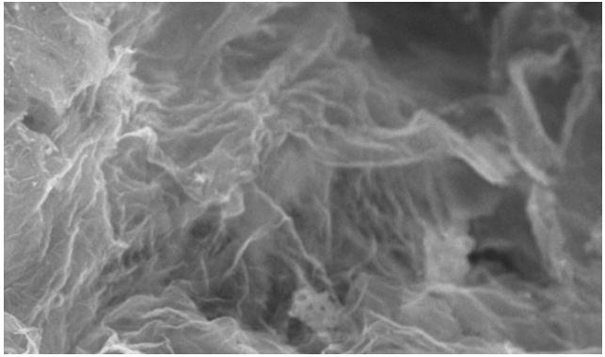

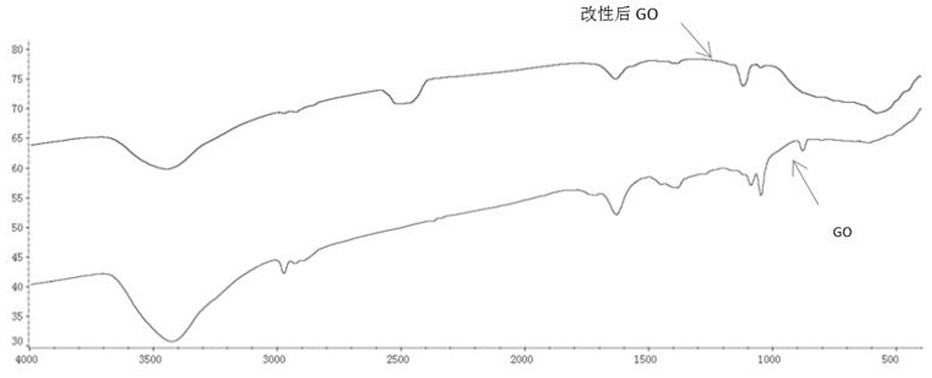

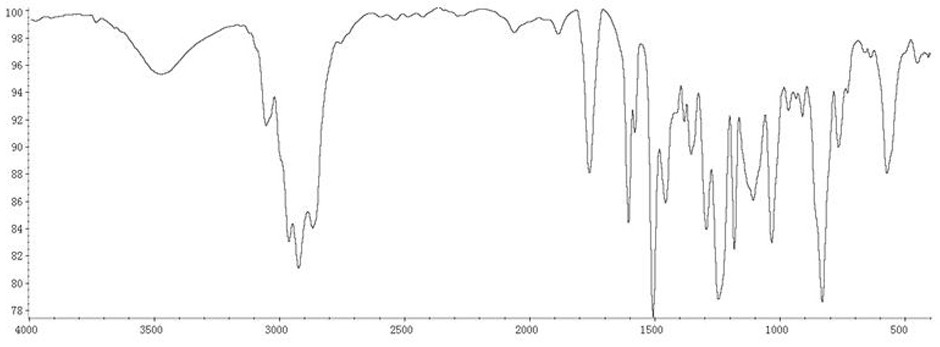

[0039] (1) Preparation of GO by modified Hummers method:

[0040] Assemble a 250 ml reaction bottle in an ice-water bath, mix 2 parts of graphite powder and 2 parts of sodium nitrate with 30 parts of concentrated sulfuric acid and 15 parts of concentrated nitric acid, and then add 8 parts of potassium permanganate several times, and control the temperature not to exceed After stirring for a period of time at 5°C, the ice bath was removed and cooled to room temperature, and the reaction bottle was transferred to an electromagnetic water bath, and the electromagnetic stirring was continued for 24 h. After that, 100 parts of deionized water was slowly added, and the temperature was raised to about 98 degrees Celsius. After stirring for 20 min, an appropriate amount of hydrogen peroxide was added to reduce the residual oxidant, and the solution turned bright yellow. The graphite oxide suspension was then centrifuged at 5000 r / pm, washed with deionized water until the separated liq...

Embodiment 2

[0051] (1) Preparation of GO by modified Hummers method:

[0052] Assemble a 250 ml reaction bottle in an ice-water bath, mix 3 parts of graphite powder and 2 parts of sodium nitrate with 40 parts of concentrated sulfuric acid and 20 parts of concentrated nitric acid, and then add 10 parts of potassium permanganate several times, and control the temperature not to exceed After stirring for a period of time at 5°C, the ice bath was removed and cooled to room temperature, and the reaction bottle was transferred to an electromagnetic water bath, and the electromagnetic stirring was continued for 24 h. After that, 100 parts of deionized water was slowly added, and the temperature was raised to about 98 degrees Celsius. After stirring for 20 min, an appropriate amount of hydrogen peroxide was added to reduce the residual oxidant, and the solution turned bright yellow. The graphite oxide suspension was then centrifuged at 5000 r / pm, washed with deionized water until the separated li...

Embodiment 3

[0063] (1) Preparation of GO by modified Hummers method:

[0064] Assemble a 250 ml reaction bottle in an ice-water bath, mix 2 parts of graphite powder and 2 parts of sodium nitrate with 30 parts of concentrated sulfuric acid and 10 parts of concentrated nitric acid, and then add 8 parts of potassium permanganate several times, and control the temperature not to exceed After stirring for a period of time at 5°C, the ice bath was removed and cooled to room temperature, and the reaction bottle was transferred to an electromagnetic water bath, and the electromagnetic stirring was continued for 24 h. After that, 100 parts of deionized water was slowly added, and the temperature was raised to about 98 degrees Celsius. After stirring for 20 min, an appropriate amount of hydrogen peroxide was added to reduce the residual oxidant, and the solution turned bright yellow. The graphite oxide suspension was then centrifuged at 5000 r / pm, washed with deionized water until the separated liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com