Preparation method of flame-retardant UV-moisture dual-curing polyurethane acrylate conformal coating

A polyurethane acrylate, dual-curing technology, used in polyurea/polyurethane coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of flammable and explosive solvents, induced occupational diseases, irritation, etc., and achieve excellent electrical insulation performance, excellent resistance. The effect of burning characteristics and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

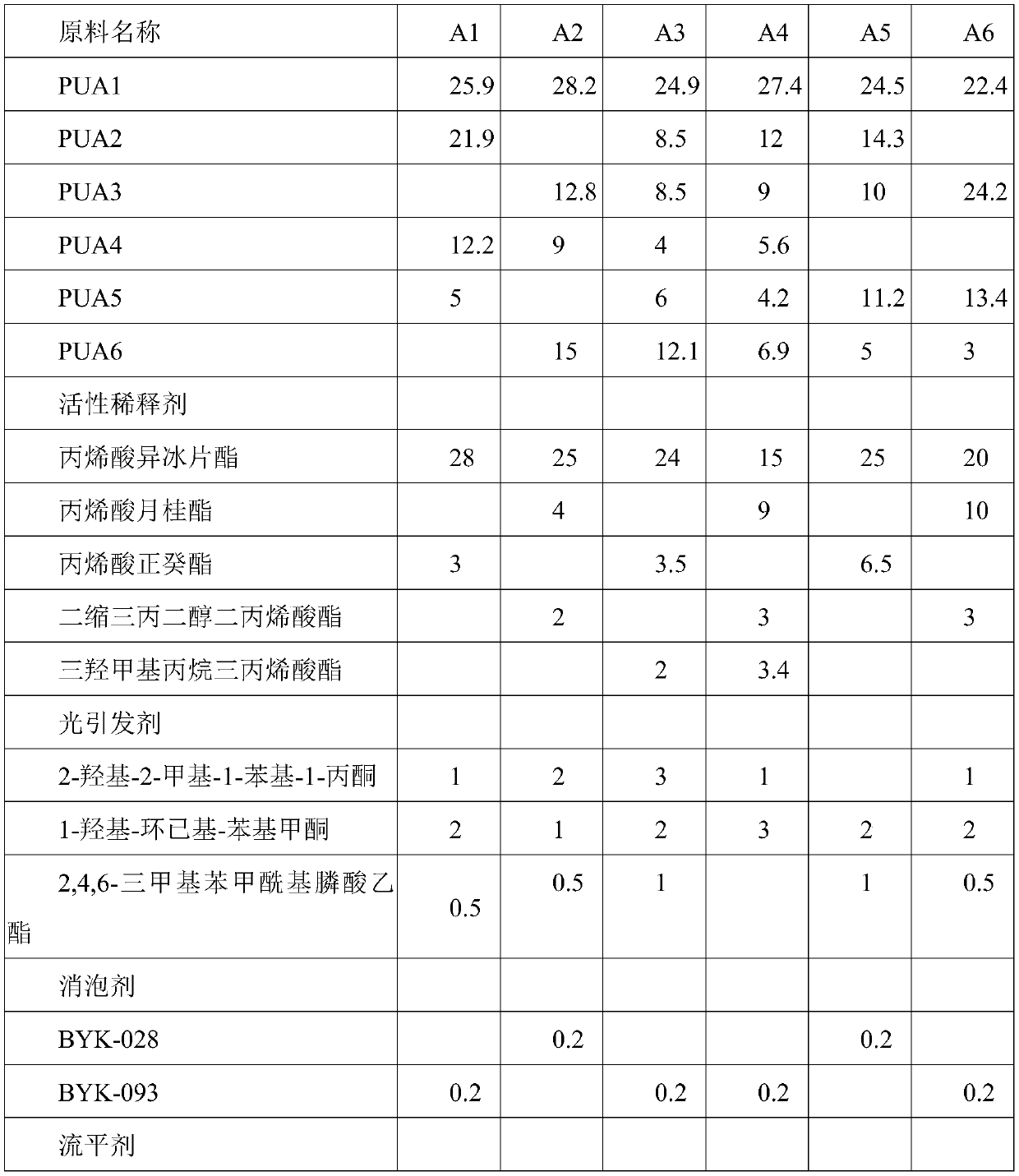

[0066] Table 1 lists six composition examples of the preparation method of the flame-retardant UV-moisture dual-curing polyurethane acrylate conformal paint of the present invention. Among them, PUA1 is a polyurethane acrylate prepolymer containing allyl groups at both ends; PUA2 is a polyurethane acrylate prepolymer containing phosphate compounds containing allyl groups at both ends; PUA3 is a polyurethane acrylate prepolymer containing allyl groups at both ends. PUA4 is a polyurethane acrylate prepolymer containing an isocyanate group at one end and an allyl group at one end; PUA5 is a polyurethane acrylate prepolymer containing an isocyanate group at one end and an allyl group at one end. PUA6 is a polyurethane acrylate prepolymer containing polyolefin groups containing isocyanate groups at one end and allyl groups at one end.

[0067]

[0068]

[0069] Table 1 Preparation method of flame-retardant UV-moisture dual-curing polyurethane acrylate conformal paint

[0070...

Embodiment 2

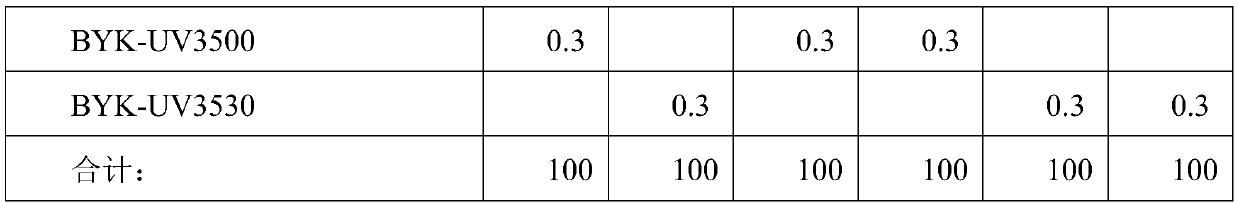

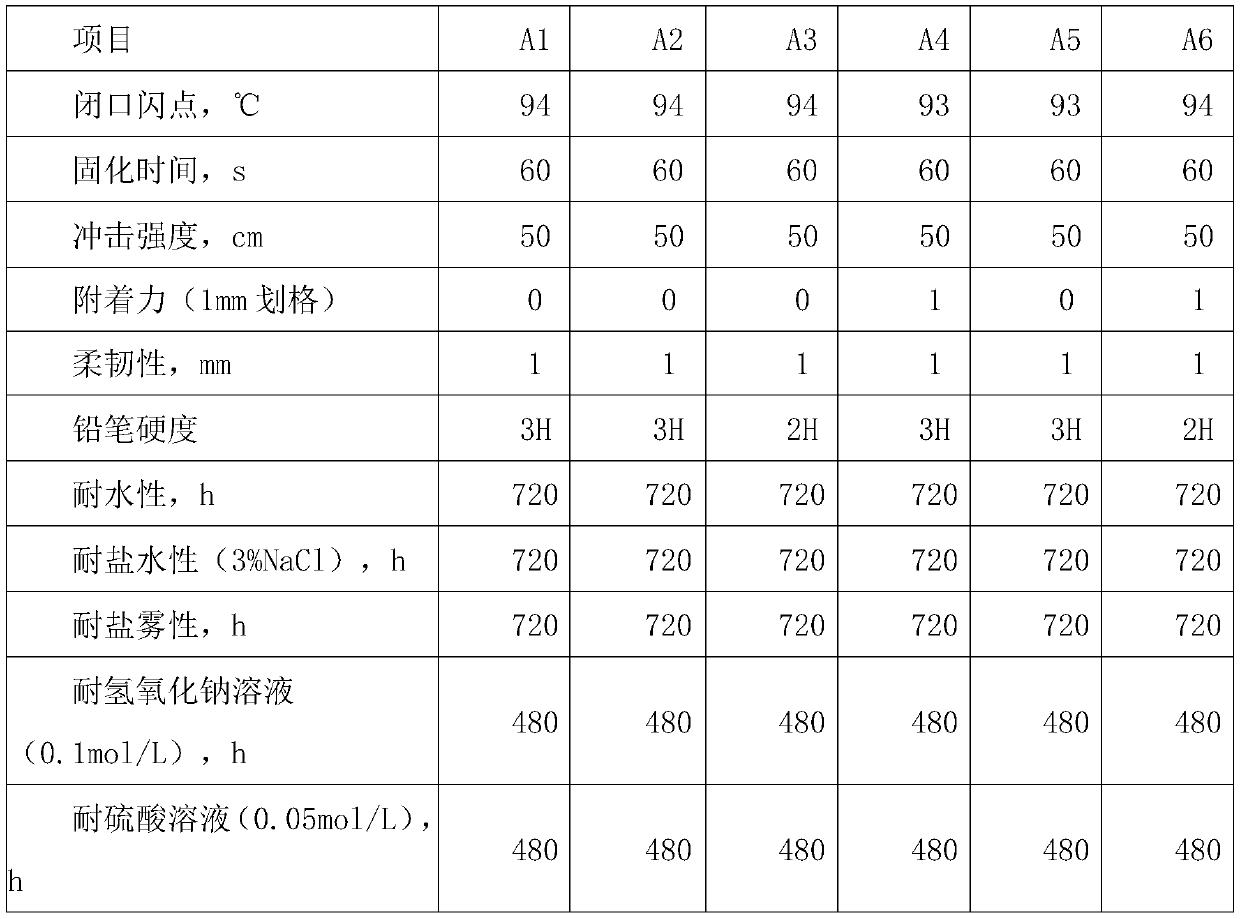

[0072] Table 2 is the performance test results of the preparation method of the flame-retardant UV-moisture dual-curing polyurethane acrylate conformal paint corresponding to Table 1.

[0073]

[0074] Table 2 Performance test results of the preparation method of flame-retardant UV-moisture dual-curing polyurethane acrylate conformal paint

Embodiment 3

[0076] A method for preparing a flame-retardant UV-moisture dual-curing polyurethane acrylate conformal paint of the present invention can be further cured by moisture in the shadow area of a circuit board. In order to test the moisture curing performance, 500 micron films were prepared and placed under the conditions of 25°C, 50%RH. As shown in Table 3, the film cured on the third day.

[0077] Moisture cured 500 micron thick film at 25°C, 50% RH first day wet the next day wet third day solidified fourth day solidified

[0078] Table 3 moisture curing situation

[0079] From the above examples, it can be concluded that by using UV-moisture dual-curing urethane acrylate resin containing phosphate compounds as the base material, using a low-odor and low-irritation reactive diluent, together with a photoinitiator, to prepare a flame-retardant UV -The preparation method of moisture dual-curing polyurethane acrylate conformal paint, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com