Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Improve process performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

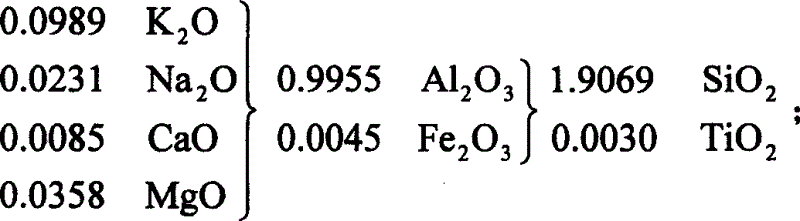

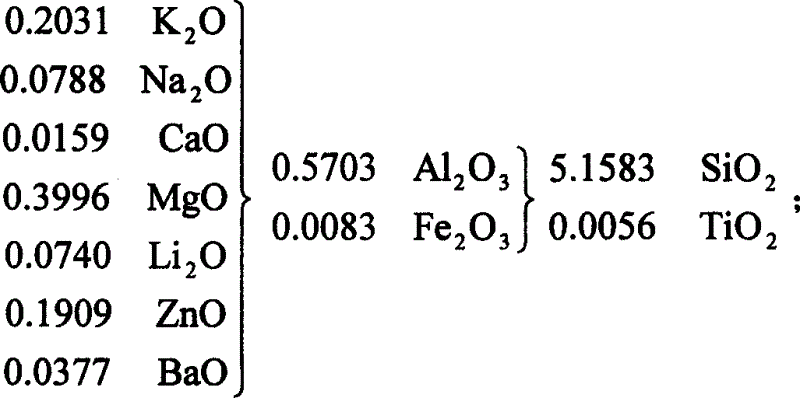

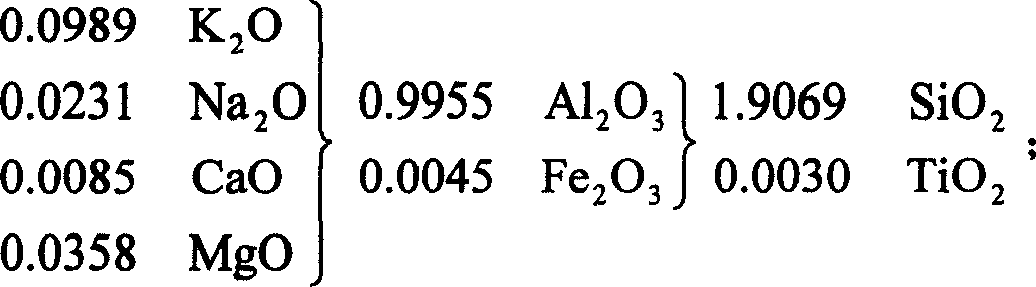

Reinforced daily ceramic manufacturing process

InactiveCN1544385AImprove process performanceImprove thermal stabilityClaywaresCordieriteCrystallite

The invention relates to a process for making reinforced diary porcelain by using porcelain clay as the principal raw material of the blank, the process comprises the steps of, charging into pre-treated super fine, talcum powder and porcelain clay oxidizing substance. The invention can be applied in producing high-grade reinforcement diary porcelain with high-intensity and good thermal stability containing nano Mullite-cordierite and corundum crystal particles.

Owner:SHANGHAI UNIV

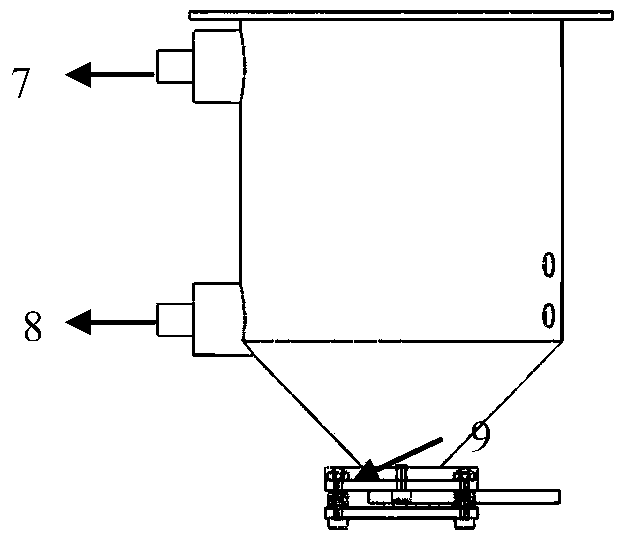

Movable hopper type powder bed powder laying device and method

ActiveCN103738747AImprove process performanceShorten the timeLoading/unloadingLevel sensorEngineering

The invention discloses a movable hopper type powder bed powder laying device. The powder bed powder laying device mainly comprises a feeding device, a movable (discharging) funnel, a powder laying device, a related transmission mechanism device and the like. The amount of powder needed by each layer is calculated, and the feeding device is controlled to accurately feed the powder to the movable funnel by using a powder level sensor in the movable funnel. The powder is discharged rapidly and evenly through control over left-and-right moving speed of the discharging funnel, the bore diameter of a discharging opening and the opening and closing degree of the discharging opening, and then the discharged powder is slicked through front and back movement of a powder slicking plate to finish the powder laying process. The powder is discharged rapidly and evenly, the usage amount of the powder is saved, the machining efficiency of rapid forming equipment is increased, and cost is reduced.

Owner:DALIAN UNIV OF TECH

High strength aluminum copper alloy vehicle wheel material and liquid forging forming method

ActiveCN103924139AImprove process performanceOvercome poor mobilityMetal-working apparatusRare-earth elementAluminium

The invention relates to a high strength aluminum copper alloy vehicle wheel material and a liquid forging forming method. The material comprises following components by weight percent: 4.5-5.5% of Cu, 0.3-0.5% of Mn, 0.15-0.35% of Ti, 0.05-0.3% of V, 0.05-0.2% of Zr, 0.005-0.06% of B, 0.01-0.3% of Cd, 0.01-0.2% of Nd, 0.01-0.1% of Er, and the balance of Al. The aluminum copper alloy vehicle wheel prepared by the liquid forging forming method has good comprehensive chemical property and high product percent of pass, has the tensile strength greater than 400MPa, the yield strength greater than 300MPa, and the elongation greater than 10%, thus meeting the technical requirement of heavy load automobiles; particularly, due to the addition of a small quantity of rare earth element Er in the alloy formula, the aluminum copper alloy material structure is further refined, and the comprehensive property of the product is obviously improved; in addition, due to the addition of rare earth element Nd and grain refined elements like Ti, Zr and B, hot crack of the aluminum copper alloy is effectively avoided in solidifying, and the percent of pass of the vehicle wheel prepared by the liquid forging forming method is sharply improved.

Owner:天津立中轻合金锻造有限公司

End-blocking slurry for flaky component

InactiveCN101728002AImprove process performanceAcid resistantConductive materialNon-conductive material with dispersed conductive materialElectrical conductorSlurry

The invention relates to an end-blocking slurry for a flaky component, which is prepared from the following raw materials in percentage by mass: 40 to 55 percent of silver powder, 4 to 15 percent of glass powder, 5 to 25 percent of inorganic filler and 20 to 40 percent of organic carrier, wherein the silver powder comprises the following silver powder in percentage by mass in the slurry: 25 to 40 percent of flaky silver powder and 15 to 30 percent of spherical silver powder. The end-blocking slurry has the advantages that: (1) the content of silver is low so as to reduce the cost of the slurry and improve the market competitiveness of the products, and 300 RMB can be saved in 1 kg of the slurry; (2) lead is not contained in the slurry, which is in favor of environmental protection; (3) a compact and flat conductor layer is formed at the end head of a substrate without pit and bulge after the processes of dipping the silver, drying and sintering, so the platability is good, the adhesive force is strong, and the glass is acid resistant. The slurry has good process use characteristics and is suitable to be used in the industries for generating the flaky components.

Owner:贵阳晶华电子材料有限公司

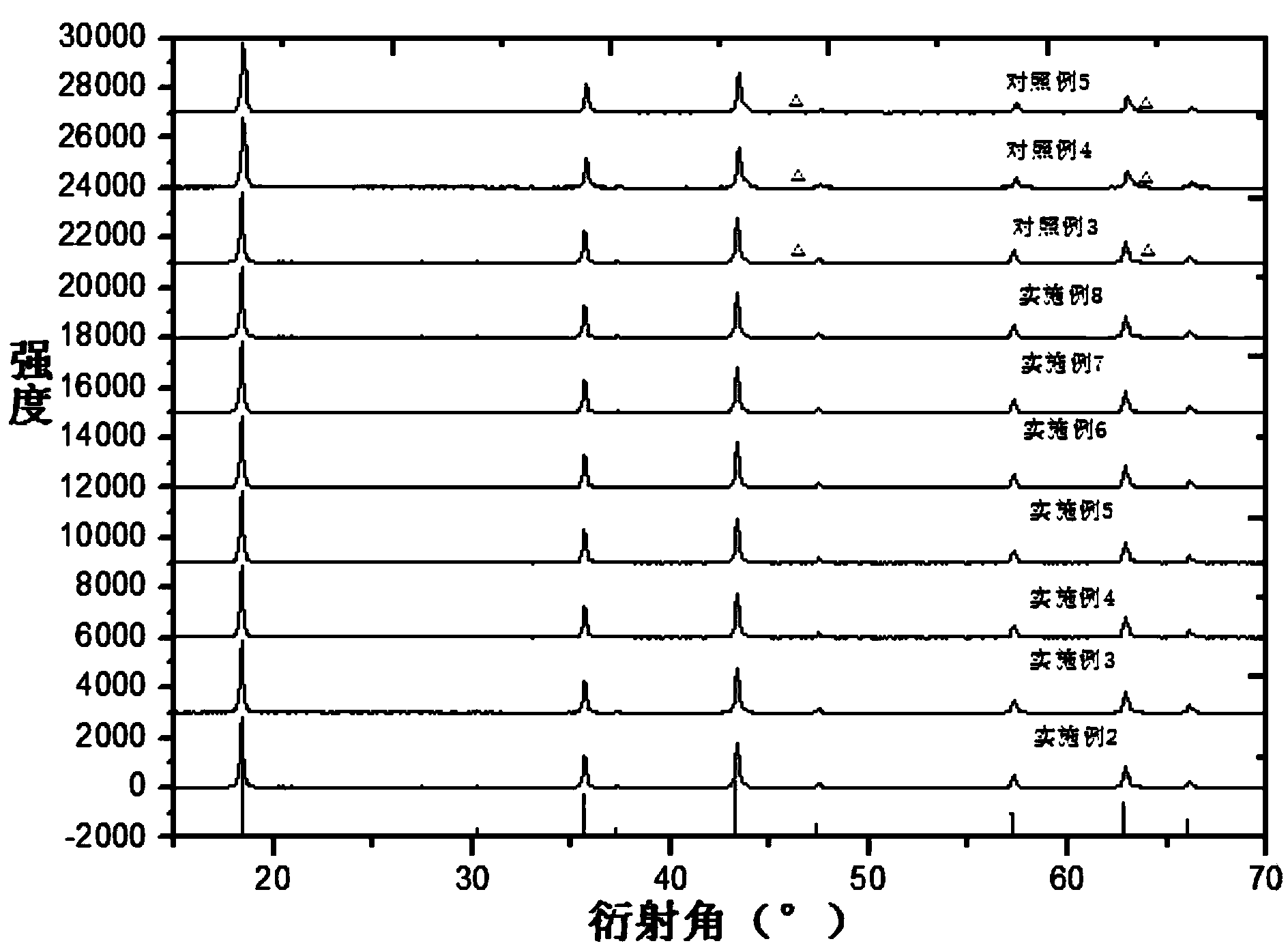

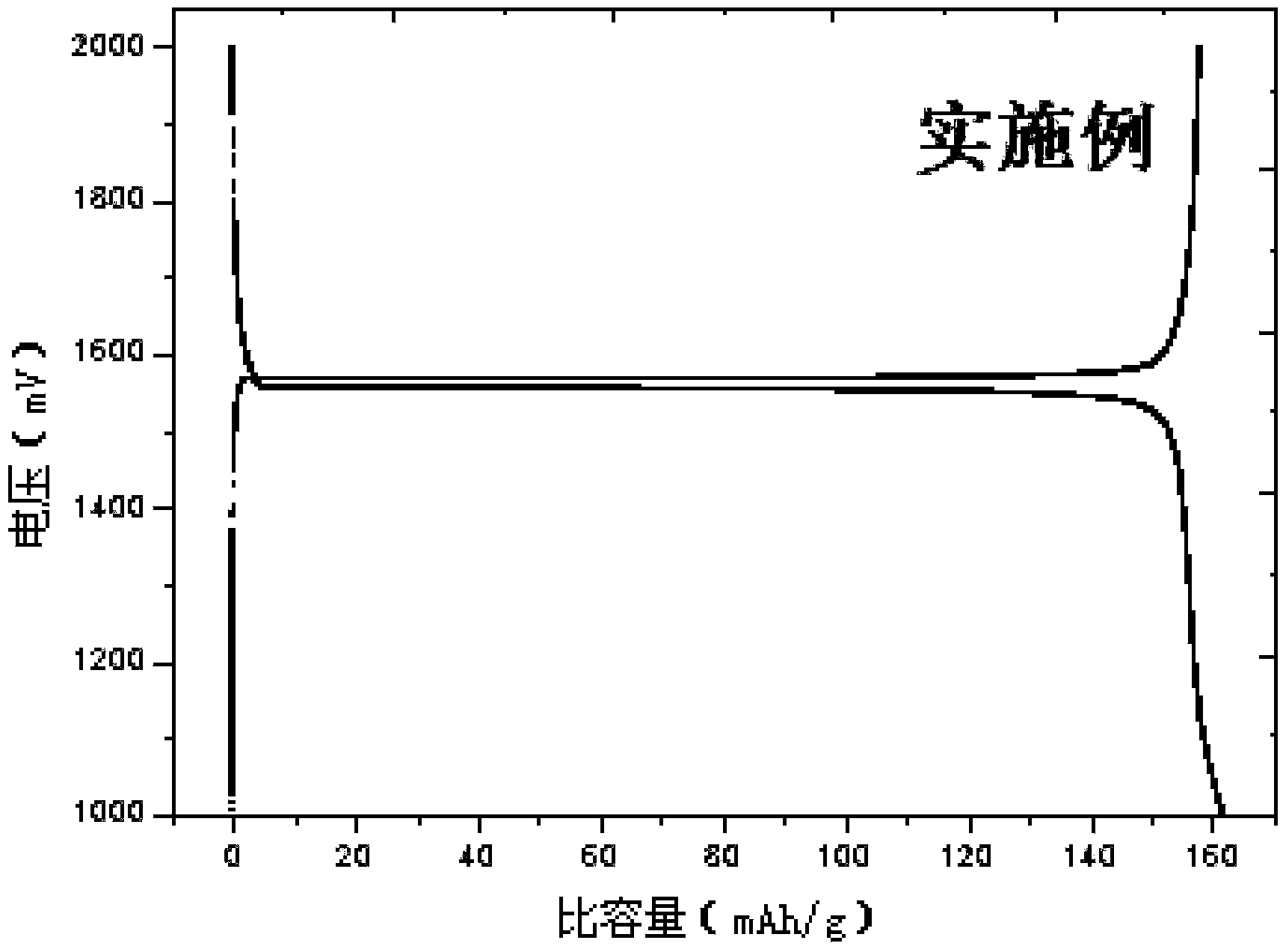

Preparation method for lithium titanate

ActiveCN103474645AImprove process performanceGood stabilityCell electrodesTitanium compoundsHigh rateNitrogen gas

The invention discloses a preparation method for lithium titanate. The preparation method comprises the following steps: (1) preparing a slurry by using a titanium source, a lithium source, an inorganic additive, an organic additive and water; (2) atomizing and drying the slurry prepared by the first step into powder in an atomizing dryer; (3) roasting the powder prepared by the second step at the atmosphere of a hydrogen and nitrogen gas mixture for 5 to 10 hours; (4) cooling the roasted powder obtained by the third step at the atmosphere of the hydrogen and nitrogen gas mixture to room temperature, thereby obtaining the lithium titanate. The lithium titanate prepared by the preparation method is stable in quality; meanwhile, the product has high-rate discharge performance and cycling performance, and is an excellent lithium ion battery anode material.

Owner:四川新锂想能源科技有限责任公司

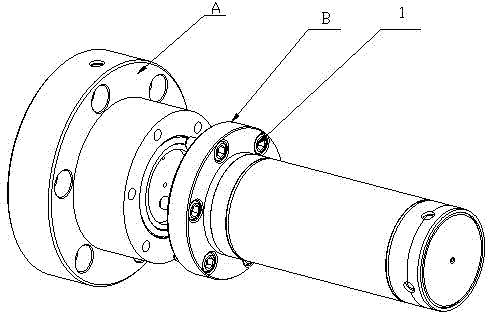

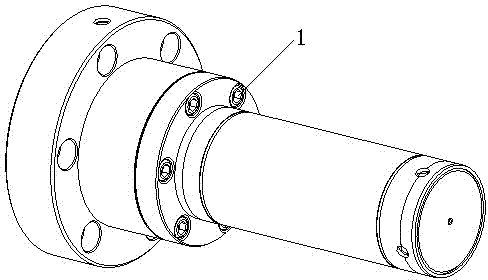

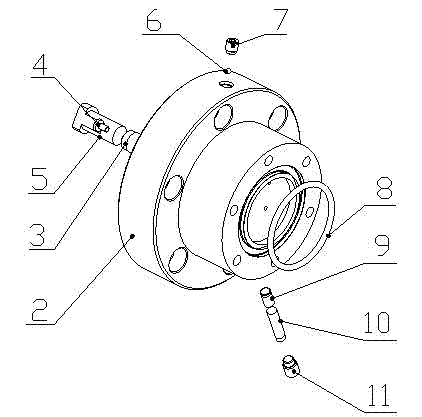

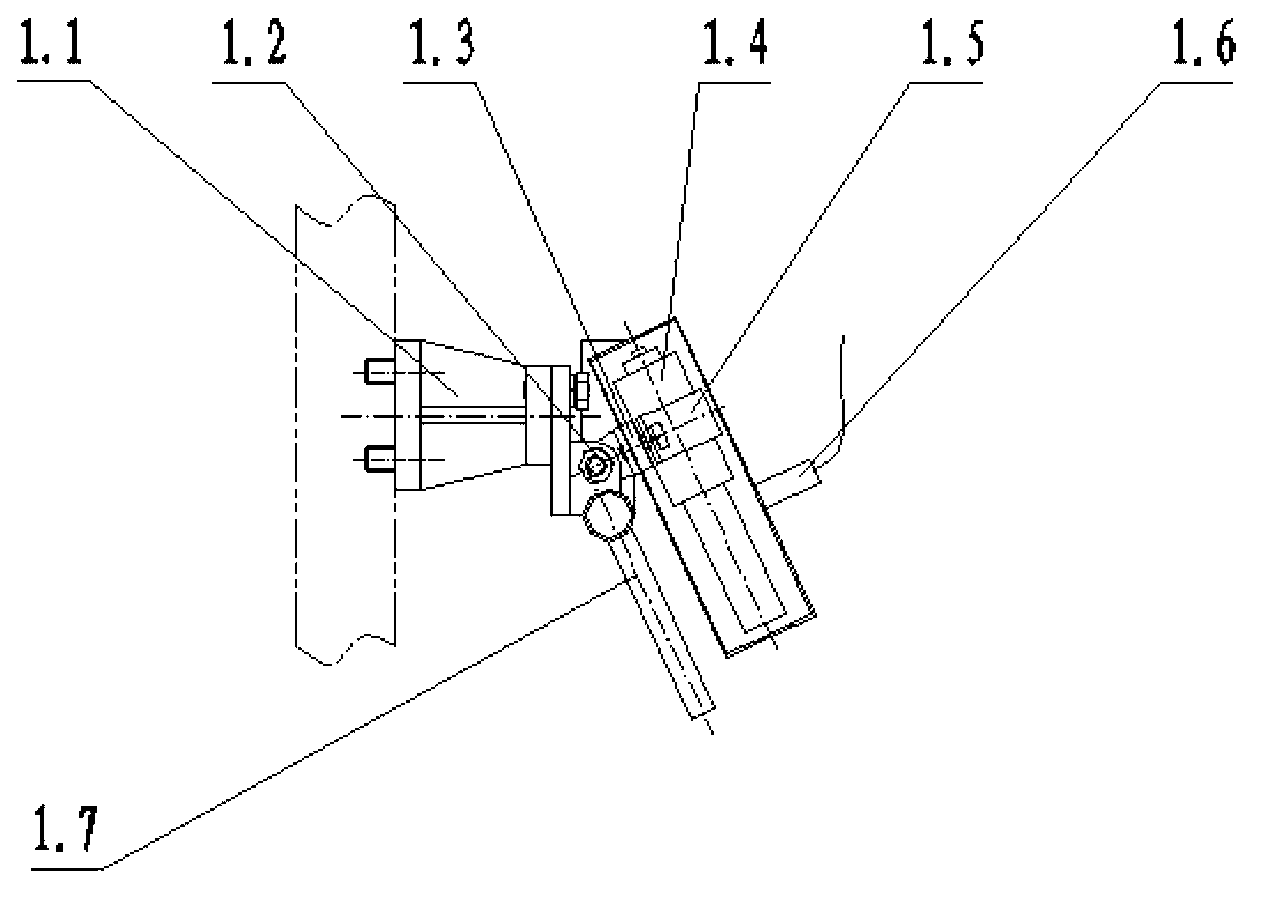

Hydraulic clamp for inner hole of high-precision thin-wall pipe fitting

InactiveCN102407354AReduce processing difficultyImprove process performanceExpansion mandrelsThin walledEngineering

The invention relates to a lathe attachment, in particular relates to a hydraulic clamp and belongs to the technical field of machining. According to a hydraulic clamp for the inner hole of the high-precision thin-wall pipe fitting provided by the invention, the traditional integral-type structure is replaced by a split-type structure. The hydraulic clamp is characterized by being composed of a hydraulic flange disc (A) which is connected with a lathe and a tensioning shaft (B), wherein the hydraulic flange disc (A) is connected with the tensioning shaft (B) in a sealing manner. In the hydraulic clamp for the inner hole of the high-precision thin-wall pipe fitting, the traditional integral-type structure is replaced by the structure composed of two parts, the processing difficulty is reduced and the performance of a processing technique is improved; the tensioning shaft can be exchanged according to different specification requirements, the whole hydraulic clamp is not necessary to replace and the processing cost is greatly reduced; and above all, the hydraulic clamp provided by the invention can be manufactured voluntarily in China and is not necessary to completely rely on imports, so that the hydraulic clamp provided by the invention lays a technical foundation to propel the development of a high-precision thin-wall pipe sleeve in China and improve the quality of the high-precision thin-wall sleeve.

Owner:SHANDONG FANGDA MACHINERY +3

High toughness and high and low temperature resistant bismaleimide resin prepolymer and preparation method thereof

The invention relates to a high toughness and high and low temperature resistant bismaleimide resin prepolymer and a preparation method thereof. The prepolymer comprises the following raw materials bymass: 100 parts of bismaleimide, 40-65 parts of an allyl compound, 30-60 parts of diallyl bisphenol A diglycidyl ether, 15-40 parts of acid anhydride, and 1-8 parts of a promoter. The high toughnessand high and low temperature resistant bismaleimide resin prepolymer provided by the invention has good solubility, is easily soluble in acetone and other common solvents, and is also suitable for preparation of prepreg by solution process. Also, the prepolymer has the characteristics of moderate melting viscosity, low volatile matters, good spreadability, long storage period, low cost, good heatresistance after curing and good toughness at low temperature, and can adapt to extreme use environments.

Owner:WUHAN UNIV OF TECH

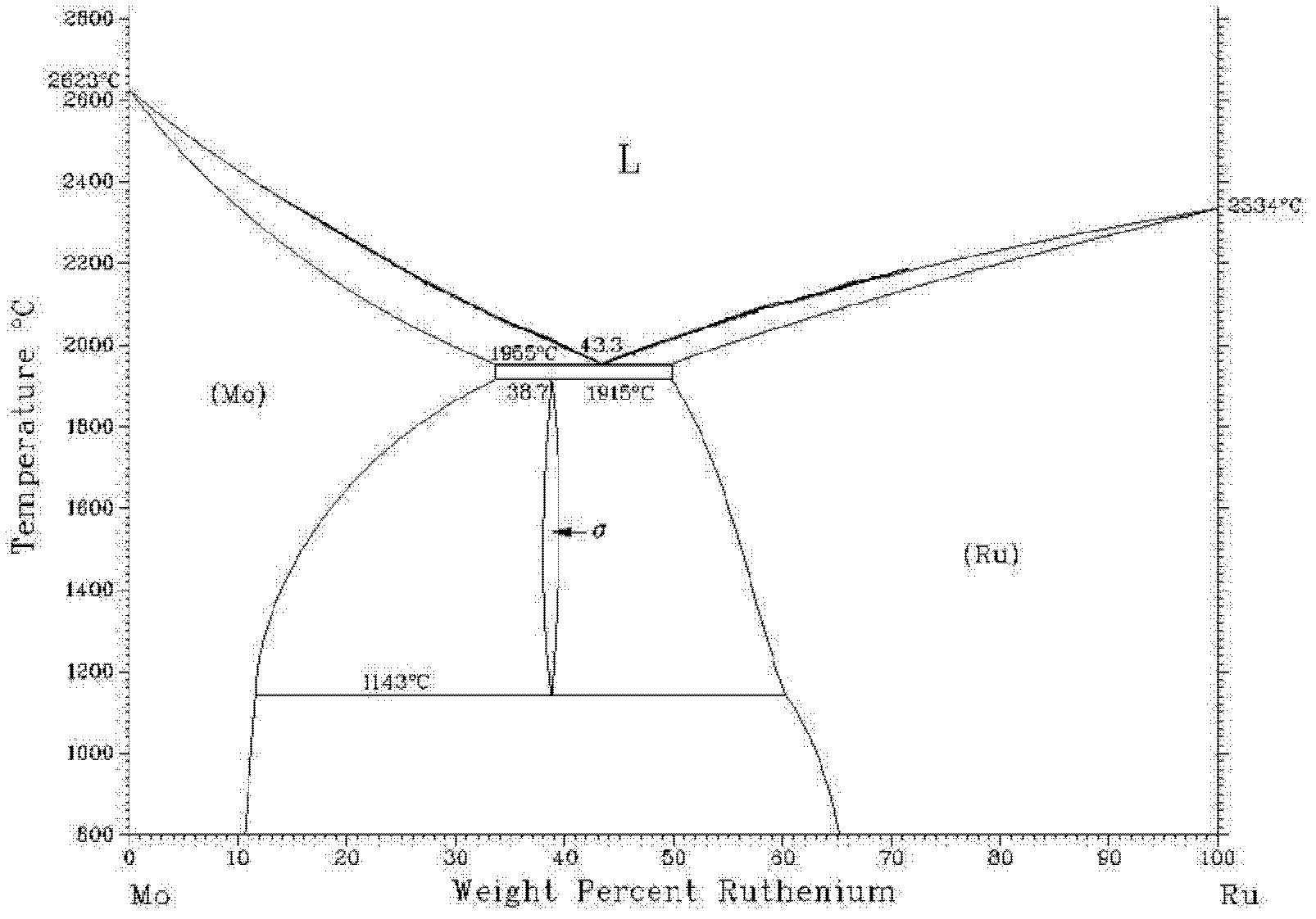

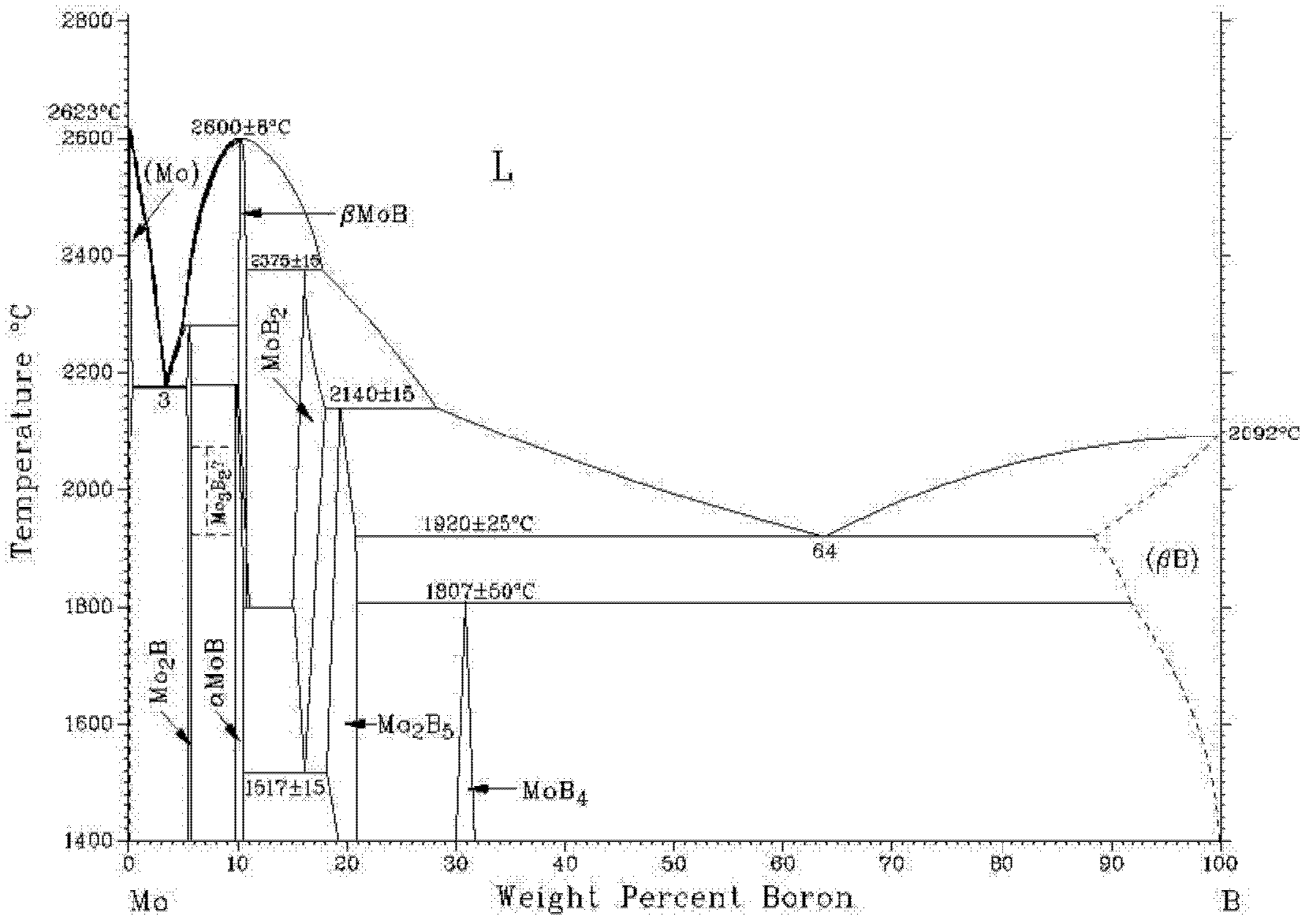

Brazing filler alloy powder and preparation method thereof

ActiveCN103170764AAvoid high demandsLess impuritiesWelding/cutting media/materialsSoldering mediaHydrogen atmosphereRuthenium

The invention discloses brazing filler alloy powder and belongs to the technical field of cathode high-temperature brazing filler powder and a preparation method of the brazing filler alloy powder. The brazing filler alloy powder comprises, by mass, 49.0%-56.0% of molybdenum, 39.0%-46.0% of ruthenium and 2.0%-5.0% of boron. The preparation method of the brazing filler alloy powder comprises the following steps: conducting hydrogen burning and impurity processing on the high-purity and hyperfine molybdenum powder, ruthenium powder and boron powder and conducting dosing, powder mixing and granulating in proportion; manufacturing a preformed bar through cold isostatic pressing, and dewaxing and sintering under the condition of hydrogen atmosphere protection; purifying the sintered preformed bar by means of electron beam melting; and processing powder through a plasma rotating electrode atomization process under the condition of high-purity inert gas protection, smashing coarse powder and achieving refining of the powder. The brazing filler alloy powder prepared through the preparation method has the advantages of being small in particle and uniform in particle size, and therefore the problems that the existing brazing filler is high in welding temperature, uneven in composition, large in solid-liquid phase line temperature difference, poor in using manufacturability and the like are solved.

Owner:GRIMAT ENG INST CO LTD

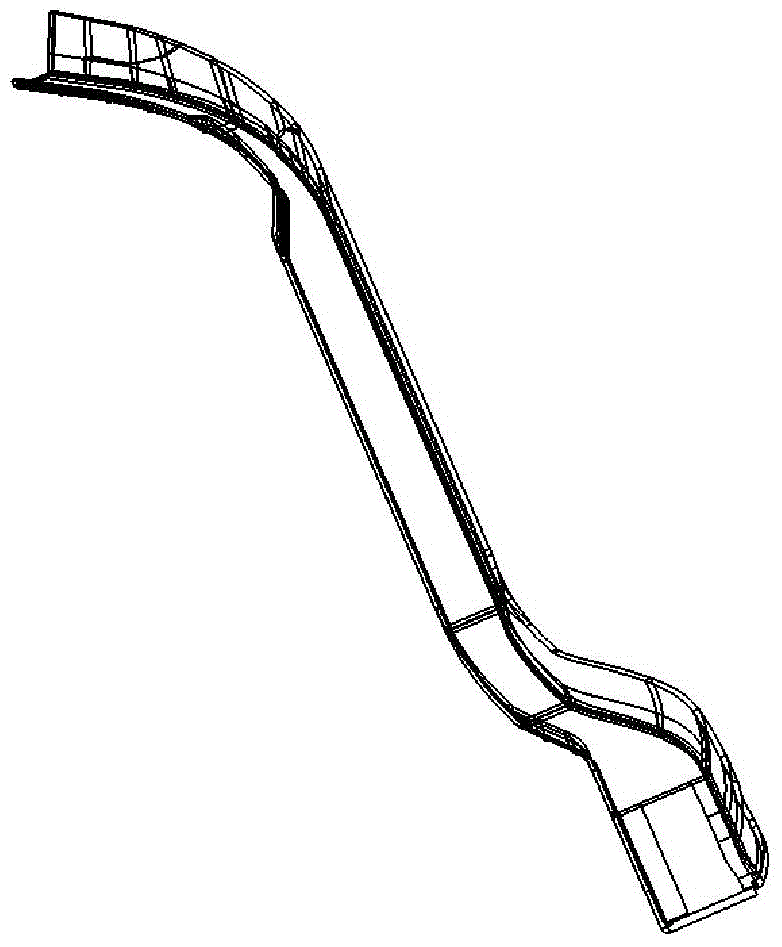

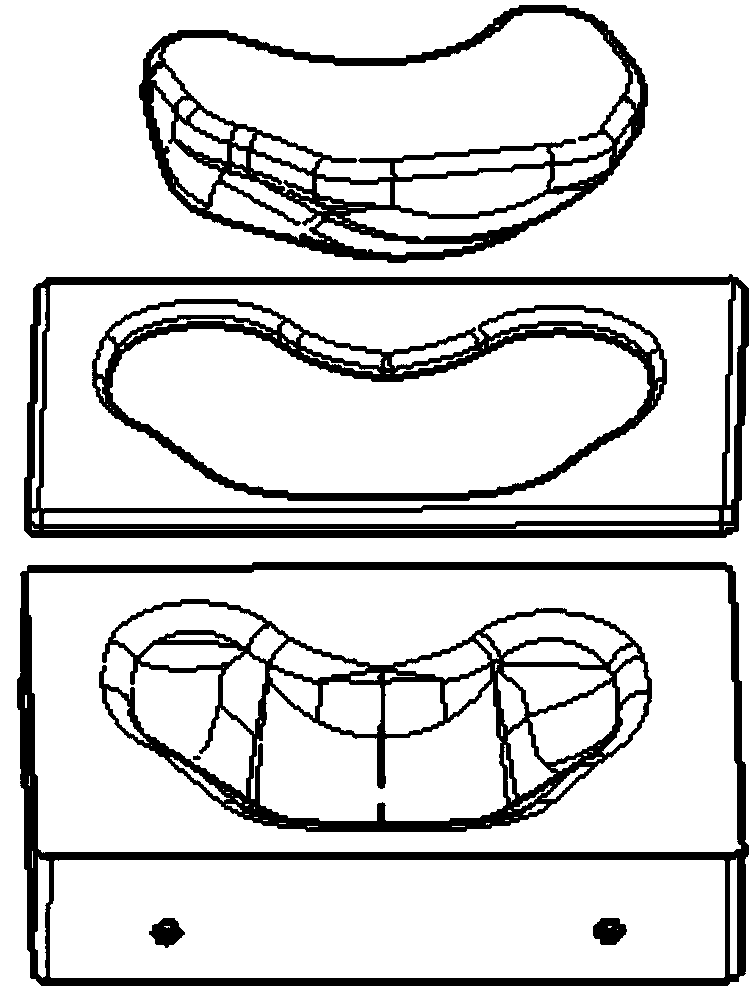

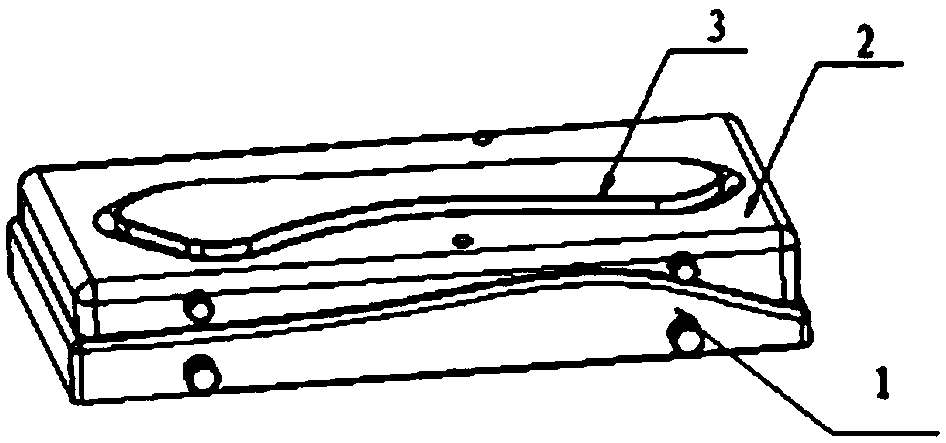

Molding method of double-curvature variable-section variable-thickness through beam

The invention discloses a molding method of a double-curvature variable-section variable-thickness through beam. The molding method comprises the steps that a molding die is manufactured according to the structural form of the double-curvature variable-section variable-thickness through beam; the molding die comprises a combined female die body and a limiting strip, and the combined female die body comprises a detachable side check block and a fixed block; prepared hot-melting prepreg and hot-melting prepreg cloth are shorn to the size of an unfolded section laying layer of the through beam, a hot-melting prepreg cloth laying layer is firstly laid on the surface of the female die body, and then vacuumizing compaction is carried out; laying layers are stacked according to the thickness of the through beam and the designed laying layer sequence, hot-pressing shaping is carried out in the laying layering stacking process according to the thickness of the laying layers, and finally a composite material prepreg lamination is manufactured; then coating, curing and combined female die body removal are carried out to obtain a product. The aerodynamic configuration requirement can be effectively guaranteed, the problems that the laying layers and size precision of a large-size double-curvature variable-section variable-thickness through beam are hard to control are solved, and finally the overall quality and size precision requirements of the through beam are guaranteed.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Cold cure high resilient foam and preparation method

The present invention discloses a cold cure high resilient foam and a preparation method, the cold cure high resilient foam comprises components A and B, the component A comprises, by weight, 60-70 parts of polyether polyol; 30-35 parts of polymer polyol; 0.25-0.55 part of a silicone surfactant; 1-2 parts of a crosslinking agent; 0.85-1.3 parts of a catalyst; and 4-6 parts of water; the B component comprises, by weight, 0.5-1.5 parts of TDI (80 / 20); 1-3 parts of polymerized MDI and 0.5-1.5 parts of modified MDI, the water is used as a foaming agent, by adjusting the catalyst, the requirements of reduced density can be met, the density of the made cold cure high resilient foam is about 35KG / m<2>, the mechanical properties of the prepared cold cure high resilient foam can meet car and furniture seat back cushion requirements, so that the seat back cushion foam is further lightweight, and has very high availability and market value.

Owner:GUANGZHOU LEADCOM SEATING CO LTD

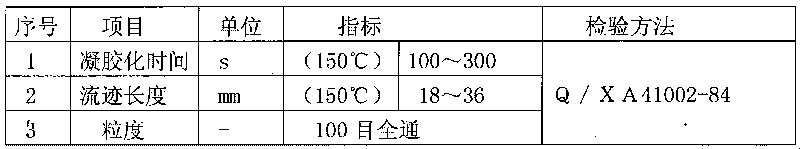

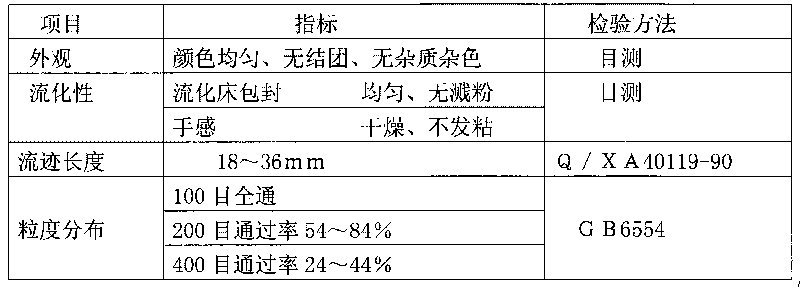

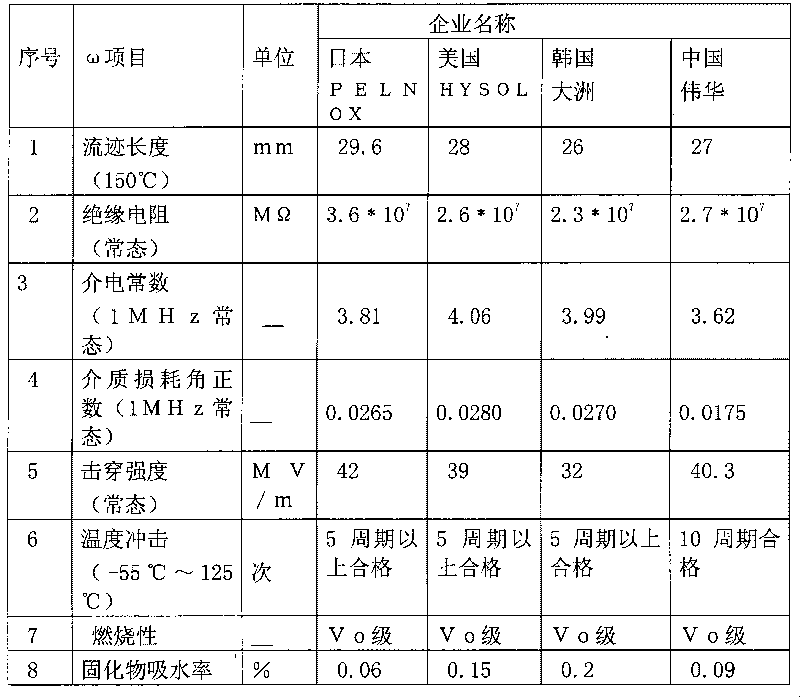

Halogen-free flame-retardant environment-friendly epoxy electronic encapsulating material

InactiveCN101747589AMeet the latest environmental protection requirements for flame retardancyImprove flame retardant performanceOther chemical processesEpoxyMoisture resistance

The invention discloses a halogen-free flame-retardant environment-friendly epoxy electronic encapsulating material, which consists of epoxy resin, silica micro-powder, a curing agent, 2-methylimidazole, an inner flame retardant agent, a flatting agent, pigment and a laser marking agent, and the weight ratio of the eight substances is: epoxy resin: silica micro-powder: curing agent: 2-methylimidazole: inner flame retardant agent: flatting agent: pigment: laser marking agent is equal to 43: 42: 5: 0.2: 4: 1: 2: 2.8. The epoxy resin is crushed, and the rest substances are dried; all materials are arranged inside a hopper of a mixing machine to be blended; the mixed material is mixed in an extruding machine; and finally the mixed material flows to a tablet press to be cooled and crushed. The product has favorable flame-retardant property, moisture resistance and good laser developing effect, is a latest halogen-free antimony-free environment-friendly electronic encapsulating material, is used for the outer encapsulation of the electronic parts, and can play the effects of moisture resistance, insulation, mechanical protection and the like.

Owner:XIANYANG WEIHUA INSULATION MATERIALS

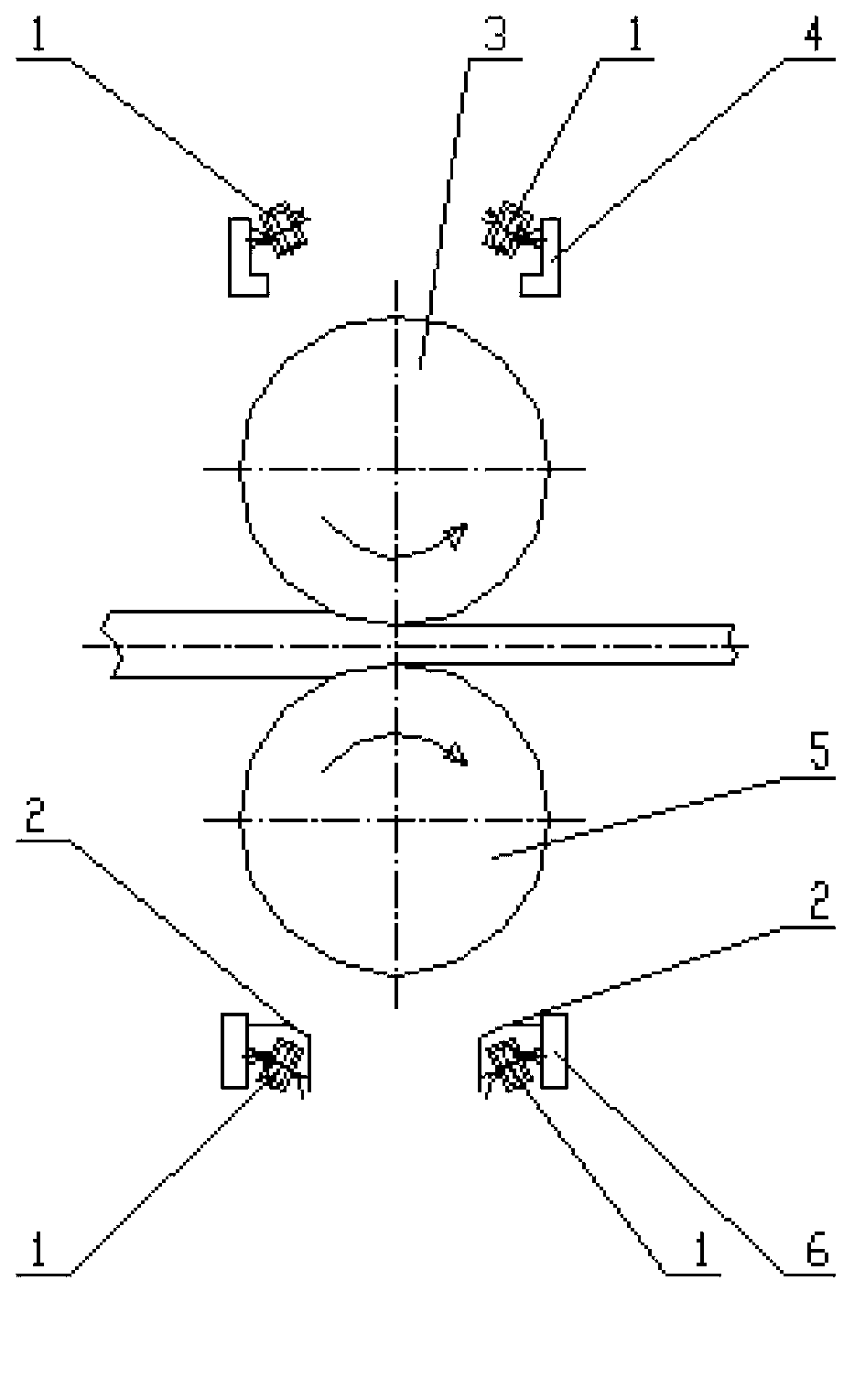

On-line temperature measuring device for surfaces of rolls of strip rolling mill and testing method of on-line temperature measuring device

ActiveCN103230945AImprove cooling performanceImprove process performanceMeasuring devicesMetal rolling arrangementsThermometerRolling mill

The invention relates to an on-line temperature measuring device for the surfaces of rolls in a strip rolling process in the field of strip rolling mill production in the metallurgy industry and a testing method of the on-line temperature measuring device. The on-line temperature measuring device is characterized by being composed of a base, an adjusting bolt, a support, a thermometer, a clamp, a protective sleeve and an air blowing device. The support and the base are connected through the adjusting bolt, the thermometer is tightly clamped by the clamp, the clamp is connected onto the support through a fixed bolt, the installation angle of the thermometer can be adjusted by the adjusting bolt as required, the protective sleeve covers the outside the thermometer, the base is connected with balance beam supports on two sides of the upper portion of an upper roll and track beams on two sides of the lower portion of a lower roll, the air blowing device is connected onto the base through a fixed bolt and close to the thermometer as far as possible, and protective plates are installed on the track beams and cover the upper portion of the temperature measuring device arranged below for surfaces of rolls.

Owner:DALIAN HUARUI HEAVY IND GROUP

Low-warping-degree solar energy aluminum paste

InactiveCN103106949AImprove process performanceEvenly heatedNon-conductive material with dispersed conductive materialThermal conductivityElectric properties

The invention relates to low-warping-degree solar energy aluminum paste. The low-warping-degree solar energy aluminum paste comprises, by mass, 73%-78% of spherical aluminum powder, 1%-2% of glass powder, 22%-25% of organic binder, and 0.1%-0.3% of crystallized state high-thermal-conductivity inorganic powder. The low-warping-degree solar energy aluminum paste greatly improves processing properties of aluminum paste in the process of sintering by adding proper amount of high-thermal-conductivity inertia inorganic filler to solar energy aluminum powder, and overcomes the defect of usage of fumed silica in a traditional method. The high-thermal-conductivity inertia inorganic filler can enable aluminum layers to be evenly heated, prevents aluminum thorns and alumina beads from being produced, and meanwhile greatly reduces warping degrees of solar energy battery pieces. Due to the fact that additive amount of the crystallized state high-thermal-conductivity inorganic powder is small, electric properties of the solar energy battery pieces can be well maintained.

Owner:NANTONG RELIANCE SOLAR TECH

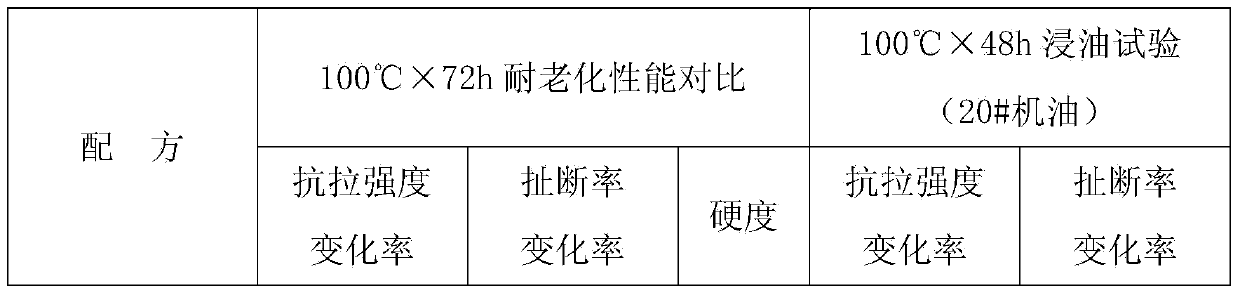

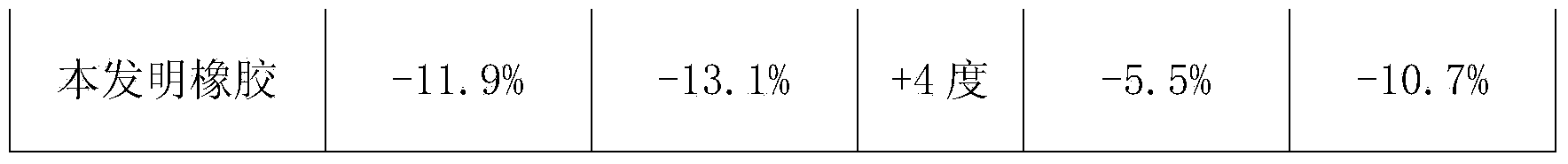

Ethylene-propylene-diene monomer and fluororubber compound sealing gasket material and preparation method thereof

The invention discloses an ethylene-propylene-diene monomer and fluororubber compound sealing gasket material which is prepared from the following raw materials in parts by weight: 100-110 parts of ethylene propylene diene monomer (4045), 10-12 parts of fluororubber, 4-6 parts of zinc oxide, 8-10 parts of magnesium oxide, 13-14 parts of tetradecyl methacrylate polymer, 10-12 parts of para-tert-butylphenol formaldehyde resin, 3-4 parts of zinc stearate, 40-45 parts of N660 carbon black, 45-60 parts of spraying carbon black, 0.5-1.5 parts of accelerant CBS (N-Cyclohexy-2-Benzothiazole Sulfonamide), 1-2 parts of accelerant M, 2-3 parts of accelerant DM (dibenzothiazole disulfide) and 10-12 parts of modified attapulgite. According to the ethylene-propylene-diene monomer and fluororubber compound sealing gasket material, by adding the modified attapulgite, the process property of a rubber material is improved; by using an environment-friendly compounding agent, the toxic and side effects and the pollution to the environment are reduced. The ethylene-propylene-diene monomer and fluororubber compound sealing gasket material is reasonable in formula, simple in process and low in cost and has better oil resistance and sealing property.

Owner:马鞍山市中澜橡塑制品有限公司

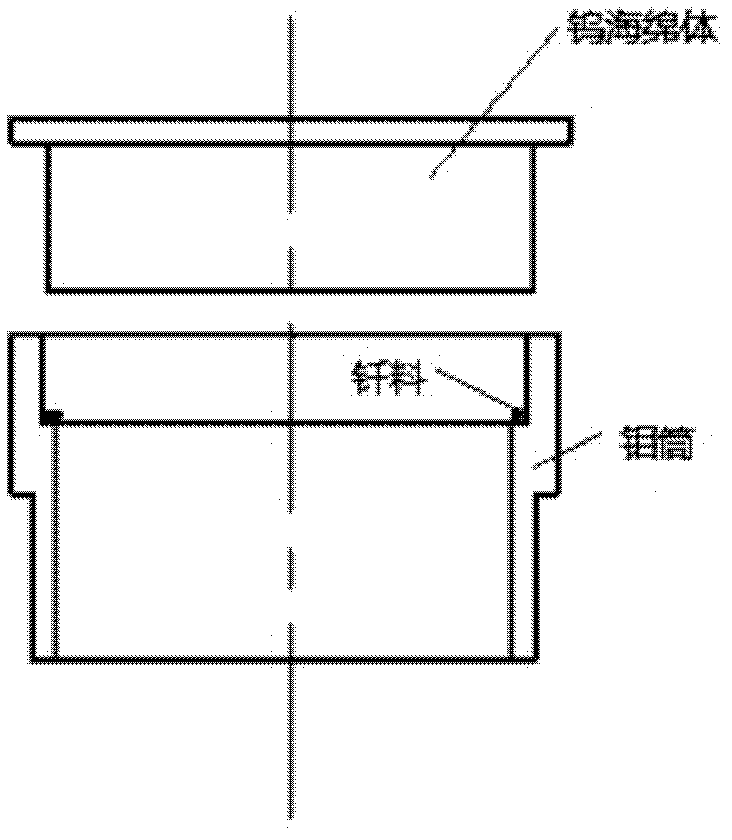

Spare part hot-dip galvanizing process

InactiveCN107858619AEasy Dip PlatingLow technical requirementsHot-dipping/immersion processesCarbonizationDip-coating

The invention discloses a spare part hot-dip galvanizing process. The spare part hot-dip galvanizing process comprises the steps of carbonizing to remove oil: carbonizing a hot forging part to removeoil by insulating the hot forging part with waste heat, and carbonizing a cold part to remove oil by burning of a continuous carbonizing furnace or gas flame; performing shot blasting: performing shotblasting on a workpiece to remove oxide skin from the surface of the workpiece; heating hydrogen to reduce: sending the workpiece to a reduction reaction channel, and heating the workpiece under thegas protection of reducing atmosphere, so that the temperature of the surface of the workpiece is increased to more than 600 DEG C, and reduction reaction occurs on the oxide layer of the surface of the workpiece; and performing dip plating: sending the workpiece to a container filled with liquid zinc through a discharge opening of the reduction reaction channel for dip plating, wherein the temperature of the liquid zinc is 420 to 580 DEG C. According to the spare part hot-dip galvanizing process, the production processes can be reduced, and severe pollution links of acid pickling, alkali washing, soaking in a plating support agent, drying after soaking in the plating support agent and soaking zinc with the plating support agent and subsequent waste liquid and waste water and waste gas treatment are omitted, so that the energy consumption is reduced, the pollution is reduced, the labor cost and the equipment cost are greatly reduced, and the production efficiency is improved.

Owner:宋德兴

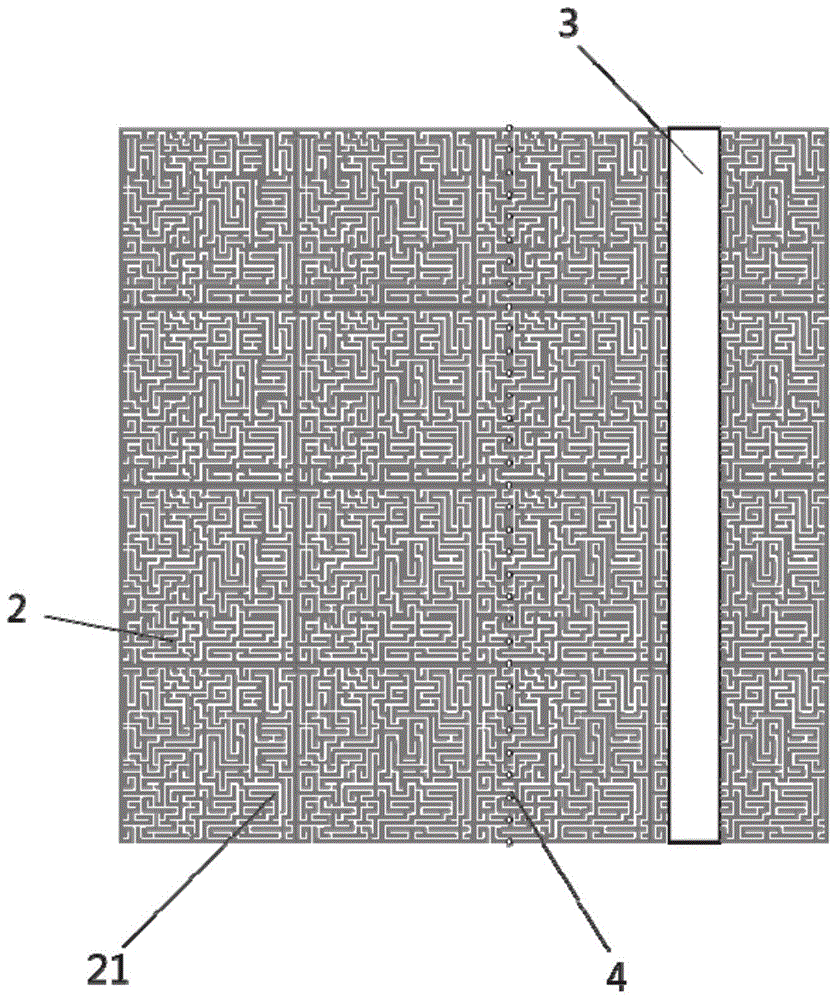

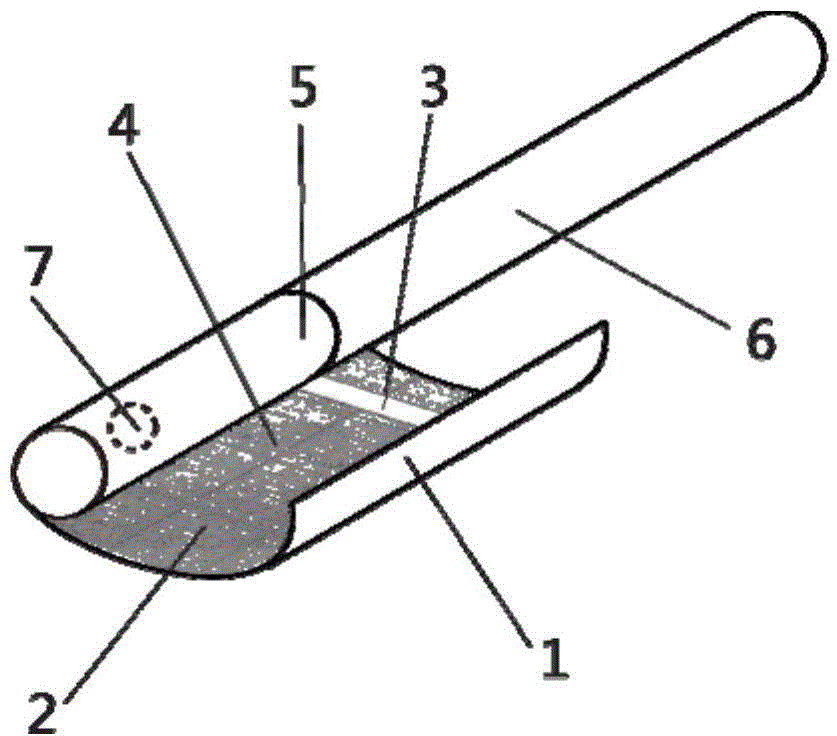

Tipping paper preventing liquid leakage, preparation method and application of same

InactiveCN104831588APrevent leakageSmooth penetrating flowSpecial paperPaper/cardboardPulp and paper industryCoating

The invention discloses tipping paper preventing liquid leakage, a preparation method and an application of the same, wherein the tipping paper comprises a tipping base paper and is characterized in that an inner surface of the tipping base paper is coated with an anti-leakage coating layer, and an axial anti-leakage bar is attached at the position of 3.0-3.5 mm on the anti-leakage coating layer from left to right. By means of the anti-leakage coating layer on common tipping paper, liquid substances are effectively prevented from leaking, thereby ensuring smooth penetrating flow of gas and reducing suction resistance of a filter rod and further solving an existing problem that suction resistance influence on a conventional tipping paper leakage preventing and stopping structure. The composite axial anti-leakage bar can effectively block and adsorb the liquid substances leaked along the anti-leakage coating layer downwardly, thereby solving the axial leakage problem in the prior art.

Owner:CHINA TOBACCO YUNNAN IND

Modified rubber composite sealing gasket material and preparation method thereof

The invention discloses a modified rubber composite sealing gasket material which is characterized by being prepared from the following raw materials in parts by weight: 90-100 parts of nitrile rubber, 3-4 parts of wool fat aluminum soap, 1-2 parts of aluminum stearate, 10-15 parts of brominated butyl rubber (BBK-232), 3-5 parts of propyleneglycoladipate, 1-2 parts of an accelerant TMTD (Tetramethyl Thiuram Disulfide), 24-28 parts of semi-reinforcing carbon black, 20-24 parts of N550 carbon black, 30-35 parts of white carbon black by a method of precipitation, 1-2 parts of an antioxidant 1010, 4-5 parts of magnesium oxide, 1-2 parts of dimercaptoacetic iso-octyl dioctyl tin, 6-8 parts of epoxy butyl oleate, 2-3 parts of zinc oxide and 10-12 parts of modified attapulgite. According to the material, the modified attapulgite is added to improve the process performance of the sizing material, and an environment-friendly accessory ingredient is used to reduce the toxic and side effects and the environmental pollution. The material disclosed by the invention has good oil resistance and corrosion resistance, and is low in cost, simple in process and wide in application prospect.

Owner:马鞍山市中澜橡塑制品有限公司

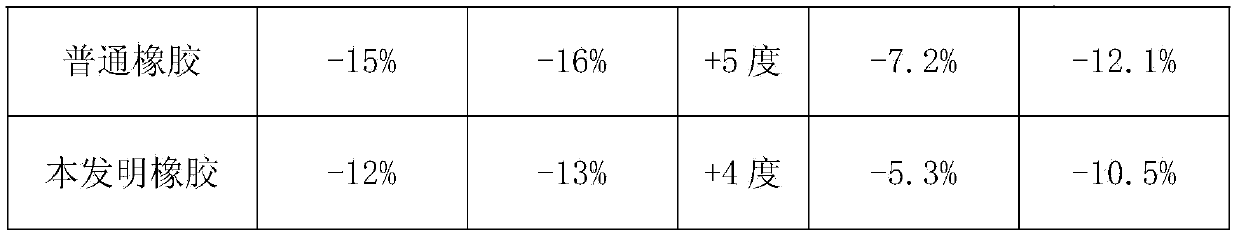

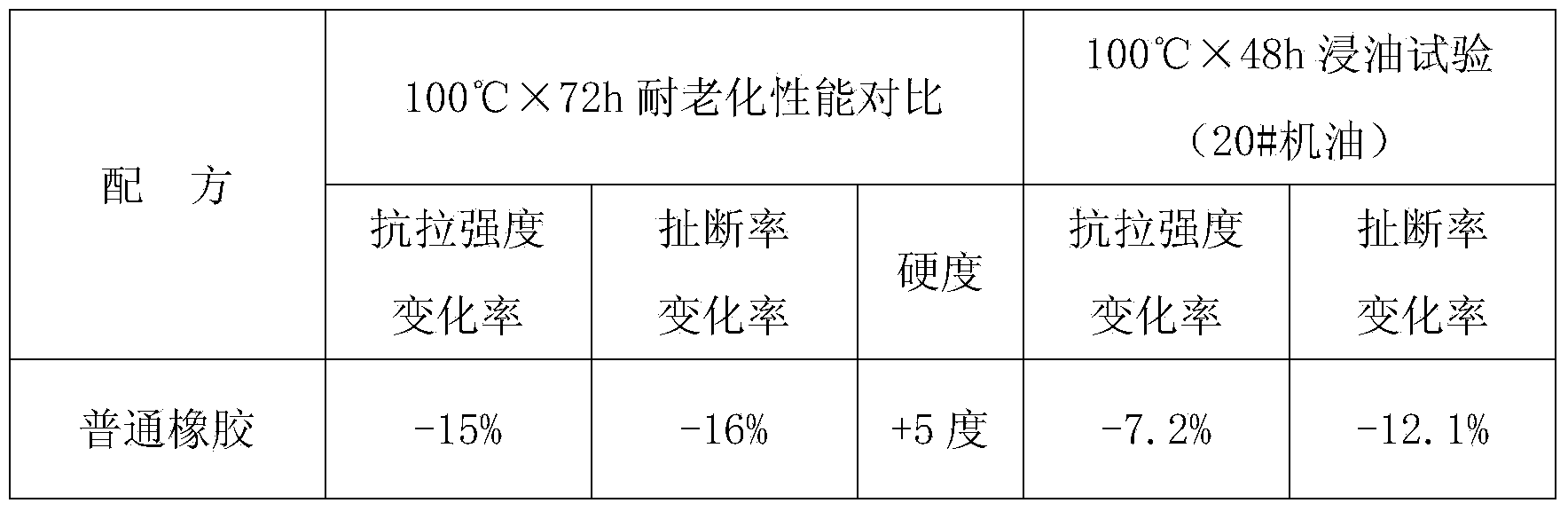

Modified compounded rubber sealing gasket material and preparation method thereof

The invention discloses a modified compounded rubber sealing gasket material. The modified compounded rubber sealing gasket material is characterized by being prepared from the following raw materials in parts by weight: 70-75 parts of tetrafluoroethylene-propylene rubber, 18-23 parts of silicone rubber, 1-2 parts of calcium hydroxide, 2-4 parts of magnesium oxide, 28-32 parts of N550 carbon black, 1-2 parts of sulphur, 1-2 parts of accelerant DM, 2-3 parts of zinc oxide, 2-4 parts of potassium citrate, 1-2 parts of 2,2',3,3',4,4',5,5',6,6'-decabromobibenzyl, 1-2 parts of acrylonitrile, 3-5 parts of methyl methacrylate, 1-2 parts of 3-aminopropyltrimethoxysilane, 0.5-1 part of crosslinking agent TAC, 16-20 parts of nanometer celestite powder and 10-12 parts of modified attapulgite. The processing property of the rubber material is improved by adding the modified attapulgite; the toxic and side effects and the pollution to environments of the rubber material are reduced by using an environmentally-friendly compounding agent; the modified compounded rubber sealing gasket material has good combination property and is long in service life; the mechanical property, the oil resistance, the ageing resistance and the like of the modified compounded rubber sealing gasket material are improved.

Owner:TONGLING SIDE TECH

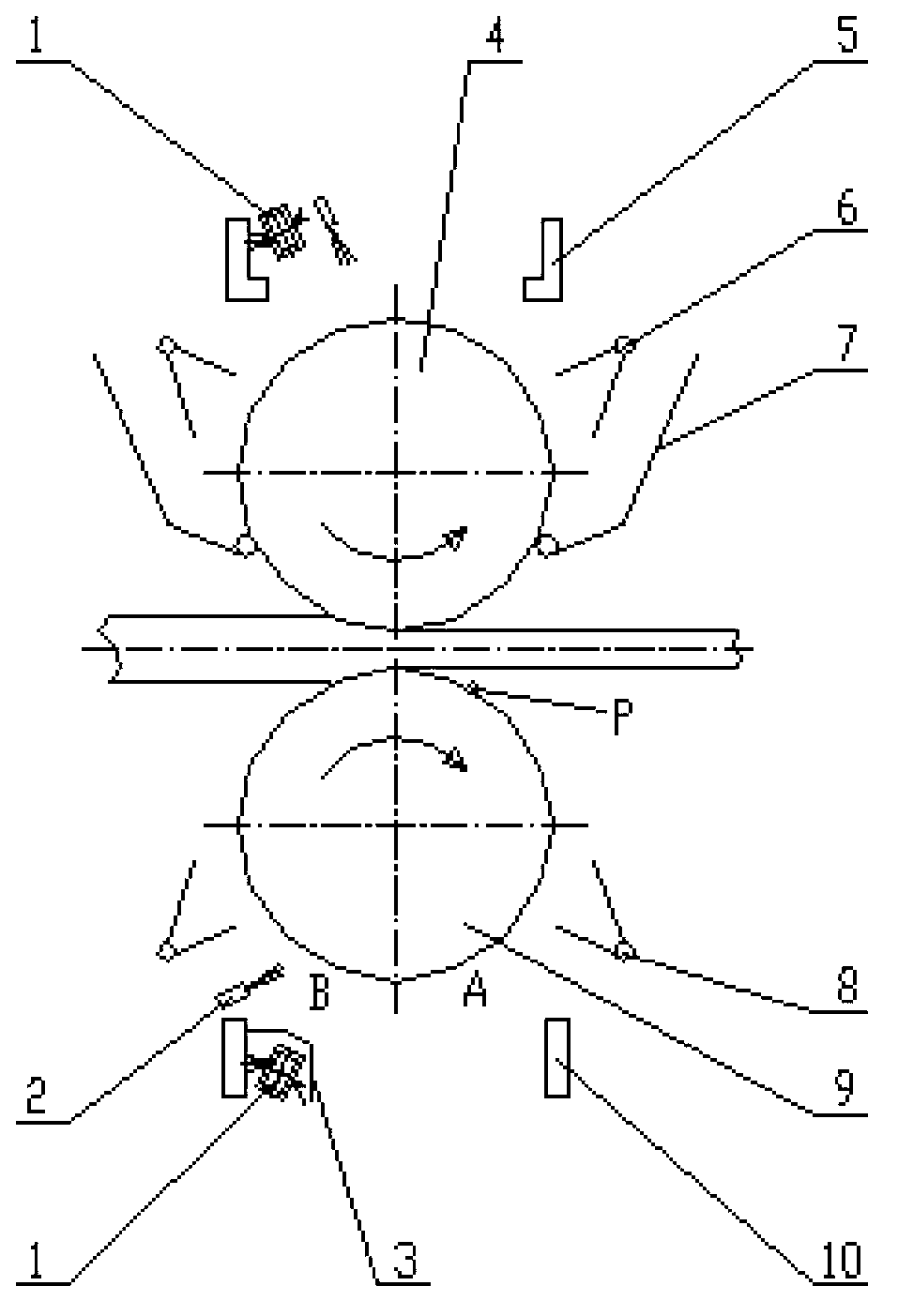

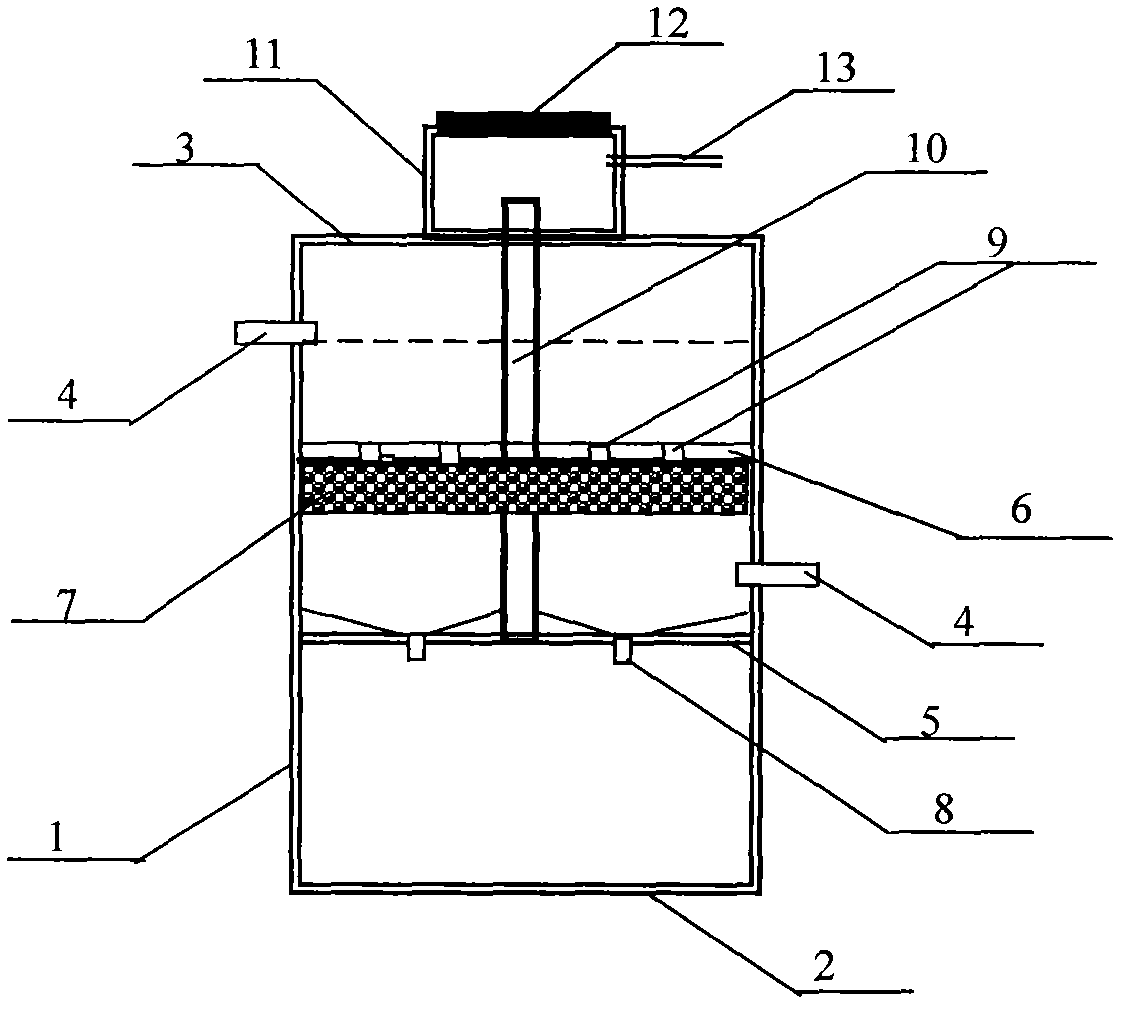

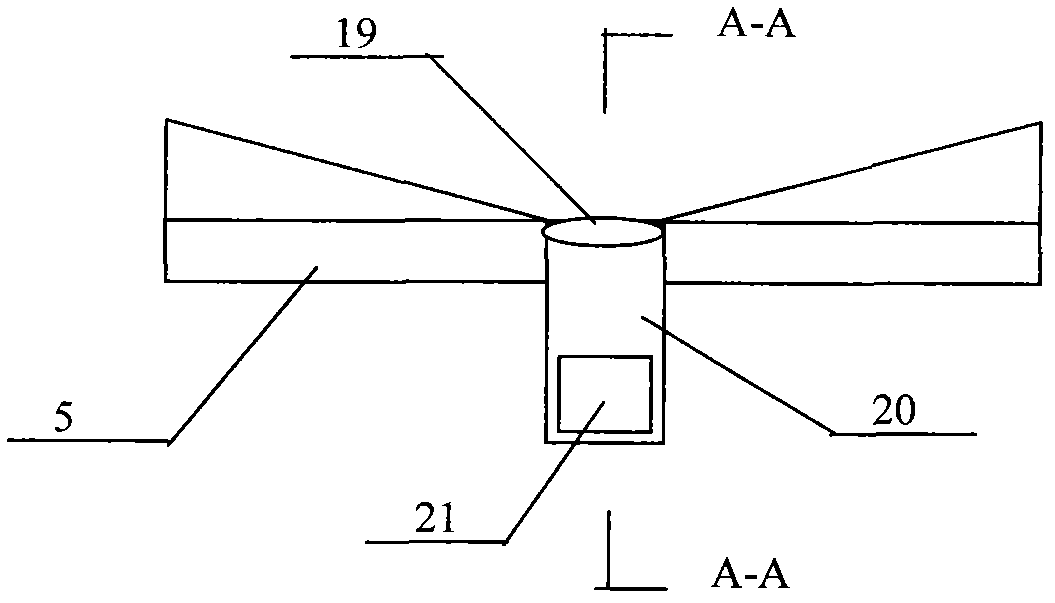

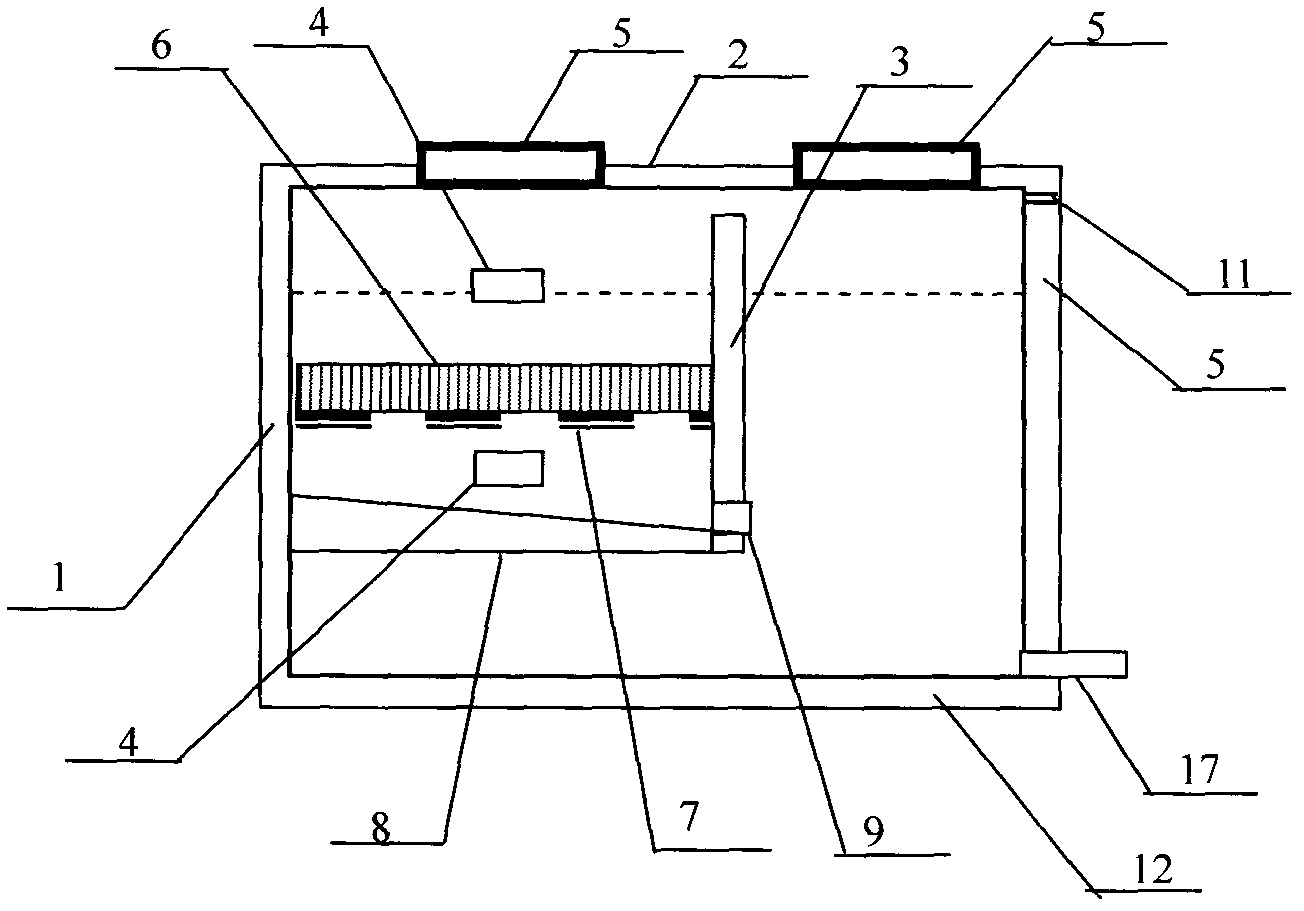

Vertical pipe type sludge-water separation treating device

InactiveCN102805956AAchieve digestionPromote digestionSolvent extractionSedimentation settling tanksWater qualityControllability

The invention provides a vertical pipe type sludge-water separation treating device, which is mainly characterized in that the tank wall of a vertical pipe type sludge-water separation treating unit is a pipe wall 1 and a tank bottom plate 2 of the tank body, a tank top plate 3 at the upper part has an inspection well, each vertical pipe type sludge-water separation treating unit is divided by a space partition board 5 and a filler arrangement plate 6 inside, below the filler arrangement plate is a suspension filler 7, on the space partition board 5 are settling sludge guide pipes 8, water holes 9 are formed in the filler arrangement plate 6, a cleaning pipe 10 has an upper opening located at the inspection well position and a lower opening located at the space partition board 5, water inlet and outlet pipes 4 are arranged above the filler arrangement plate 6 and between the filler arrangement plate 6 and the space partition board 5, a settling sludge guide pipe 20 is installed at the settling sludge hole 19, and a sludge guide pipe sludge discharge opening 21 is formed below the space partition board 5. The inventive device can simplify construction, separate sewage treatment from sludge treatment, reduce the influence of sludge on sewage treatment, and facilitate stabilization of controllability of water quality and process of sewage treatment.

Owner:赵峰

Steam generating device

PendingCN112944307AComponent stabilityIncrease contentSteam generation heating methodsBoiler controlTemperature controlHeat conservation

The invention provides a steam generating device. The steam generating device comprises a liquid medicine storage tank; a medium heat preservation tank, wherein the medium heat preservation tank is used for containing a heat preservation medium with a set temperature, the liquid medicine storage tank is arranged in the medium heat preservation tank, and the liquid medicine storage tank makes contact with the heat preservation medium so that the liquid medicine can be kept at the set temperature; a carrier gas supply module, wherein the carrier gas supply module comprises a carrier gas source and a carrier gas supply pipeline, the carrier gas supply pipeline comprises a gas inlet end and a gas outlet end, the gas inlet end is connected with the carrier gas source, and the gas outlet end extends into the liquid medicine, and the carrier gas supply module further comprises a carrier gas distribution unit which is used for distributing carrier gas into bubbles and keeping a set distance from the liquid level of the liquid medicine; and a steam output pipeline, wherein the steam output pipeline is connected to the upper portion of the liquid medicine storage tank and is used for outputting carrier gas carrying liquid medicine steam. Constant temperature control is carried out through the water bath, potential safety hazards caused by direct heating are avoided, stable carrier gas supply is combined, the supplied isopropanol steam is high in content and stable in component, and it is ensured that stable process effect of the isopropanol is achieved.

Owner:ACM RES SHANGHAI

Design method of rubber forming mold of variable cross-section high-curvature differential flow adjusting cover part

The invention belongs to the sheet metal rubber forming technology, and relates to a design method of a rubber forming mold of a variable cross-section high-curvature differential flow adjusting coverpart. The design mainly comprises a male mold, a female mold and a pressing plate, wherein the male mold is firstly designed according to the size of an inner contour of a part and the distribution of compression deformation; the female mold and the pressing plate are manufactured according to the male mold in a matching mode correspondingly; gaps are formed in the female mold and the pressing plate; an upper molded surface of the female mold is consistent with the deformation form of the part; a rib or a ridge is arranged on the female mold according to the compression deformation condition,and a lower molded surface of the pressing plate is manufactured according to the upper molded surface of the female mold in the matched mode. According to the method, the structure is simple, and only comprises the female mold, the pressing plate and the male mold; hydraulic forming equipment can be adopted for one-step forming, the time is short (for about 5 minutes), efficiency is high, afterthe rubber forming is carried out on the part, the part is free of defects such as fracture and wrinkling, a qualified rate can reach 100%, the surface of the part is smooth, a model profiling degreeis high, quality is good, manufacturability is stable, operability is high, and dependence on the technical level of operators is low.

Owner:HARBIN

Preparation method of Mo-Ru brazing filler metal powder

ActiveCN112170858AImprove process performanceGood brazingWelding/cutting media/materialsSoldering mediaMetallurgyRuthenium

The invention relates to a preparation method of Mo-Ru brazing filler metal powder. The method is used for preparing the Mo-Ru brazing filler metal powder by roasting and reducing pure ruthenium powder and ammonium molybdate, and the Mo-Ru brazing filler metal powder is uniform in component, small in particle size (the particle size range is 10-100 microns, and the grain size of 90% of brazing filler metal powder particles is less than or equal to 40 microns), high in apparent density, good in melting characteristic, excellent in process characteristic, high in cost performance, and suitable for industrial mass production.

Owner:CHONGQING MATERIALS RES INST

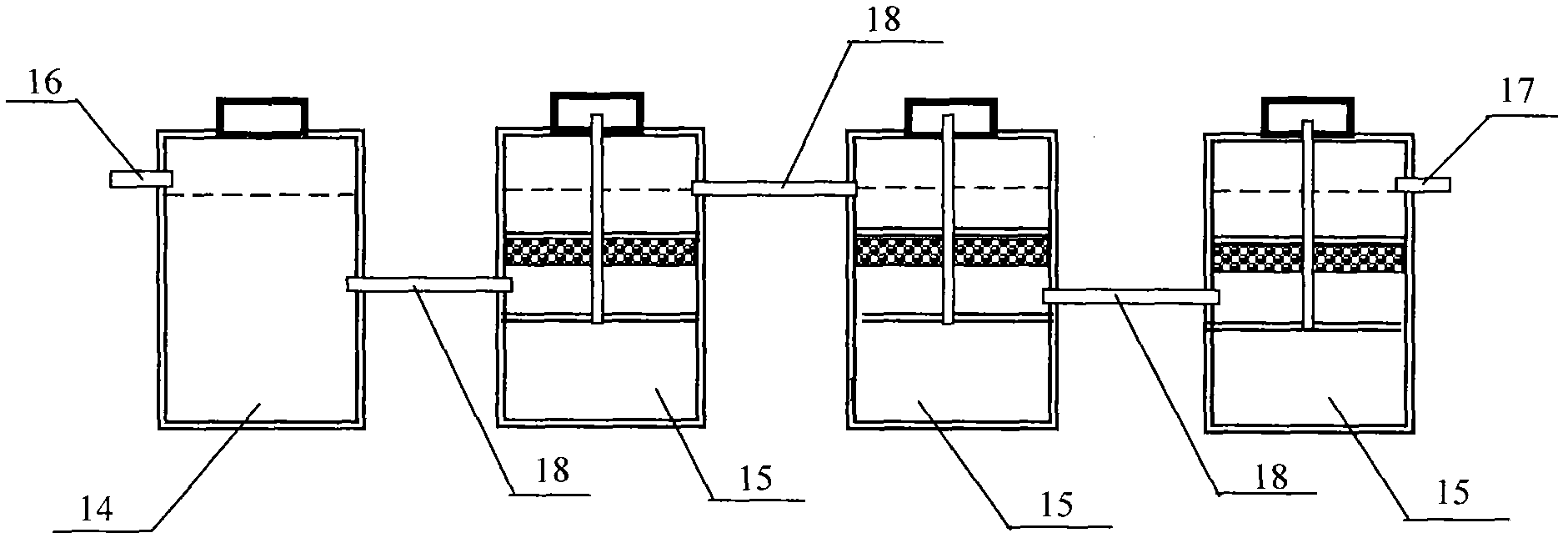

Solid-liquid separation sewage treatment device

InactiveCN103204604AAchieve digestionPromote digestionMultistage water/sewage treatmentReduction treatmentSewage

The invention provides a solid-liquid separation sewage treatment device which is characterized in that the sewage treatment device comprises a deposition tank positioned on the front end and connected in series with three solid-liquid separation treatment units. Each Solid-liquid separation sewage treatment device is divided into a sewage treatment space and a sludge treatment space by using a sludge-sewage separation bottom plate 8 and a sludge-sewage separation side wall plate 3. An interception device 6 is arranged in the sewage treatment space. At least one deposited sludge side discharge port 9 is arranged at the lower part of the sludge-sewage separation side wall plate 3. The upper surface of the sludge-sewage separation bottom plate 8 is inclined to the deposited sludge side discharge port 9. Rinsing ports 4 are respectively provided on side walls on the two sides corresponding to the sewage treatment space, and are positioned on the side walls above or below the interception material or device 6. Inspection ports 5 are provided on the top plate of the tank bodies of the sewage treatment space and the sludge treatment space. A ventilation hole (pipe) 11 is provided on the upper part of the side wall. With the device and the method, sewage treatment and sludge treatment can be separated, such that the influence on sewage treatment caused by digestion gas and sludge degradation products is reduced, and sewage treatment and sludge reduction treatment can be realized simultaneously.

Owner:赵峰

Recovery method for salt crystals in brine refining mother liquor used for salt production

ActiveCN107098361ARich varietyHigh purityAlkali metal chloridesAlkali metal halide purificationRecovery methodEvaporation

The invention discloses a recovery method for salt crystals in brine refining mother liquor used for salt production. The recovery method comprises the following steps: (1) subjecting well brine to raw brine clarification, addition of chemicals for a reaction and refined brine clarification, then carrying out centrifugation with a centrifuge to remove liquid and subjecting salt slurry obtained after centrifugation to thickening; (2) after thickening, subjecting the salt slurry to standing, allowing supernatant to enter a mother liquor tank through overflowing, pumping salt slurry deposited on the bottom of the mother liquor tank into a dissolving barrel, adding water to fully dissolve the deposited salt slurry and carrying out filtering so as to obtain filtered liquid; (3) allowing the filtered liquid to pass through ion exchange resin so as to remove Ca<2+>, Mg<2+> and a part of sulfate ions, then carrying out heating and pressure-reduced evaporation, maintaining temperature and pressure unchanged after occurrence of crystals, and adding a mixed solution of hydrogen peroxide and ethanol for solvating-out; and (4) after solvating-out, carrying out filtering and pumping obtained filtrate into an evaporator for evaporative crystallization so as to form salt crystals. The recovery method saves cost and can increase output worth3, 400, 000 yuan every year on the base of the annual output of 1, 000, 000 tones of a conventional salt-Glauber's salt combined production apparatus; and impurity ions like Ca<2+>, Mg<2+> and SO4<2-> in the recovered salt crystals are substantially removed.

Owner:JIANGXI JINGHAO SALINIZATION

Method for automatically detecting touch key state and display device

ActiveCN103207370AImprove process performanceImprove market qualityCircuit interrupters testingDisplay deviceComputer module

The invention relates to the field of display, in particular to a method for automatically detecting a touch key state and a display device. The method is characterized in that a control chip is provided to be connected with a touch module so as to be used for converting touch key signals sent by the touch module into a signal-noise ratio and sensitivity; and a display module is provided to be connected with the control chip so as to display the signal-noise ratio and the sensitivity. The touch key signals are converted into the sensitivity and the signal-noise ratio to be displayed on a factory menu of the display device through an on-screen display (OSD) display chip of the control chip, so that the operators can visually read data of keys through the factory menu.

Owner:TPV ELECTRONICS (FUJIAN) CO LTD

Environment-friendly and energy-saving type printing ink cleaning agent and preparation method thereof

ActiveCN103509400AImprove process performanceSmall side effectsChemical paints/ink removersChemistryDamage effects

The invention discloses an environment-friendly and energy-saving type printing ink cleaning agent which is characterized by comprising the following raw materials in parts by weight: 4-5 parts of nonyl phenol polyoxyethylene ether, 3-4 parts of polyoxyethylene fatty alcohol ether, 5-7 parts of olein, 3-4 parts of oleic acid, 3-4 parts of linoleic acid, 1-2 parts of alkenyl succinic acid, 20-24 parts of propylene glycol, 4-5 parts of glycerinum, 2-3 parts of disodium hydrogen phosphate, 1-2 parts of lithium bis(trifluoromethanesulphonyl)imide, 4-5 parts of assistants and 100-110 parts of water. According to the method provided by the invention, the assistants are added, so that the processing property of the cleaning agent is improved, and the toxic or side effects and the pollution to the environment are reduced. The environment-friendly and energy-saving type printing ink cleaning agent is non-toxic, non-hazardous, pollution-free, non-flammable and non-combustible, has a less damage effect on the rubber covered roller of a printing machine, and is convenient to use.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

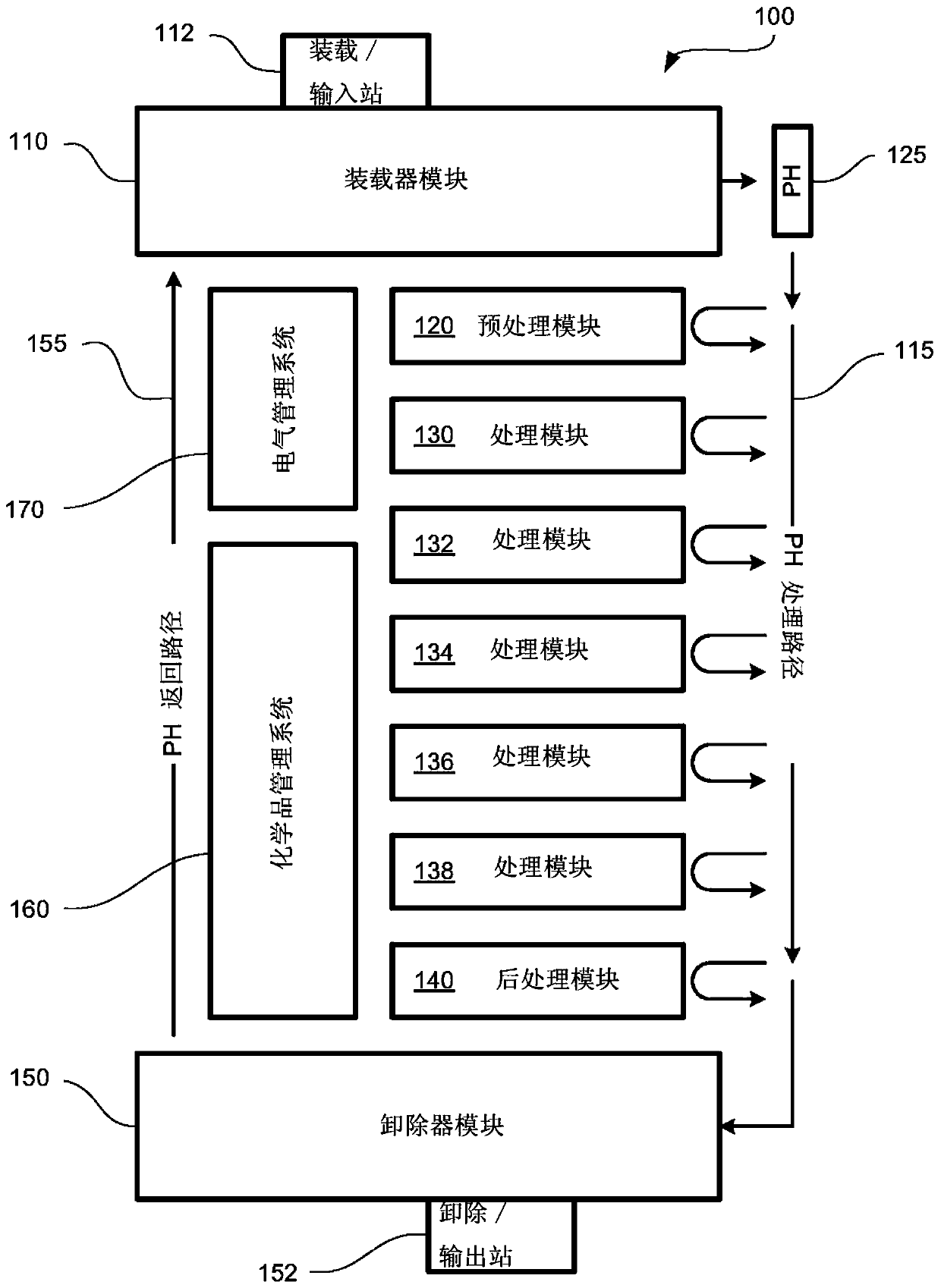

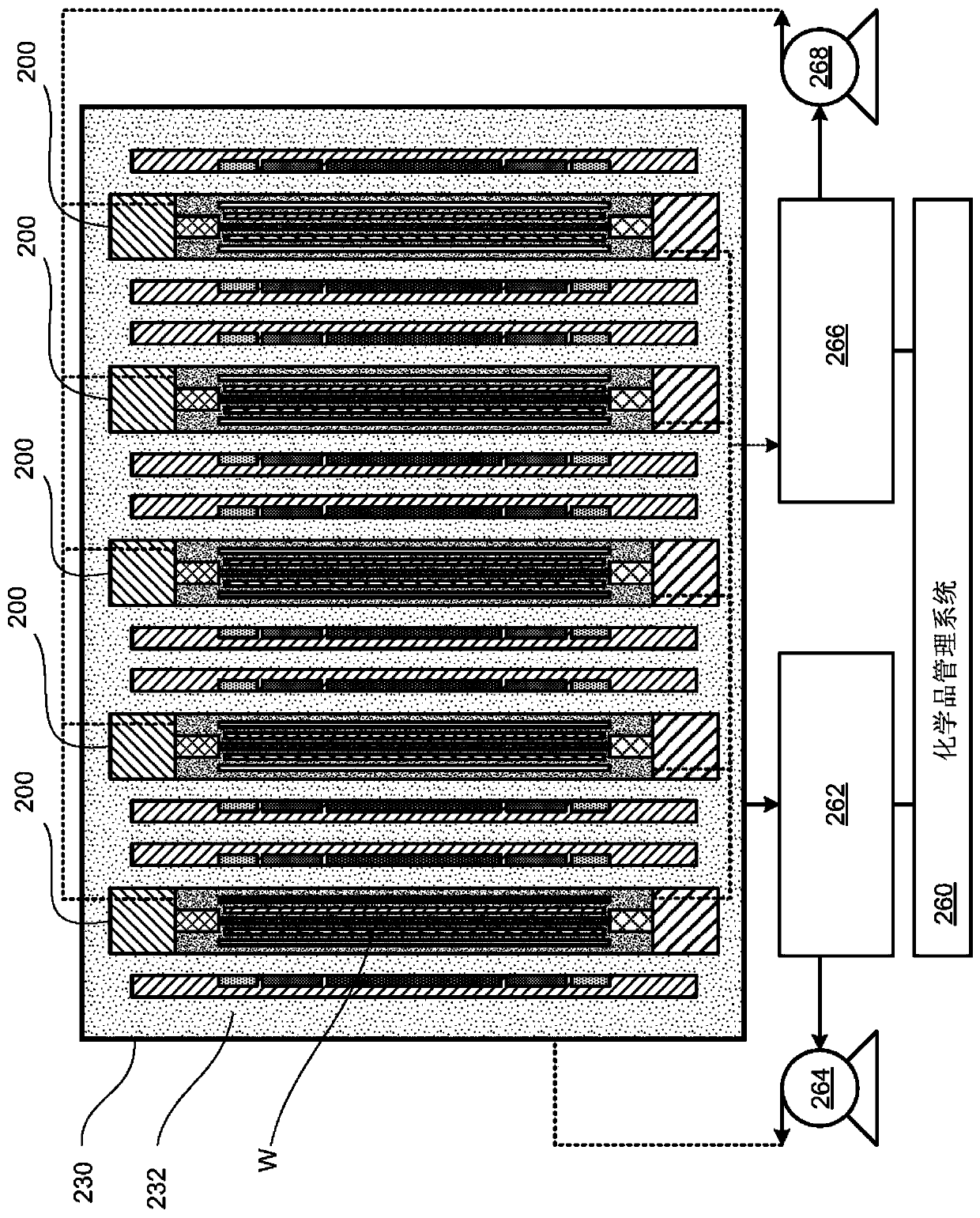

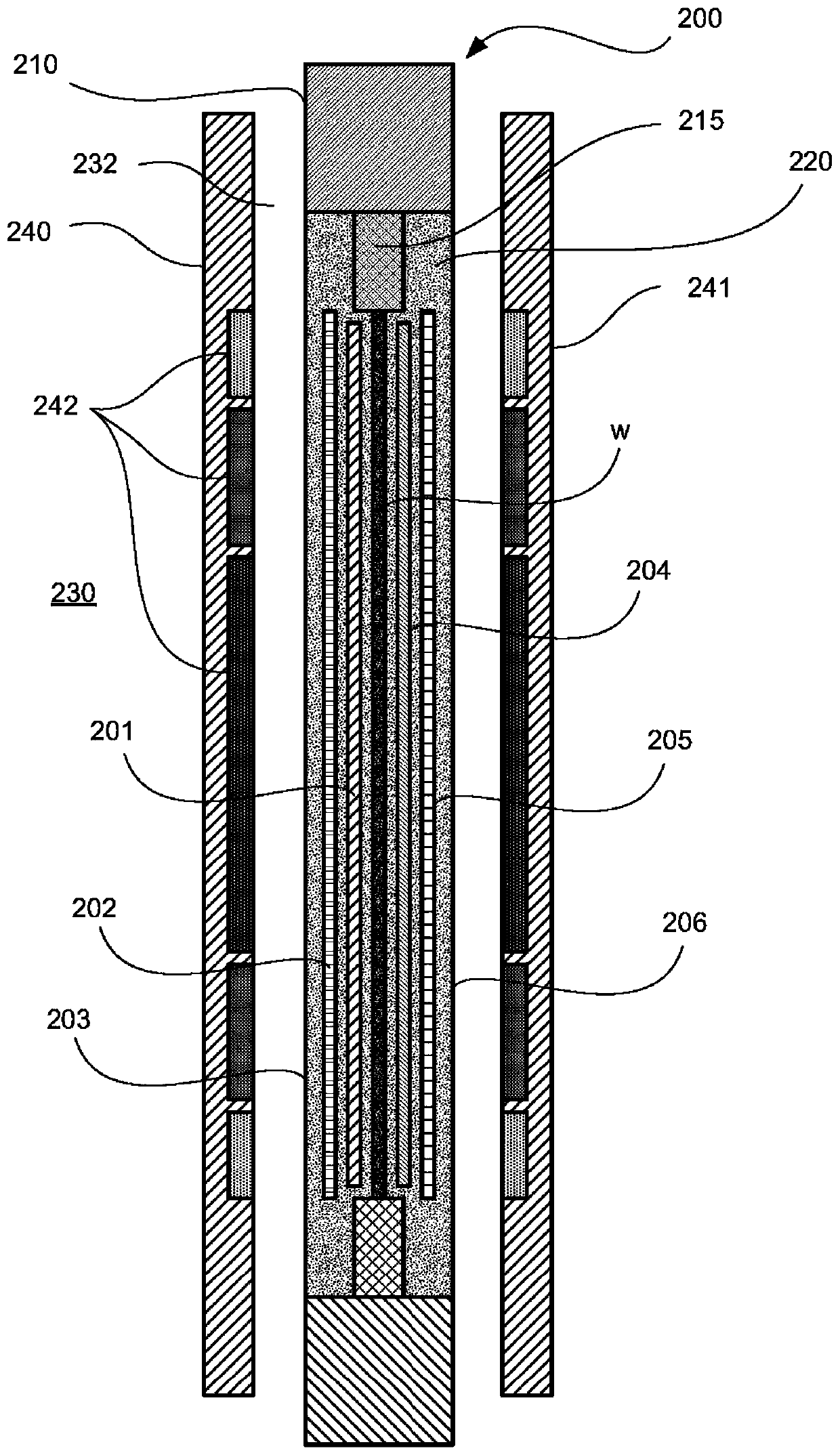

Wet processing system and method of operating

InactiveCN109715866AReduce pollutionEasy Concentration ManagementCellsTanksEngineeringHandling system

An electrochemical deposition system having two or more electrochemical deposition modules arranged on a common platform and configured for depositing one or more metals on a substrate is described. Each electrochemical deposition module includes an anode compartment configured to contain a volume of anolyte fluid, a cathode compartment configured to contain a volume of catholyte fluid, and a membrane separating the anode compartment from the cathode compartment. Each electrochemical deposition module further includes a workpiece holder configured to hold opposing edges of a flexible workpiecebetween first and second leg members via a clamping mechanism, and a loader module configured to position the flexible workpiece in the workpiece holder while holding the flexible workpiece using anair cushion on each opposing planar surface of the flexible workpiece.

Owner:TEL NEXX INC

Fine Mo-Ru-B brazing filler metal powder and preparing method thereof

ActiveCN104014803ASolve for uniformitySolve process problemsWelding/cutting media/materialsSoldering mediaReduction treatmentMicrowave tube

The invention discloses fine Mo-Ru-B brazing filler metal powder and a preparing method of the fine Mo-Ru-B brazing filler metal powder and further discloses a method for preparing the Mo-Ru-B brazing filler metal powder through chemical coprecipitation. The preparing method of the fine Mo-Ru-B brazing filler metal powder comprises the steps that a mixed solution is prepared through ruthenium trichloride, ammonium molybdate and ammonium biborate, the mixed solution is heated after being dried at a low temperature so that ammonium chloride can be removed, reduction treatment is conducted through hydrogen, grinding and screening are conducted, and then the Mo-Ru-B brazing filler metal powder containing required components is obtained. The particle size of 90% of the prepared brazing filler metal powder is smaller than or equal to 6 microns, and the maximum particle size of the prepared brazing filler metal powder is smaller than or equal to 10 microns. The Mo-Ru-B brazing filler metal powder prepared with the method has the advantages that the powder is fine, namely the particle size of 90% of the Mo-Ru-B brazing filler metal powder is smaller than or equal to 6 microns, the components are even, and thus the requirement for enabling a micro-part of a high-power efficient microwave tube cathode assembly to be coated with the powder for brazing can be met.

Owner:SINO PLATINUM METALS CO LTD

Hydraulic hammer head and preparation method thereof

InactiveCN106238738AImprove wear resistanceImprove process performanceAdditive manufacturing apparatusMechanical machines/dredgersCorrosionHigh energy particle

The invention provides a hydraulic hammer head. The hydraulic hammer head comprises a hydraulic hammer head body. A metal ceramic layer with a gradient structure is covered on the surface of the hydraulic hammer head body. The metal ceramic layer is formed by painting through a 3D printer and comprises, by weight, 10-30 parts of chromium, 5-12 parts of silicon, 30-40 parts of iron, 5-13 parts of carbon, 30-40 parts of nickel, 1-2 parts of molybdenum and 1-2 parts of wolfram. The preparation method of the hydraulic hammer head body comprises the steps that (A) all raw materials forming the metal ceramic layer are mixed and stirred evenly to prepare mixed powder; and (B) the mixed powder is laser-melted by a high-energy beam of particles generated by the 3D printer, and is painted to the surface of the hydraulic hammer head body by the 3D printer. The hydraulic hammer head is largely improved in physical performance such as corrosion resistance, toughness and rigidity and good in stability.

Owner:四川中久红宇科技有限公司

Modified fluororubber sealing gasket material and preparation method thereof

The invention discloses a modified fluororubber sealing gasket material which is characterized by being prepared from the following raw materials in parts by weight: 65-70 parts of fluororubber, 3-4 parts of graphite, 10-12 parts of phenolic resin, 2-3 parts of silane coupling agent KH-550, 4-6 parts of dibutyl phthalate, 2-3 parts of polyisobutene, 2-5 parts of diethylene glycol benzoate, 2-3 parts of magnesium oxide, 2-3 parts of zinc oxide, 1-2 parts of anti-aging agent ODA, 1-2 parts of accelerant CZ, 1-2 parts of monobutyl tin oxide, 1-2 parts of sulfur, 30-35 parts of N550 carbon black, 10-12 parts of calcium carbonate powder, 15-18 parts of nano clay and 10-12 parts of modified attapulgite clay. Due to the added modified attapulgite clay, the process performance of the size is improved, and the toxic and side effects and environmental pollution are reduced by using an environment-friendly compounding agent. The modified fluororubber sealing gasket material has high sealing property, compression resistance, ageing resistance, oil resistance and friction resistance.

Owner:马鞍山市中澜橡塑制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com