On-line temperature measuring device for surfaces of rolls of strip rolling mill and testing method of on-line temperature measuring device

A roll surface, temperature measuring device technology, applied in length measuring device, metal rolling, metal rolling and other directions, can solve the problems of poor detection timeliness, inaccurate measurement results, inability to quantify, etc., to achieve accurate detection results and improve technology. performance, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

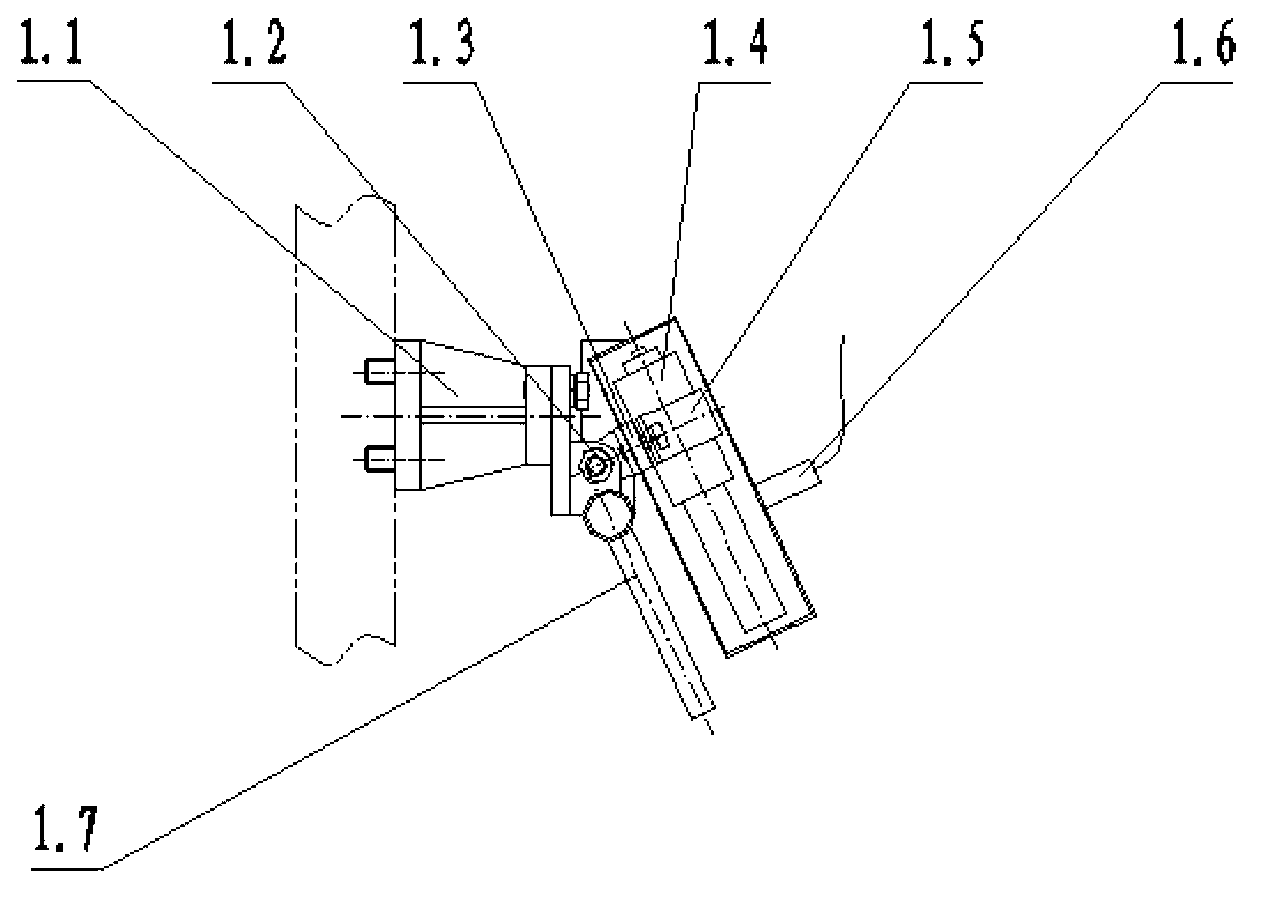

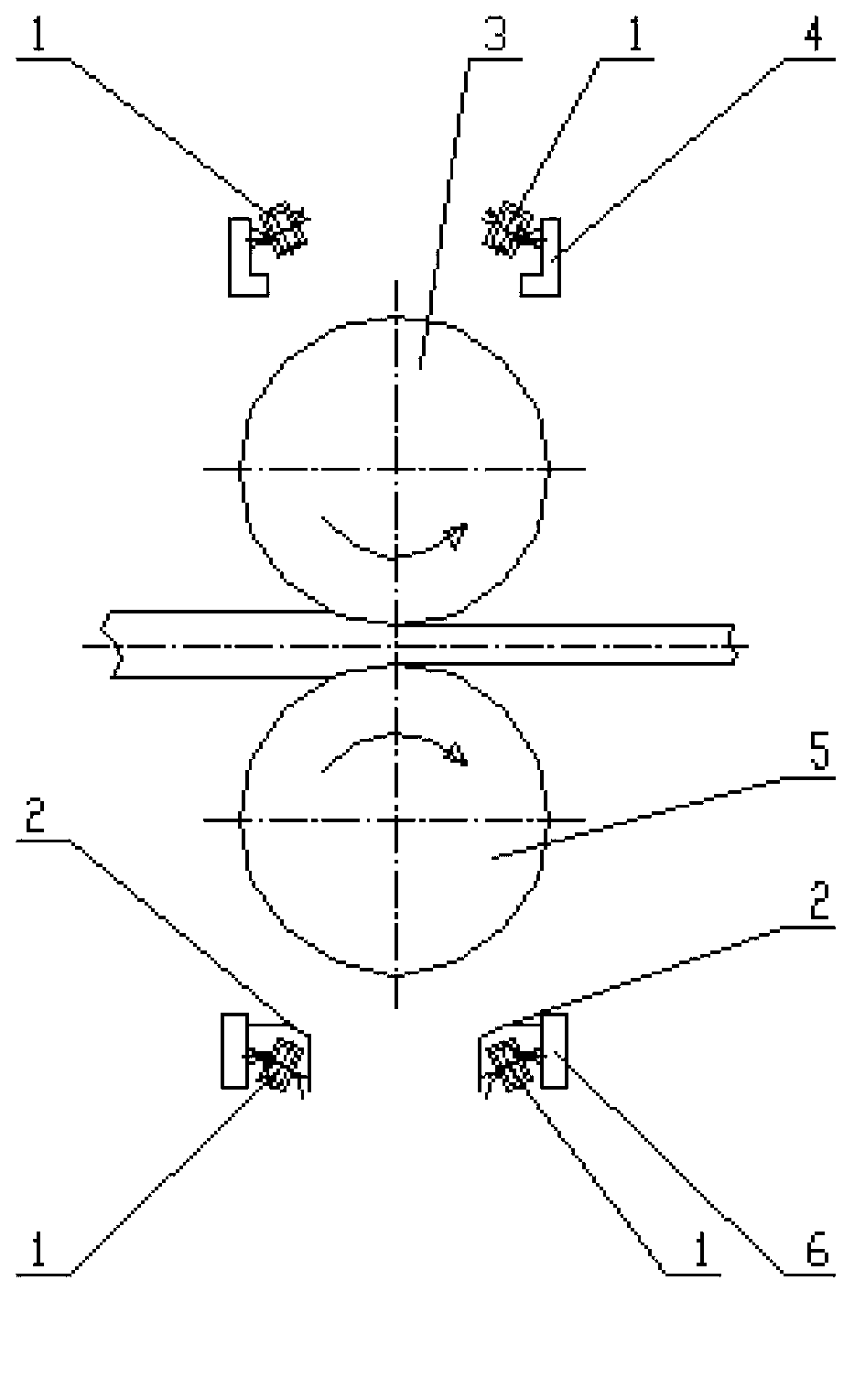

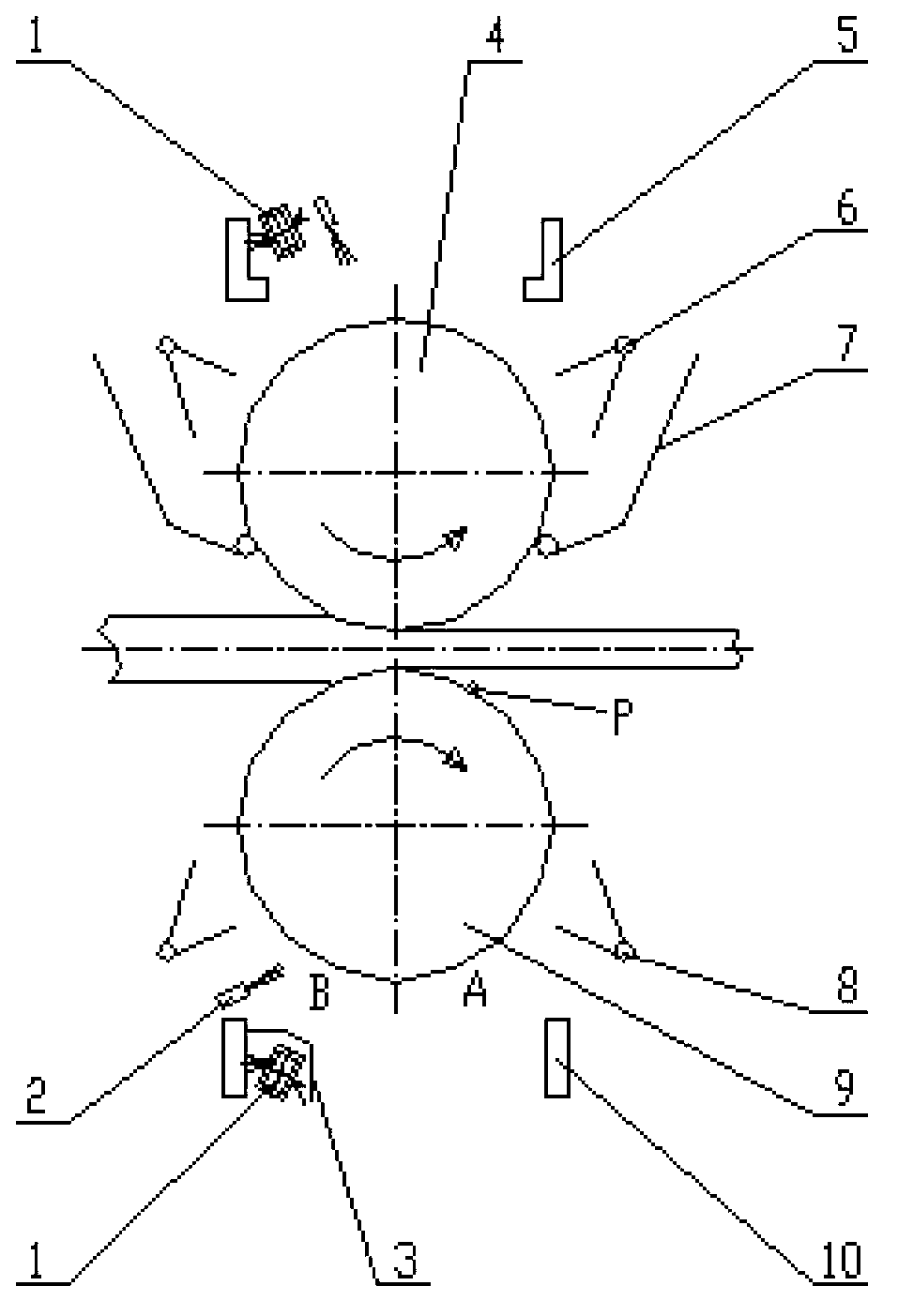

[0037] The specific embodiment of the present invention is shown in accompanying drawing, it is characterized in that roller surface temperature measuring device 1 is made of base 1.1, adjusting bolt 1.2, support 1.3, thermometer 1.4, clip 1.5 and protective cover 1.6 and air purging device 1.7 The bracket 1.3 and the base 1.1 are connected by the adjusting bolt 1.2; the thermometer 1.4 is clamped by the clip 1.5, and the clip 1.5 is connected to the bracket 1.3 by the fixing bolt; the installation angle of the thermometer 1.4 can be adjusted according to the adjustment bolt 1.2 It needs to be adjusted; the protective cover 1.6 is covered outside the thermometer; the base 1.1 is connected to the balance beam bracket 4 on both sides of the upper part of the upper roller 3 and the track beam 6 on both sides of the lower part of the lower roller 5 by means of fixing bolts; air purging The device 1.7 is connected with the base 1.1 by fixing bolts, and its position is as close as po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com