Hydraulic clamp for inner hole of high-precision thin-wall pipe fitting

A technology of hydraulic fixtures and thin-walled tubes, which is applied in the field of mechanical processing, can solve the problems of low precision of mechanical fixtures, restrict the development of thin-walled steel sleeves, and rely on imports, etc., to achieve the effects of improving processing performance, reducing processing costs, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

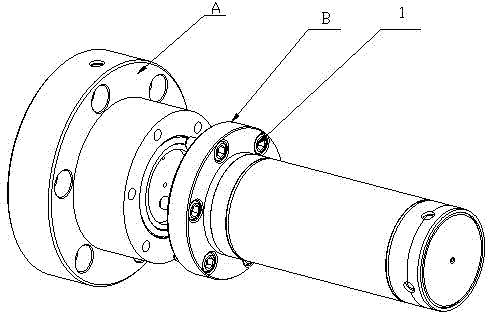

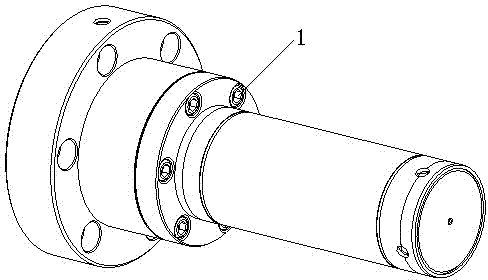

[0023] A kind of high-precision thin-walled pipe fitting inner hole hydraulic clamp reference in this embodiment Figure 1-10 , mainly composed of two parts, the hydraulic flange A connected with the machine tool and the tensioning shaft B, figure 1 . Both can be connected together by screw 1. figure 2 .

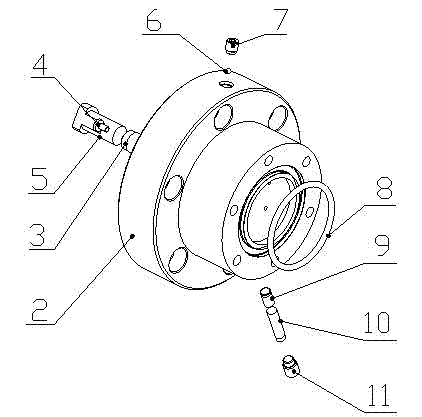

[0024] image 3 It is the basic component diagram of hydraulic flange A, which is composed of flange body 2, pressure plug 3, pressure shaft limit screw 4, pressure shaft 5, plugging steel ball 6, plugging screw 7, outer ring O-shaped seal Ring 8, adjustment seal 9, adjustment shaft 10, adjustment adjustment screw 11.

[0025] Figure 4 It is the basic component diagram of the tensioning shaft B, which is composed of an inner ring O-ring seal 12, a main shaft 13, an expansion sleeve 14, and two O-ring seals 15.

[0026] The function of each component, the principle of clamping (expansion) and the basic structure of hydraulic clamps will be described in detail below wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com