Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "High material hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Encapsulated Preformed Shapes

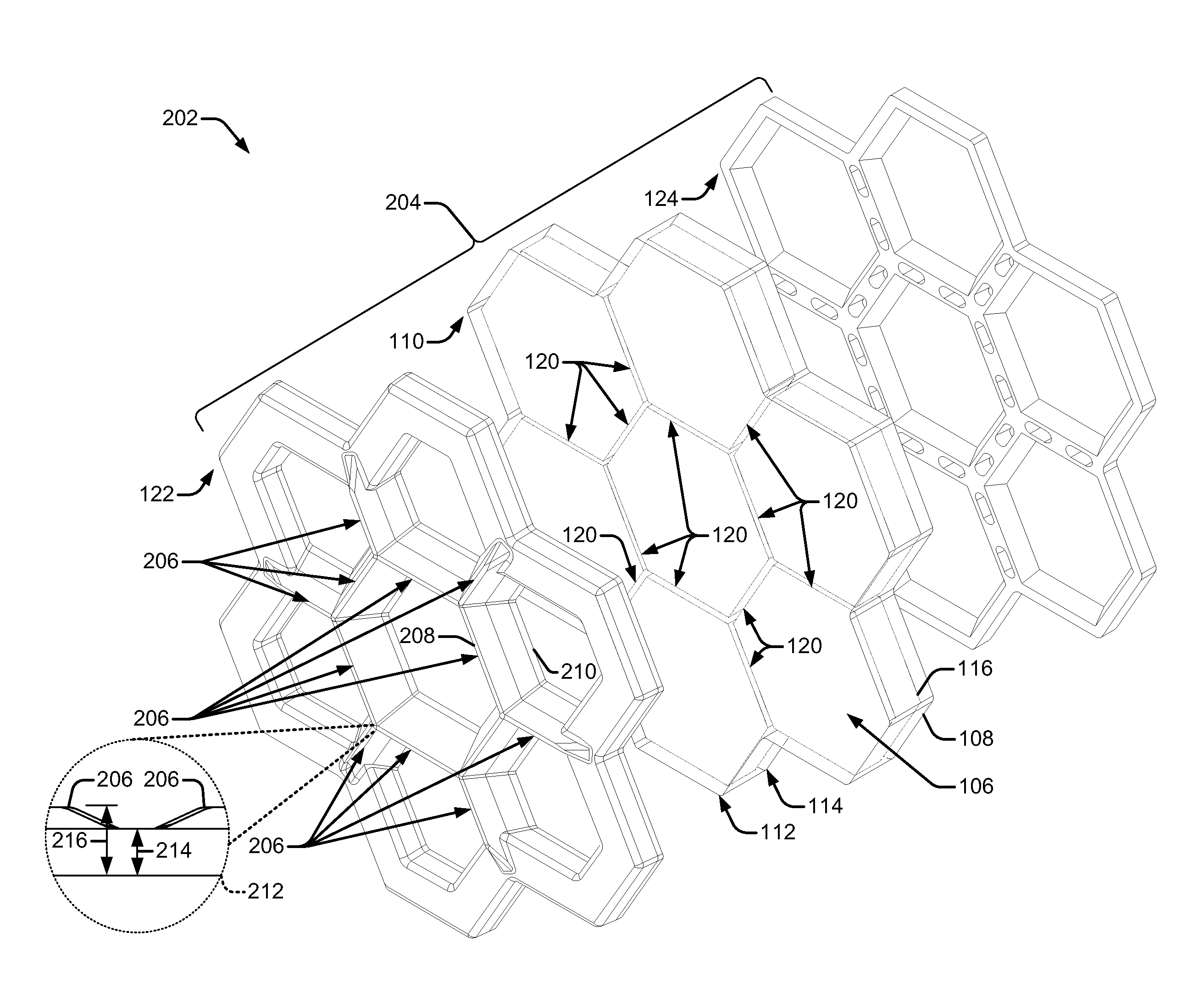

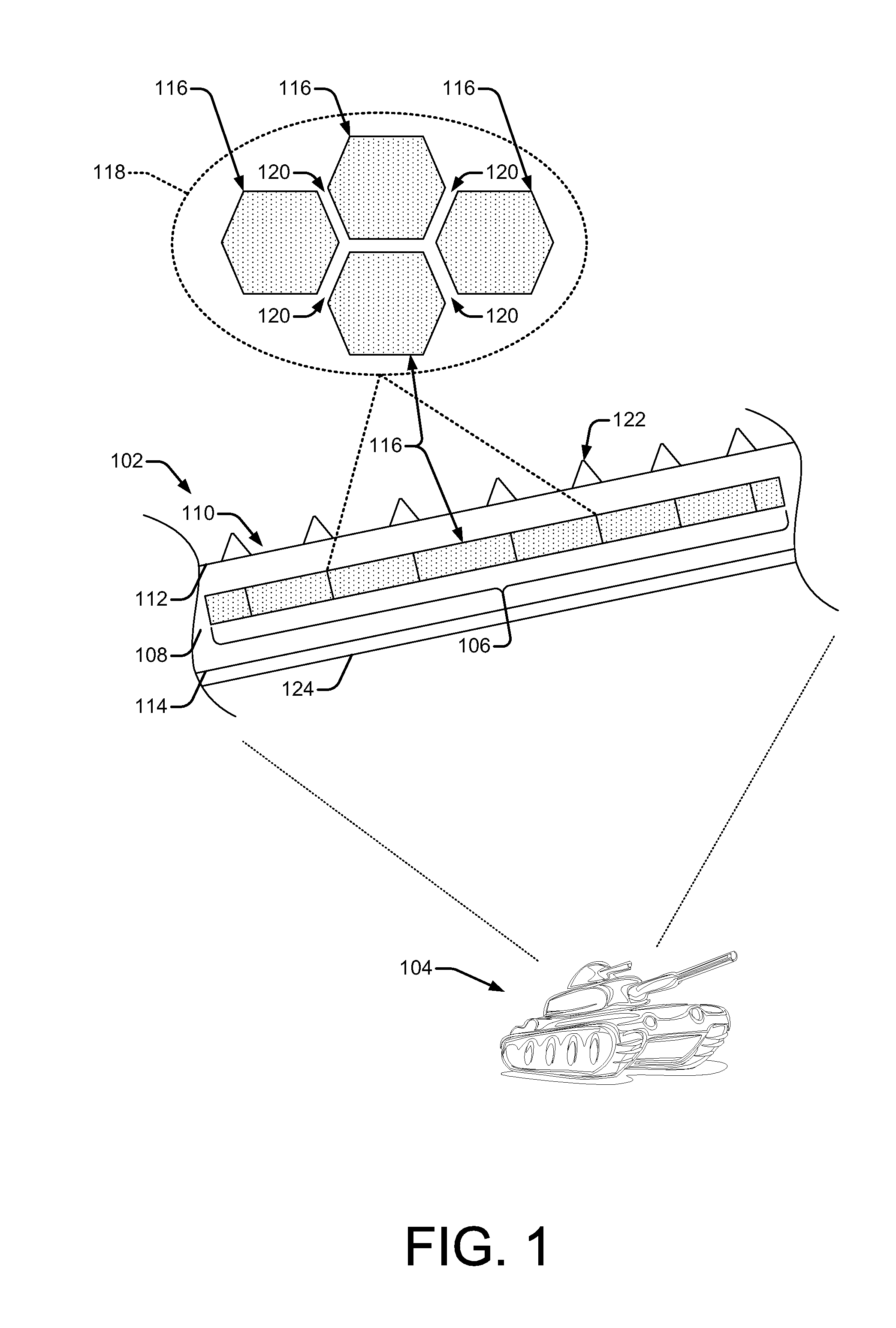

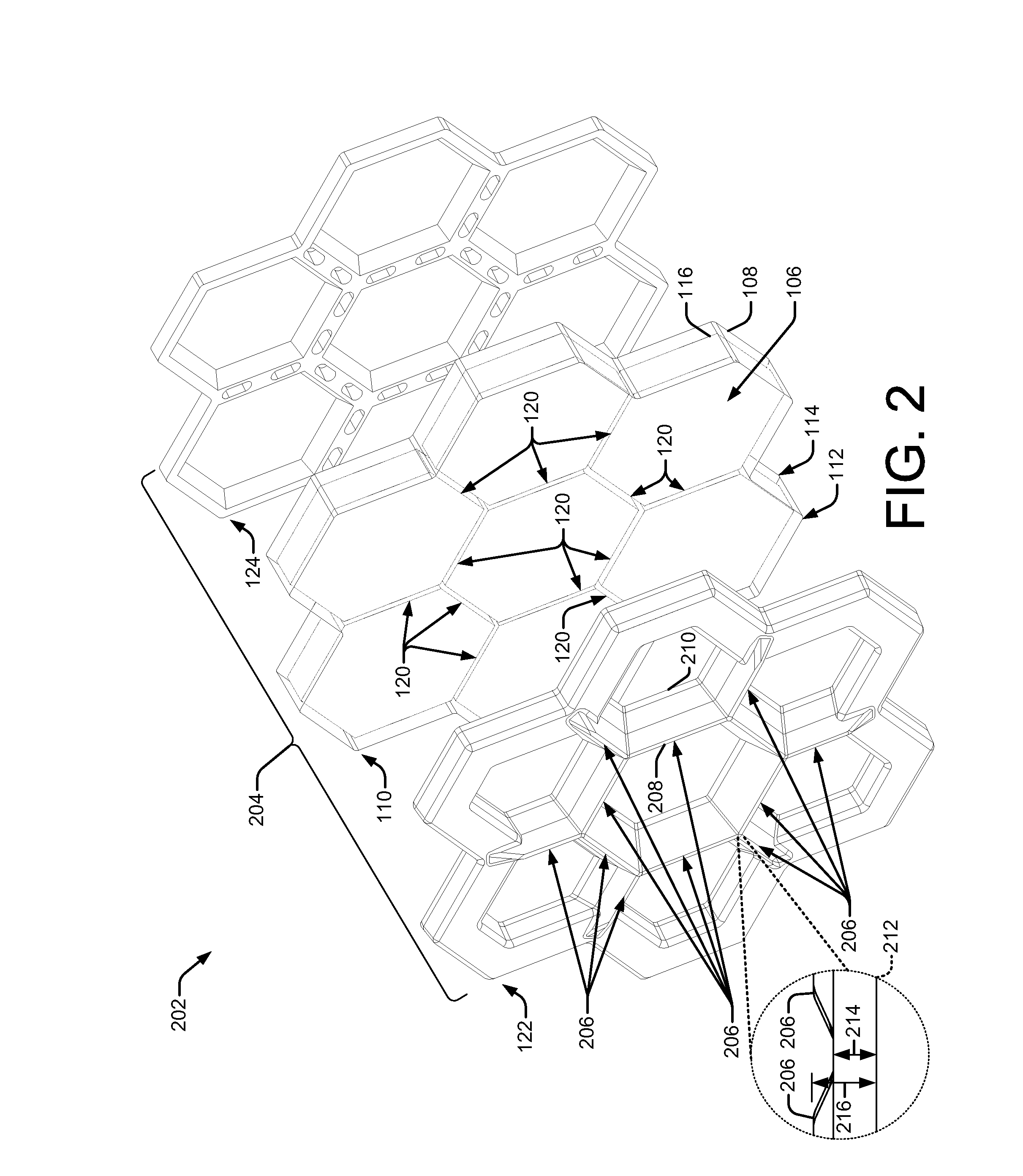

Anti-ballistic component including encapsulated preformed ceramic shapes are disclosed. Preformed ceramic shapes having a preformed geometry are encapsulated in a metal alloy to stiffen and lighten an anti-ballistic component. The preformed ceramic shapes may be arranged in layers of uniform arrays of preformed ceramic shapes and contained in a porous container to receive the metal alloy during a casting process. A truss structure may be integrated in the preformed ceramic shapes to compartmentalize the preformed ceramic shapes into multiple isolated sub regions to stiffen the anti-ballistic component.

Owner:SPOKANE INDS

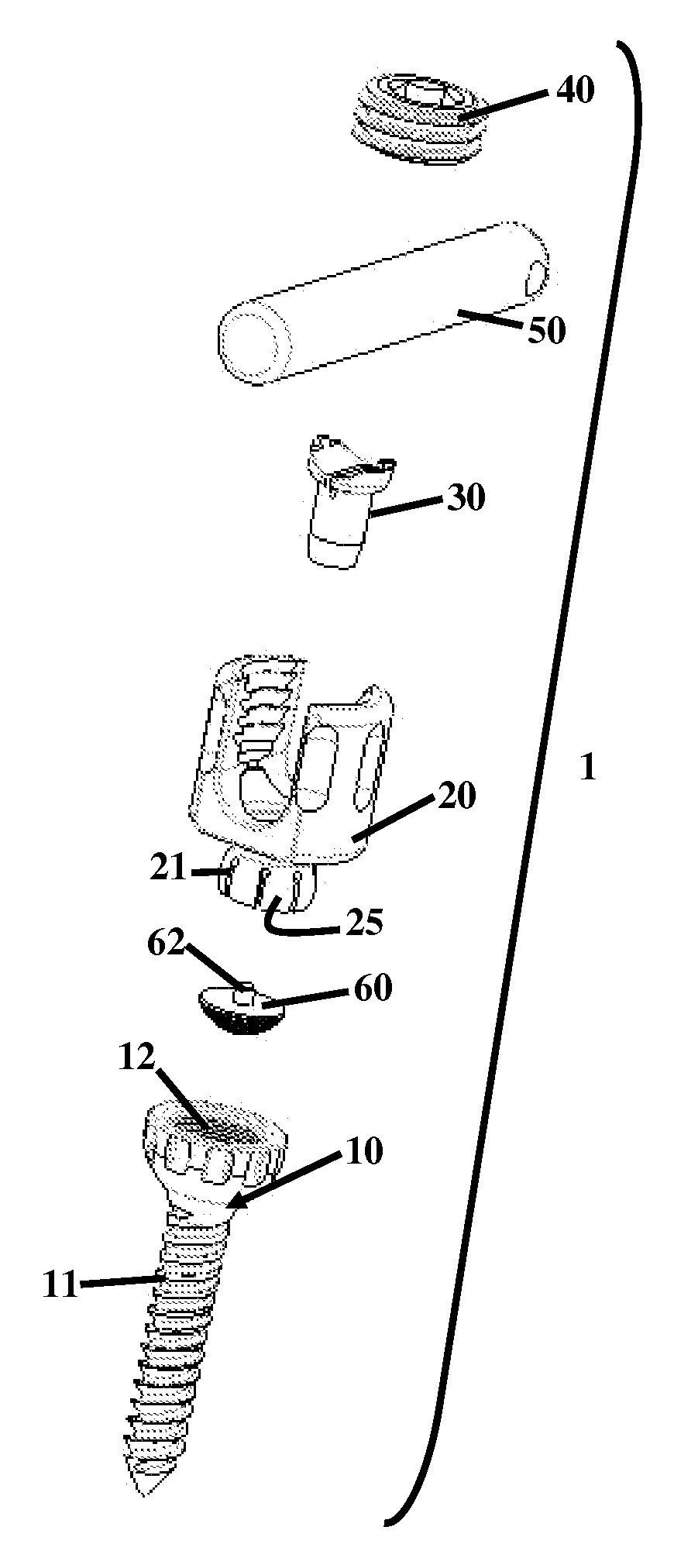

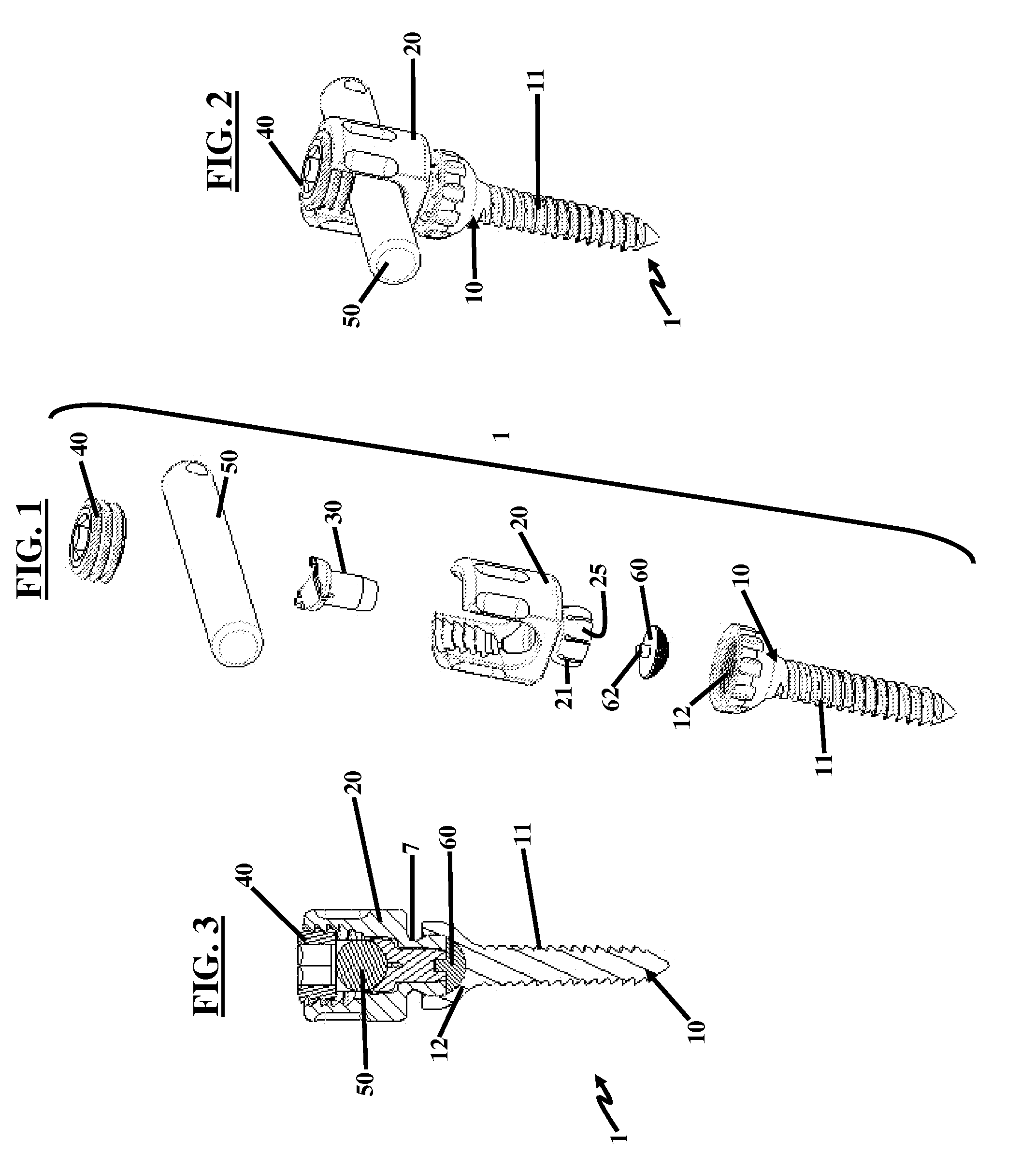

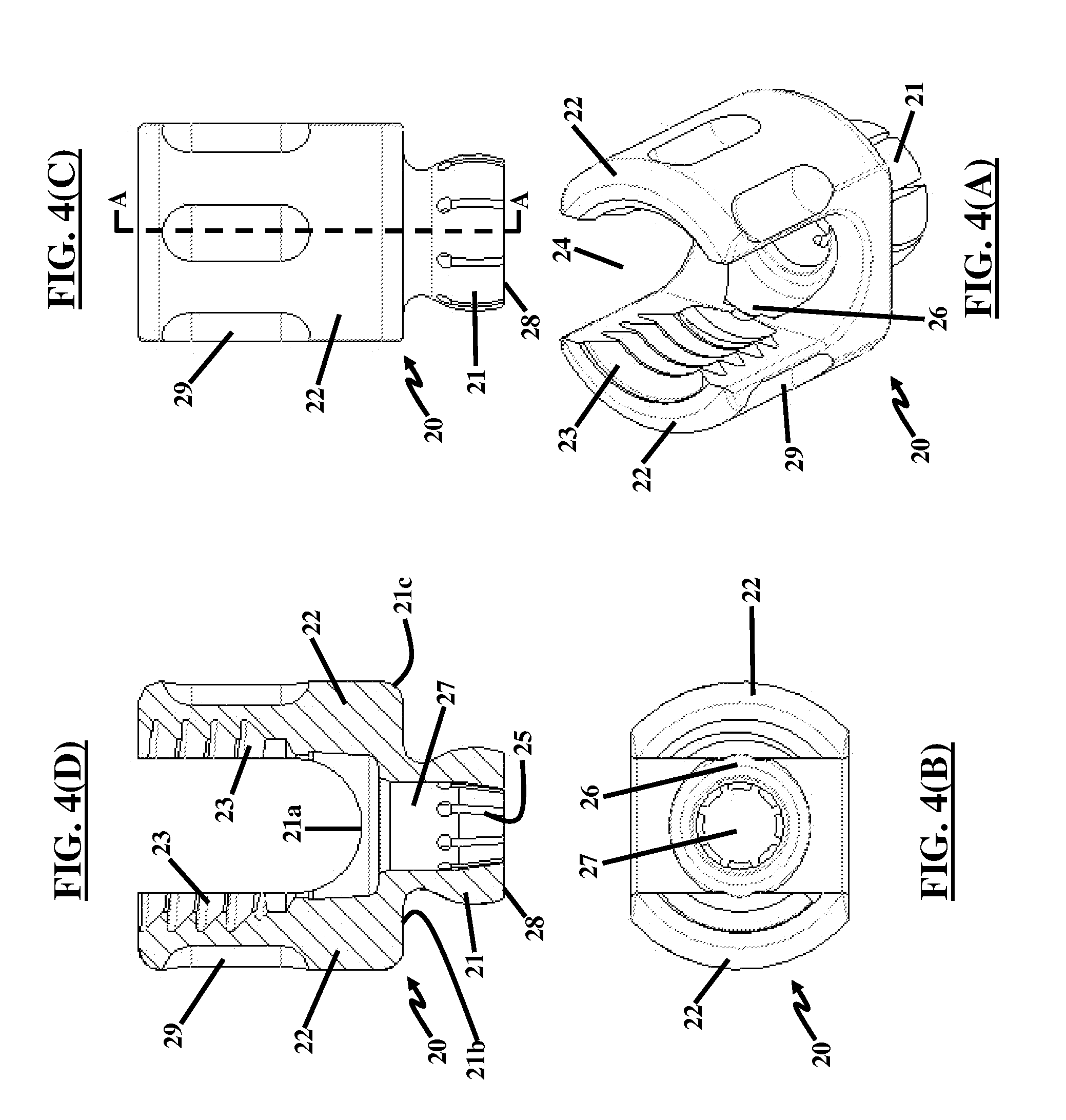

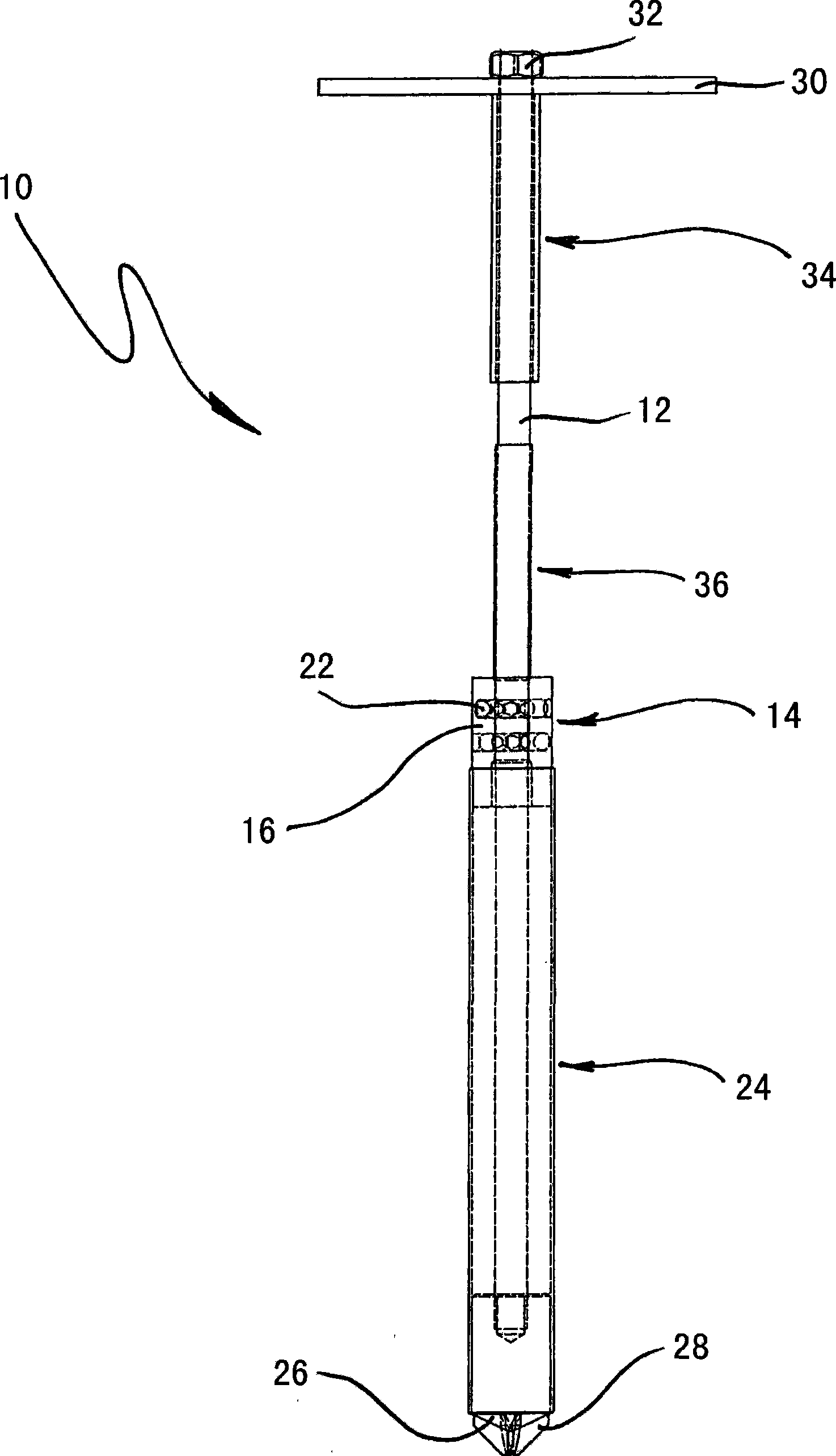

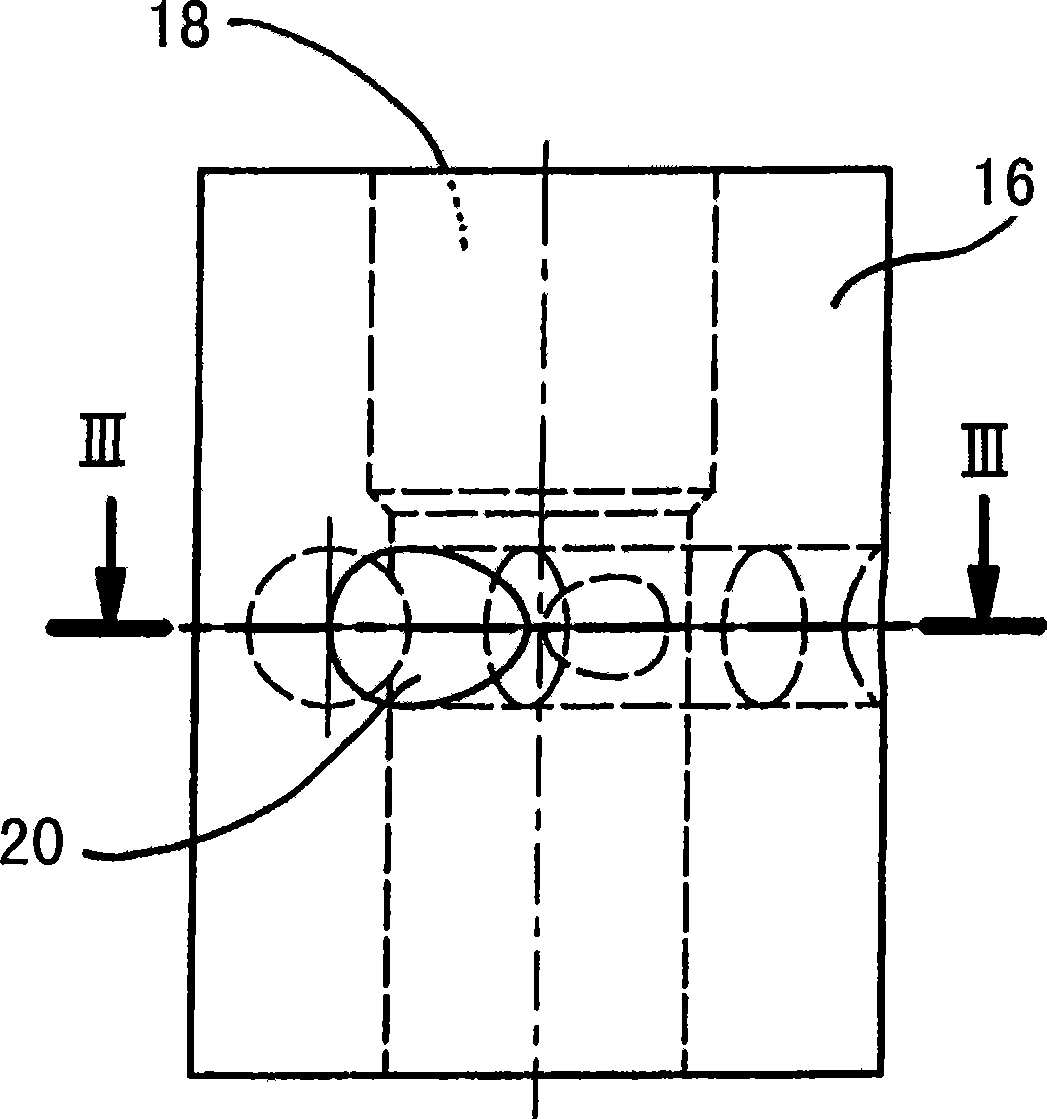

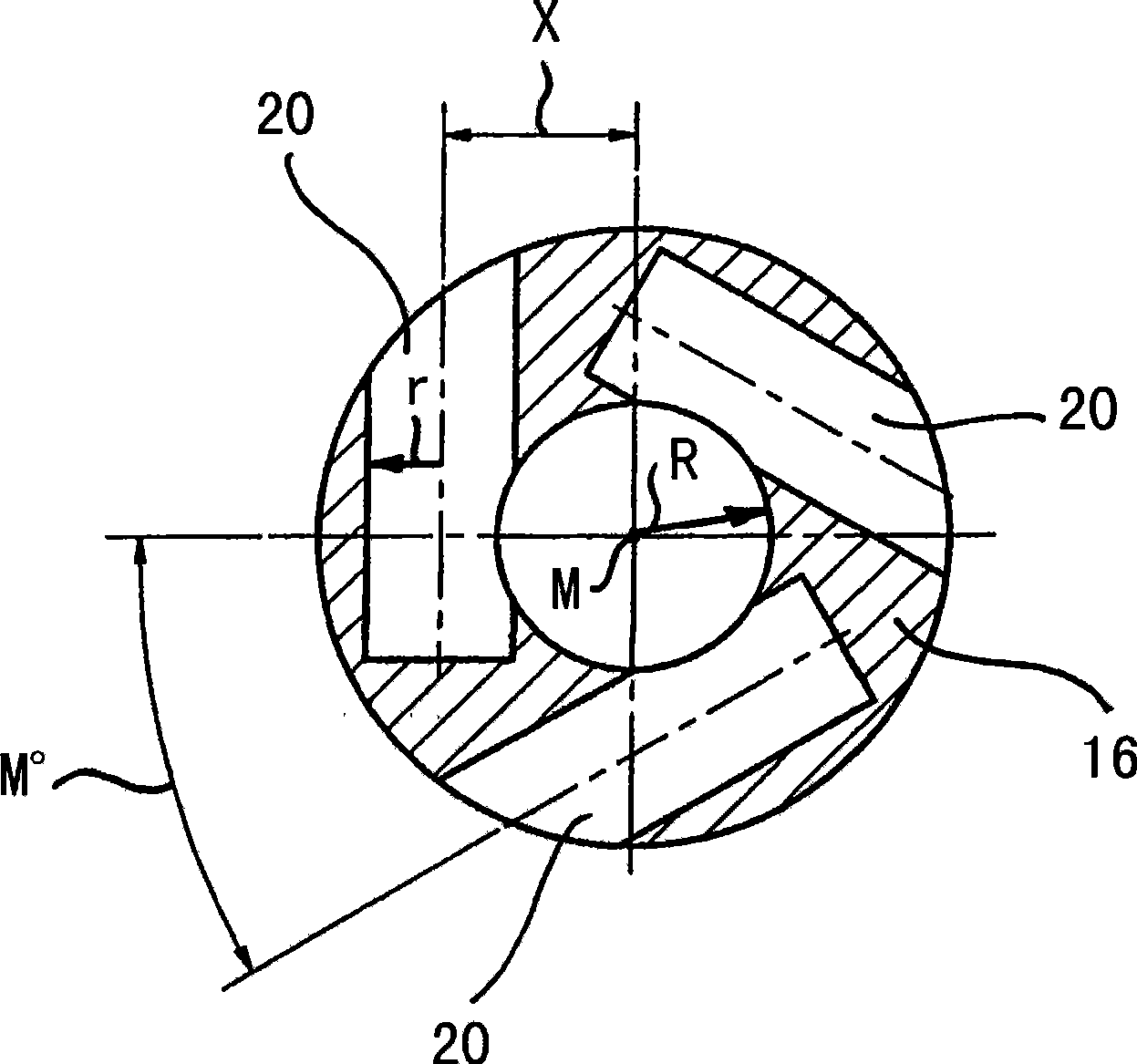

Screw Assembly and Method

InactiveUS20110046684A1High material hardnessHigh compressive yield strengthSuture equipmentsInternal osteosythesisBiomedical engineering

A screw assembly and method includes a coupling member comprising a semi-bulbous end; a fixator component that receives the semi-bulbous end of the coupling member; a resisting member mounted in the coupling member and comprising a mating member; a connection pin comprising a resisting member socket operatively connected to the mating member of the resisting member; and a blocker that engages the coupling member.

Owner:CUSTOM SPINE INC

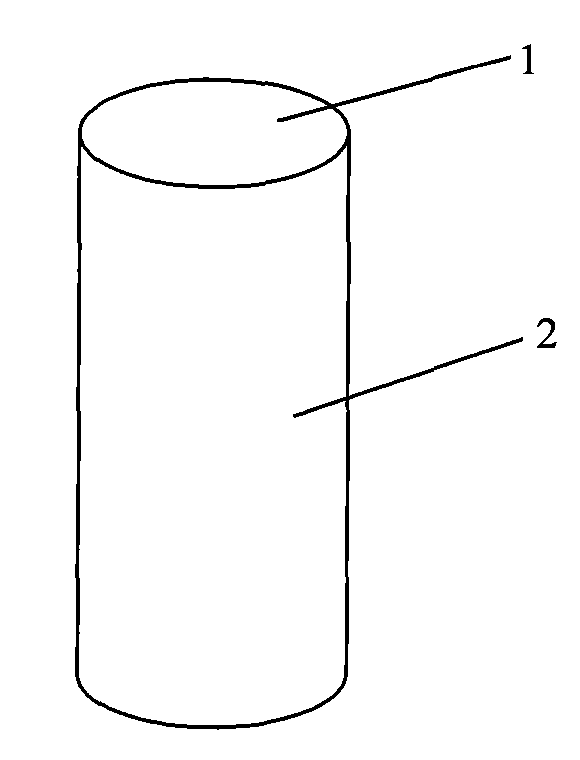

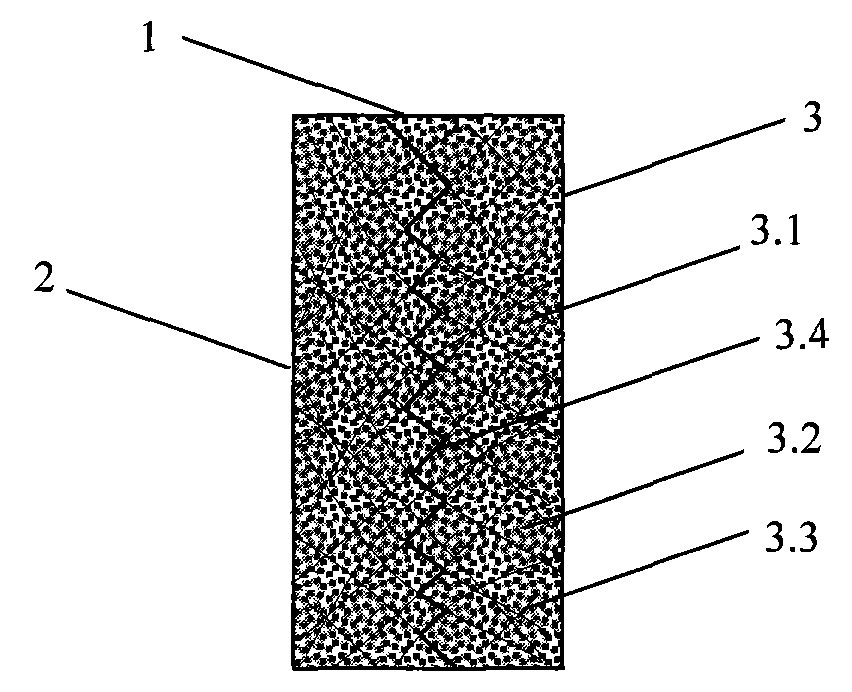

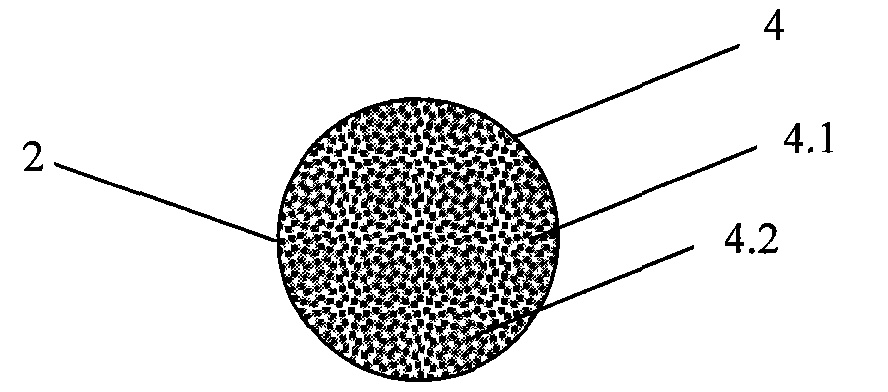

Standard test piece based on calibration permeability test

InactiveCN101587055ASolve the problem of changing permeability coefficientPrecise specification of permeabilitySurface/boundary effectPermeability/surface area analysisHeat resistanceOsmotic coefficient

The invention discloses a standard test piece based on a calibration permeability test. The standard test piece is in the shape of a solid cylinder and composed of a solid framework, gaps and pore canals. The solid framework has a firm structure and stably material properties. The material has high rigidity, good toughness, corrosion resistance, rust resistance, heat resistance and pressure resistance. The gaps are near-spherical, the aperture sizes are uniform, and the apertures are controlled in the range of 1-50 microns, the gaps are uniformly distributed inside the test piece and on surface thereof. The pore canals are intersected and the average pore opening extent of the interconnected pore canals passing through two end faces is controlled in the range of 0.1-5% on the cross section. The invention is detected by permeation for a long time, has constant permeability parameters, high efficiency, high reliability and strong practicality. By using the permeation coefficients of the invention as a reference standard, the invention provides a detection method and tool as reference for global permeability test technique. The standard test piece based on a calibration permeability test is applicable to all permeability tests and in particular to the precision and measuring range of a calibration low-permeability testing method and device.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Beryllium copper alloy

The Be-Cu alloy contains Be 0.2-0.6 wt%, Cr 0-0.5 wt%, Mn 1.8-3.0 wt%, Fe 1.8-3.0 wt% and Al 12.5-14.5 wt%, except Cu and inevitable small amount of impurity. It has hardness of HRC 42-52 deg, high heat conductivity, small friction coefficient, high wear resistance, high anticorrosion, smoothness and long service life.

Owner:宋协福

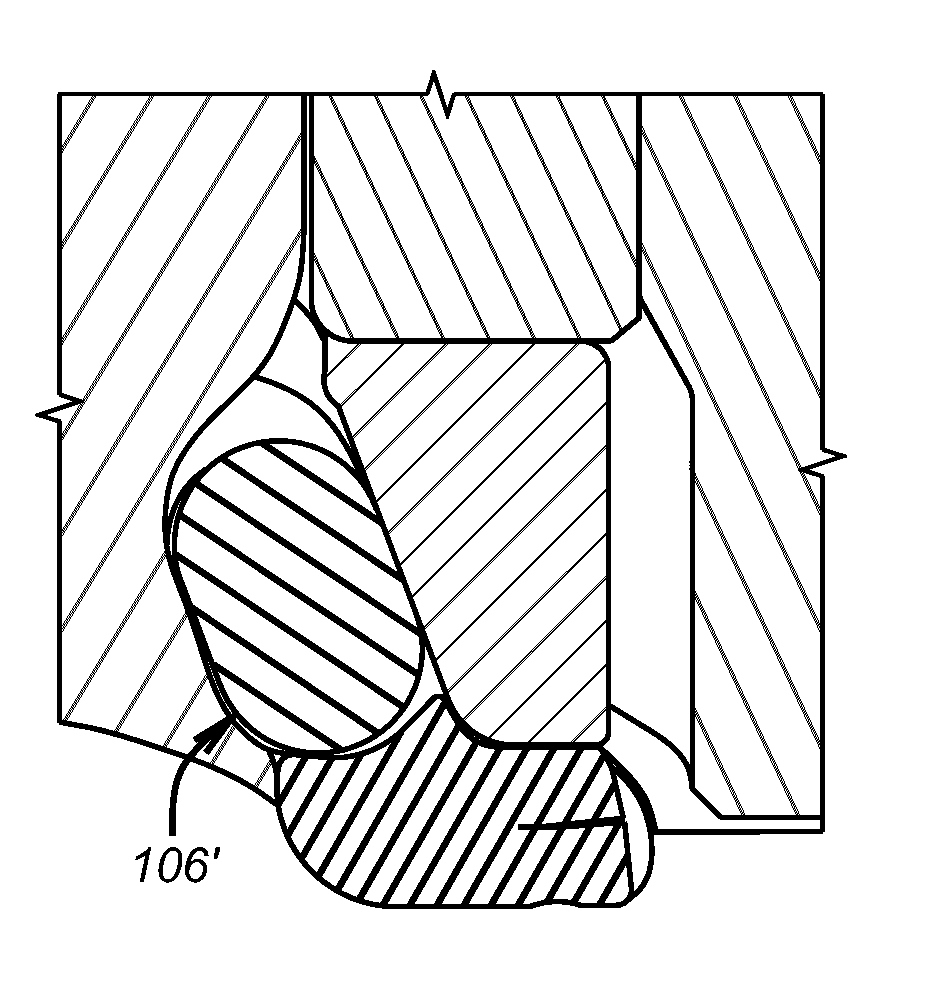

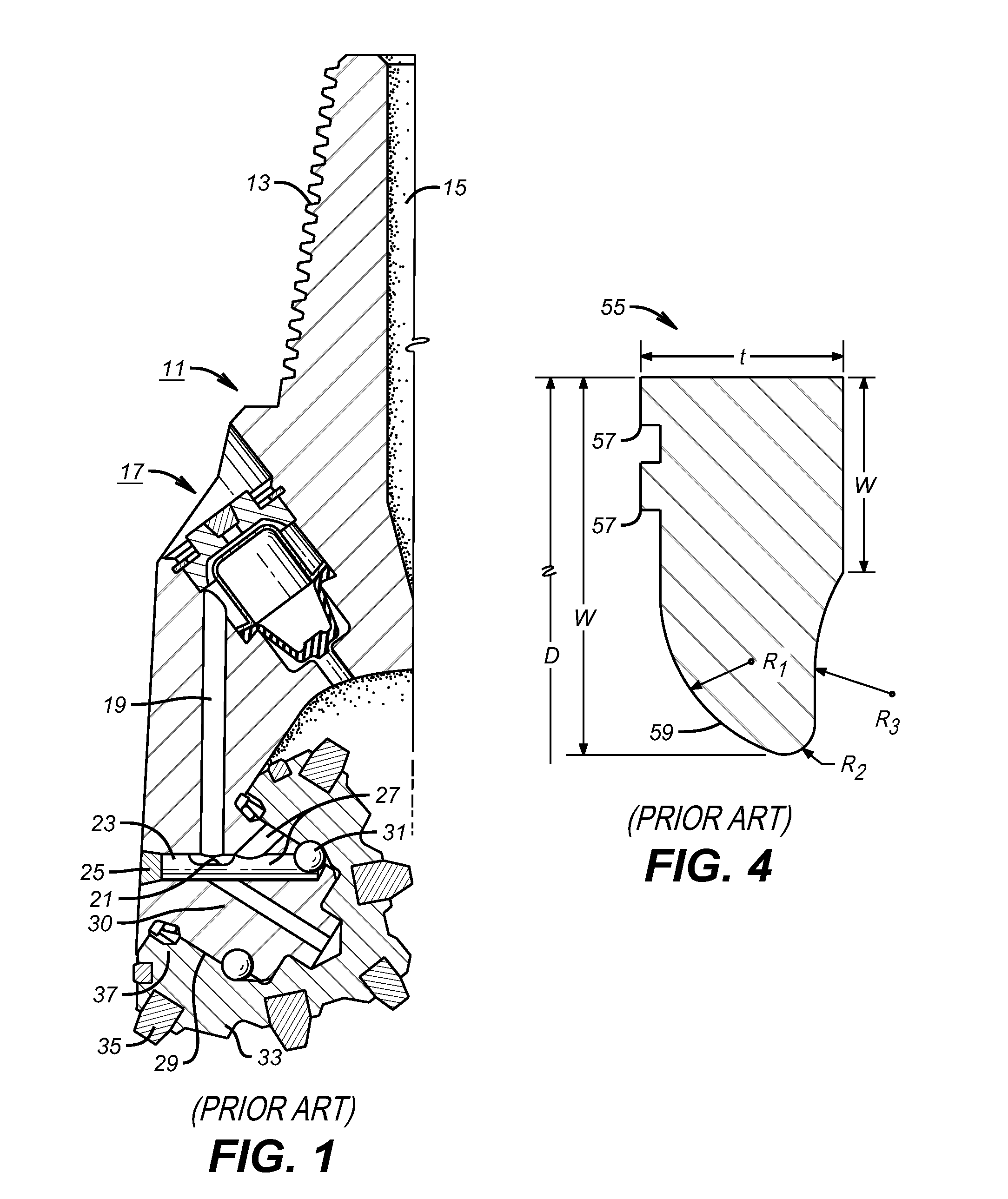

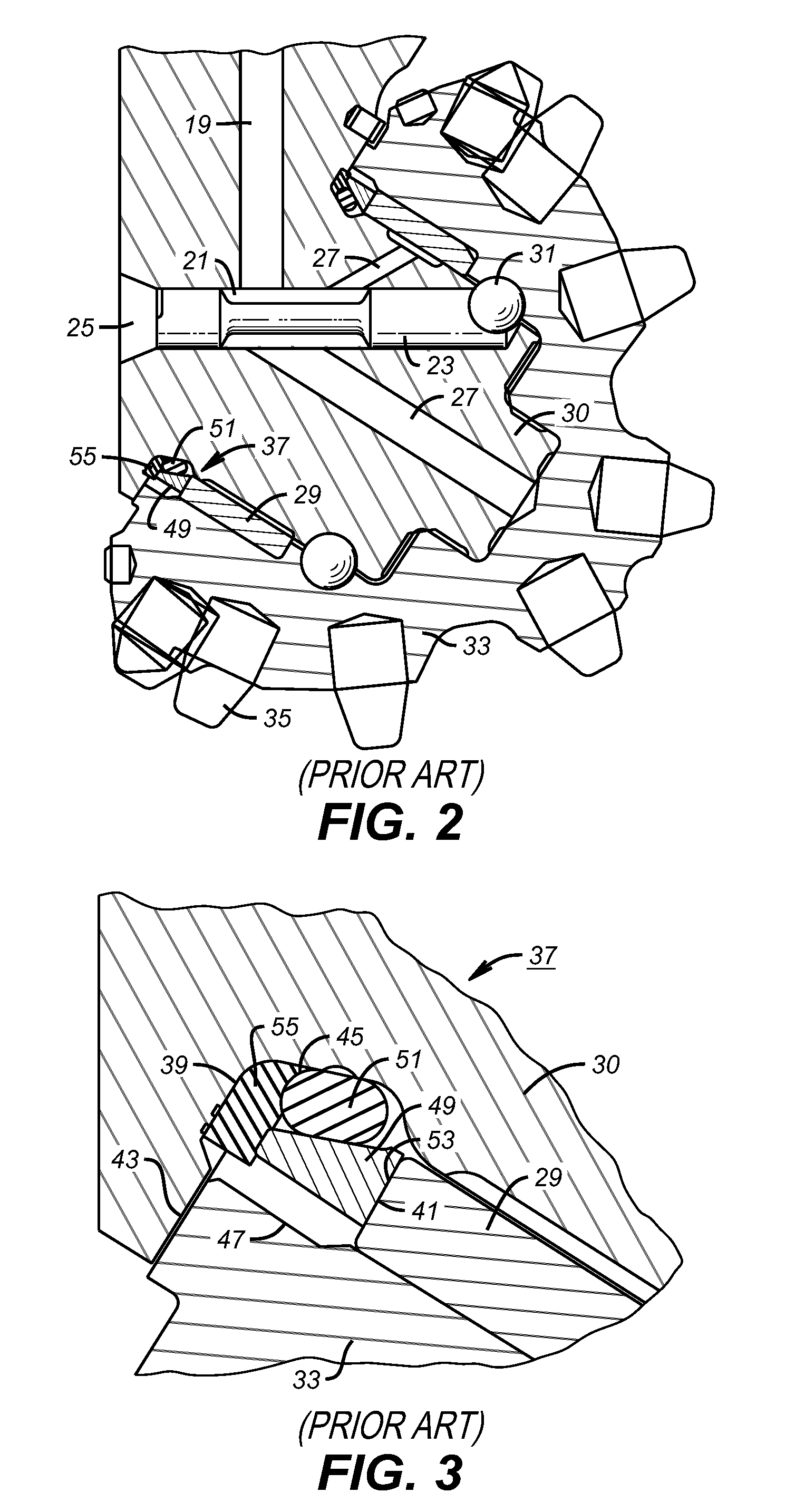

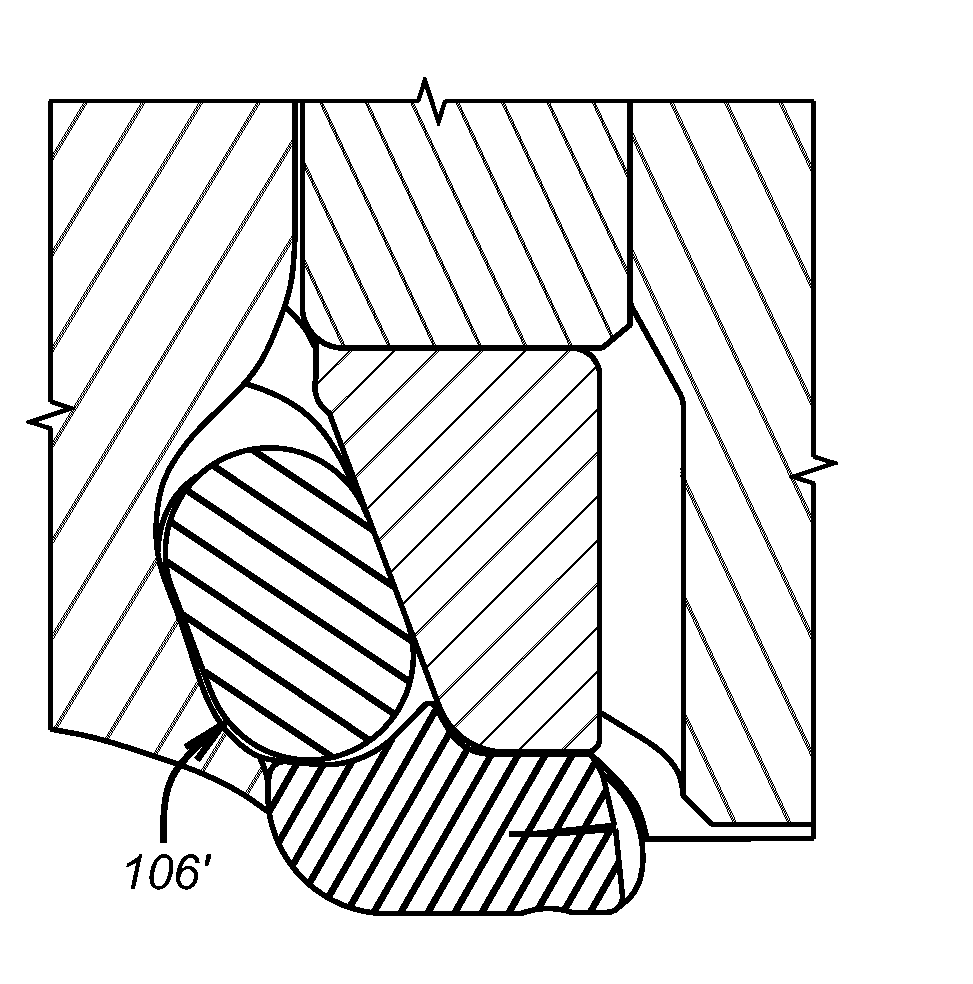

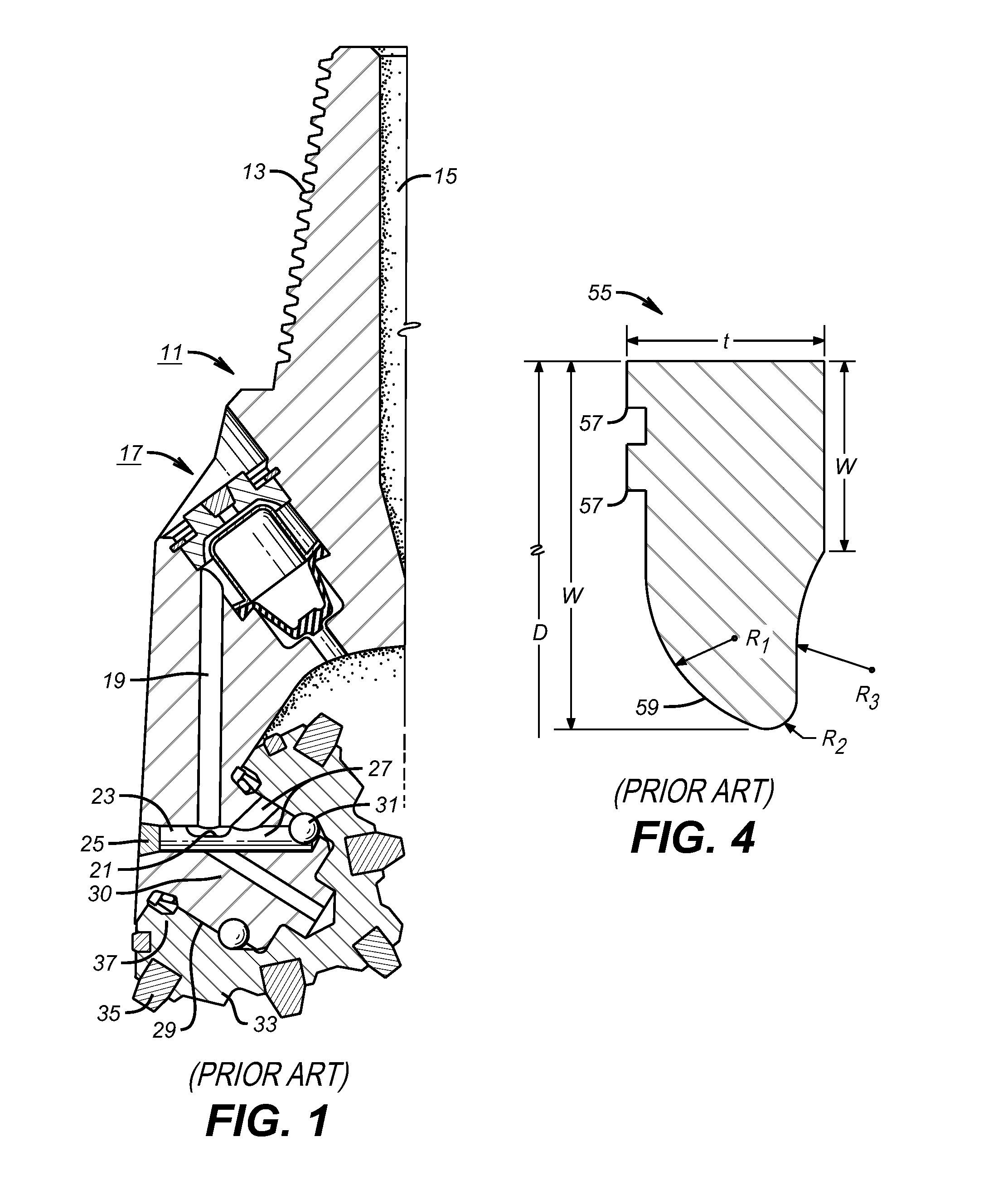

Enhanced Backup Ring Features for Metal Face Seal in Roller Cone Drill Bits

ActiveUS20140225327A1Increase forceIncrease edge densityEngine sealsConstructionsEdge regionEngineering

A backup ring for a face seal in a roller cone bit is configured to resist wear from drilling fluids present adjacent exposed faces of the backup ring. Portions are removed from an exposed end face in a variety of shapes while the hardness of the material is increased. The removal of material offsets an increase in force that would be transmitted through the backup ring on face seal assembly due to flexing. A spring can optionally be included in the removed material location. Another way is to increase the edge density of all or part of the exposed edges while leaving the interior portions unaffected by using electron beam radiation to increase the crosslink density or by other techniques that allow a unitary structure with a more durable edge region.

Owner:BAKER HUGHES INC

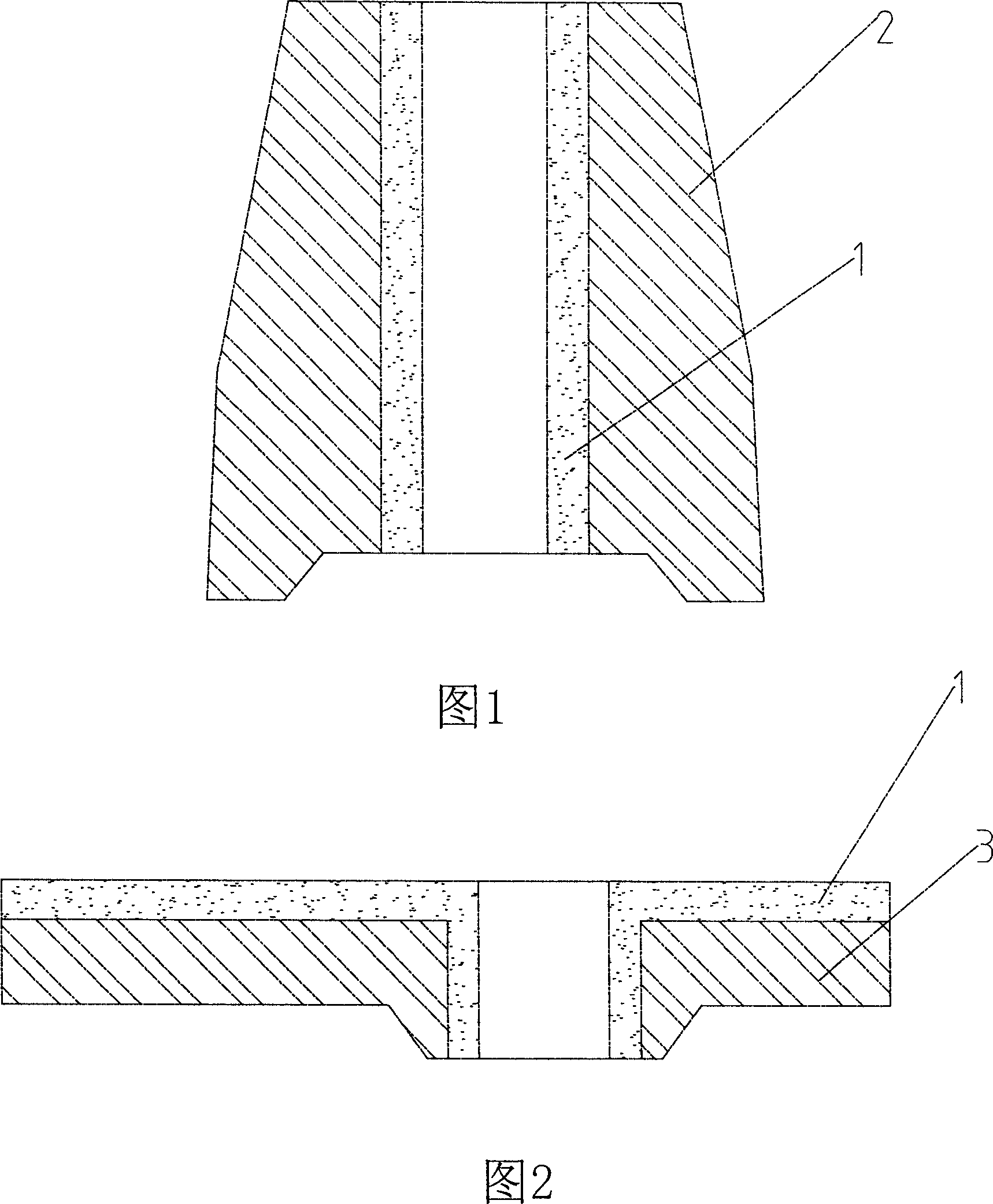

Slide gate nozzle brick utilized in metallurgic cast and prepn. thereof

InactiveCN1415447AHigh material hardnessImprove surface finish and hardnessMelt-holding vesselsCorrosionMaterial hardness

A sliding sprue brick for metallurgical casing features that at least its surficial working layer is prepared from high-Al2O3 refractory aggragate (75-98 wt.%) and metallic microparticles (2-25 wt% whose smelting point is less than 1000 deg.C through mixing and calcining at 400-1300 deg.C in neutral or reductive atmosphere. Its advantages are high resistance to oxidization, corrosion, heat shock and high-temp water, and high strength.

Owner:YIXING REFRACTORY MATERIAL

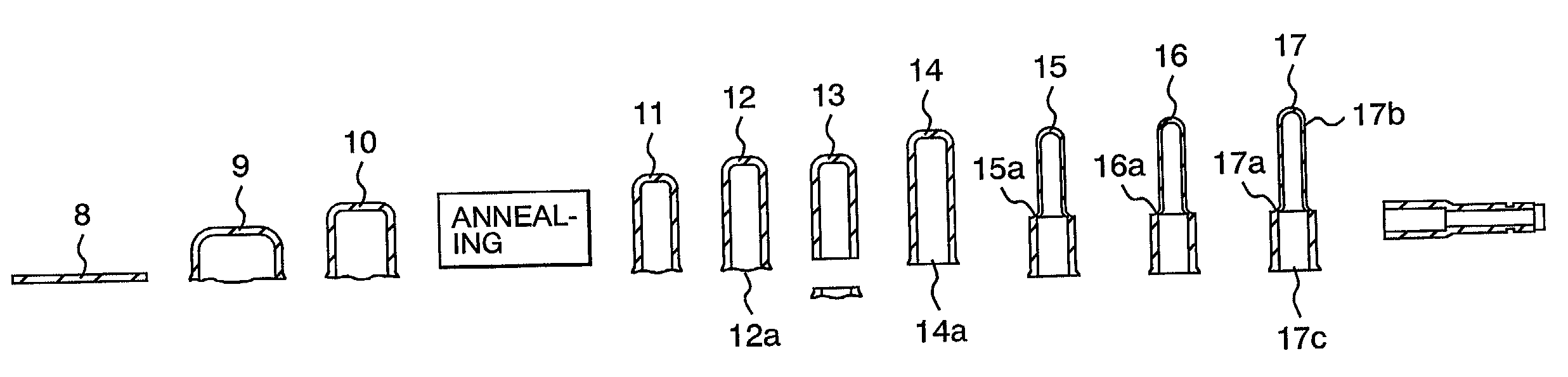

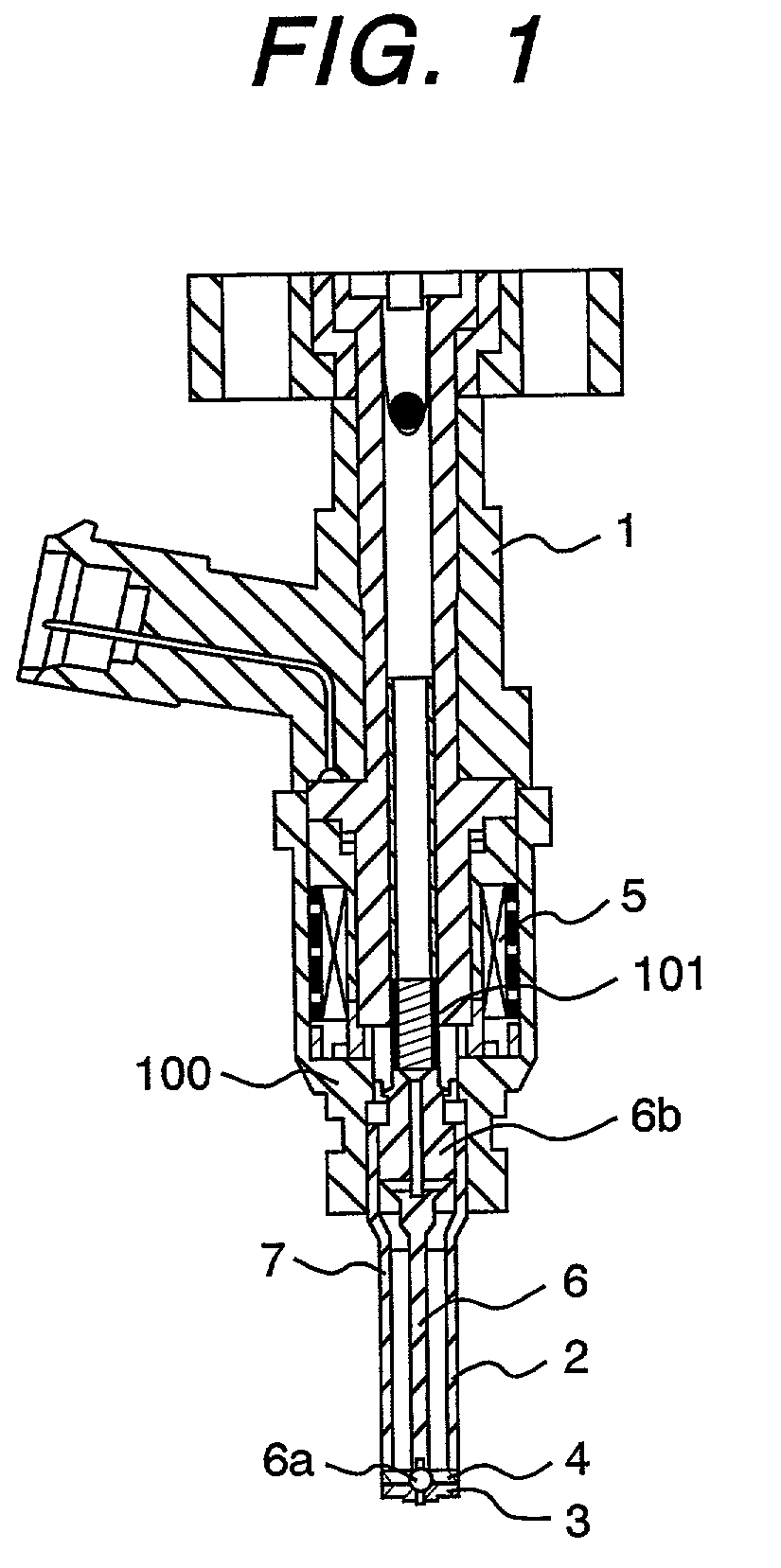

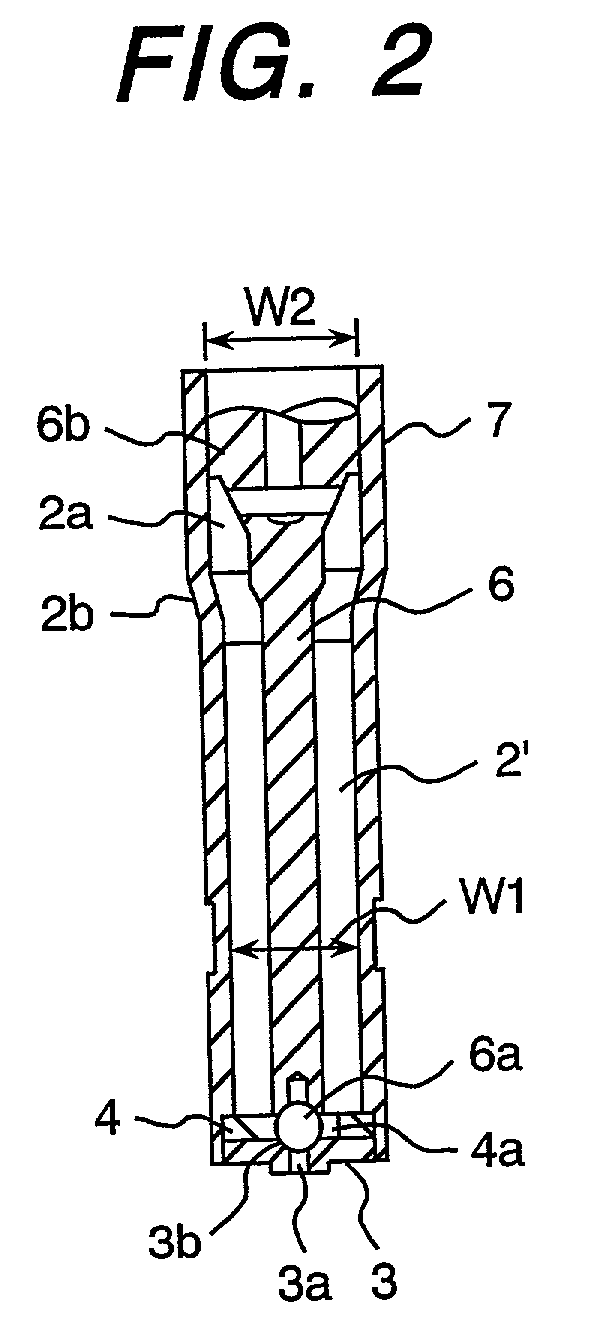

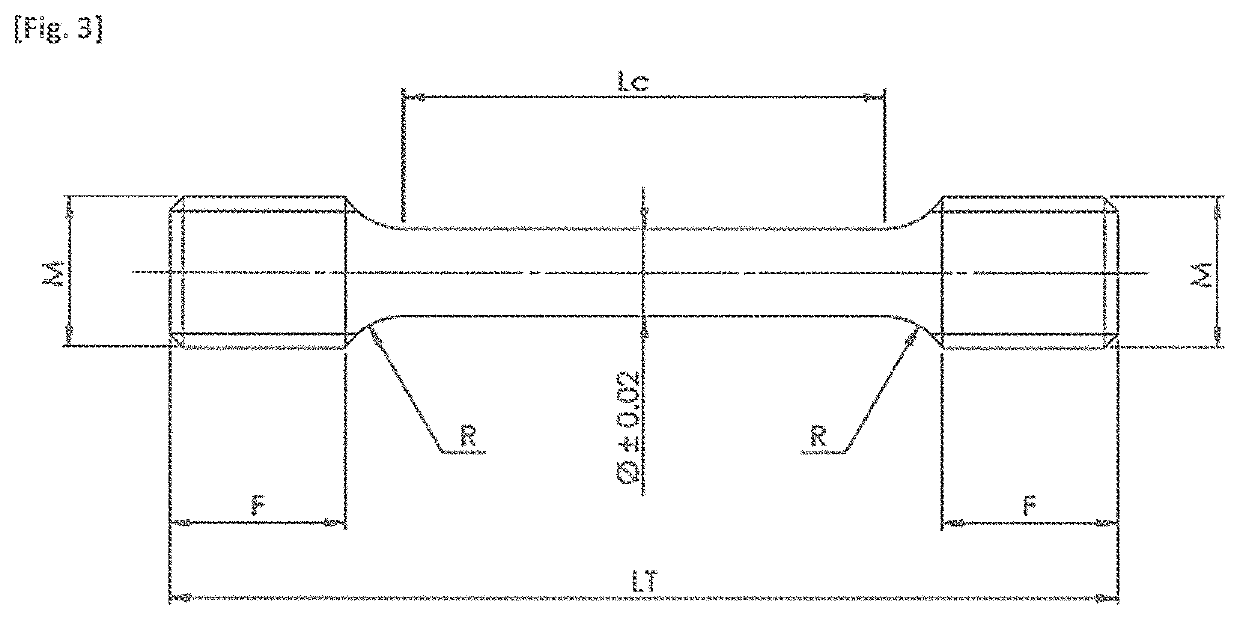

Fuel injector, nozzle body, and manufacturing method of cylindrical part equipped with fluid passage

InactiveUS6976381B2Great drawing ratioReduce residual stressOperating means/releasing devices for valvesSpray nozzlesProduction rateHigh productivity

To manufacture a cylindrical member, such as the nozzle body of a fuel injector, in which a fluid passage is formed at high productivity and to improve the reliability.A cylindrical member, such as the nozzle body of a fuel injector, in which a fluid passage is formed is manufactured by drawing martenstic stainless steel. In addition, during the drawing process of martenstic stainless steel, an intermediate product is annealed and lug is removed after another drawing process, and then is subjected to drawing again to obtain a product.

Owner:HITACHI LTD

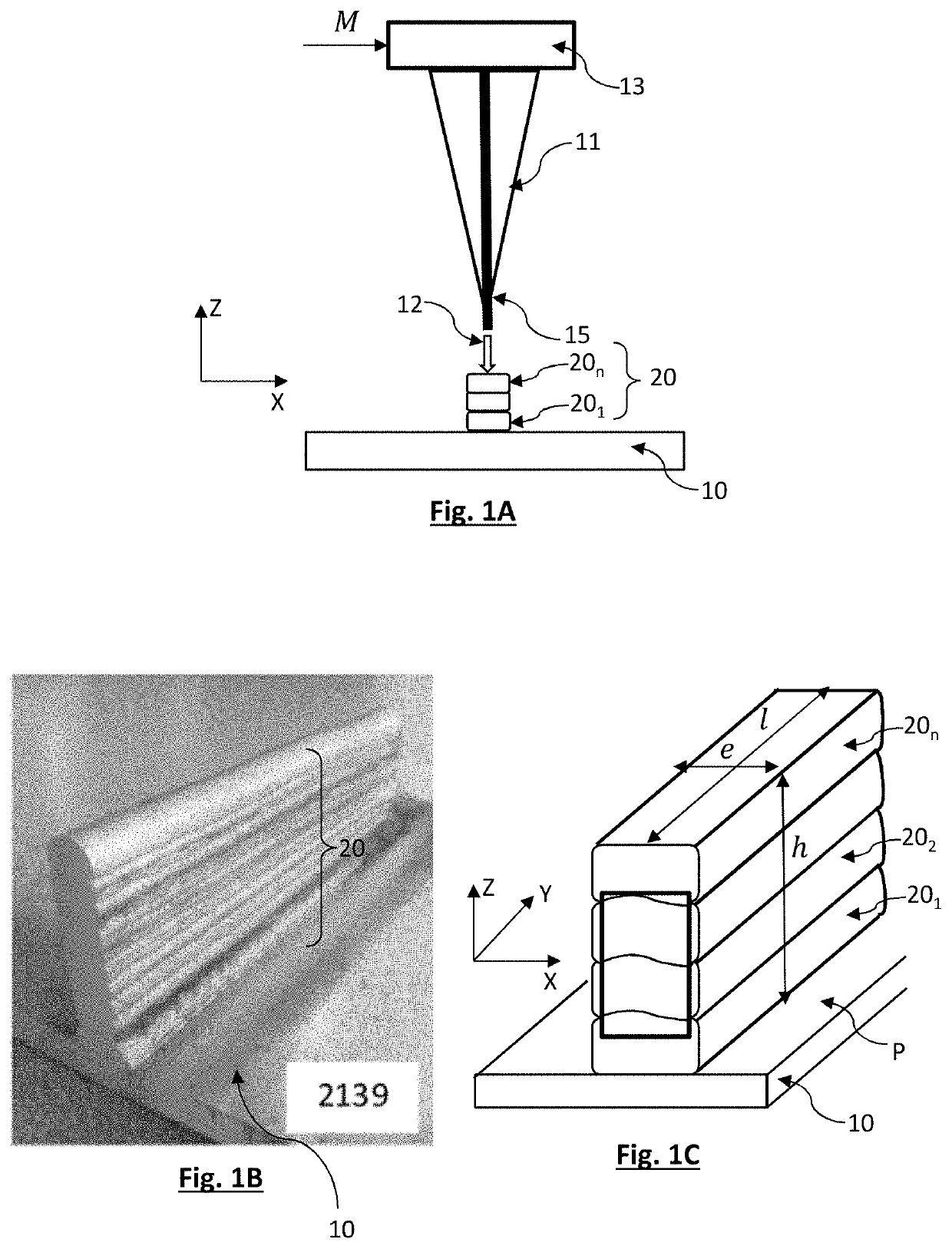

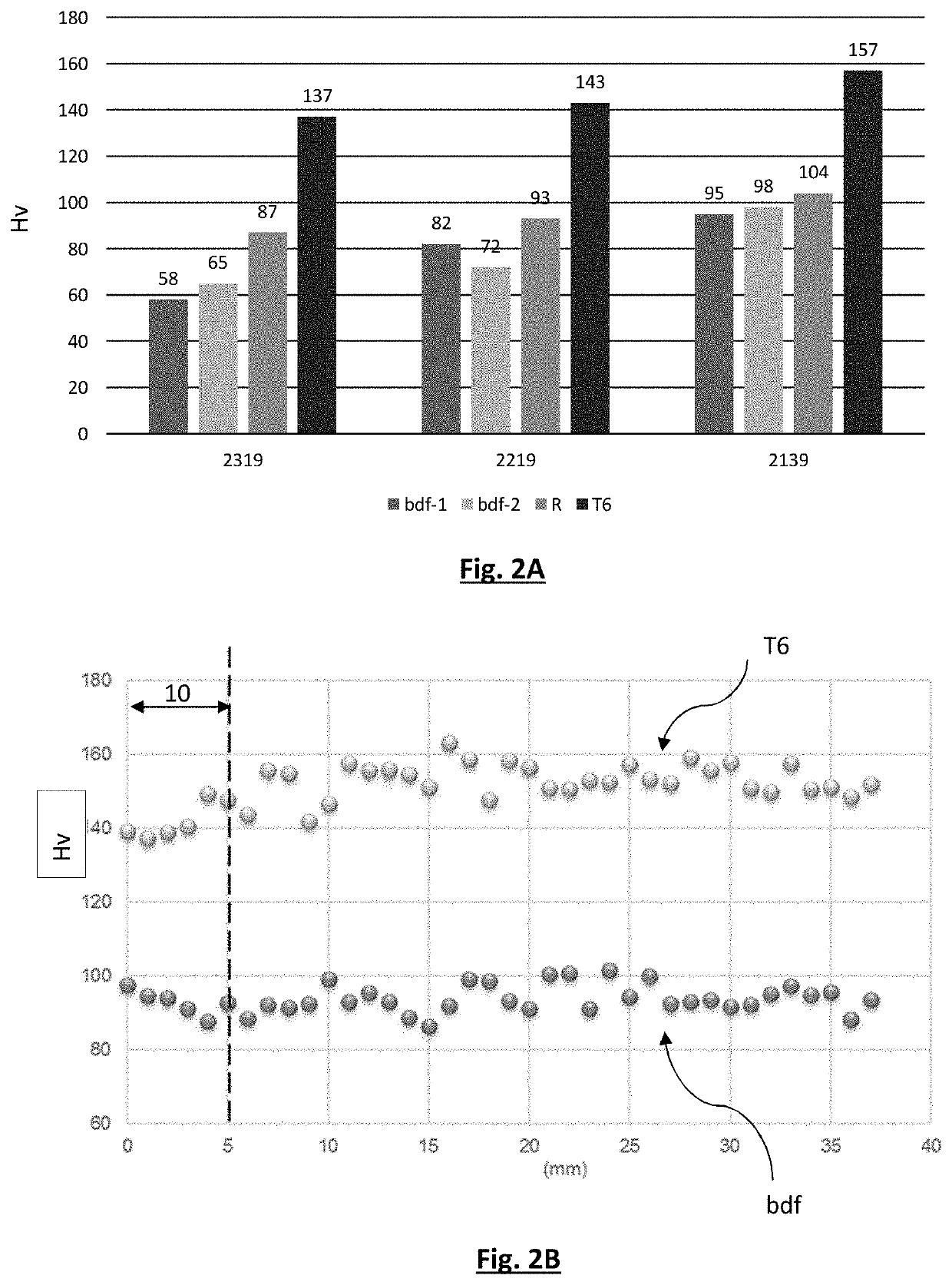

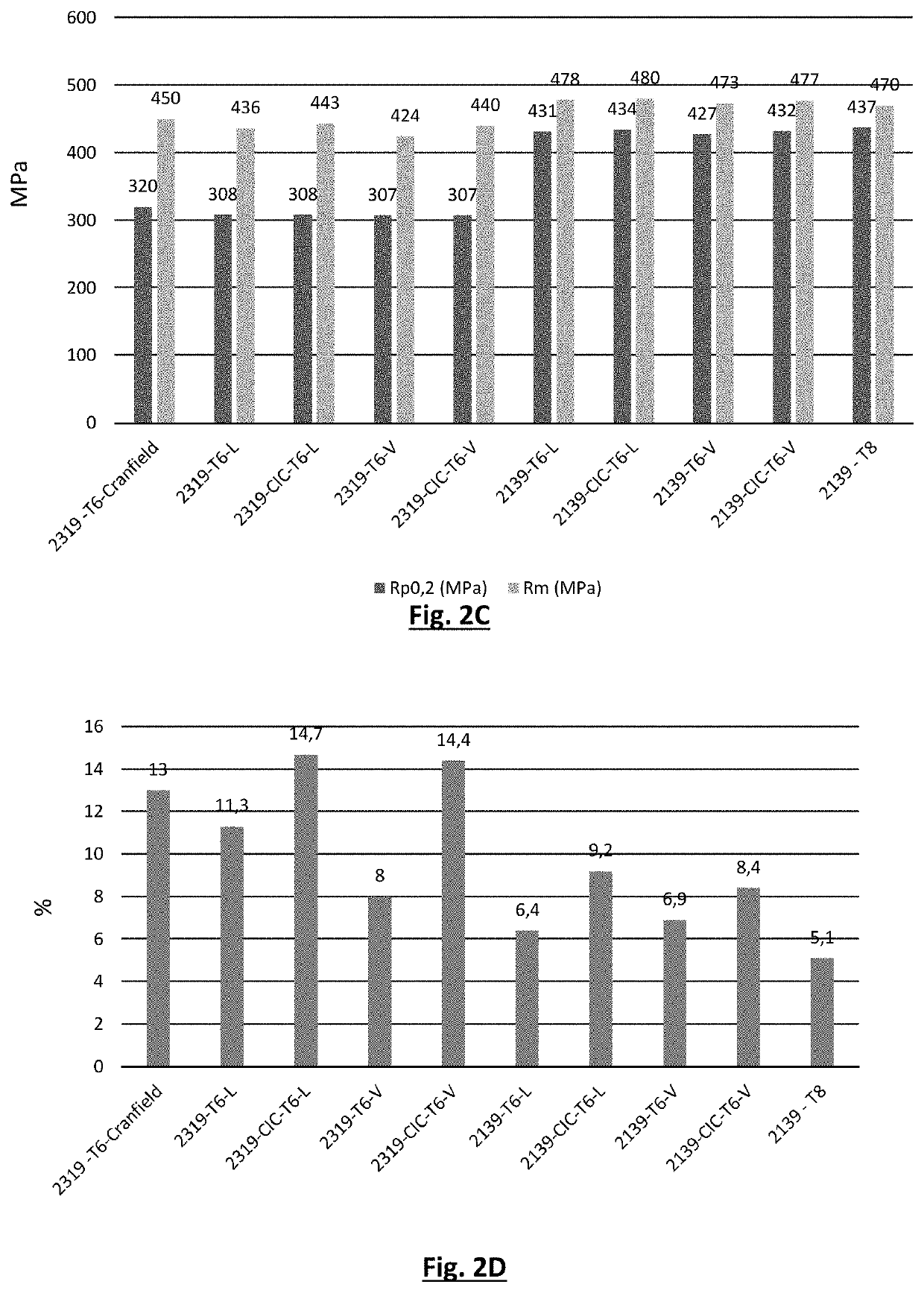

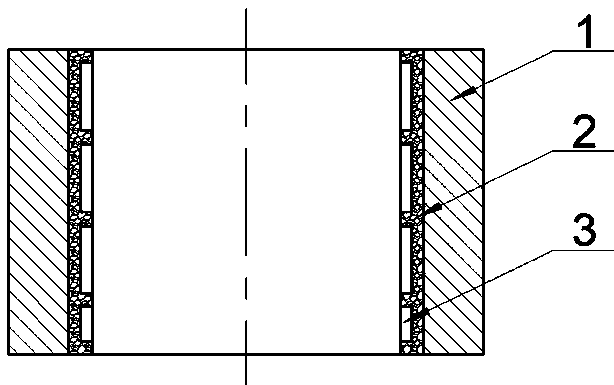

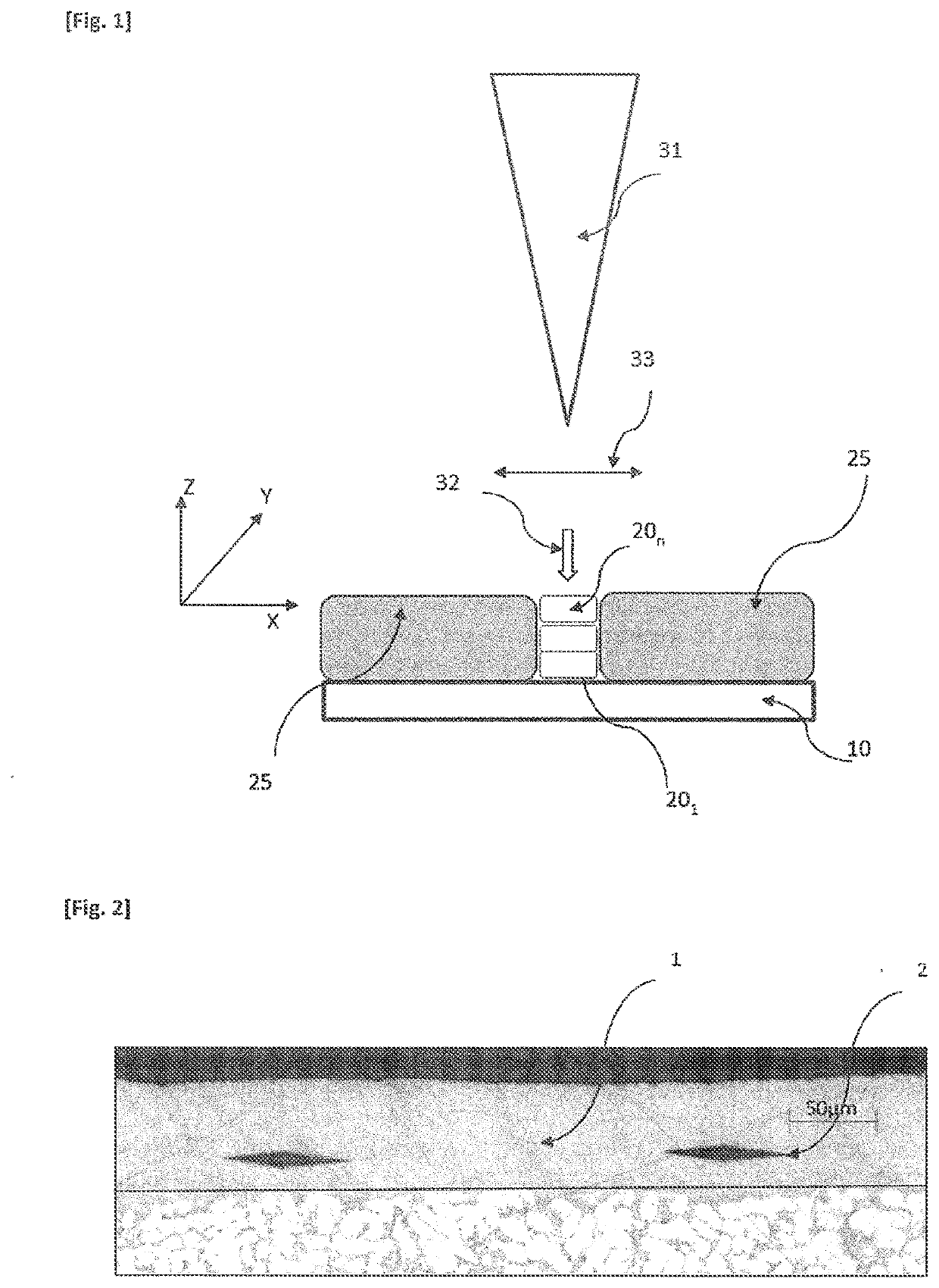

Process for manufacturing an aluminum alloy part

PendingUS20200156154A1High material hardnessHigh hardnessAdditive manufacturing apparatusIncreasing energy efficiencyAlloy elementFiller metal

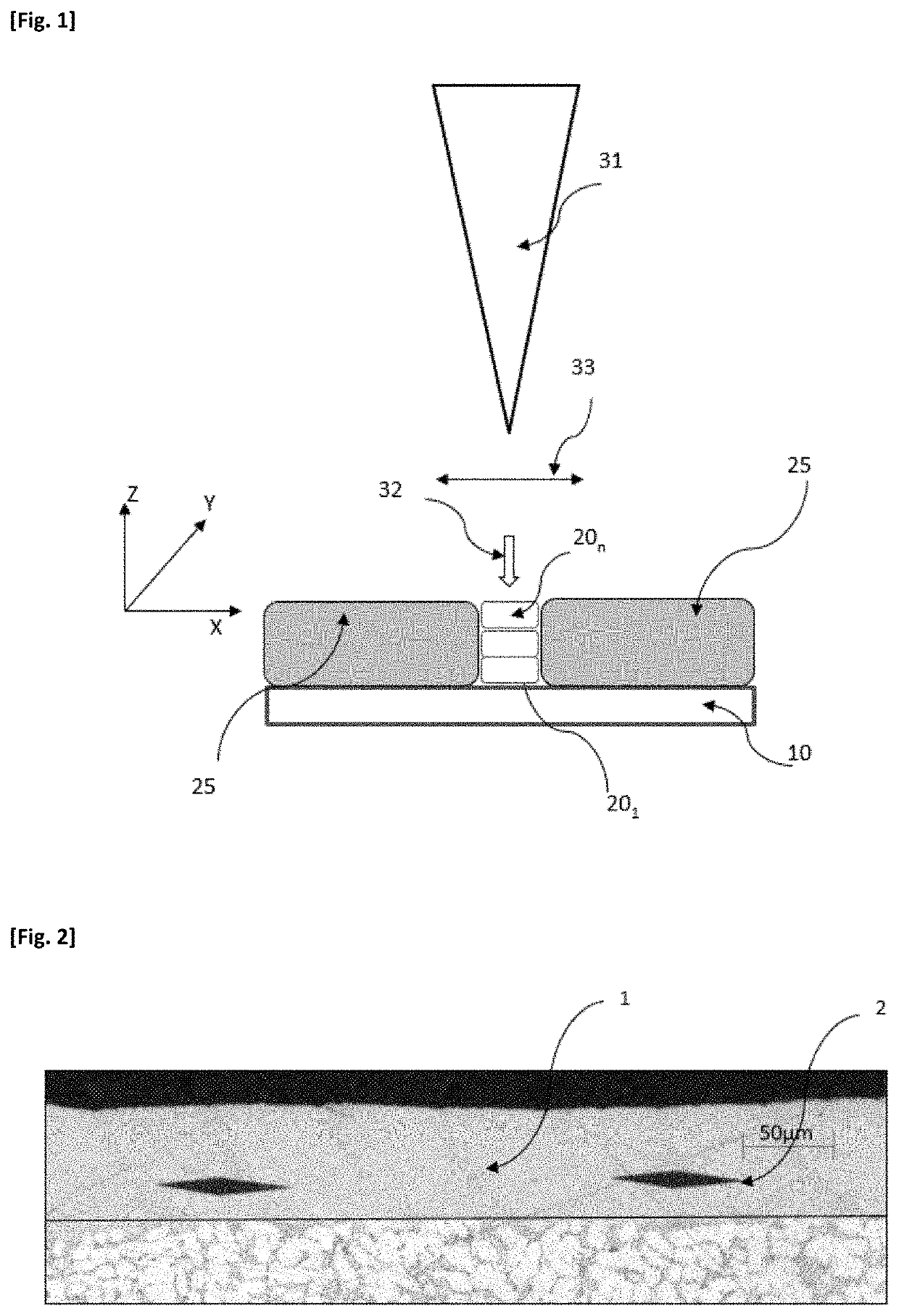

The present invention relates to a process for manufacturing a part (20) comprising a formation of successive metal layers (201 . . . 20n), superimposed on one another, each layer describing a pattern defined from a numerical model, each layer being formed by the deposition of a metal (15, 25), referred to as a filling metal, the filling metal being subjected, at a pressure greater than 0.5 times the atmospheric pressure, to an input of energy so as to melt and constitute said layer, the process being characterized in that the filling metal is an aluminium alloy of the 2xxx series, comprising the following alloying elements:Cu, in a weight fraction of between 3% and 7%;Mg, in a weight fraction of between 0.1% and 0.8%;at least one element, or at least two elements or even at least three elements chosen from:Mn, in a weight fraction of between 0.1% and 2%, preferably of at most 1% and in a preferred manner of at most 0.8%;Ti, in a weight fraction of between 0.01% and 2%, preferably of at most 1% and in a preferred manner of at most 0.3%;V, in a weight fraction of between 0.05% and 2%, preferably of at most 1% and in the preferred manner of at most 0.3%;Zr, in a weight fraction of between 0.05% and 2%, preferably of at most 1% and in a preferred manner of at most 0.3%;Cr, in a weight fraction of between 0.05% and 2%, preferably of at most 1% and in the preferred manner of at most 0.3%; andoptionally at least one element, or at least two elements or even at least three elements chosen from:Ag, in a weight fraction of between 0.1% and 0.8%;Li, in a weight fraction of between 0.1% and 2%, preferably 0.5% and 1.5%;Zn, in a weight fraction of between 0.1% and 0.8%.

Owner:C TEC CONSTELLIUM TECH CENT

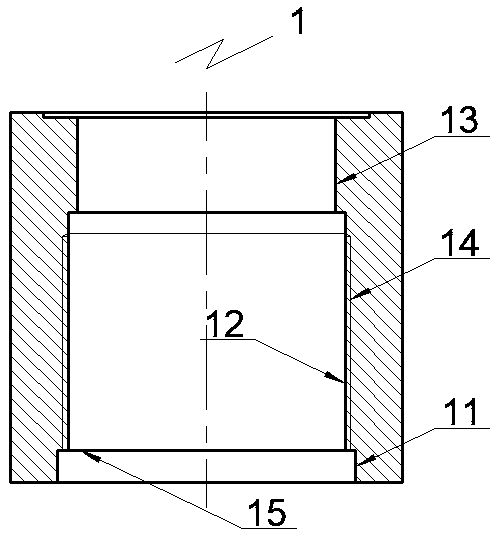

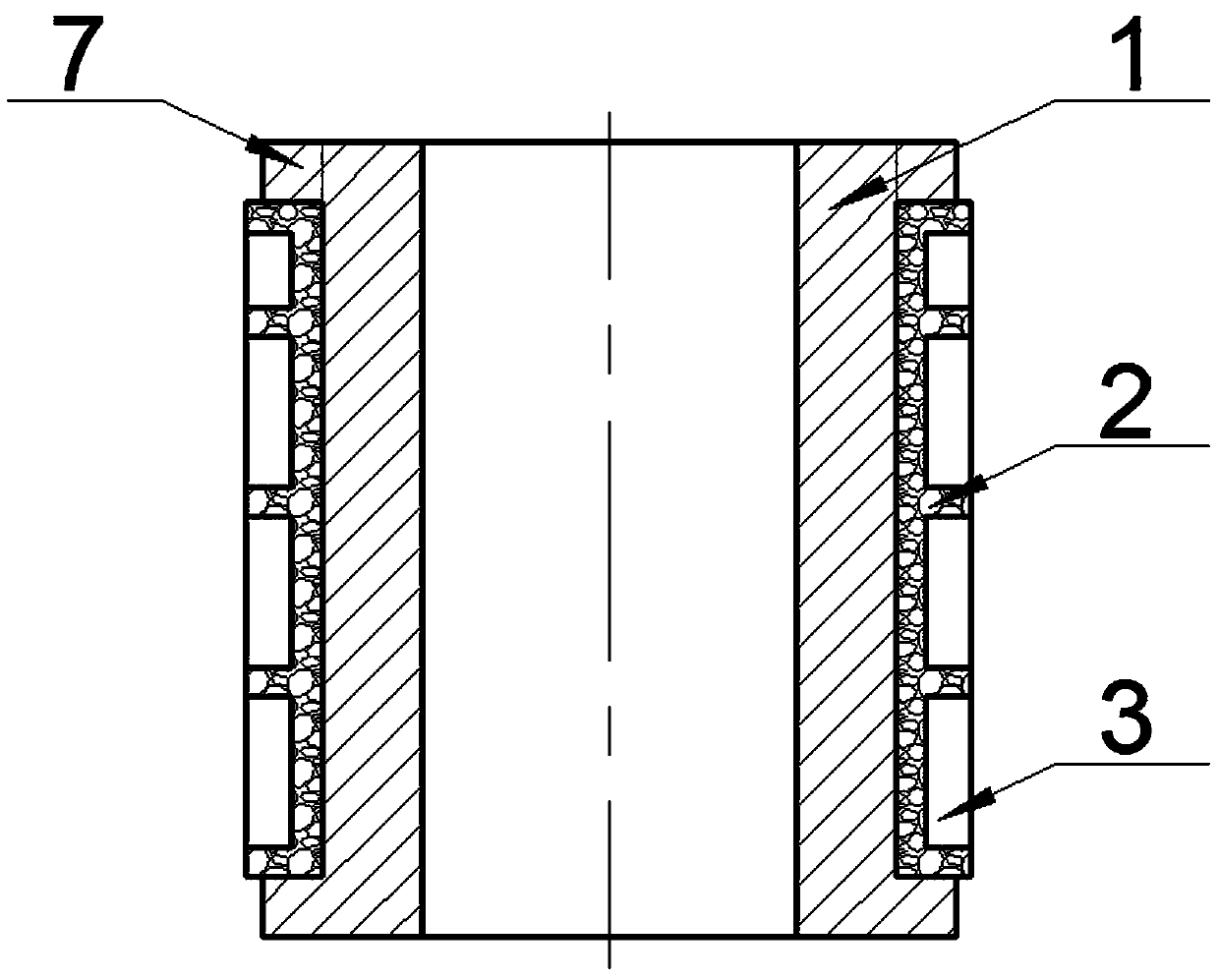

Manufacturing method of radial strengthening sliding bearing static ring

The invention provides a manufacturing method of a radial strengthening sliding bearing static ring. The method comprises the steps that a static ring manufacturing mold is acquired, the mold comprises a core mold and a matrix coaxially placed outside the core mold, annular space is formed between the core mold and the matrix, and containing space is formed among the core mold, the matrix and a cover plate; a locating datum is arranged, a to-be-bonded component is cleaned, and a wear-resisting part is bonded to the outer cylinder face of the core mold; filler is assembled, cast tungsten carbide powder is dumped into the residual clearance of the annular space, locating powder is placed into the position above the cast tungsten carbide powder to form a locating layer, then a certain quantity of a bonding alloy is placed according to the proportion, a certain quantity of a fluxing agent is evenly scattered on the bonding alloy according to the proportion, and the mold is covered with thecover plate; the assembled and filled mold is sintered, and a static ring blank is obtained; and after air cooling, the static ring blank is machined, and the size of the static ring can meet the design requirements. By means of the method, the work life of a radial strengthening sliding bearing can be prolonged, and meanwhile the machining difficulty and manufacturing cost can be reduced.

Owner:BEIJING CHUNLUN PETROLEUM TECH DEV CO LTD

Copper alloy of drawing mould

The Cu alloy for drawing mold contains Cr 0-0.5 wt%, Mn 1.8-4.0 wt%, Fe 1.8-4.0 wt% and Al 12.5-14.5 wt%, except Cu and inevitable small amount of impurity. It has hardness of HRC 42-50 deg, high heat conductivity, good machinability, small friction coefficient, high wear resistance, high anticorrosion, smoothness and long service life. It is used mainly in machining stainless steel drawing mold, thin sheet drawing mold, steel pipe forming roller, automobile and motorcycle steel ring machining roller, gear for heavy machinery, etc.

Owner:宋协福

Process for manufacturing an aluminum alloy part

PendingUS20210269896A1High hardnessEffect mechanical strengthAdditive manufacturing apparatusIncreasing energy efficiencyNumerical modelsFiller metal

The invention relates to a process for manufacturing a part, involving forming consecutive solid metal layers (201 . . . 20n) that are stacked on top of one another, each layer describing a pattern defined on the basis of a numerical model {M), each layer being formed by depositing a metal (25), referred to as filling metal, the filling metal being subjected to an input of energy so as to melt and constitute said layer upon solidifying, the filling metal being in the form of a powder (25) that is exposed to an energy beam (32), resulting in melting followed by solidification such that a solid layer (201 . . . 20n) is formed, the process being characterized in that the filling metal (25) is an aluminum alloy comprising at least the following alloying elements: —Ni, in a moiety of 1 to 6%, preferably 1 to 5.5%, more preferably 2 to 5.5%; —Cr, in a moiety of 1 to 7%, preferably 3 to 6.5%; —Zr, in a moiety of 0.5 to 4%, preferably 1 to 3%; —Fe, in a moiety of no more than 1%, preferably between 0.05 and 0.5%, more preferably between 0.1 and 0.3%; —Si, in a moiety of no more than 1%, preferably no more than 0.5%. The invention also relates to a part obtained by said process. The alloy used in the additive manufacturing process according to the invention makes it possible to obtain parts with remarkable features.

Owner:C TEC CONSTELLIUM TECH CENT

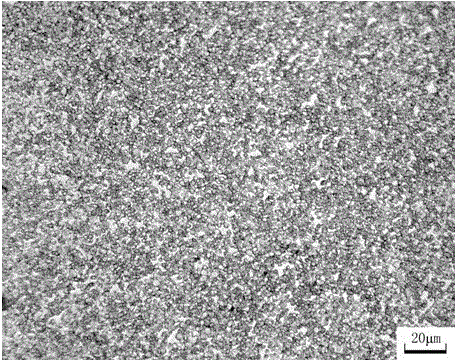

Method for preparing SiGe thermoelectric material

InactiveCN108258110APrevent oxidationRapid alloyingThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsAlloy

The invention discloses a method for preparing a SiGe thermoelectric material. According to the method, Si powder, Ge powder, B powder or P blocks are mixed according to a determined molar ratio; obtained mixtures are loaded into hard steel ball mill tanks under the protection of an Ar inert atmosphere; ball-milling and alloying are performed on the mixtures through using a planetary ball mill, sothat single-phase SiGe thermoelectric material powder is obtained; the single-phase SiGe thermoelectric material powder is subjected to discharge plasma sintering at 1150 DEG C, so that dense blockscan be obtained. The P type and N type SiGe alloy prepared by the method for preparing the SiGe thermoelectric material of the present invention have high electrical conductivity, high Seebeck coefficients and high power factors. The method for preparing the SiGe thermoelectric material of the invention has the advantages of high synthesis speed, simplicity, convenience, high efficiency and wide application prospect.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

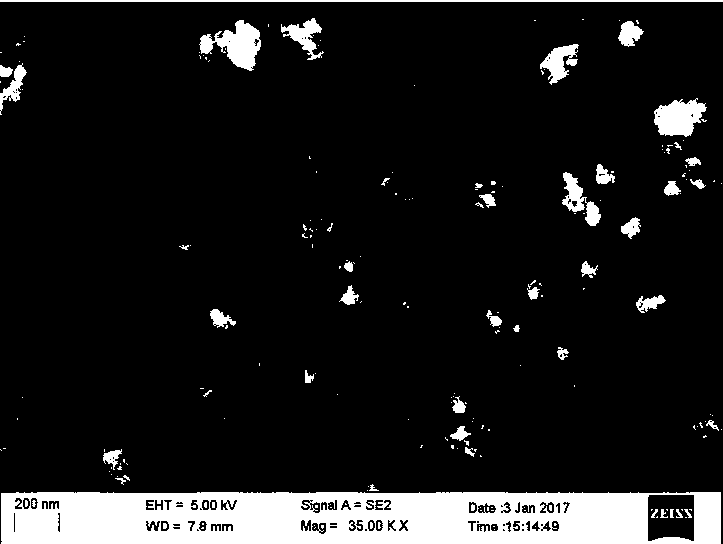

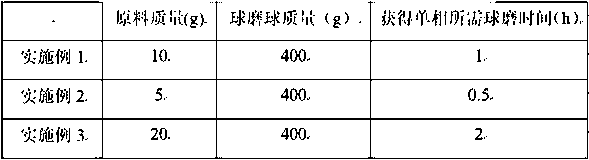

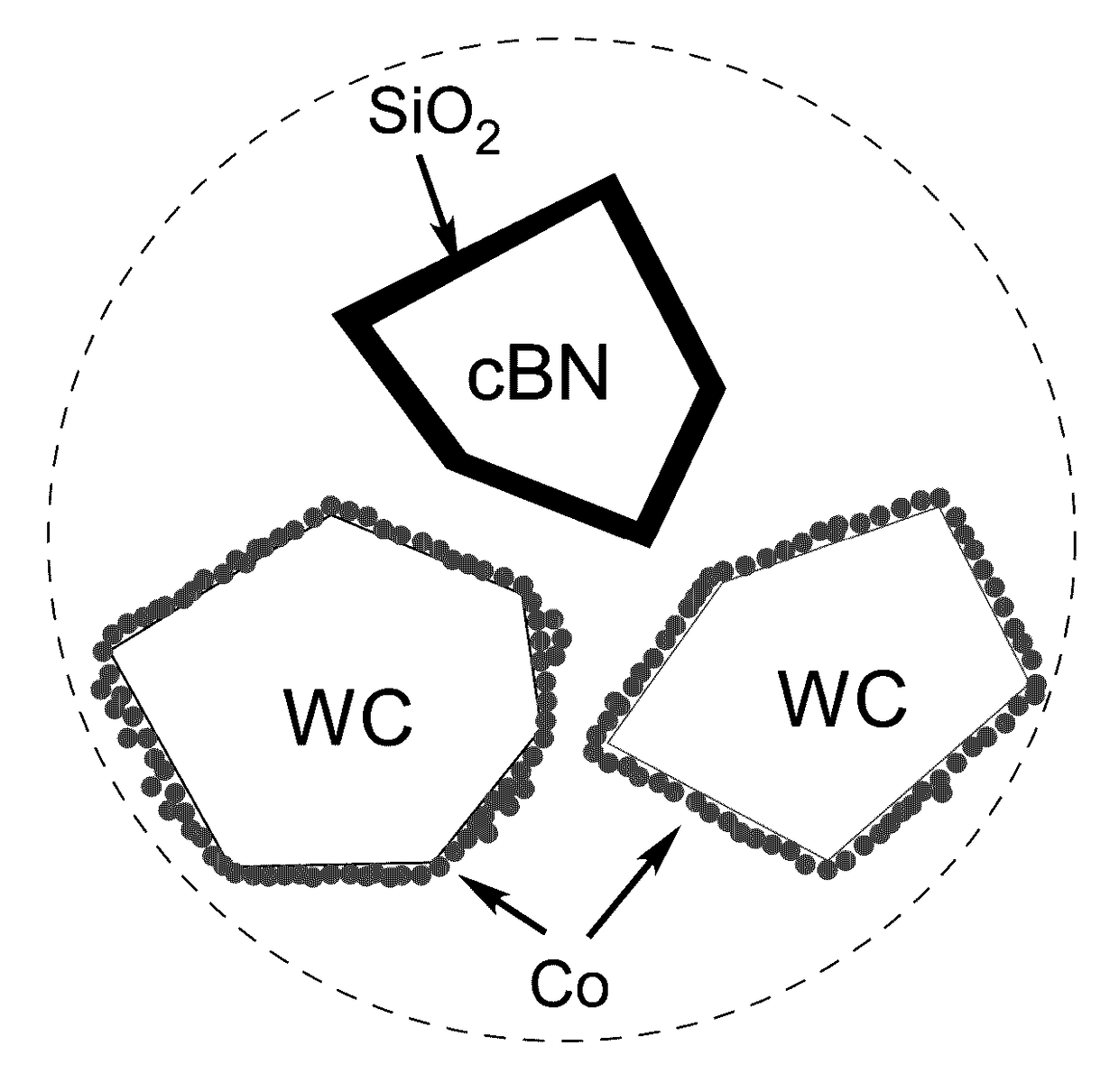

Tungsten carbide-cubic boron nitride composite material and preparation method thereof

A tungsten carbide-cubic boron nitride composite material and preparation method thereof mainly includes WC and cBN, wherein the WC powder is coated with Co nano-layer and the cBN powder is coated with SiO2 nano-layer, and hardness and toughness of the composition material can be improved by coating. The method for preparing a tungsten carbide-cubic boron nitride composite material adopts chemical vapor deposition method and high temperature sintering method. First nano-layers were coated on the surface of WC and cBN, and then the bulk materials can be obtained via high-temperature sintering.

Owner:HOHAI UNIV

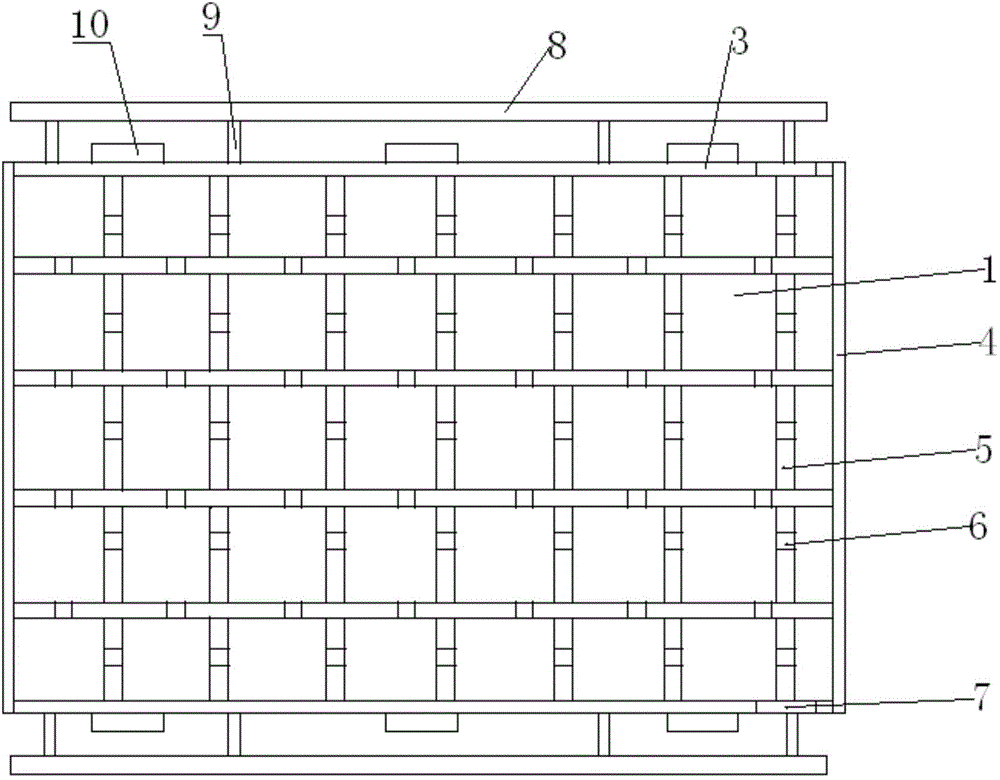

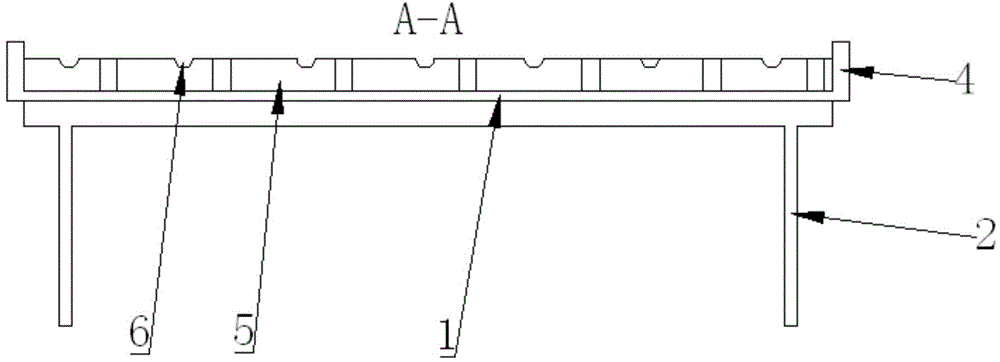

Reinforcement cage binding clamping fixture

The invention provides a reinforcement cage binding clamping fixture. The reinforcement cage binding clamping fixture comprises a baseplate, a support base, a vertical baffle plate and a positioning device; the support base is positioned under the baseplate; the vertical baffle plate includes transverse baffle plates and longitudinal baffle plates; the longitudinal baffle plates are arranged at the front and back ends of the baseplate; the transverse baffle plates are arranged on two sides of the baseplate; the positioning device is positioned on the baseplate, and consists of multiple criss-cross support plates; multiple limiting clamping grooves are formed in the support plates; and grounding terminal grooves are formed in two ends of the transverse baffle plates. The reinforcement cage binding clamping fixture can satisfy the demand that CRTS III type rail plates need to realize positioned binding of criss-cross two-dimensional reinforcements; a clamping fixture body is formed by machining a steel material; the material is higher in hardness and small in deformation, so that the problem of incapability of accurately positioning the reinforcement position caused by long-time use of the reinforcement clamping fixture is effectively solved; the grounding terminal grooves are reserved in two ends of a side mold of the clamping fixture for preventing use accidents caused by no connection of grounding terminals by a reinforcement cage in the machining process; and lifting lugs are convenient for the movement of the clamping fixture.

Owner:SILVERY DRAGON PRESTRESSED MATERIALS CO LTD

Preparation method of abrasive wheel for cutting of blue glass infrared cut-off optical filter

ActiveCN106002650AEasy to controlPromote sheddingAbrasion apparatusGrinding devicesBoron carbideHardness

The invention belongs to a preparation method of an abrasive wheel for cutting of a blue glass infrared cut-off optical filter. Ultrafine-grain-size powder is adopted as raw materials of a metallic bond, better holding force on diamonds is achieved, the service life of the abrasive wheel can be prolonged, and the cutting speed of the abrasive wheel can be increased. By means of the composite mixing process adopting a three-dimensional mixer for premixing and ultrasonic wet mixing, the quality stability of the abrasive wheel and consistency of the cutting performance of the abrasive wheel are guaranteed. A certain amount of boron carbide and a certain amount of titanium diboride are added into the bond, do not participate in sintering and can fall off from the bond in time in the cutting process, and therefore keenness of the abrasive wheel is improved, the stable cutting capacity of the abrasive wheel is improved, and tool repair is avoided in the cutting process; and meanwhile due to the fact that the hardness of the two kinds of matter is high, the cutting assisting effect is achieved, and the cutting capacity of the diamond abrasive wheel is improved. The re-pressing process is adopted, an abrasive wheel blank obtained through hot-pressing sintering is strengthened, and therefore the density, rigidity and strength of the abrasive wheel are improved, and the mechanical performance of the abrasive wheel is further guaranteed.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Spheroidal graphite cast iron production method and spheroidal graphite cast iron prepared by method

The invention discloses a spheroidal graphite cast iron production method and spheroidal graphite cast iron prepared by the method, which relate to the field of a metallurgical industry. The production method disclosed by the invention comprises the steps of adding a nucleating agent when covering a spheroidizing agent, adding a nucleating agent before discharging molten iron for the second time after spheroidizing reaction is finished, adding a nucleating agent after discharging all molten iron and slagging-off, and adding a nucleating agent during pouring, so that molten iron is still at aneffective nucleating state during a whole pouring process, qualified spheroidal graphite form and quantity can be obtained, and the quality of the produced spheroidal graphite cast iron is ensured.

Owner:浙江杭机铸造有限公司

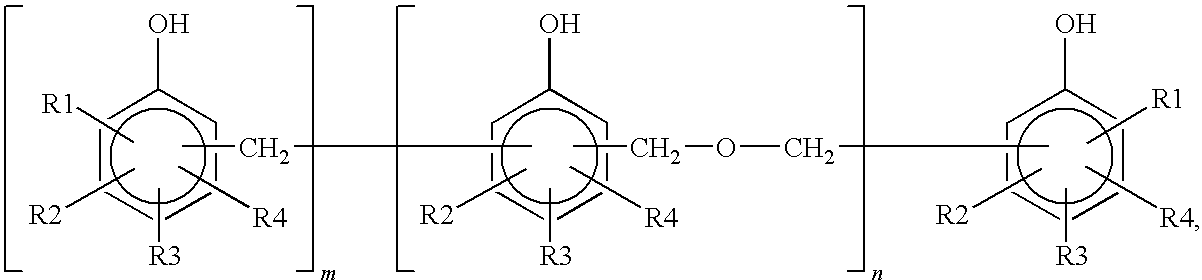

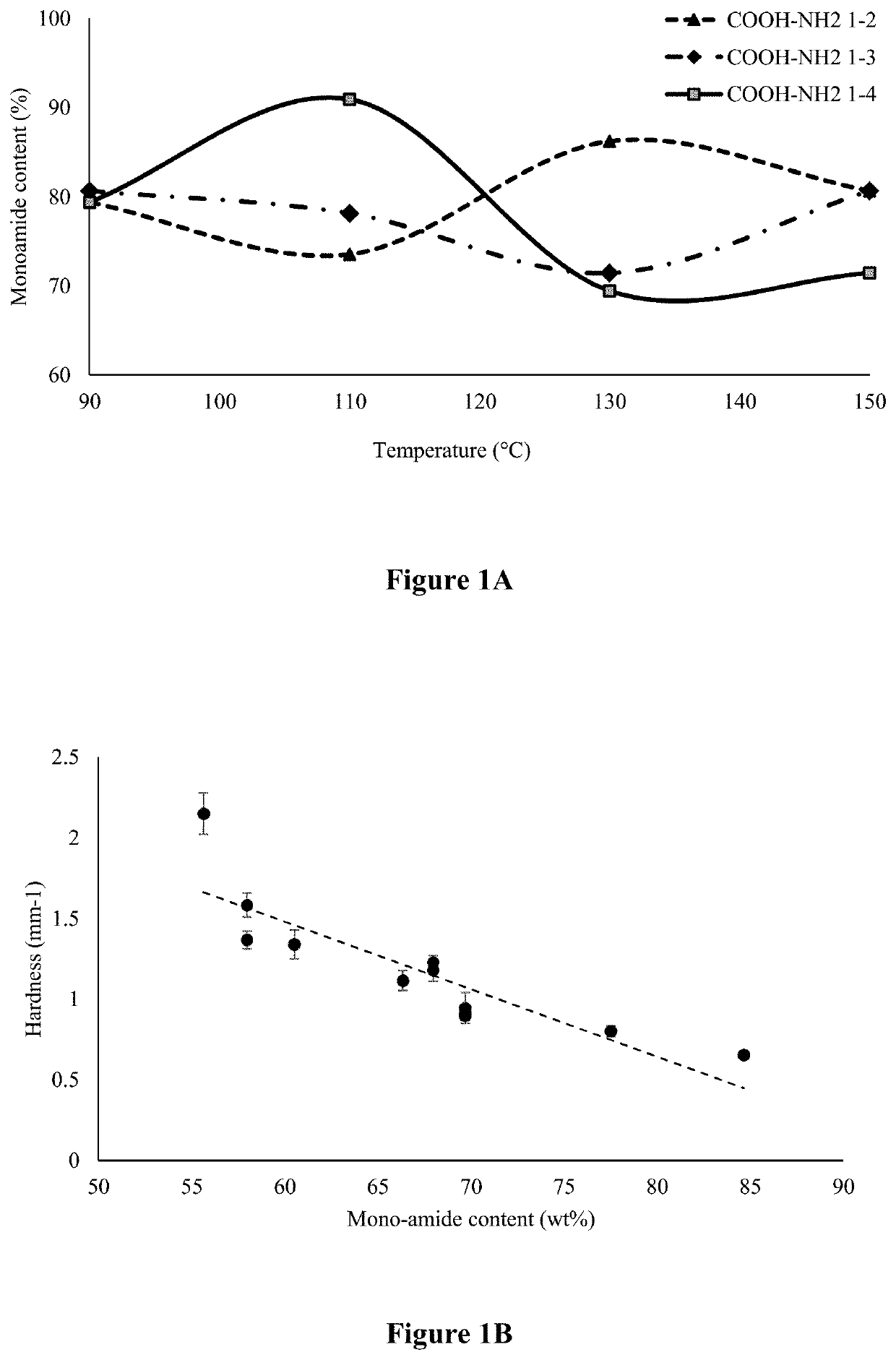

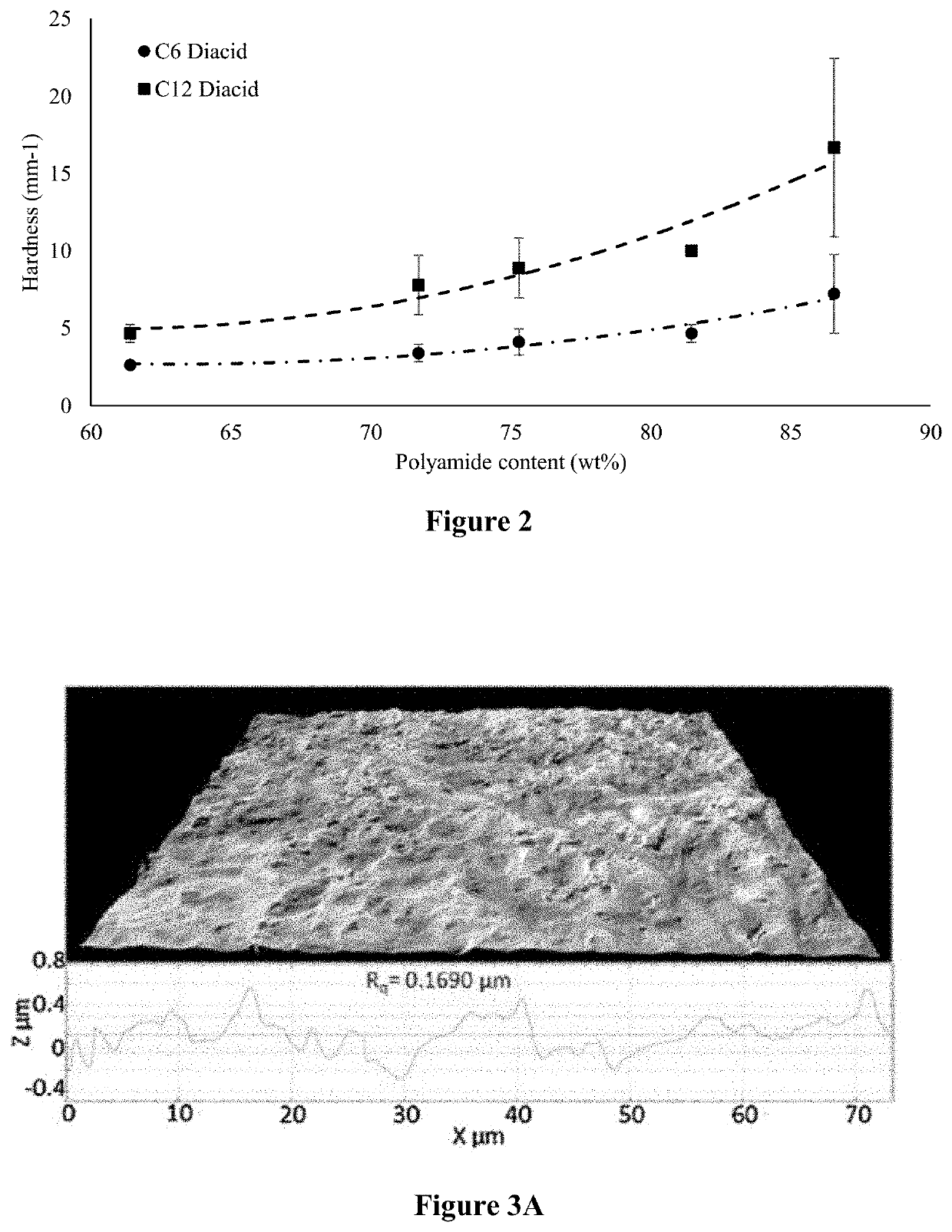

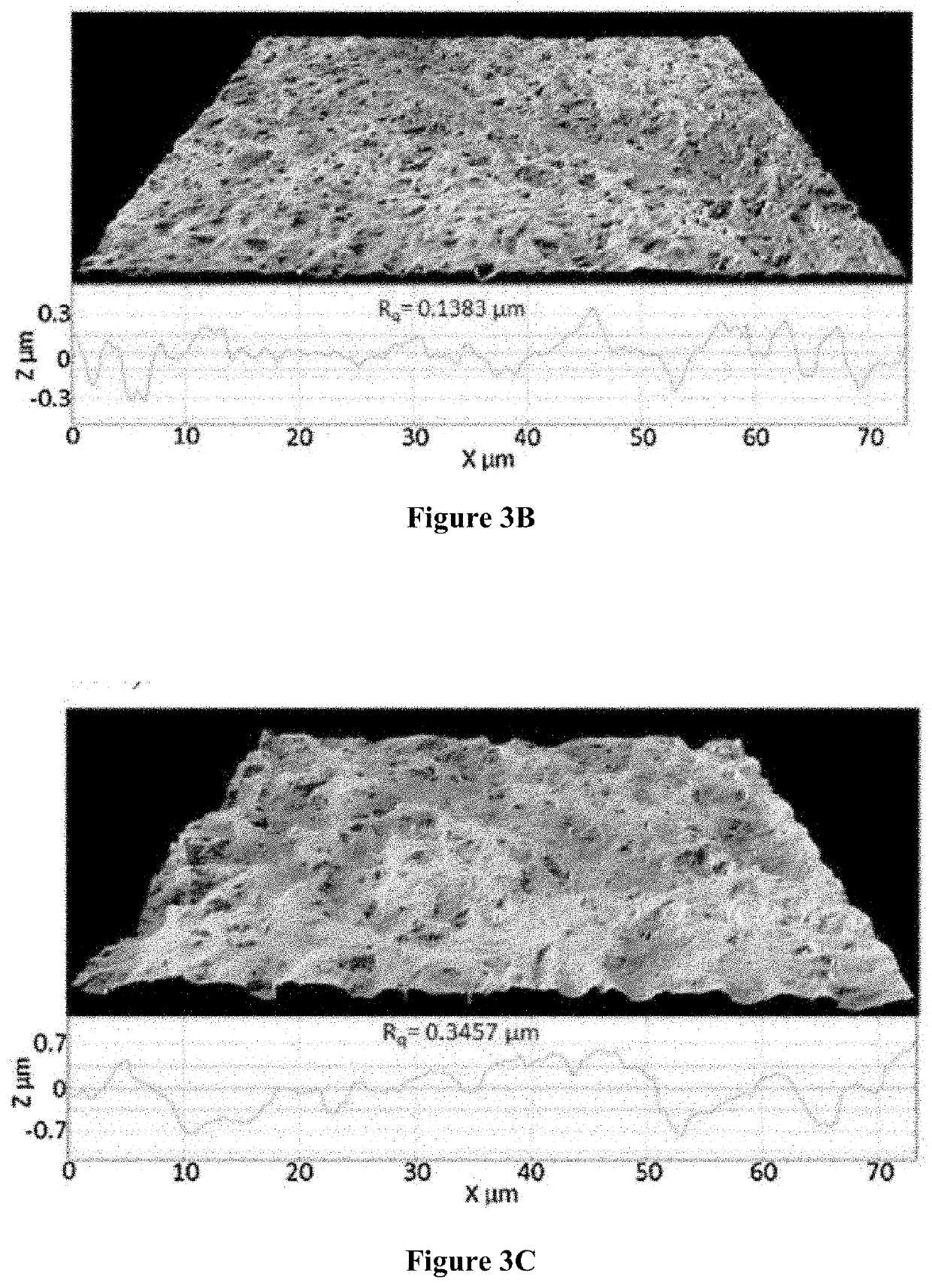

Golf ball material, golf ball and method for preparing golf ball material

The present invention provides a golf ball material which is made of an ionomer composition that includes a phenolic resin component. The invention provides also a golf ball composed of a core and a cover layer, or a core, a cover layer and at least one intermediate layer therebetween, wherein the golf ball material is used in at least one layer of the core or cover. The invention additionally provides a method for preparing the golf ball material by using (i) or (ii) below:(i) melt blending an ionomer and a phenolic resin;(ii) melt blending an ionomer base resin, a metal cation source and a phenolic resin.The golf ball material of the invention has improved properties, including rebound resilience, durability, and a higher hardness. By using this golf ball material as the material for an essential part of a golf ball, the golf ball properties can be improved.

Owner:BRIDGESTONE SPORTS

Enhanced Backup Ring Edge Features for Metal Face Seal in Roller Cone Drill Bits

InactiveUS20140225328A1High densityHigh material hardnessEngine sealsConstructionsHardnessVolumetric Mass Density

A backup ring for a face seal in a roller cone bit is configured to resist wear from drilling fluids present adjacent exposed faces of the backup ring. Portions are removed from an exposed end face in a variety of shapes while the hardness of the material is increased. The removal of material offsets an increase in force that would be transmitted through the backup ring on face seal assembly due to flexing. A spring can optionally be included in the removed material location. Another way is to increase the edge density of all or part of the exposed edges while leaving the interior portions unaffected by using electron beam radiation to increase the crosslink density or by other techniques that allow a unitary structure with a more durable edge region.

Owner:BAKER HUGHES INC

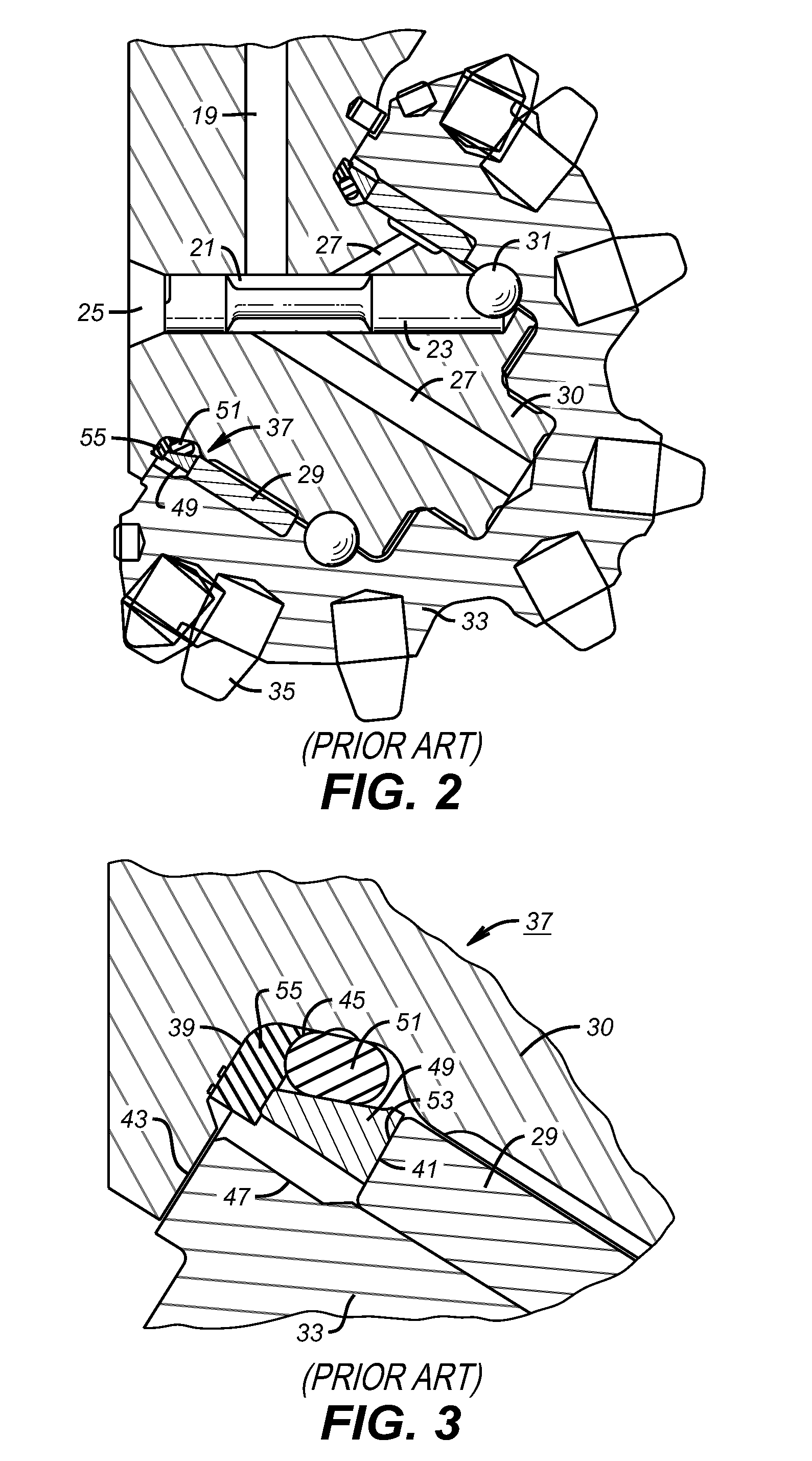

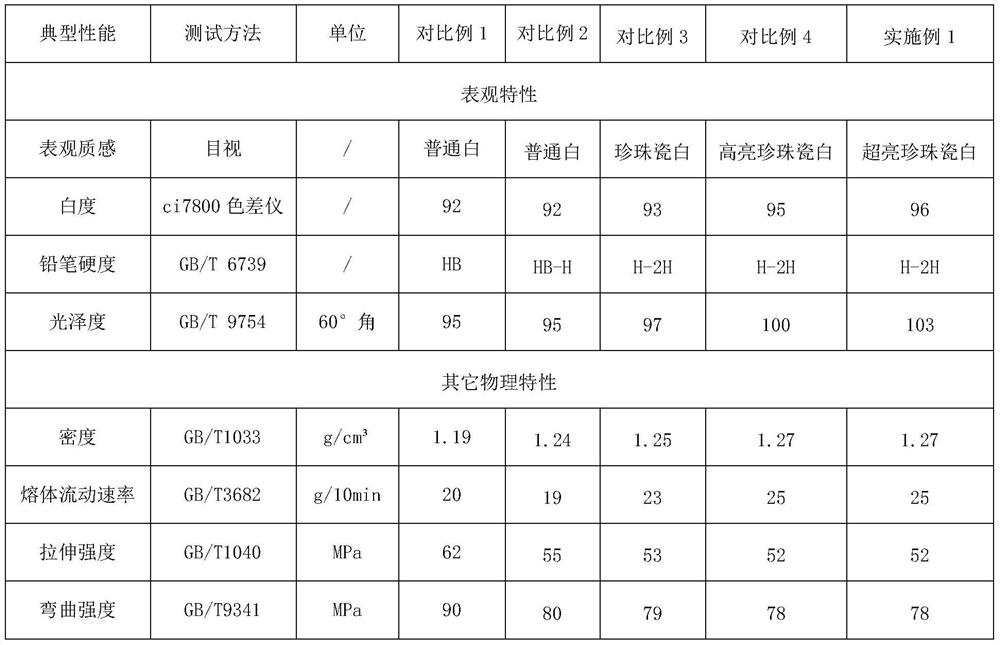

PC material with super ceramic texture and preparation method thereof

ActiveCN111732824AStrong impact resistanceExcellent surface hardnessPolycarbonateMethacrylate methyl

The invention discloses a PC material with a super ceramic texture. The PC material comprises the following raw materials in parts by weight: 50 to 60 parts of polycarbonate, 30 to 35 parts of polymethyl methacrylate, 2 to 4 parts of a compatilizer, 6 to 10 parts of ceramic powder, 1 to 3 parts of glass beads, 0.2 to 0.5 part of modified pearl powder, 0.5 to 1 part of titanium dioxide, 0.2 to 0.5part of a light stabilizer, 0.2 to 0.5 part of an antioxidant and 0.3 to 1 part of a lubricant. The invention also discloses a preparation method of the PC material with the super ceramic texture. Compared with an existing ceramic-imitated material, the PC material with the super ceramic texture has the advantages of being high in material hardness, resistant to scraping, environmentally friendlyand capable of being repeatedly used, can present the special silver-white super-ceramic gloss texture, is superior to a conventional ceramic texture in appearance, and is simple in process and suitable for batch production.

Owner:重庆会通科技有限公司

Ceramic steel composite material and its preparation method

The invention discloses a ceramic steel composite material and its preparation method. The ceramic steel composite material comprises 1-10wt% of B, 20-65wt% of Mo, 1-10wt% of Ni, 0.1-5wt% of Mn, 1-15wt% of Cr, 0.2-2wt% of C, and the balance of Fe. The preparation method comprises the following steps: burdening according to the above components and contents thereof, adding a forming agent accounting for 2-6wt% of the total amount of the components, placing the obtained mixture in a ball mill, carrying out wet milling for 20-100h, carrying out vacuum drying at 50-80DEG C for 5-8h, screening, and carrying out compression forming on the screened powder; placing the formed blank in a sintering furnace, sequentially heating to 320-500DEG C, 750-850DEG C and 900-1000DEG C according to a rate of 3-10DEG C / min, and respectively carrying out heat insulation for 30-60min; and heating to 1100-1400DEG C according to a rate of 2-6DEG C / min, and carrying out heat insulation for 30-90min to obtain the ceramic steel composite material. The preparation method has the advantages of low cost and simple process, and the prepared ceramic steel composite material has the advantages of high hardness, excellent acid and alkali resistance, and good wear resistance.

Owner:WUHAN UNIV OF SCI & TECH

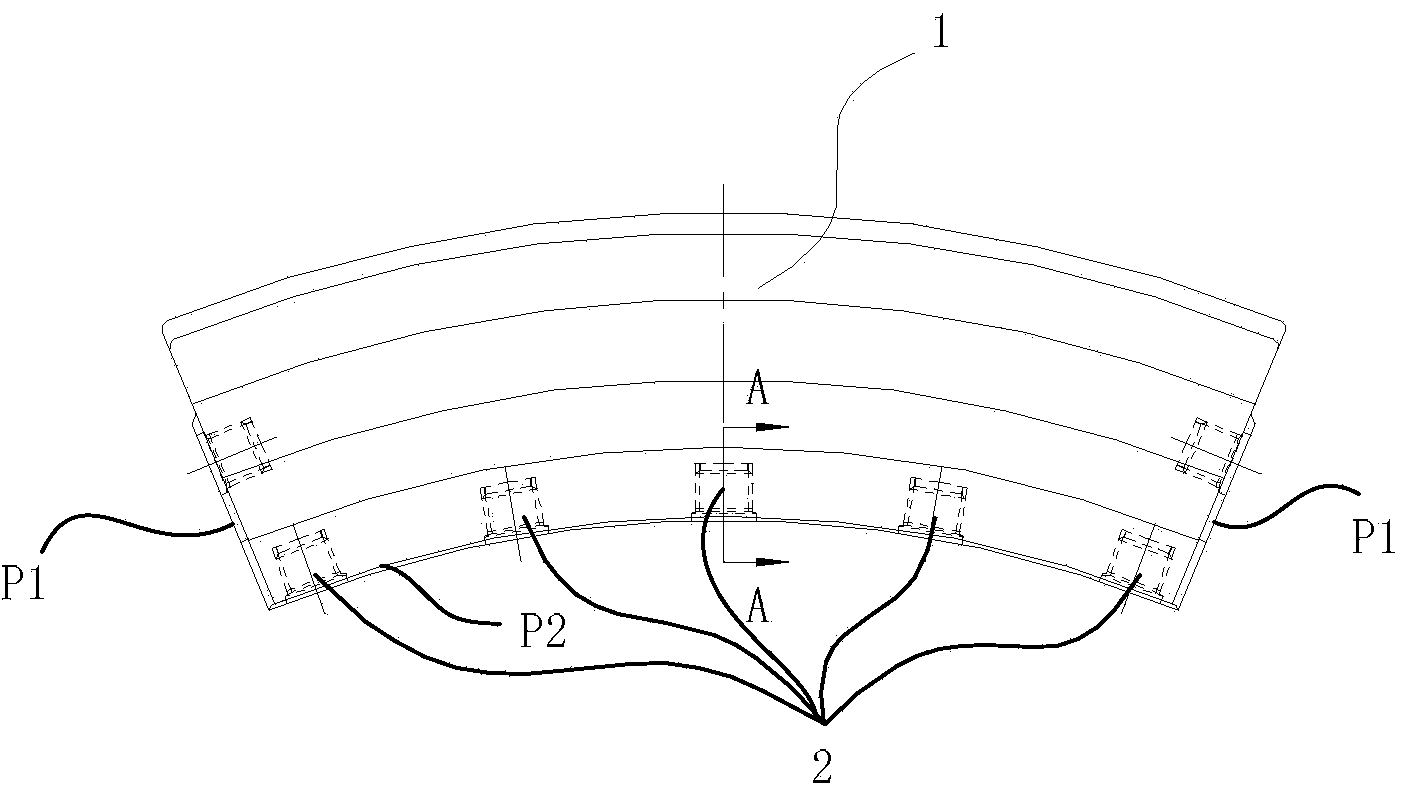

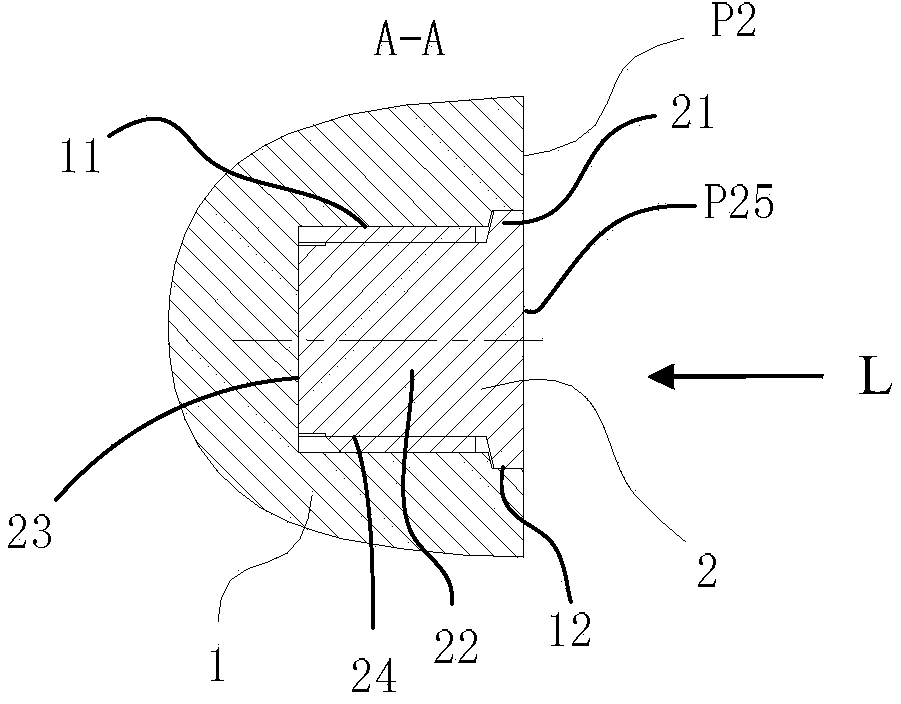

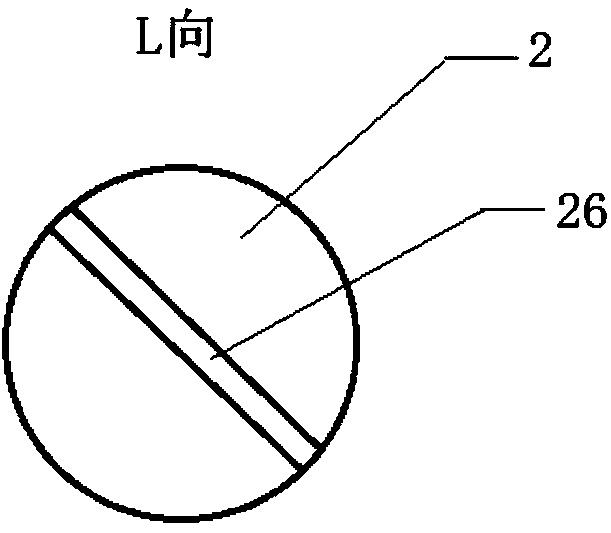

Pattern block protective structure, pattern block and tire segmental mold

The invention provides a pattern block protective structure, a pattern block and a tire segmental mold. The pattern block protective structure is used for the pattern block of the tire segmental mold, the pattern block protective structure comprises a protective block which is assembled in a groove of a surface to be protected of the pattern block, the hardness of the protective block material is more than that of the pattern block, and the protective block is used for reducing abrasion of the pattern block to the to-be-protected surface when the pattern block is used. The pattern block protective structure has the hardness higher than that of a pattern block matrix, can reduce the abrasion of the pattern block when the pattern block is used, can prolong the service life of the pattern block, and can reduce the using cost of the segmental mold composed of the pattern block.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Method used for cleaning surfaces of castings, surfaces of pouring gates and surfaces of dead heads

The invention discloses a method used for cleaning the surfaces of castings, the surfaces of pouring gates and the surfaces of dead heads. The castings, the pouring gates and the dead heads are arranged in a roller of a casting machine. The method comprises the steps that cleaning blocks are placed in the roller of the casting machine, the cleaning blocks, the castings, the pouring gates and the dead heads are made to roll over along with the roller of the casting machine, the cleaning blocks continuously conducts friction on the castings, the pouring gates and the dead heads so as to remove sands on the surfaces of the castings, the surfaces of the pouring gates and the surfaces of the dead heads, and therefore the purpose of cleaning the surfaces of the castings, the surfaces of the pouring gates and the surfaces of the dead heads is achieved.

Owner:苏州石川制铁有限公司

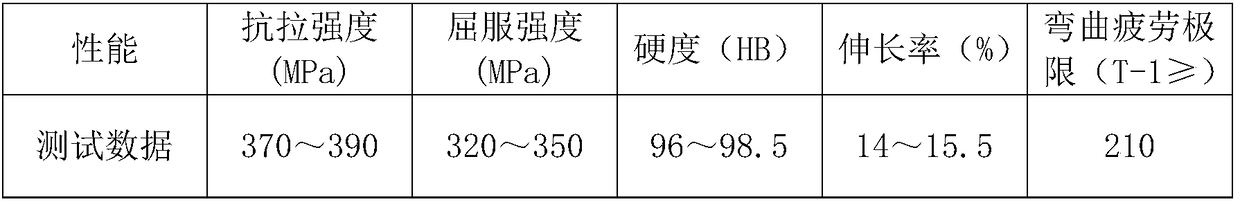

Preparation method of high strength and high hardness spheroidal graphite cast iron

The invention belongs to the field of metallurgical industry and in particular relates to a preparation method of high strength and high hardness spheroidal graphite cast iron. The preparation methodcomprises the preparation steps of 1) calculating raw material amounts in proportion and preparing raw materials; 2) blowing a modifier into a smelting furnace, wherein the modifier and molten metal in the smelting furnace are fully and uniformly stirred, and leaving the mixture to stand and keeping the temperature; 3) casting ladle pre-treatment: paving a first nucleating agent on the outer surface of a spheroidizing agent and then paving a dregs remover on the outer surface of the first spheroidizing agent for spheroidizing treatment and first time nucleation; adding a second nucleating agent after drossing for second time nucleation and adding a nitrogen getter for quenching and tempering treatment; 4) carrying out casting to obtain a prefabricated part; and 5) carrying out thermal treatment. The technical scheme of the invention has the technical advantages that the prepared spheroidal graphite cast iron with high tensile strength and high material hardness is obtained as well under a circumstance that alloys such as Mo, Ni and V high in price are avoided, the production cost is lowered greatly, and the market competitiveness of a product is improved.

Owner:东亚科技(苏州)有限公司

Process for manufacturing an aluminium alloy part

PendingUS20210260661A1High hardnessReduce roughnessAdditive manufacturing apparatusIncreasing energy efficiencySolid metalAluminium alloy

The invention relates to a process for manufacturing a part comprising a formation of successive solid metal layers (201 . . . 20n), superposed on one another, each layer describing a pattern defined using a numerical model (M), each layer being formed by the deposition of a metal (25), referred to as solder, the solder being subjected to an input of energy so as to start to melt and to constitute, by solidifying, said layer, wherein the solder takes the form of a powder (25), the exposure of which to an energy beam (32) results in melting followed by solidification so as to form a solid layer (201 . . . 20n), the process being characterized in that the solder (25) is an aluminium alloy comprising at least the following alloy elements: —Si; in a weight fraction of from 0 to 4%, preferably from 0.5% to 4%, more preferably from 1% to 4% and more preferably still from 1% to 3%; —Fe in a weight fraction of from 1% to 15%, preferably from 2% to 10%; —V in a fraction of from 0 to 5%, preferably from 0.5% to 5%, more preferentially from 1% to 5%, and more preferentially still from 1% to 3%; at least one element chosen from Ni, La and / or Co, in a weight fraction of from 0.5% to 15%, preferably from 1% to 10%, more preferably from 3% to 8% each for Ni and Co, in a weight fraction of from 1% to 10%, preferably from 3% to 8% for La, and in a weight fraction of less than or equal to 15%, preferably less than or equal to 12% in total. The invention also relates to a part obtained by this process. The alloy used in the additive manufacturing process according to the invention makes it possible to obtain parts with remarkable characteristics.

Owner:C TEC CONSTELLIUM TECH CENT

Hard alloy used for producing 3D curved surface glass and preparation method thereof

The invention discloses a hard alloy used for producing 3D curved surface glass and a preparation method thereof. The hard alloy comprises the following components of, by mass, 81% of tungsten carbide, 3% of cobalt, 8% of nickel, 2% of chromium dicarbonate, 1% of vanadium, 2% of tantalum and 3% of titanium. The hard alloy used for producing the 3D curved surface glass has good wear resistance, strength, and good conductivity, and further comprises the characteristics of strong corrosion resistance and excellent high-temperature strength under the working environment, the material can work continuously for 90 days or above, and the service life of the material is greatly prolonged.

Owner:株洲众诚新材料科技股份有限公司

Output shaft material for pneumatic performing mechanism and preparation method for output shaft

InactiveCN108728753AImprove wear resistanceHigh material hardnessShaftsFurnace typesEngineeringThermal expansion

The invention relates to an output shaft material for a pneumatic performing mechanism and a preparation method for an output shaft. The output shaft material consists of the following components in percentage by weight: 1.2%-2.5% of Cu, 0.65%-1.0% of Mg, 0.15%-0.2% of Mn, 1.2%-2% of Ni, 1.6-2.4% of Zn, 0.42%-0.58% of B2O3, 1.5%-2.5% of SiO2, 1.2%-2.8% of TiC, 0.5%-1.5% of Re and the balance of Fe. The preparation method for the output shaft comprises the following steps of: preparing blank, pre-treating the blank, performing finish machining and performing quenching treatment. The output shaft has the characteristics of being relatively high in wear resistance, high in material hardness, small in thermal expansion coefficient, low in friction coefficient and the like. Meanwhile, the formula and the preparation process of the process material are improved, so that the output shaft material has good mechanical performance.

Owner:WUXI CHENGTIANNUO ACTUATOR MFG CO LTD

Improved sliding anchor

InactiveCN101506468AHigh hardnessClamping force achieved repeatedlyAnchoring boltsEngineeringMechanical engineering

Owner:ATLAS COPCO MAI

Vegetable oil-based material as a substitute for carnauba wax

ActiveUS20210047264A1Improve usabilityIncrease the lengthFatty acid hydrogenationFatty acid esterificationVegetable oilCarnuba wax

Owner:IOWA STATE UNIV RES FOUND

Chromium-containing copper infiltrant and preparation method thereof

InactiveCN111014690AHigh material hardnessGood formabilityTransportation and packagingMetal-working apparatusPowder metallurgyChromium

The invention belongs to the technical field of powder metallurgy and discloses a chromium-containing copper infiltrant and a preparation method thereof. The copper infiltrant is prepared from the compositions in percentage by mass: 1.3-2.9% of iron, 0.5-1.7% of carbon, 0.01-0.2% of chromium and the balance of copper. The preparation method comprises the steps that raw materials are weighed according to the ratio, ceramic balls or stainless steel balls and a diffusion promoter are added, after mixing, powder is fed into a hydrogen reduction furnace to be diffused, the diffusion temperature is300-1000 DEG C, the diffusion time is 0.5-25 h, cooling, discharging out of the furnace for crushing and screening for collection are conducted, and then a lubricant is added for blending. The copperinfiltrant prepared by the preparation method has the characteristics that formability is good, the infiltration efficiency is high, no erosion exists, residue is less, and the material density and mechanical properties are significant improved. The method is simple in process, required equipment is easy to operate, and mass production can be achieved.

Owner:WUXI HENGTELI METAL PROD

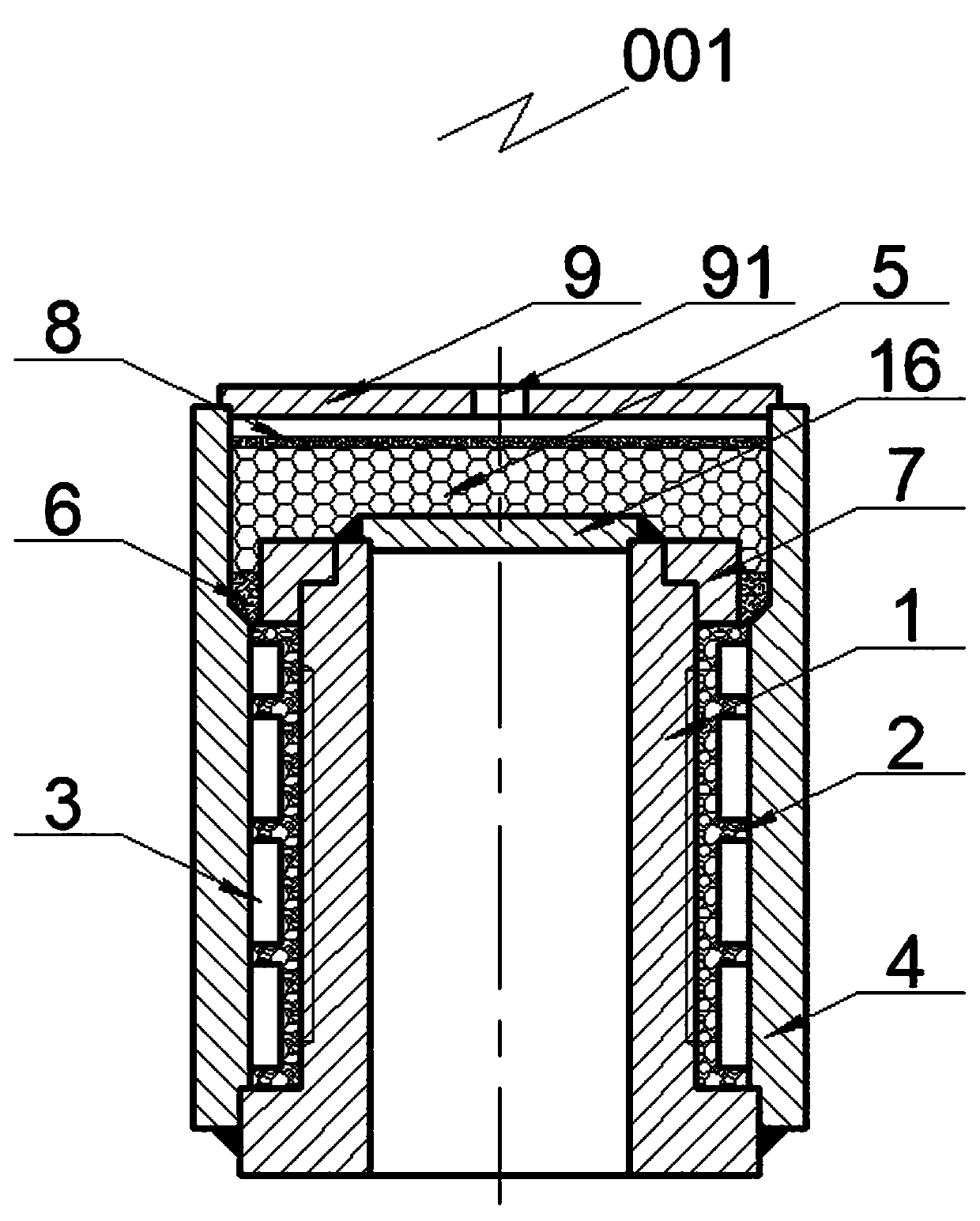

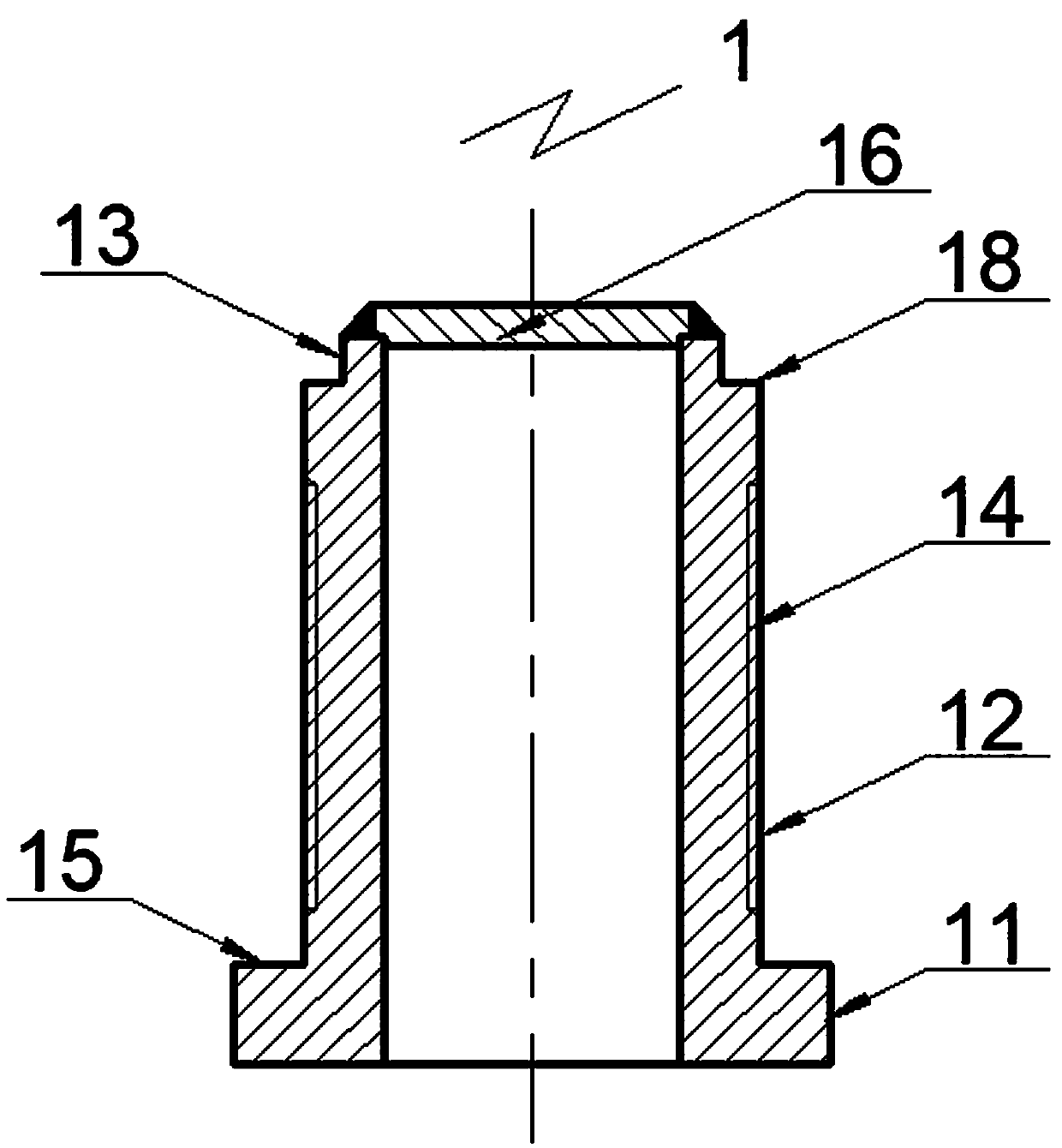

Manufacturing method of movable ring of radially straightened sliding bearing

ActiveCN111482609AExtend working lifeReduce processing difficultyTransportation and packagingMetal-working apparatusSlider bearingStructural engineering

The invention provides a manufacturing method of a movable ring of a radially straightened sliding bearing. The method comprises the following steps of acquiring a movable ring manufacturing die whichcomprises a matrix and a sleeve die coaxially placed outside the matrix, wherein an annular space is formed between the matrix and the sleeve die, and an accommodation space is formed among the matrix, the sleeve die and a cover plate; arranging positioning reference, cleaning a to-be-bonded part, and bonding a wear-resistant part to an inner cylindrical surface of the sleeve die; assembling filler: pouring cast tungsten carbide powder into residual gaps of the annular space, putting positioning powder above the cast tungsten carbide powder to form a positioning layer, then placing a certainamount of bonding alloy in proportion, spraying a certain amount of fluxing agent uniformly to the bonding alloy in proportion, and carrying out covering by a cover plate; sintering an assembled and filled die to obtain a movable ring blank; and machining the air-cooled movable ring blank, wherein the dimension of the movable ring meets a designed demand. The service life of the radially straightened sliding bearing can be prolonged, and meanwhile, the machining difficulty and the manufacturing cost are lowered.

Owner:BEIJING CHUNLUN PETROLEUM TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com