Enhanced Backup Ring Edge Features for Metal Face Seal in Roller Cone Drill Bits

a technology of roller cone drill bits and edge features, which is applied in the direction of engine seals, mechanical equipment, construction, etc., can solve the problems of sealing failure, material deformation, loss of function, and typical failure, so as to increase the hardness of the material, increase the edge density, and increase the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

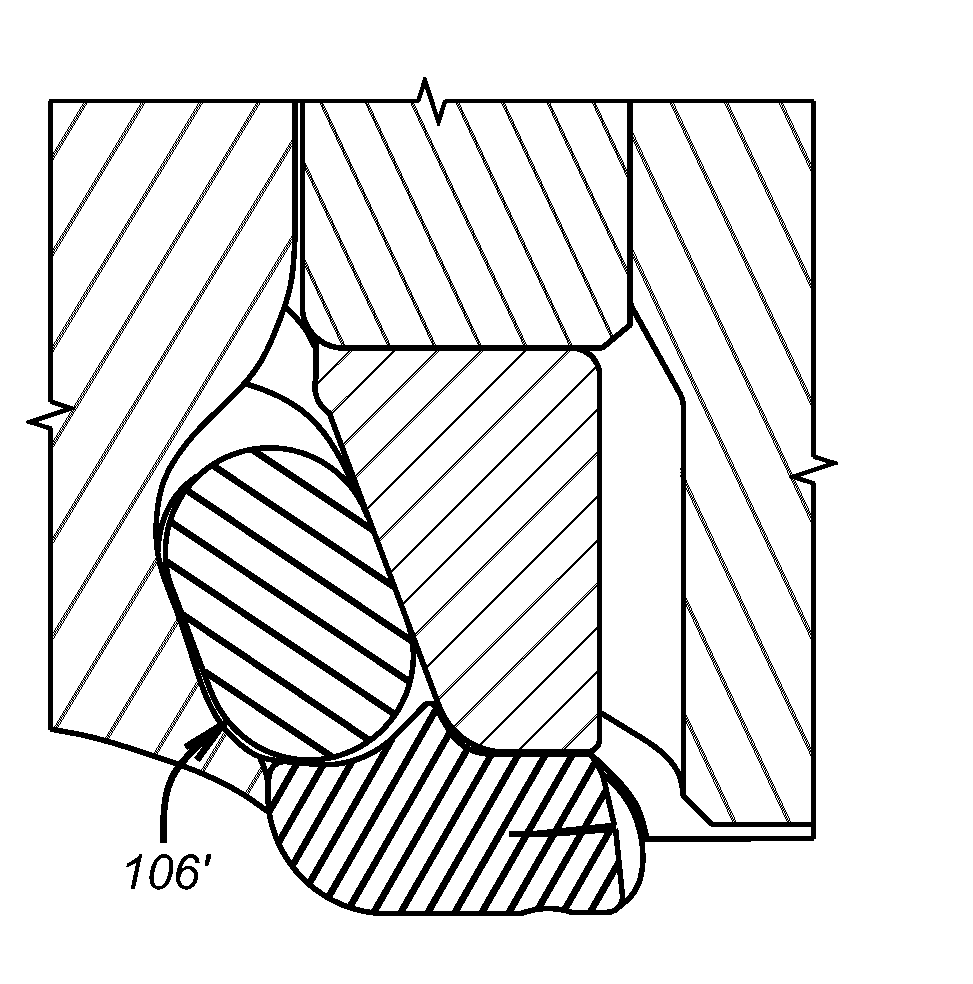

[0034]FIG. 5 shows the backup ring 100 of the present invention with an outer edge 102 that has a curved recess 104. When assembled to a roller cone face seal assembly 106 as previously described opposing forces 108 and 110 are represented by arrows. Assembly causes the recess 104 to get smaller than its relaxed uninstalled shape. The hardness of the ring 100 is increased as compared to the previously discussed prior embodiment where the hardness was 40-45 durometer (Shore A). The increase in hardness, modulus or density addresses the issue of cracking or pieces coming off from contact with the abrasives in well fluids notably drilling mud. However, the increase in hardness or density also increases the reaction forces to the forces represented by arrows 108 and 110. For that reason some material is removed from edge 102 that creates cantilevered components 112 and 114 that under loading from assembly and then during operation can flex toward each other to compensate for the increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com