Pattern block protective structure, pattern block and tire segmental mold

A tire active mold and protective structure technology, applied to tires, household appliances, and other household appliances, can solve the problems of increasing tire manufacturing costs, damage, and reducing the service life of tread blocks, so as to improve service life and reduce use costs , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

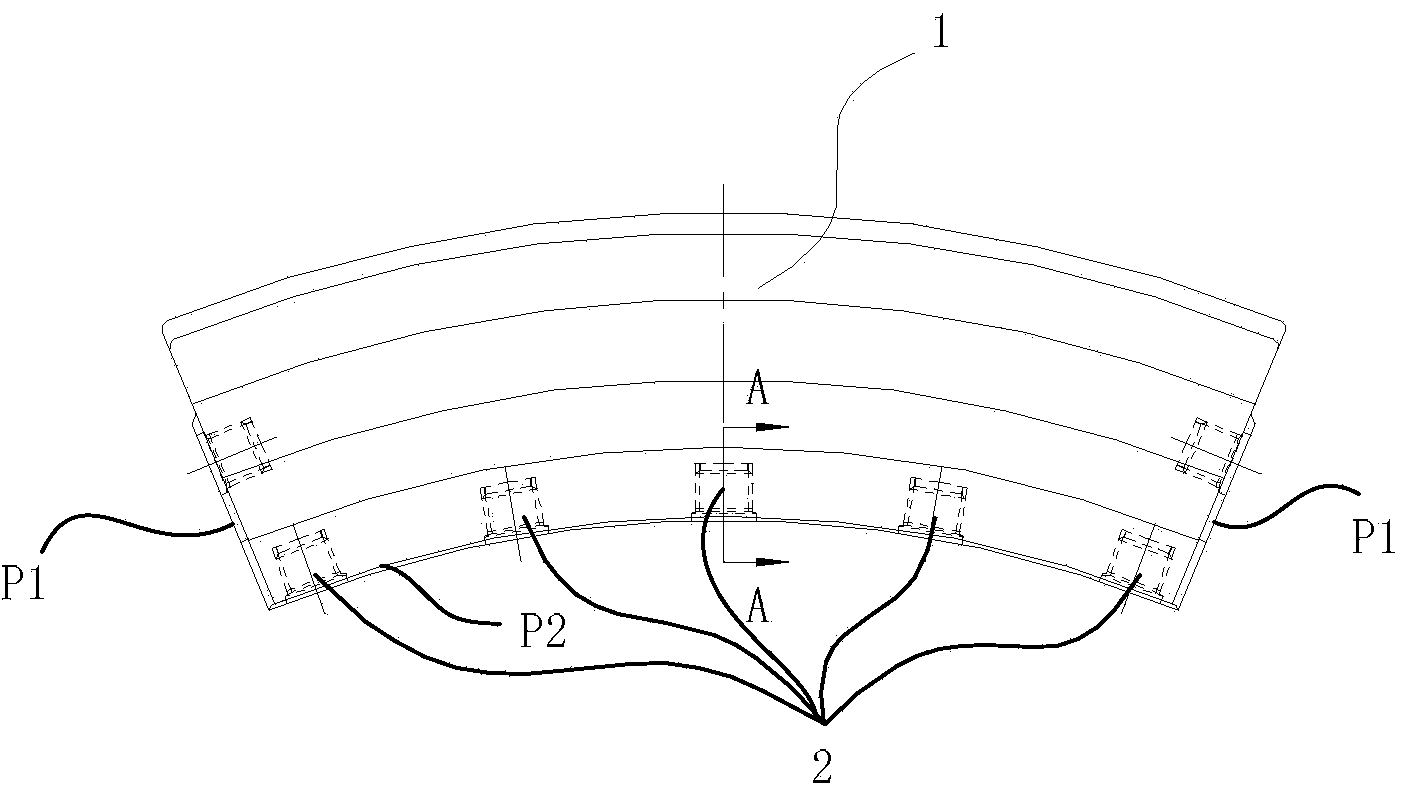

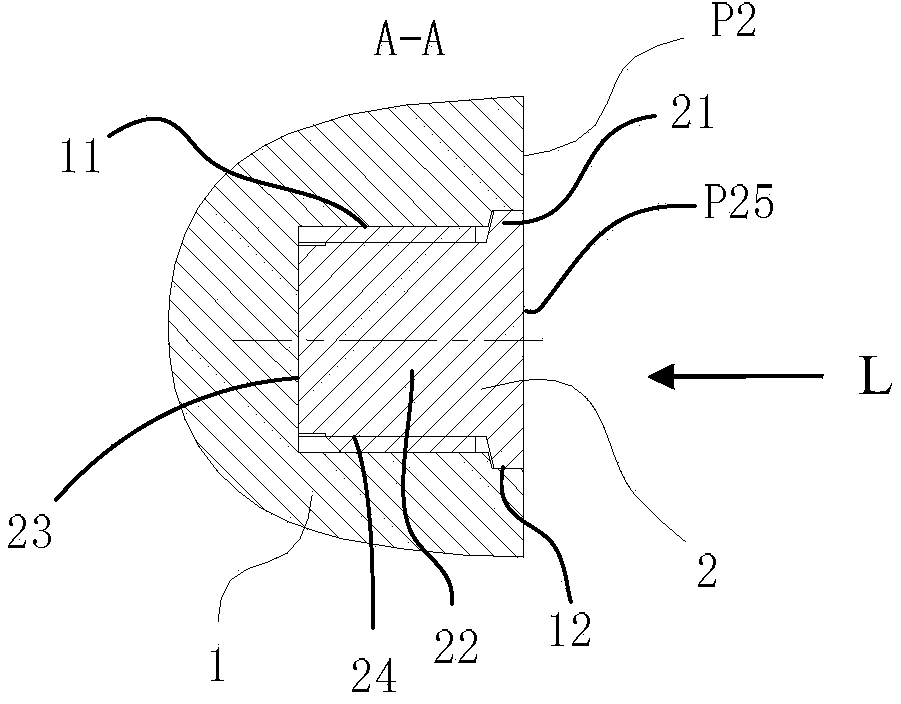

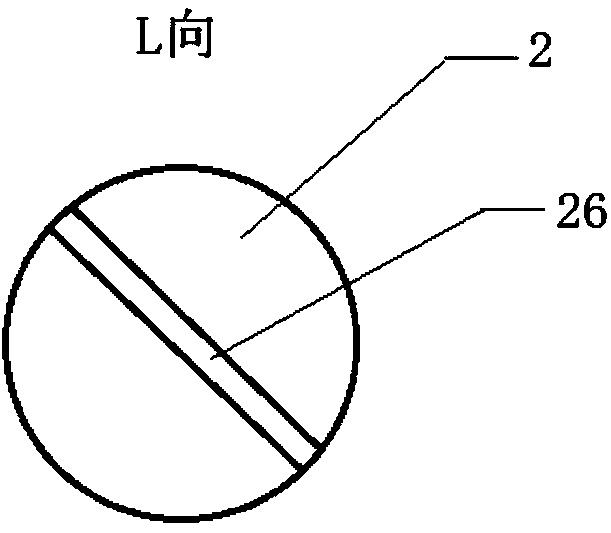

[0032] The pattern block protection structure of the embodiment of the present invention is used for the pattern block of the active tire mold, so as to reduce the wear on the surface to be protected caused by the pattern block of the active tire mold during use (such as opening and closing the mold). The pattern block protection structure of the embodiment of the present invention includes a protection block, which is installed in the groove on the surface of the pattern block to be protected, and the hardness of the material of the protection block is greater than th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com