Reinforcement cage binding clamping fixture

A technology of reinforced skeleton and mould, which is applied in the application field of track slab processing reinforced skeleton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

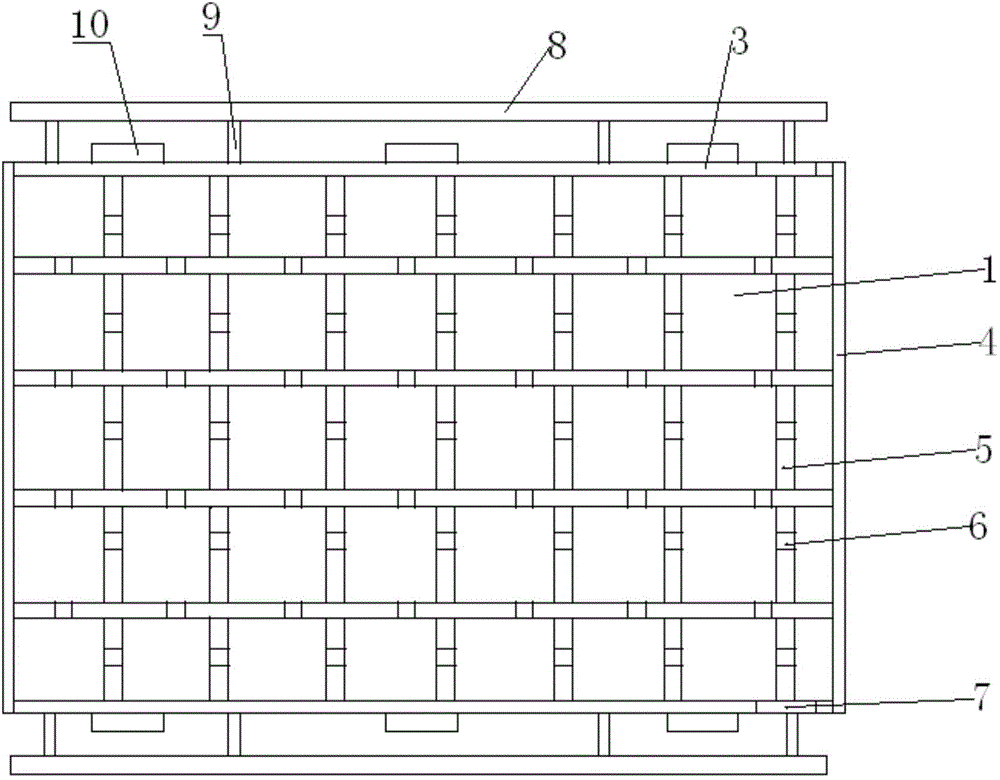

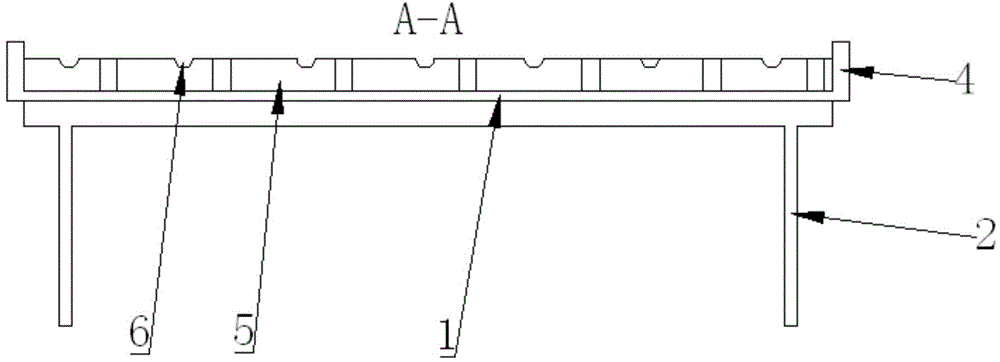

[0015] Such as Figure 1-2 As shown, the steel frame binding tire includes a bottom plate 1, a support seat 2, a vertical baffle and a positioning device. The support seat 2 is located below the bottom plate 1 and is used to support the bottom plate 1. The vertical baffle The board includes a transverse baffle 3 and a longitudinal baffle 4, the longitudinal baffles 4 are provided at the front and rear ends of the bottom plate 1, the transverse baffles 3 are provided on both sides of the bottom plate 1, and the positioning device is located at On the bottom plate 1, the positioning device is composed of several support plates 5 criss-crossing, the support plates 5 are provided with a number of limit card slots 6, and the two ends of the transverse baffle plate 3 are provided with grounding terminal slots 7 .

[0016] It also includes an auxiliary hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com