Encapsulated Preformed Shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example method

of Forming An Encapsulated Array With Barrier Layer Covered Tiles

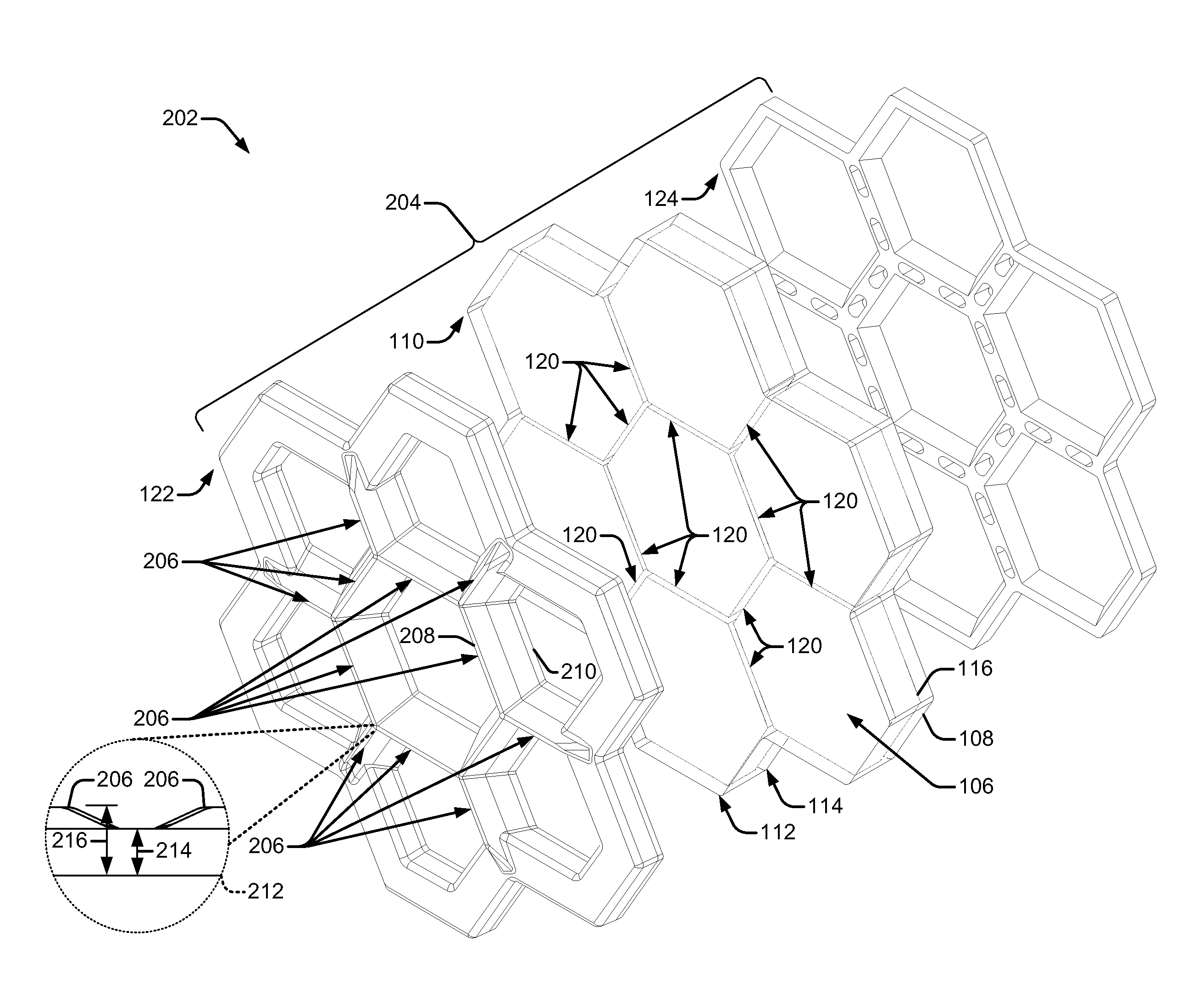

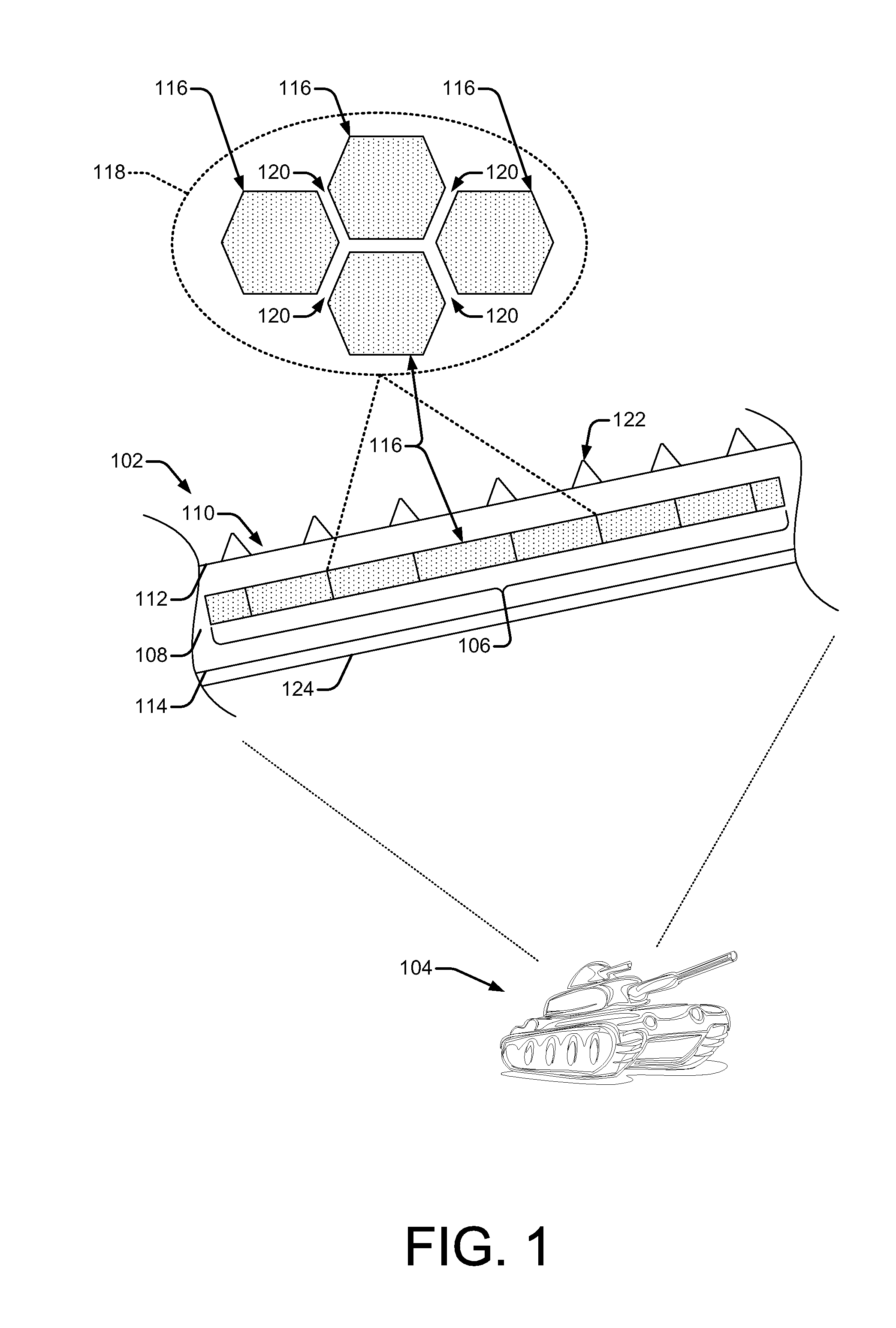

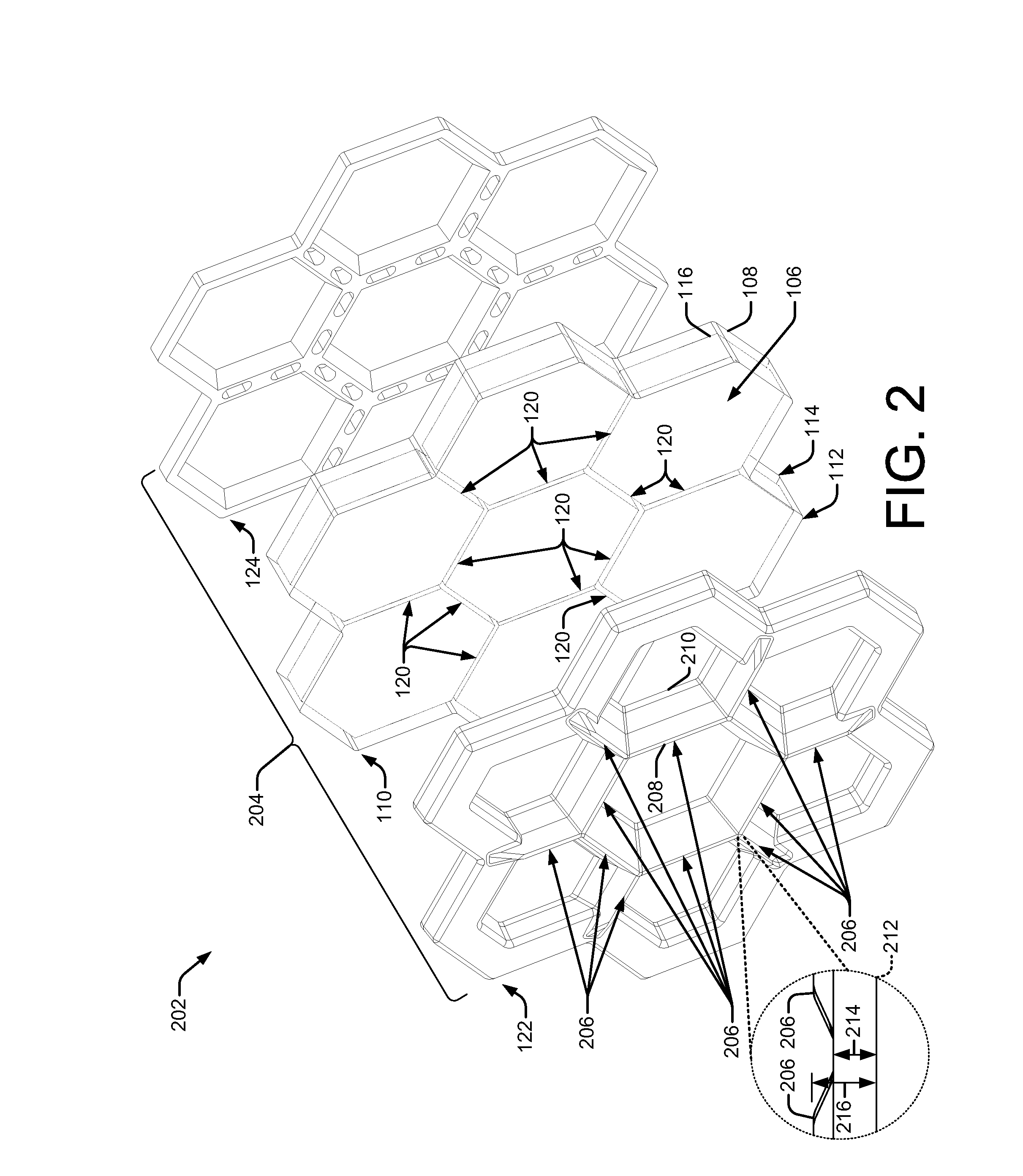

[0100]FIG. 10 illustrates an example process 1000 of manufacturing an encapsulated array (e.g., encapsulated array 110) with ceramic elements (e.g., ceramic elements 116) covered with a barrier layer (e.g., barrier layer 508), alongside corresponding schematic diagrams illustrating the operations being described in the process 1000. By way of example and not limitation, this process may be performed at a manufacturing facility, a plant, a foundry, a factory, or the like.

[0101]Process 1000 includes operation 1002, which represents covering (e.g., wrap, coat, enclose, etc.) each solid ceramic element in an array of solid ceramic elements (e.g., array of ceramic elements 106) with the barrier layer. For example, a foundry casting the array of solid ceramic elements may manually cover each ceramic element, or the foundry casting the array of solid ceramic elements may be provided with the ceramic elements already covered w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com