Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Guaranteed fatigue resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

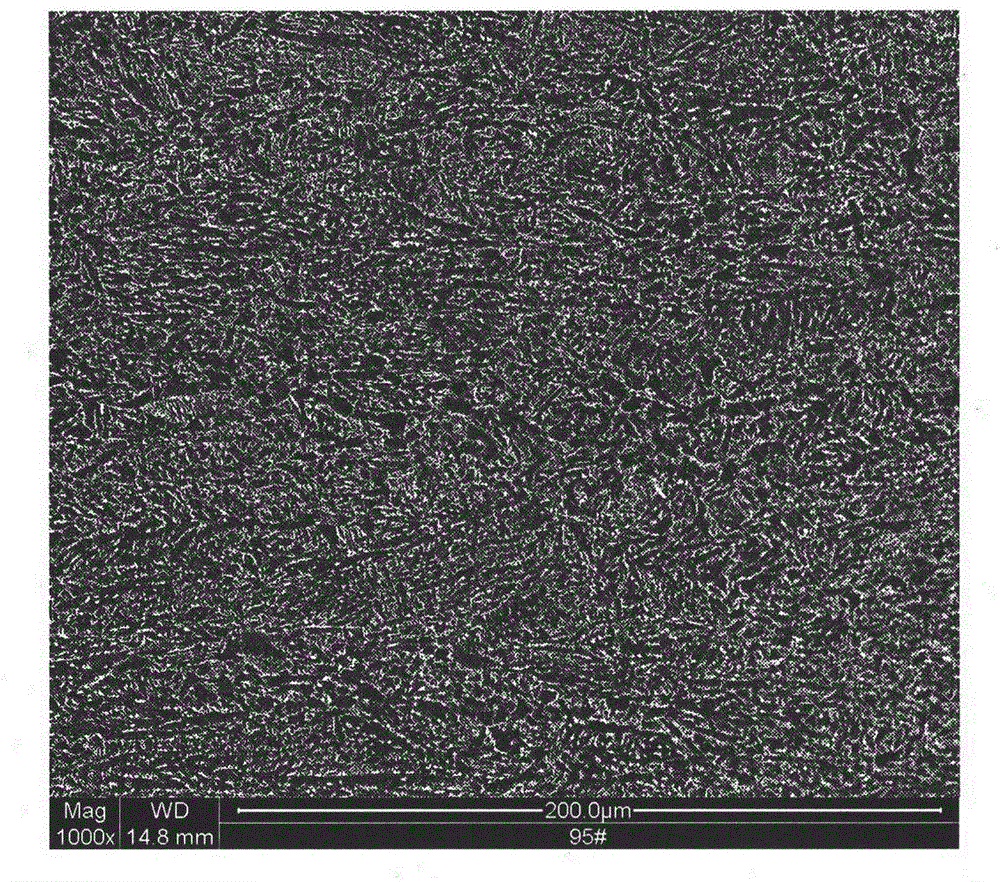

Large-diameter seamless steel tube for high-pressure gas cylinders and manufacturing method thereof

The invention belongs to the technical field of metallurgy, and provides a large-diameter seamless steel tube for high-pressure gas cylinders and a manufacturing method thereof. The large-diameter seamless steel tube for high-pressure gas cylinders comprises the following chemical components in percentage by mass: 0.30-0.60% of C, 0.20-0.50% of Si, 0.20-0.60% of Mn, at most 0.010% of P, at most 0.010% of S, 0.90-1.70% of Cr, 2.50-3.50% of Ni, 0.25-0.55% of Mo, 0.05-0.25% of V and the balance of Fe. The manufacturing method adopts spongy iron and scrap steel as raw materials for steelmaking. The large-diameter seamless steel tube has the advantages of high heat stability, high strength, impact toughness, stable enduring plasticity, high heat resistance, excellent corrosion resistance and excellent fatigue resistance, and the yield strength is not lower than 1000 MPa.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

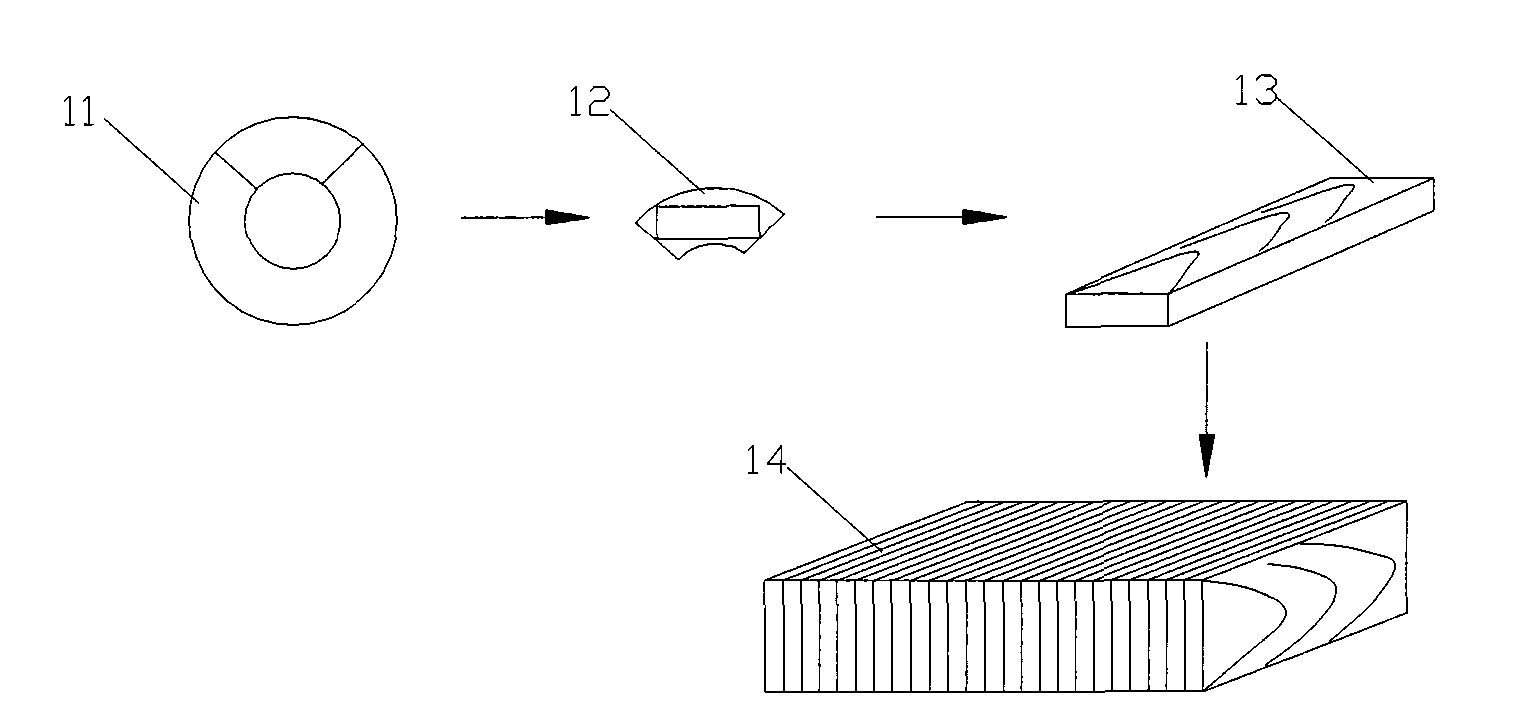

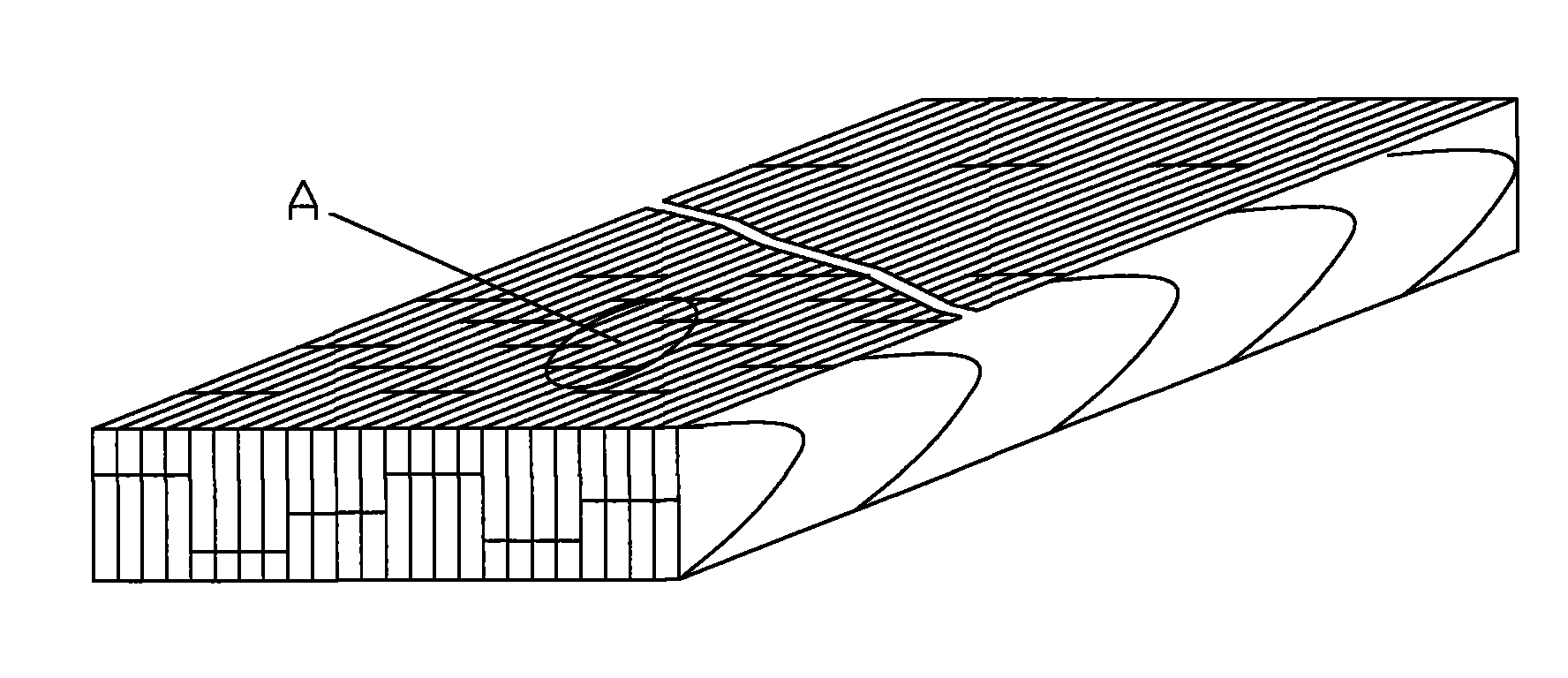

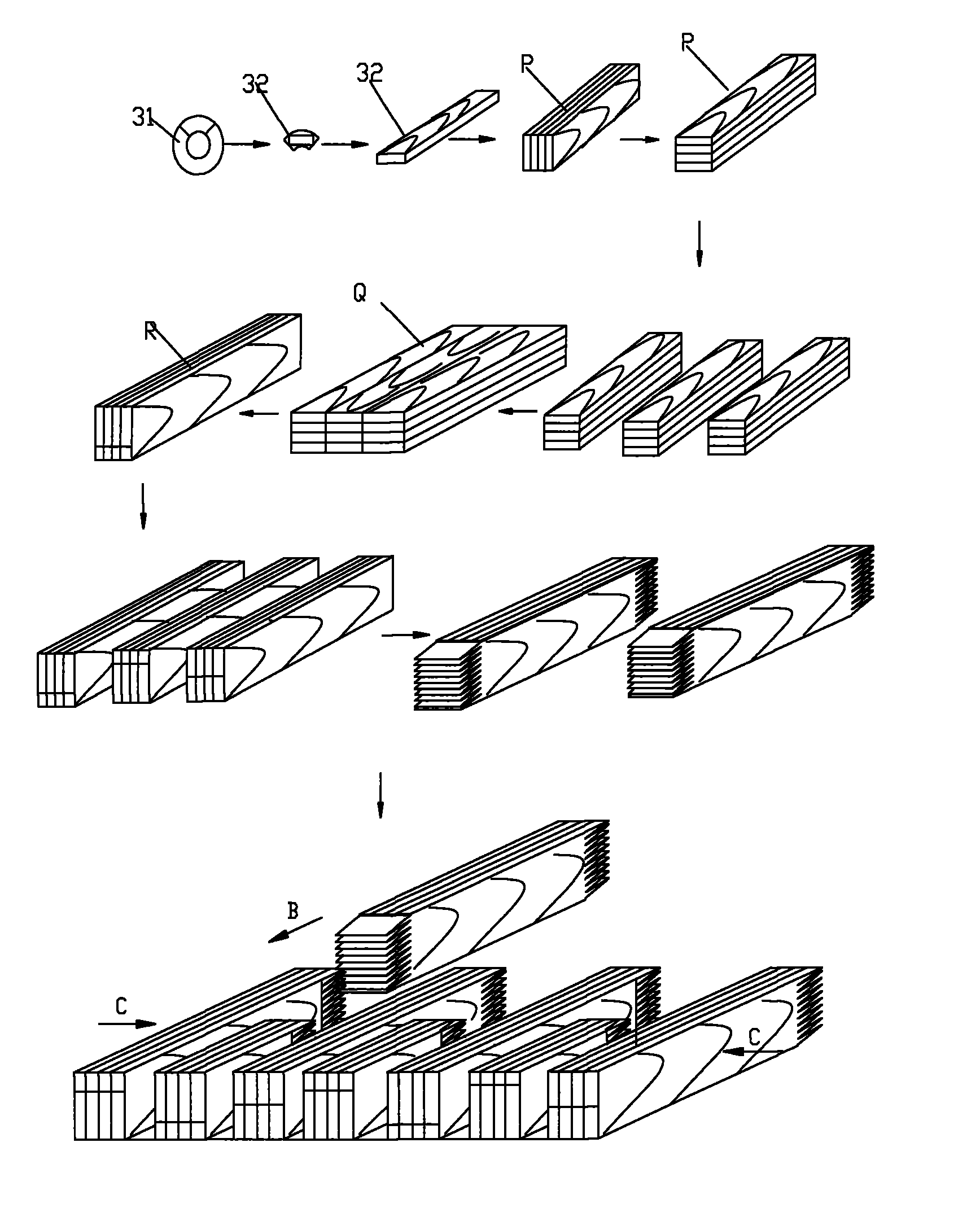

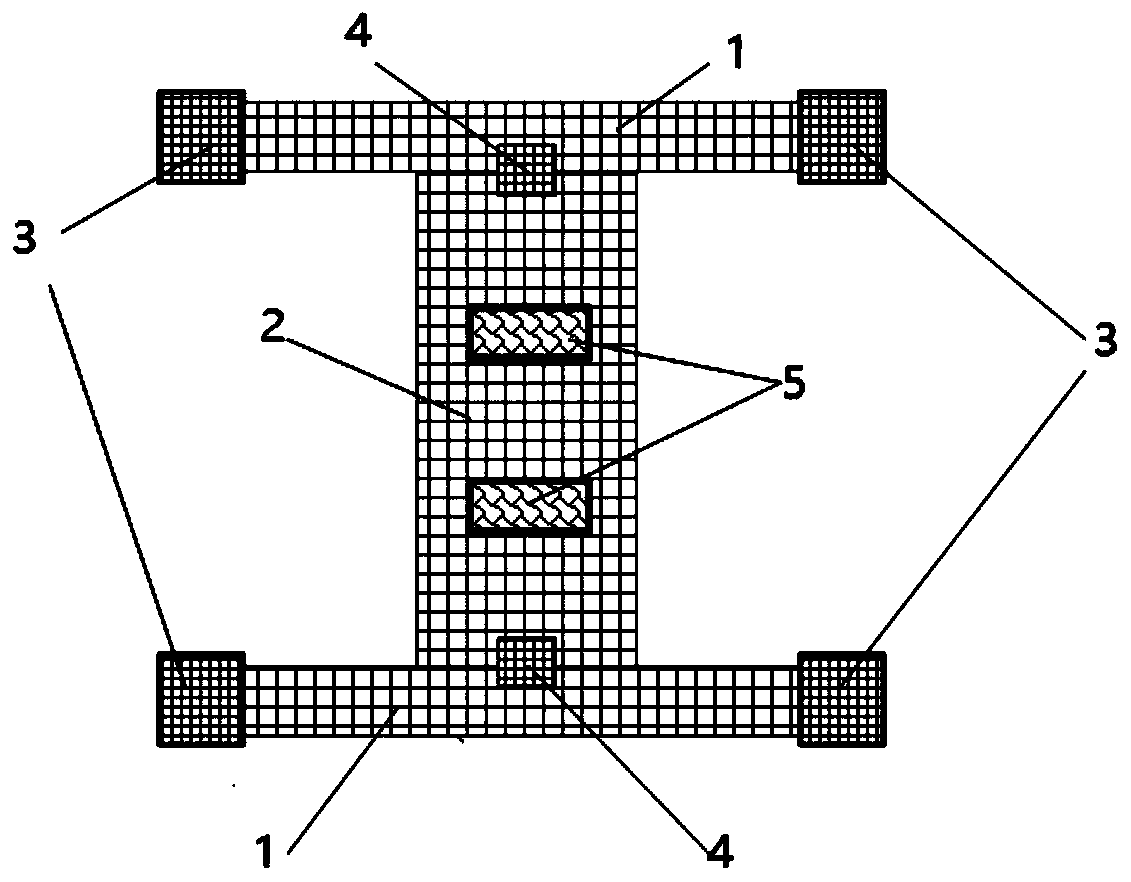

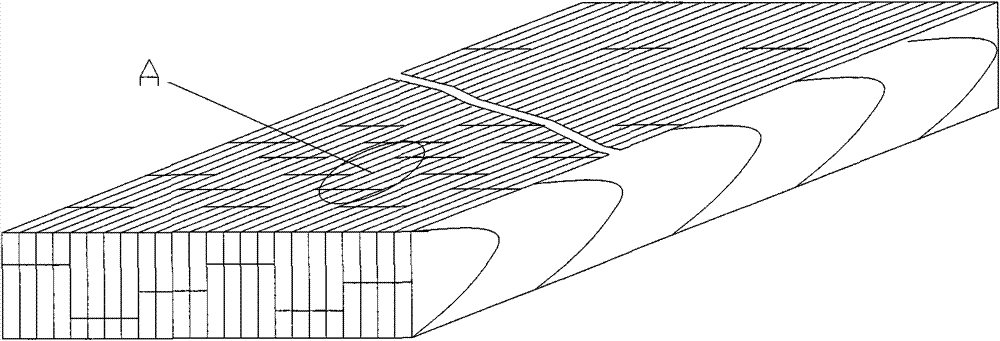

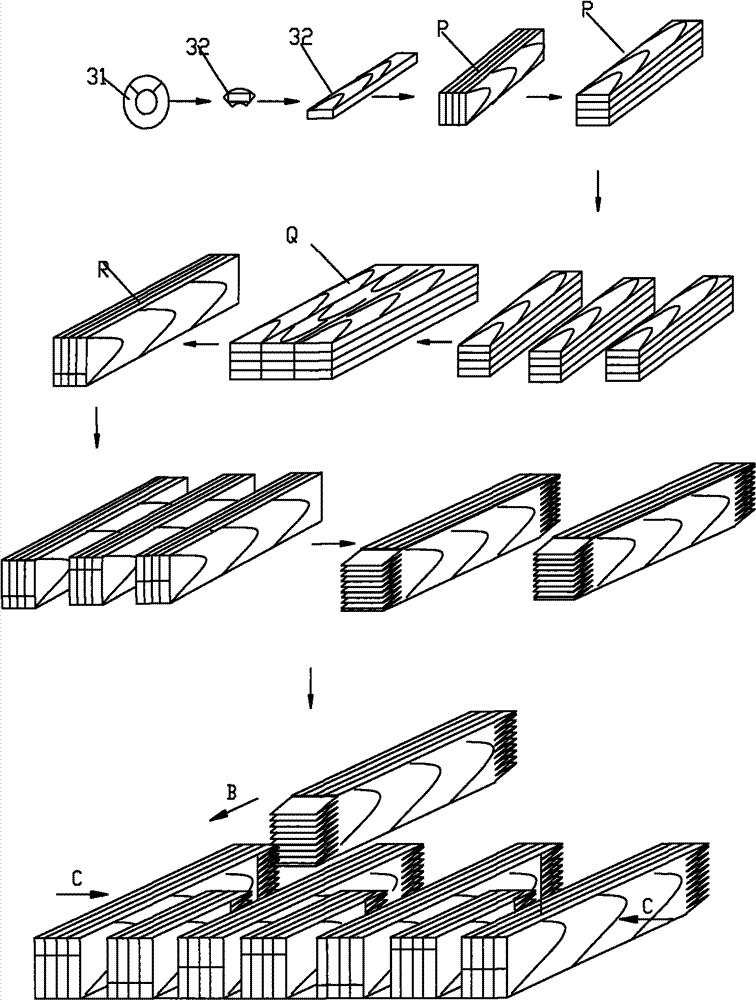

Glued laminated bamboo floor and manufacturing method thereof

ActiveCN101891047AReduce consumptionMeet the use requirementsBio-packagingLarge containersEngineeringBamboo floor

The invention discloses a method for manufacturing glued laminated bamboo floors. The bamboo is applied to containers, so the consumption of wood resources in inland container floors is reduced, the use requirement of the container floors is better met, and the manufacturing cost of the container floors is reduced; meanwhile, an intermittent continuous production method is adopted, so the method for manufacturing the glued laminated bamboo floors can produce various specifications of inland container floors, and better meets the requirements on the strength and fatigue resistance of the inland container floors.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

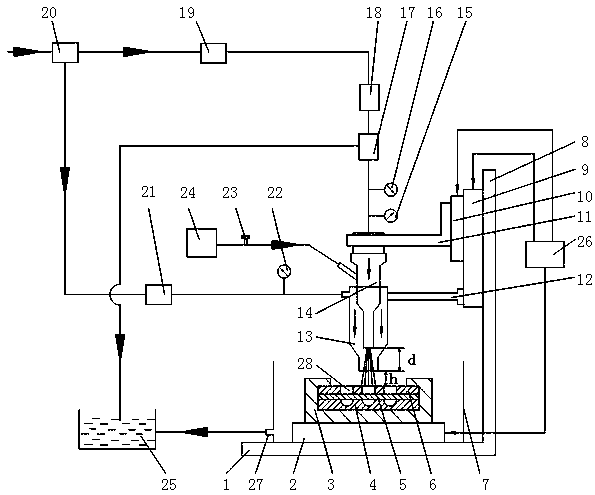

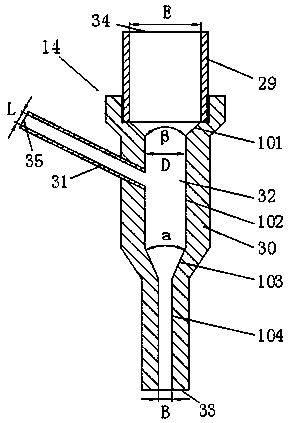

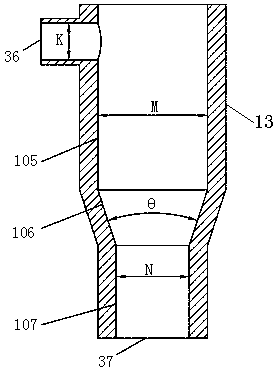

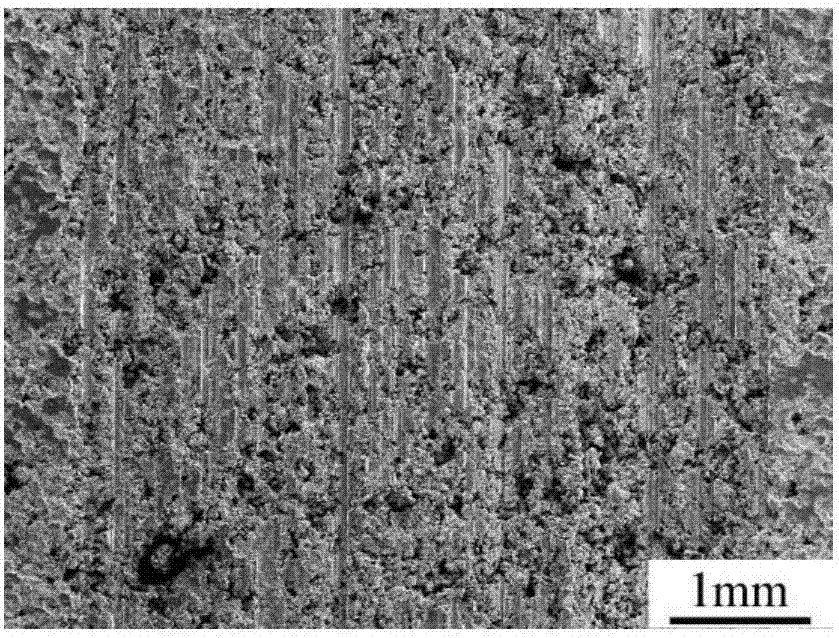

Device and method for plastic formation of micro parts through manual submerging type cavitation jetting

ActiveCN108890541AAppropriate intensityEasy to moveBlast gunsAbrasive feedersWorking fluidCavitation

The invention discloses a device and method for plastic formation of micro parts through manual submerging type cavitation jetting. The method comprises the following steps: enabling a working fluid to flow towards a pressurizing cylinder and a speed-regulating valve through an outlet of a three-way valve, and enabling the working fluid to enter a nozzle after the pressure and flow of the workingfluid are increased; opening a stop valve, spraying nano-scale abrasive particles in a micro-sized abrasive particle tank into the nozzle to be mixed with the fluid, and spraying the fluid out throughan outlet in the lower end of the nozzle; and introducing the residual fluid in the three-way valve to enter a casing pipe from another outlet of the three-way valve through a depressurizing valve. When uniformly mixed nano-scale abrasive particles and the fluid are sprayed out from the outlet of the nozzle and collide with the low-pressure fluid in the casing pipe, strong shear is generated, anda large number of vacuoles are generated and are sprayed to to-be-machined micro parts; and cavitation jetting is combined with the nano-scale abrasive particles, a mutual promotion effect is achieved, the cavitation is promoted, the plastic formation of the micro parts is promoted, the machined positions are not cracked, and the surface polishing and strengthening effects on a formed site of a workpiece are promoted, so that the device can meet the requirements on the strength, fatigue durability and the like of the workpiece.

Owner:JIANGSU UNIV

Aluminum matrix composite plate rolling method

ActiveCN106424196AImprove performanceImprove billet structureTemperature control deviceMetal rolling arrangementsHigh intensityLarge deformation

The invention discloses an aluminum matrix composite plate rolling method and belongs to the field of metal matrix composite molding machining. According to the method, on the basis that the density of a composite billet used for rolling is regulated, a plate blank is manufactured through multidirectional free forging and extruding, and the thickness of a rolled plate is 1-150 mm; sectional temperature rolling is adopted, cogging and reversing rolling are both conducted in a recrystallization temperature region so as to avoid detects generated in subsequent rolling, the rest of passes are subjected to large deformation rolling at a dynamic recovery temperature, and the rolling efficiency is improved; the regions of the rolling temperature and the rolling speed are narrowed so that organization can be precisely controlled and detects can be avoided; and medium and low temperature finish rolling is adopted so as to ensure the plate performance. In this way, the manufactured aluminum matrix composite plate has high strength and good corrosion resistance and fatigue resistance, and efficient rolling of large-size plates can be achieved.

Owner:中科复材(滨州)新材料有限公司

Preparing method of titanium fire resistance coating

ActiveCN107138878AHigh hardnessHigh temperature oxidation resistanceWelding/cutting media/materialsSoldering mediaAlloyFire resistance

The invention discloses a preparing method of a titanium fire resistance coating. A continuous strip-shaped Ti-37.5Zr-15Cu-10Ni base amorphous alloy is selected to serve as brazing filler metal, CBN particles are selected as hard wear-resisting particles, strip-shaped brazing filler metal is placed on the blade tip in advance, and wraps the blade tip required to be coated with the titanium fire resistance coating, an organic bonding agent is used for being mixed with Ni-plated CBN particles, and the brazing filler metal is evenly coated with the bonding agent; in the vacuum environment, a medium-frequency induction coil is used for locally heating a rotor blade tip, the heating temperature is kept between 840 DEG C to 850 DEG C and is kept for a certain time, the brazing filler metal can be completely molten, the brazing filler metal is naturally cooled in the high-vacuum environment, and the titanium fire resistance coating is formed; and the titanium fire resistance coating obtained through the preparing method of the titanium fire resistance coating has high hardness, high wear resistance, high impact resistance, high temperature oxidability resistance, high fire resistance and high combination strength, meanwhile, the property of the base body cannot be affected, and the base body anti-fatigue property is ensured.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

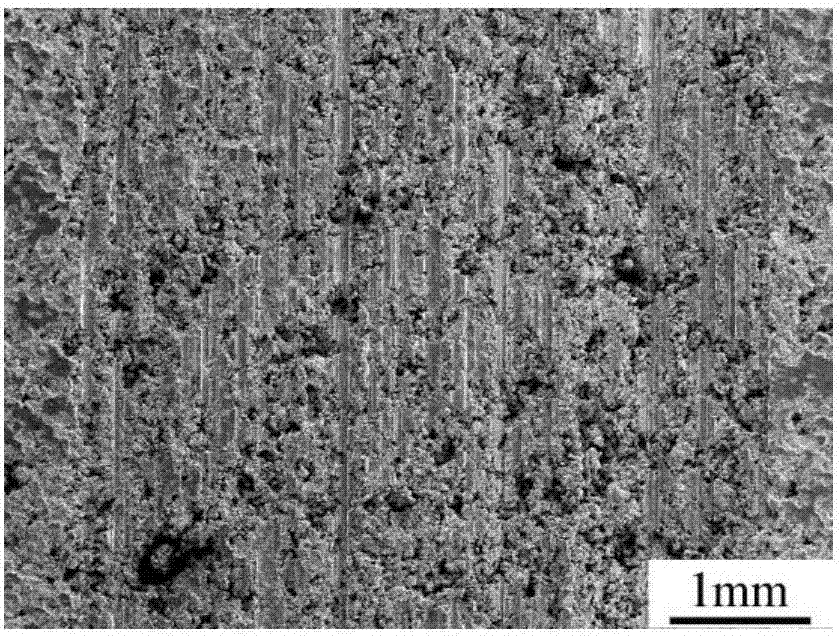

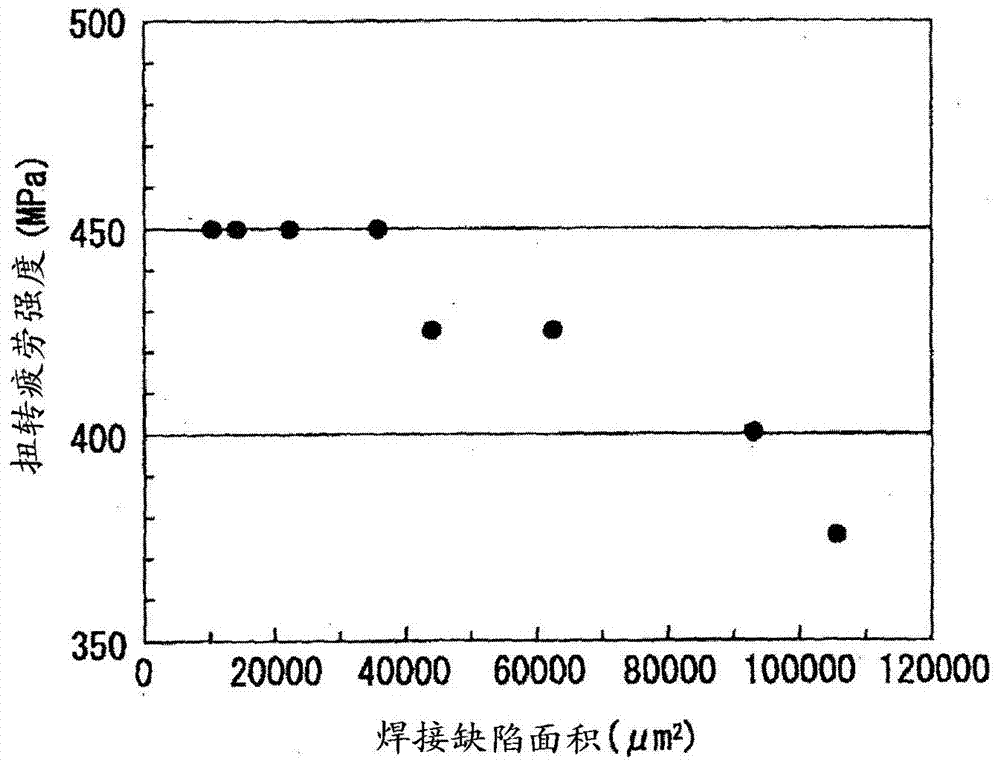

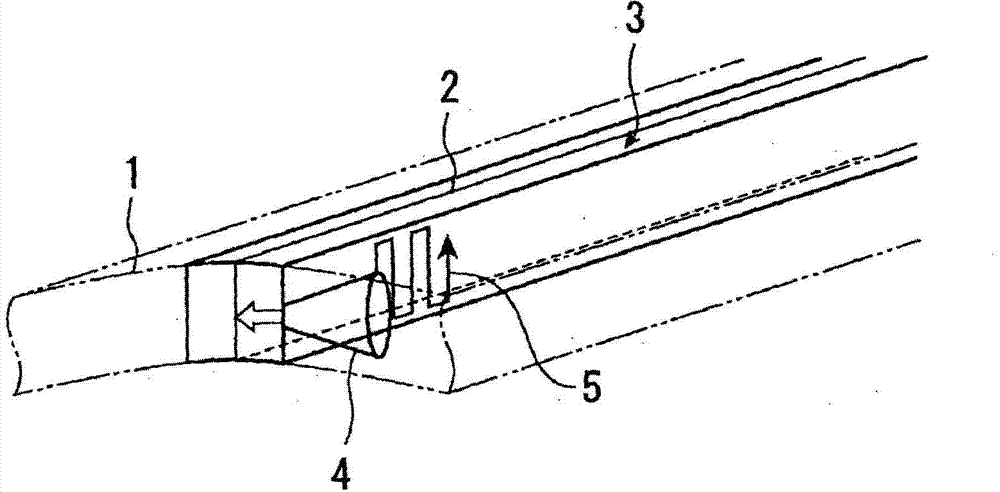

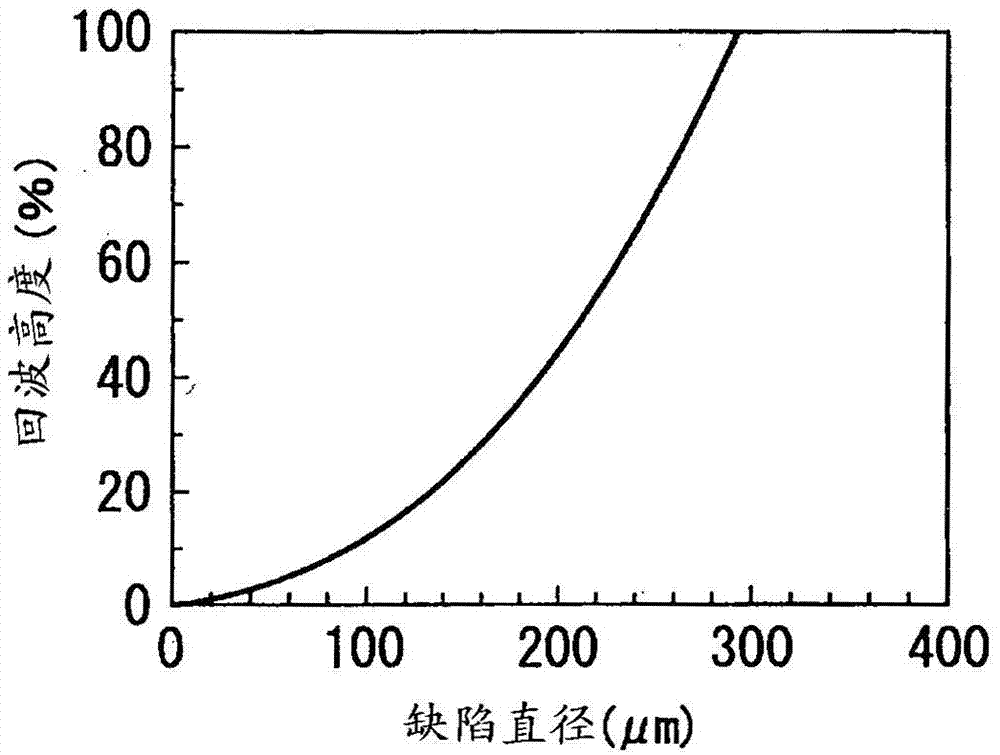

Electric-resistance-welded steel pipe with excellent torsion fatigue resistance and process for producing same

ActiveCN102906293AGuaranteed fatigue resistanceArc welding apparatusFurnace typesElectrical resistance and conductanceTorsion fatigue

Owner:JFE STEEL CORP

Glass fiber reinforced plastic flue gas jetting pipe used in desulphurization technology, and manufacturing method thereof

The invention discloses a glass fiber reinforced plastic flue gas jetting pipe used in a desulphurization technology. The glass fiber reinforced plastic flue gas jetting pipe comprises components of, from the inner side to the outer side: an inner antiseptic layer, a resin-rich structural layer, and an outer antiseptic layer. The inner antiseptic layer comprises a glass fiber surface felt layer and a glass fiber chopped strand felt layer manufactured from pasted oxirene-based resin. Oxirene-based resin takes 70-80wt% of the inner antiseptic layer. According to the weight of oxirene-based resin, 1-10% of silicon carbide and 1-2% of conductive carbon powder are mixed in oxirene-based resin. The resin-rich structural layer comprises normal thickness sections and thickened sections arranged along an axial direction of the jetting pipe. The thickened sections are arranged at connection positions between the glass fiber reinforced plastic flue gas jetting pipe and a separating plate, and between the glass fiber reinforced plastic flue gas jetting pipe and a grate. The resin-rich structural layer comprises alternately paved glass fiber check cloth layers and glass fiber chopped strand felt layers. The surfaces of the glass fiber check cloth layers and glass fiber chopped strand felt layers are pasted by using oxirene-based resin. Oxirene-based resin takes 55-70wt% of the resin-rich structural layer. Correspondingly, the invention provides a manufacturing method of the glass fiber reinforced plastic flue gas jetting pipe used in the desulphurization technology.

Owner:BAOSHAN IRON & STEEL CO LTD +1

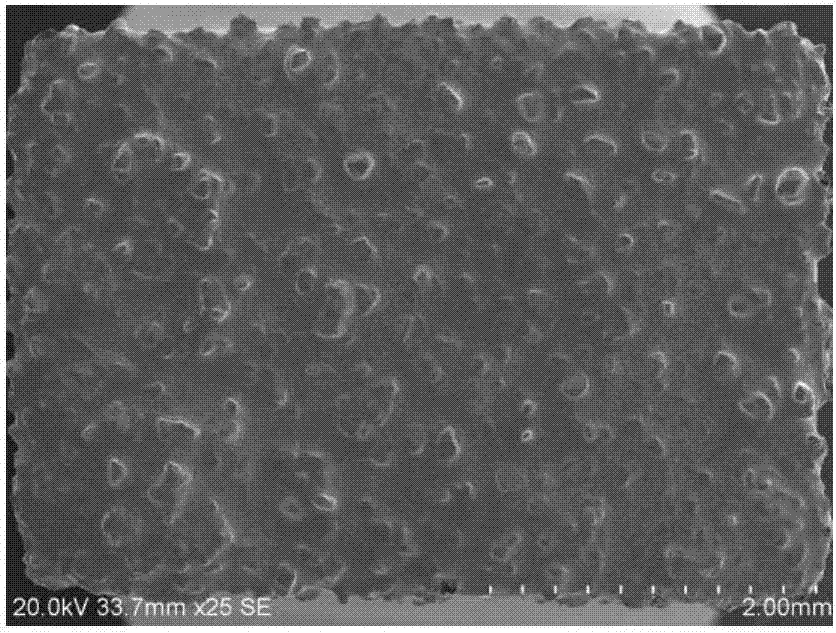

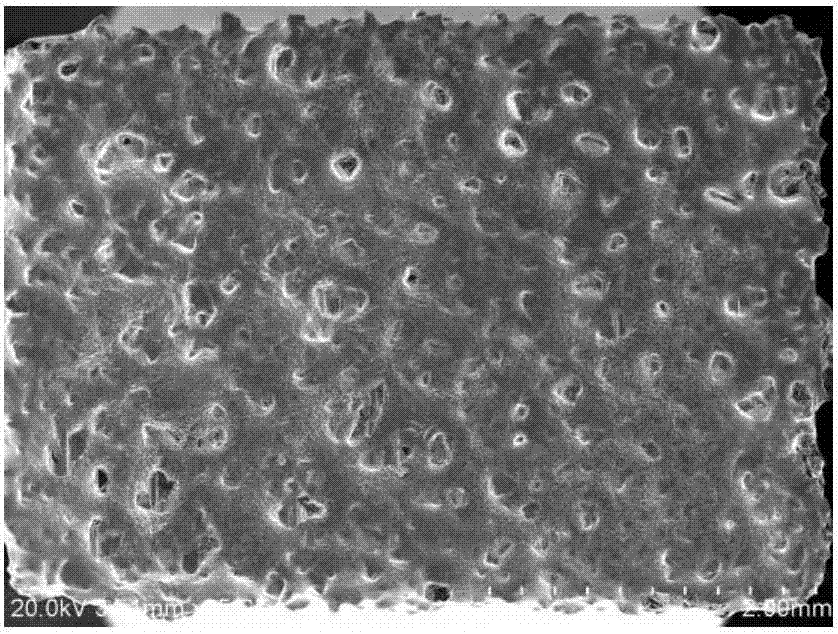

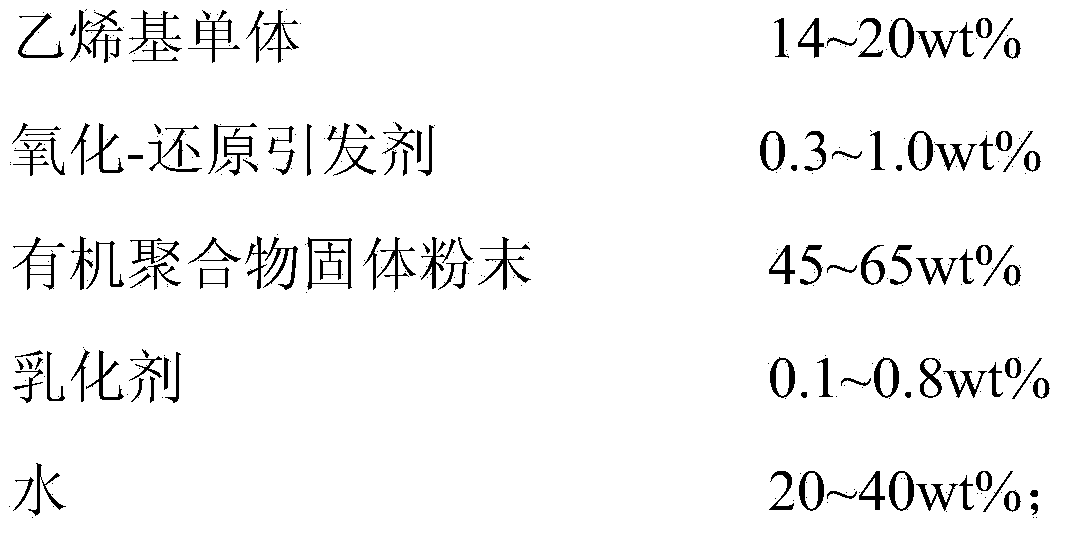

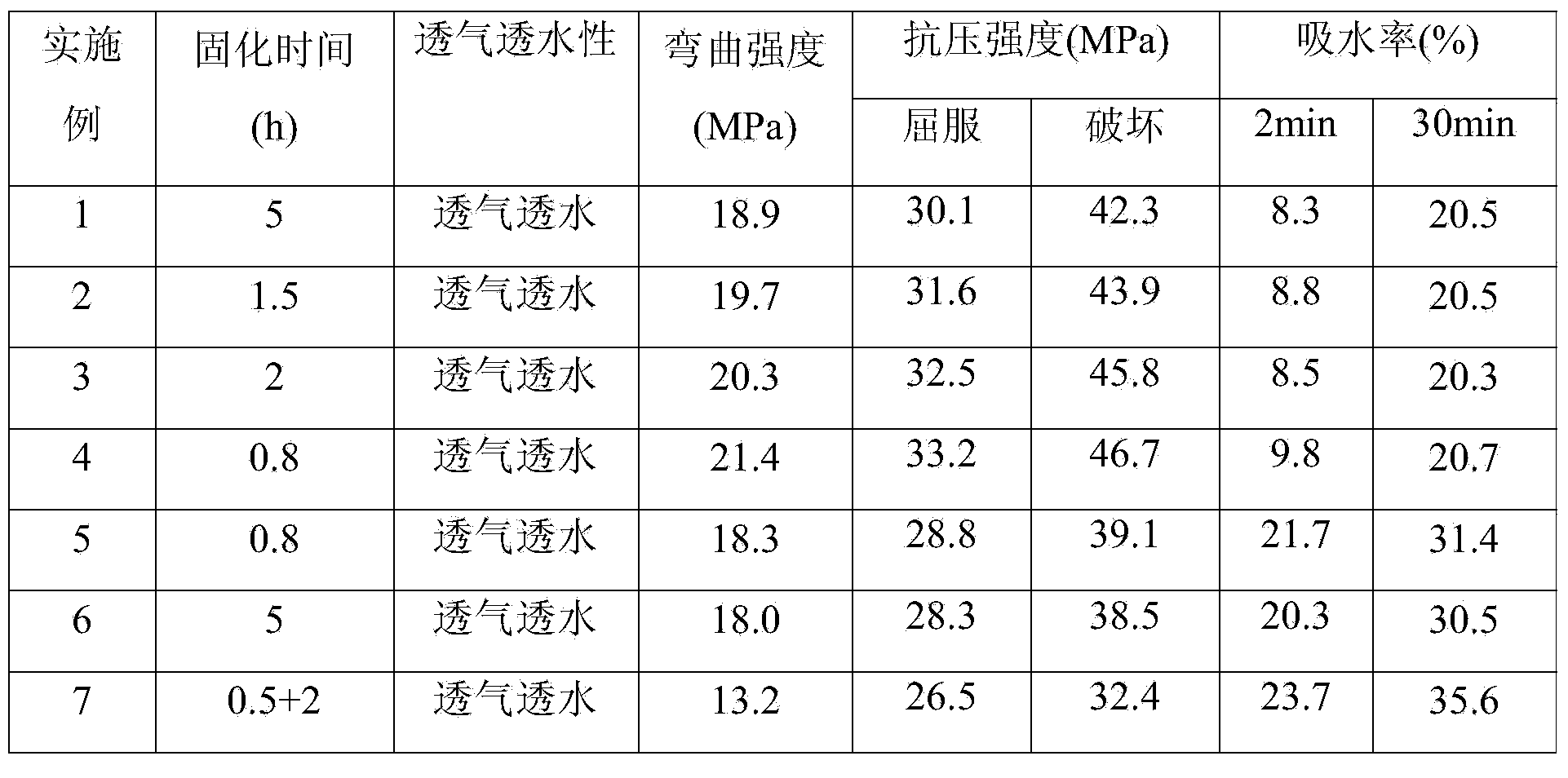

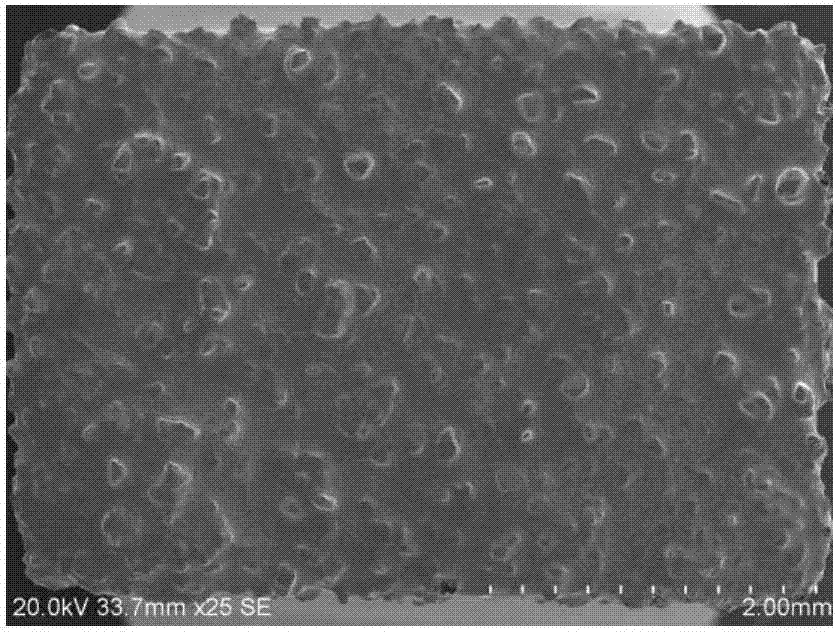

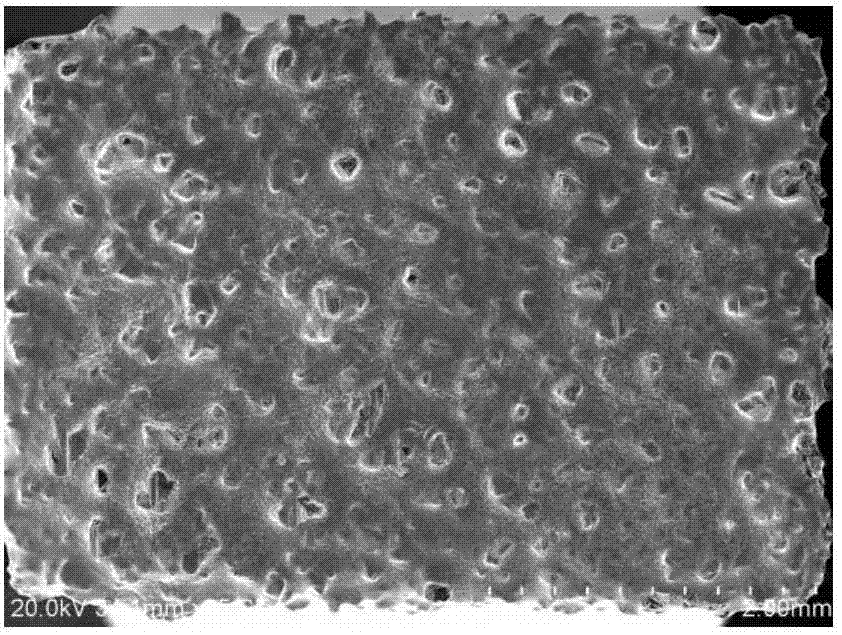

High-strength open-cell micro-porous plastic as well as preparation method and application thereof

ActiveCN103849096AGuaranteed mechanical strengthGuaranteed toughnessCompressive resistancePolymer science

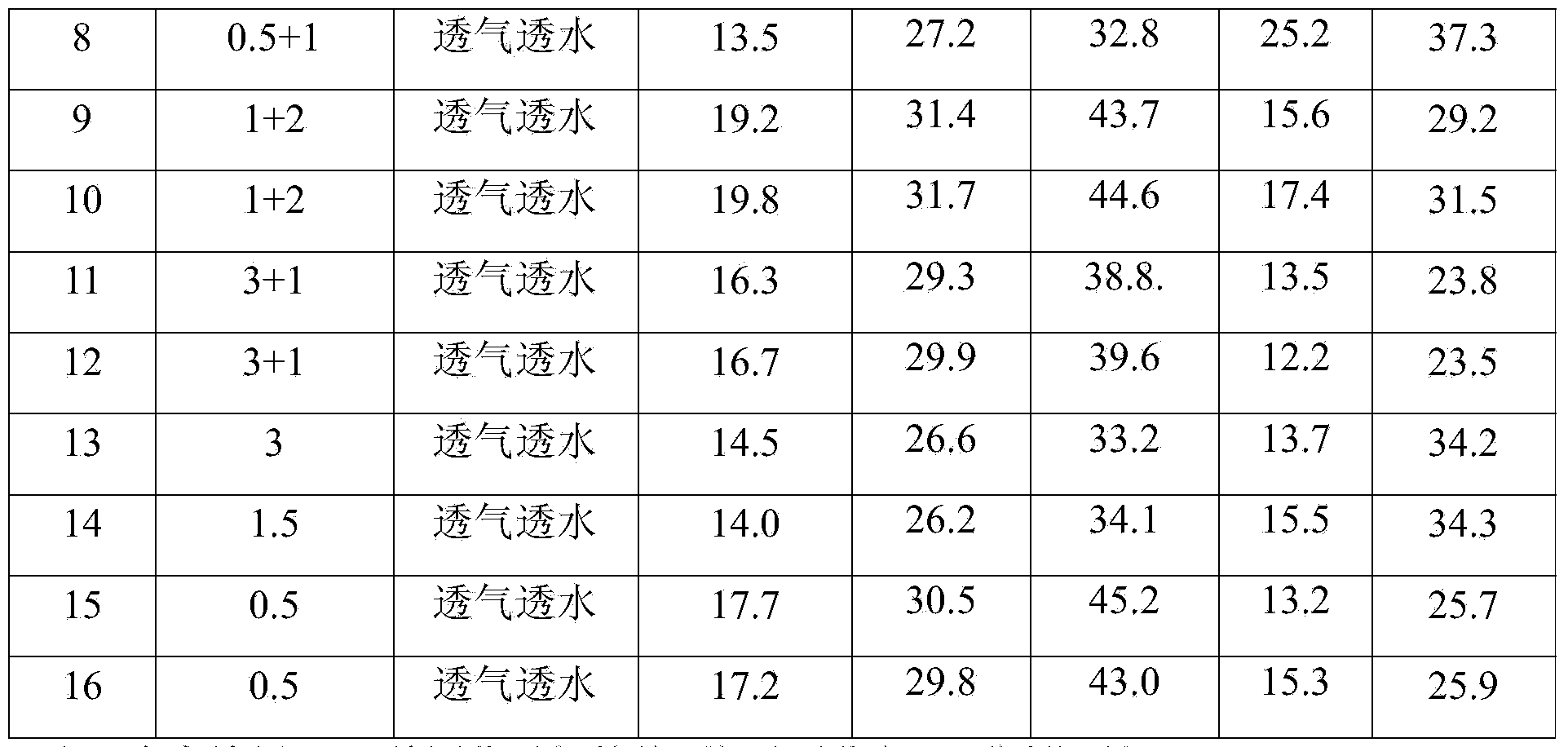

The invention discloses high-strength open-cell micro-porous plastic as well as a preparation method and application thereof. The preparation method comprises the following steps: rapidly mixing 14-20 percent by weight of vinyl monomer, 0.3-1.0 percent by weight of an oxidation-reduction initiator, 45-65 percent by weight of organic polymer solid powder, 0.1-0.8 percent by weight of emulsifier and 20-40 percent by weight of water uniformly at the temperature of 1-15 DEG C; rapidly adding into a mold for curing to obtain the high-strength open-cell micro-porous plastic. The yield compressive strength of the high-strength open-cell micro-porous plastic is more than 26MPa, the bending strength is more than 13MPa, and the water absorption is more than 20 percent. The high-strength open-cell micro-porous plastic has remarkable air permeability and water permeability, and can be used repeatedly. The preparation method is simple and convenient in process, can be cured and molded quickly at room temperature or in a way of heating slightly, is easy for industrial production, can be taken as a filter material, and has a wide application prospect.

Owner:国科广化(南雄)新材料研究院有限公司

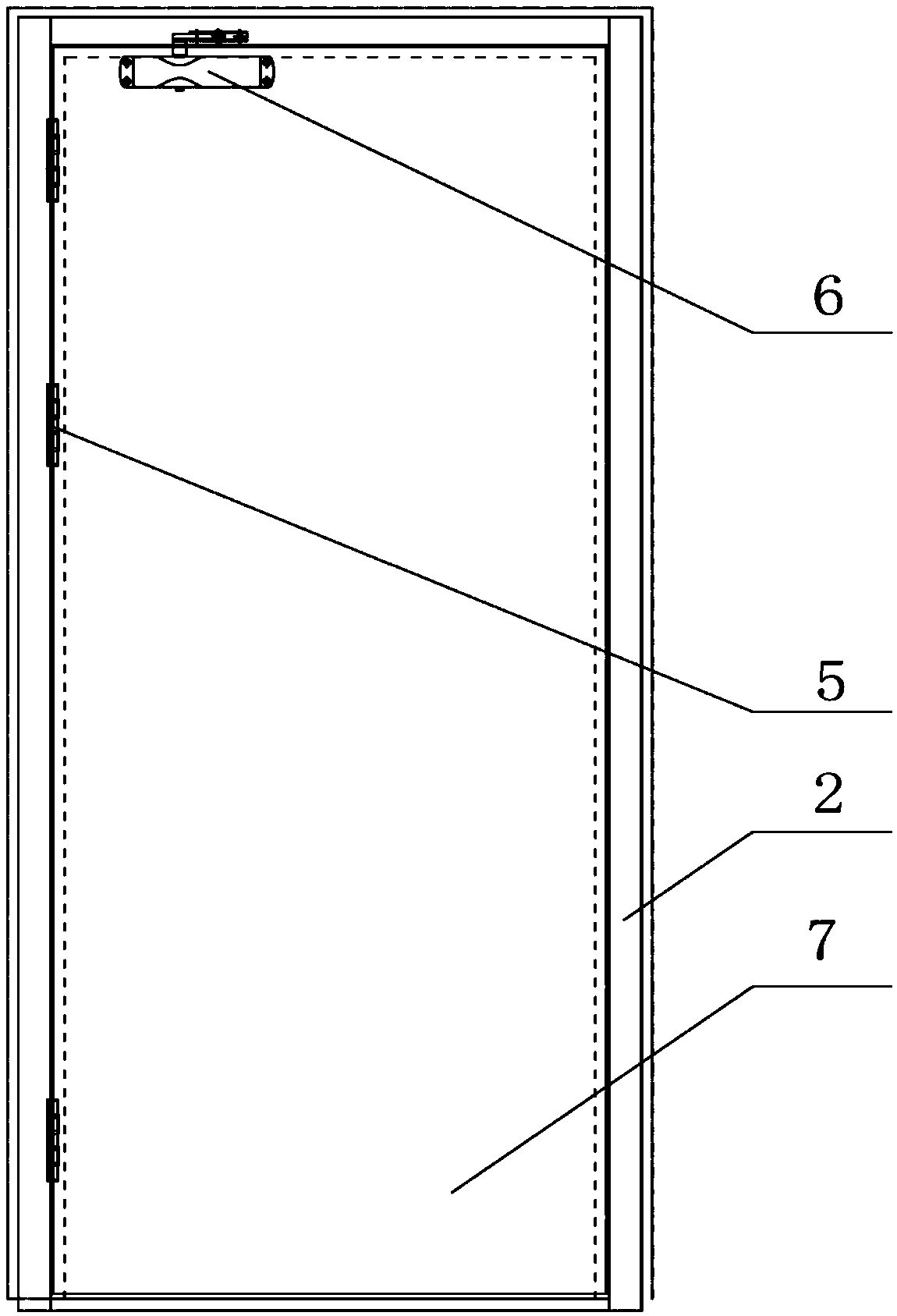

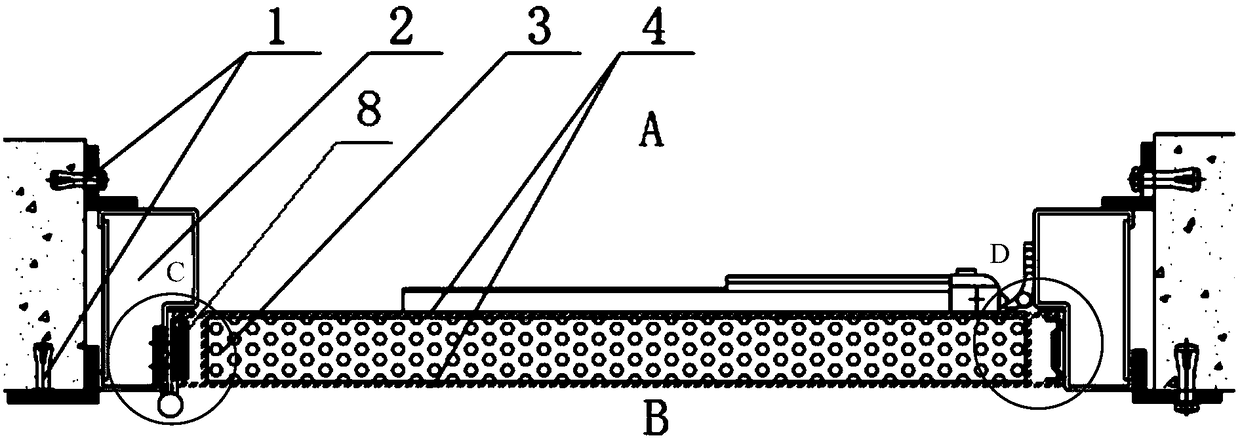

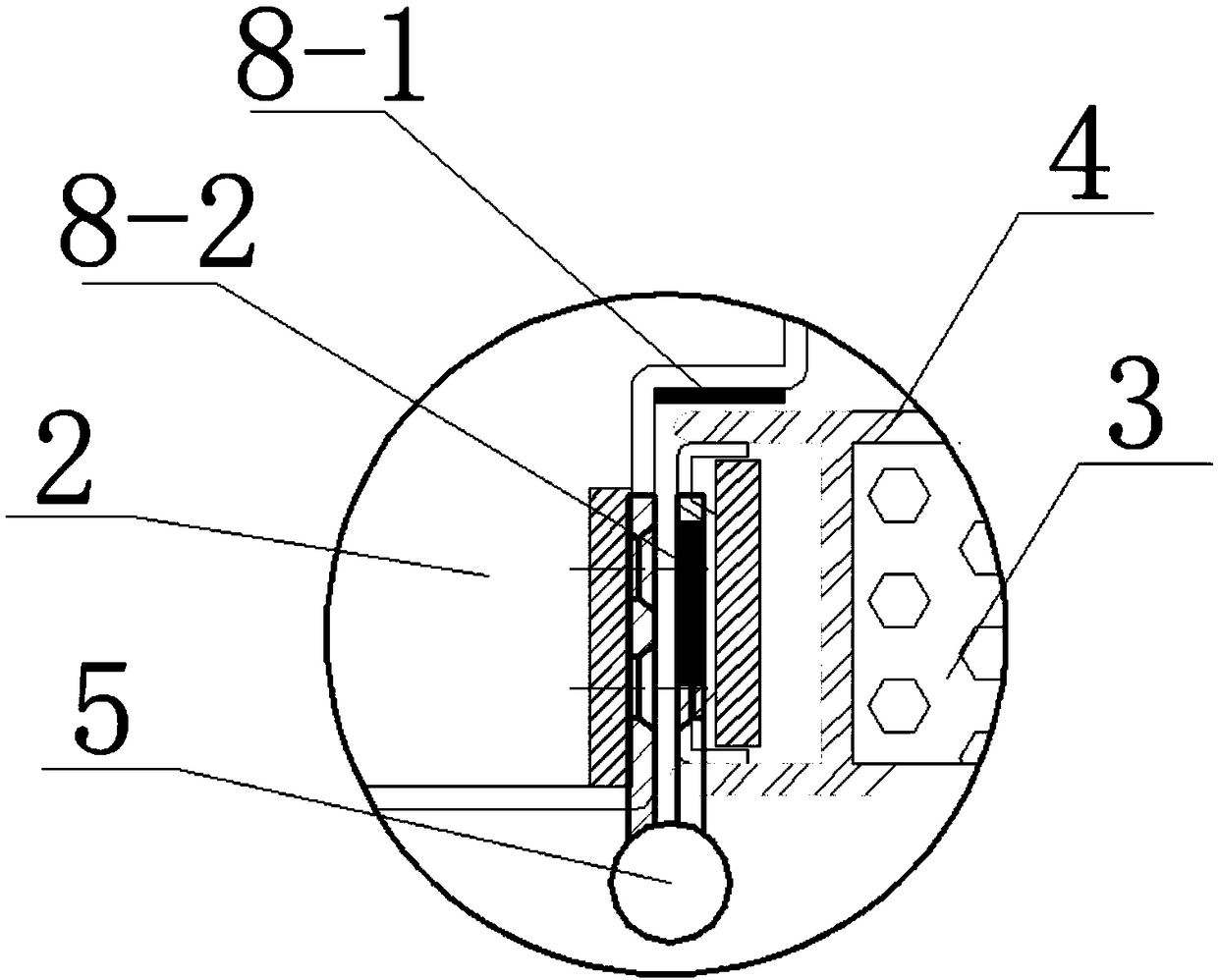

Composite tunnel fireproof door, fireproof door system and preparation method

PendingCN108757032AGuaranteed AntiknockGuaranteed wind resistanceMining devicesSynthetic resin layered productsGlass fiberCorrosion resistant

The invention belongs to the field of tunnel fireproof doors, and particularly discloses a composite tunnel fireproof door, a fireproof door system and a preparation method. The composite tunnel fireproof door is of a three-layer composite structure composed in the mode that a fireproof layer is sandwiched between two composite surface layers. The fireproof layer is made of a fireproof heat-resistant material, and the composite surface layers are made of high-strength corrosion-resistant materials. The fireproof door system comprises a door frame and the fireproof door mounted in the door frame, and the fireproof door is mounted in a tunnel doorway through the door frame. The preparation method comprises the steps that the fireproof layer is prepared, and a resin solution is prepared; theresin solution is smeared on the two surfaces of the fireproof layer to prepare fireproof layer prepreg; glass fibers are soaked in the resin solution and then dried to prepare prepreg; the prepreg issuperimposed on the two surfaces of the fireproof layer prepreg and then preheated and subjected to heat preservation to obtain a raw material plate; and the raw material plate is hot-pressed to prepare the composite tunnel fireproof door. The requirements of explosion resistance, wind pressure resistance, fatigue resistance and corrosion resistance are met while the fireproof performance is achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Making method of copper alloy wire for automobiles

InactiveCN104046831AImproves tensile strength and fatigue resistanceEnhanced flex resistanceCopper alloyFatigue resistance

The invention discloses a making method of a copper alloy wire for automobiles. The copper alloy wire comprises 0.3-0.6wt% of Mg, 0.2-0.4wt% of Ag, 0.4-0.7wt% of Sn, 0.15-0.25wt% of V, 0.12-0.18wt% of Nb, 0.05-0.1wt% of Ca, 0.04-0.08wt% of Sr, 0.03-0.05wt% of In, 0.02-0.03wt% of Se, 0.03-0.04wt% of La, 0.02-0.03wt% of Pr, 0.01-0.02wt% of Gd, 0.005-0.01wt% of P, and the balance Cu and inevitable impurities. The addition of a proper amount of Ag, In, Sr, Ca and the like in copper alloy substantially improves the tensile strength and the fatigue resistance of the alloy, enhances the flex resistance, and improves the elongation performance, so the reduction of the diameter of the wire and the reduction of the weight of a wire harness are realized on the premise that the mechanical strength and the fatigue resistance of a wire conductor are guaranteed.

Owner:RUIZHAN TONGLING TECH

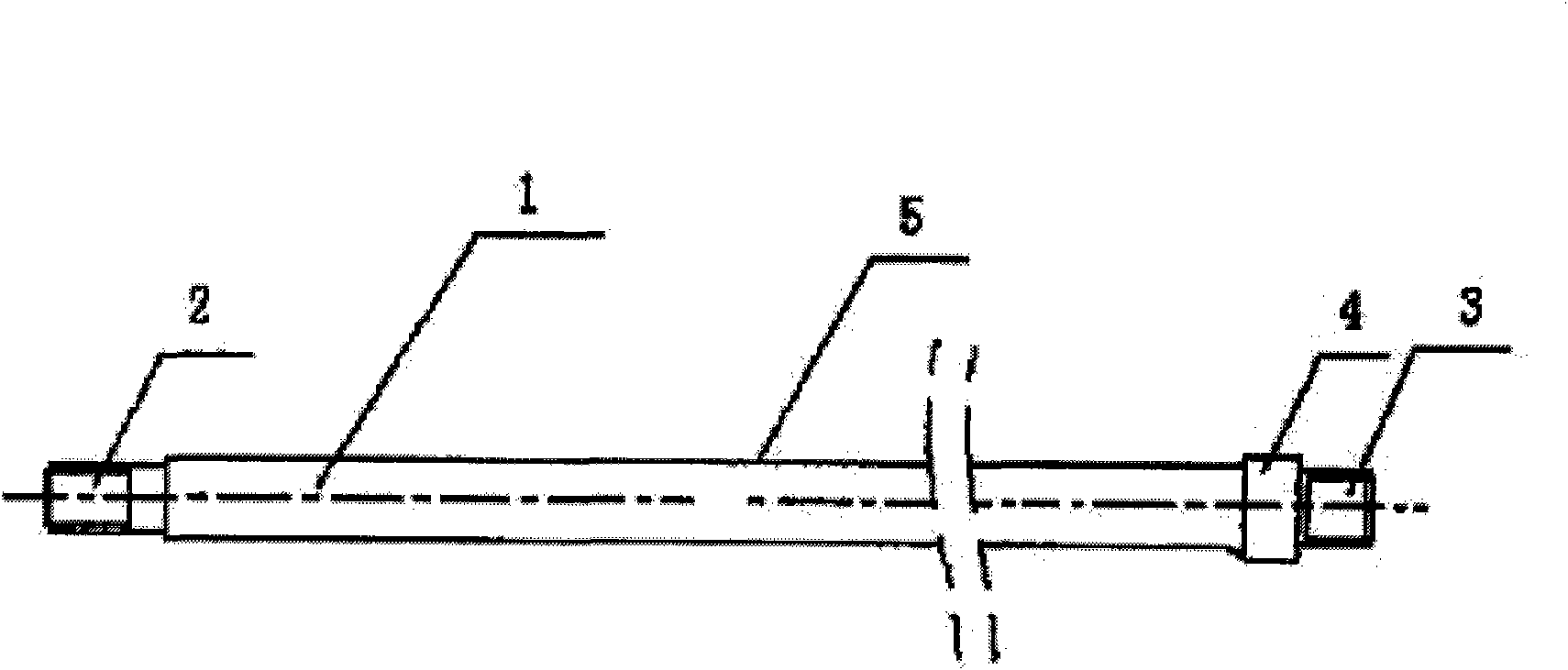

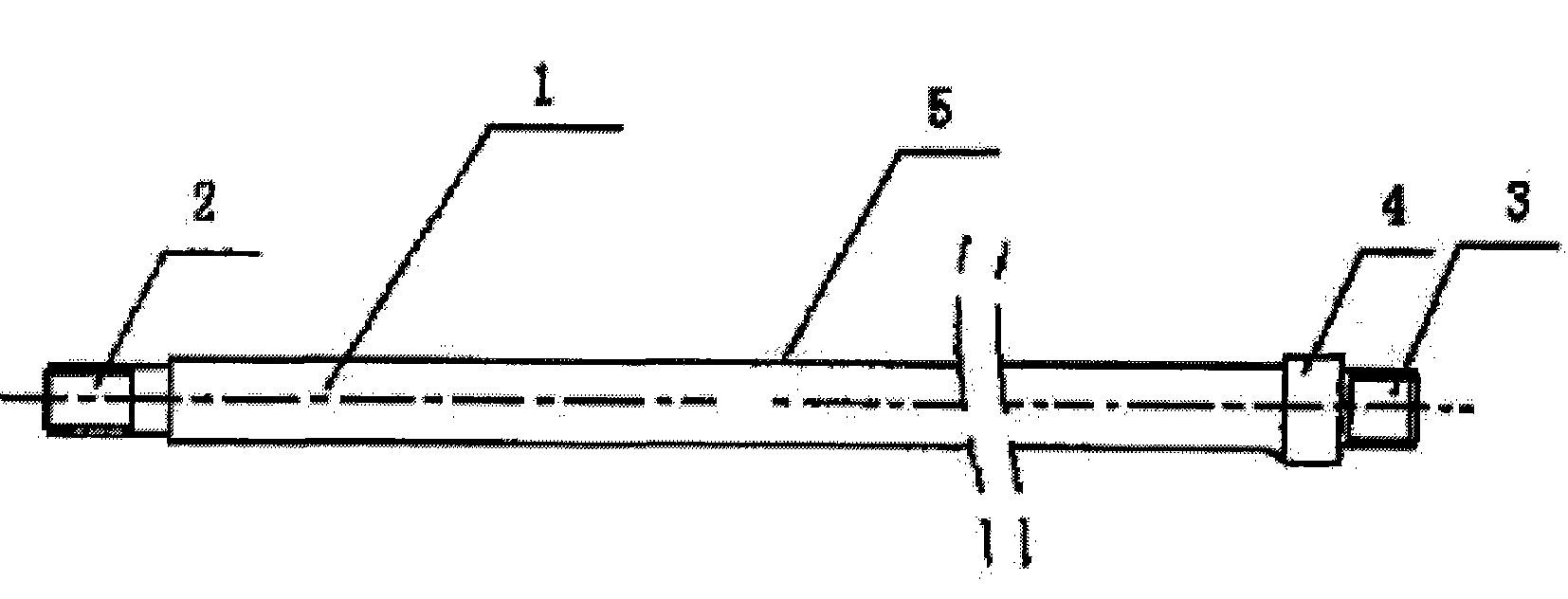

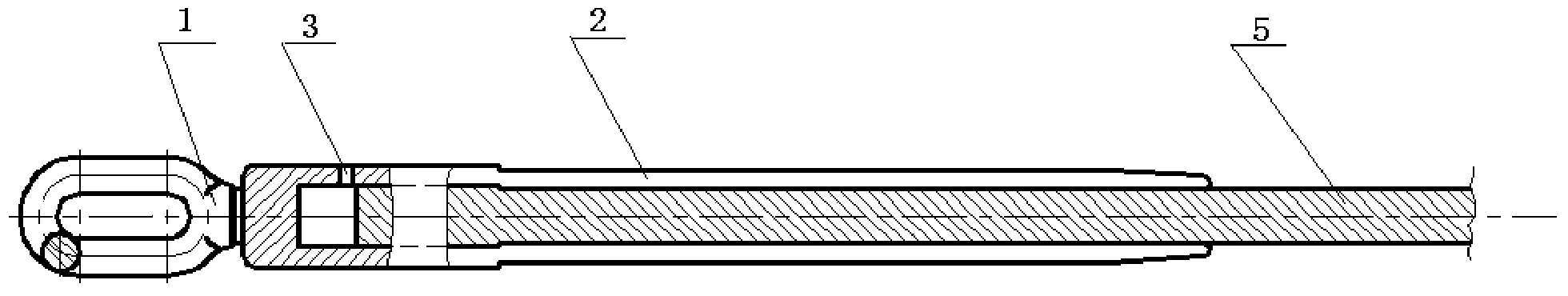

Oil pumping polish rod

InactiveCN102061891ALow costGuaranteed fatigue resistanceMolten spray coatingDrilling rodsManganeseAlloy coating

The invention relates to an oil pumping polish rod, consisting of an oil pumping polish rod base body and a nickel-based alloy coating layer on the surface of the oil pumping polish rod base body, wherein the oil pumping polish rod base body comprises the following chemical components in percent by weight: 0.12-0.20 percent of carbon, 0.50-1.60 percent of silicon, 0.50-1.10 percent of manganese, less than or equal to 0.025 percent of phosphorus, less than or equal to 0.025 percent of sulphur, more than or equal to 1.50 percent of chromium, nickel and molybdenum and the balance of ferrum. The oil pumping polish rod has the advantages of better comprehensive mechanical property, high intensity, high stretchability and high fatigue resistance. Through spraying and welding the nickel-based alloy coating layer on the surface of steel materials, the corrosion resistance is also improved so that the made alloy polish rod can excellently meet the increasingly-demanding high load and corrosive service environment in the oil field.

Titanium fire resistance coating

ActiveCN107142474AHigh hardnessHigh temperature oxidation resistanceMetallic material coating processesBand shapeAlloy

The invention discloses a titanium fire resistance coating. A continuous strip-shaped Ti-37.5Zr-15Cu-10Ni base amorphous alloy is selected to serve as brazing filler metal, CBN particles are selected as hard wear-resisting particles, strip-shaped brazing filler metal is placed on the blade tip in advance, and wraps the blade tip required to be coated with the titanium fire resistance coating, an organic bonding agent is used for being mixed with Ni-plated CBN particles, and the brazing filler metal is evenly coated with the bonding agent; in the vacuum environment, a medium-frequency induction coil is used for locally heating a rotor blade tip, the heating temperature is kept between 840 DEG C to 850 DEG C and is kept for a certain time, the brazing filler metal is completely molten, the brazing filler metal is naturally cooled in the high-vacuum environment, and the titanium fire resistance coating is formed; and the titanium fire resistance coating obtained through the preparing method of the titanium fire resistance coating has high hardness, high wear resistance, high impact resistance, high temperature oxidability resistance, high fire resistance and high combination strength, meanwhile, the property of the base body cannot be affected, and the base body anti-fatigue property is ensured.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

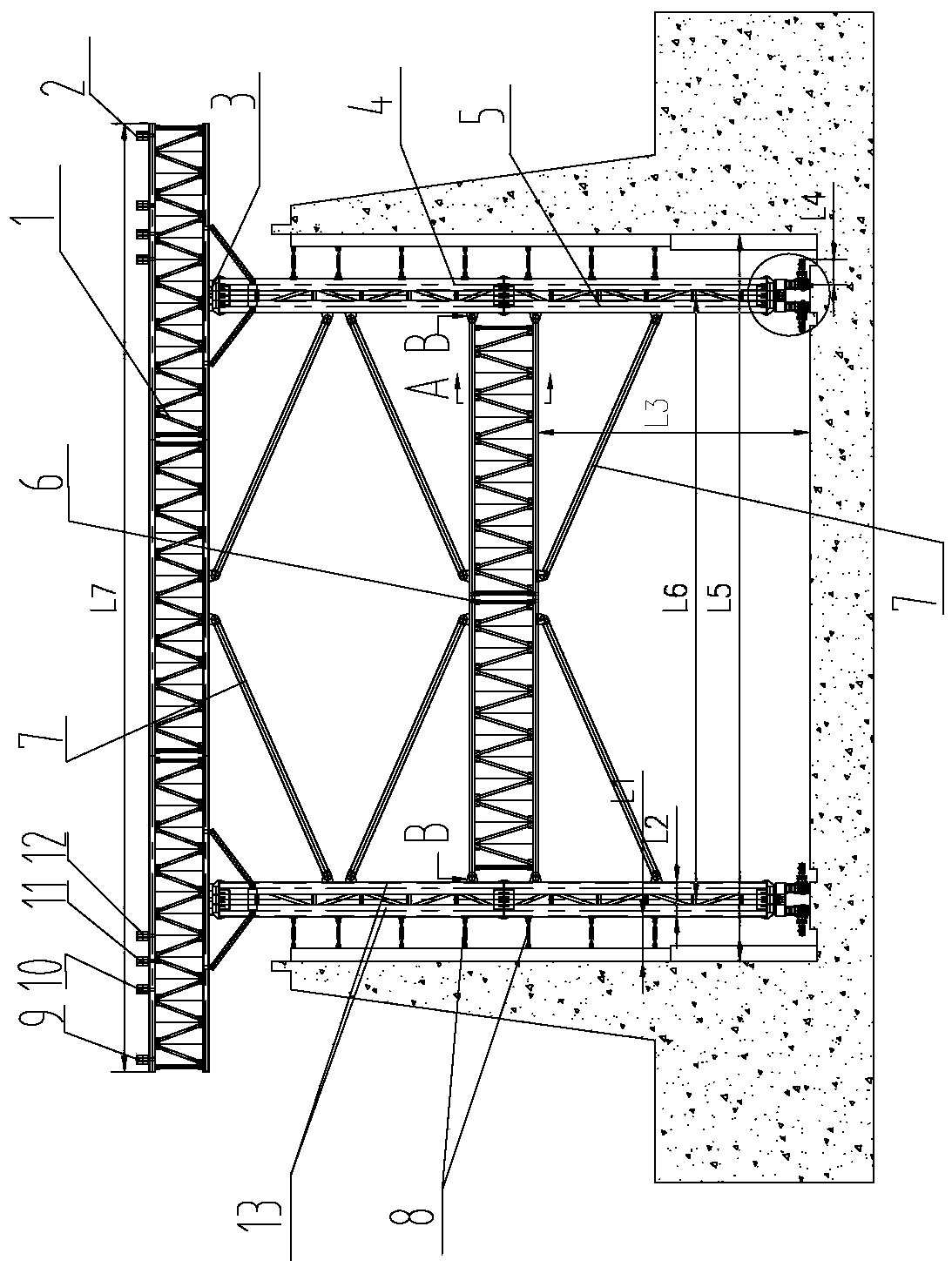

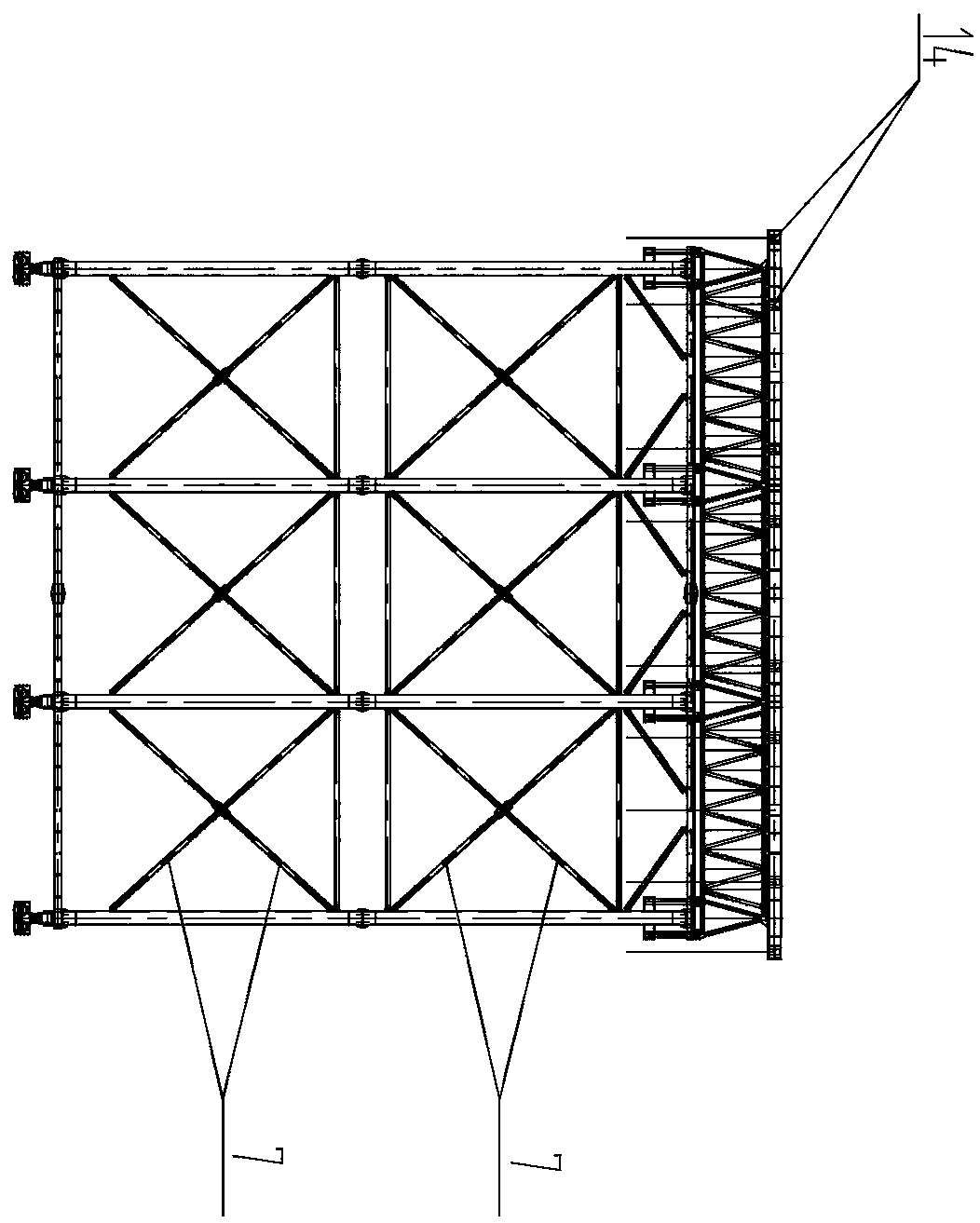

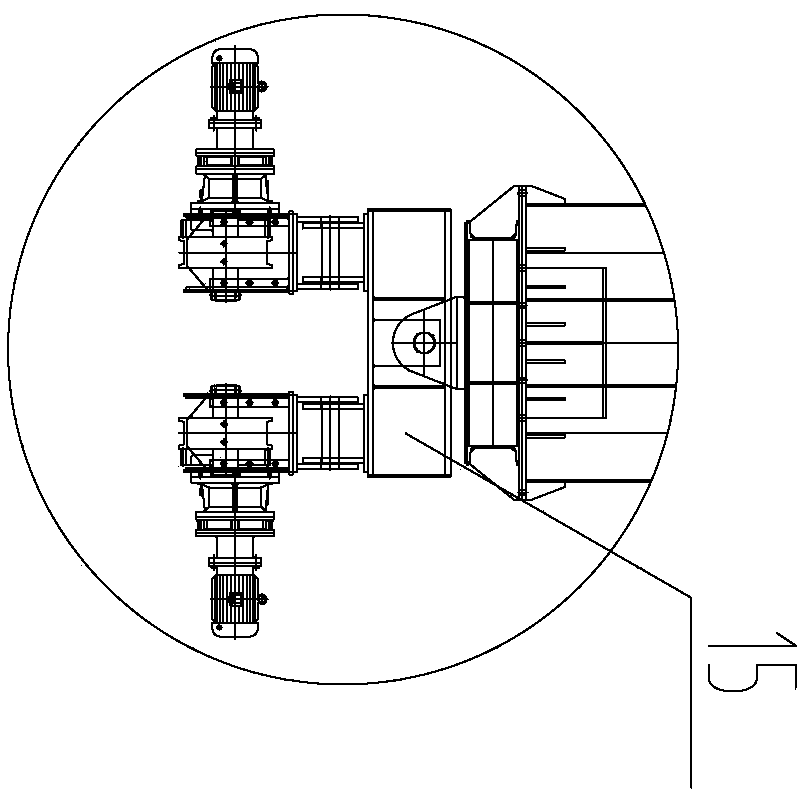

Construction method for movable mold frame for lock chamber wall of ship lock

InactiveCN107386246AReduce equipmentReduce labor intensityDry-docksClimate change adaptationSingle sectionBuilding construction

Owner:周学顺

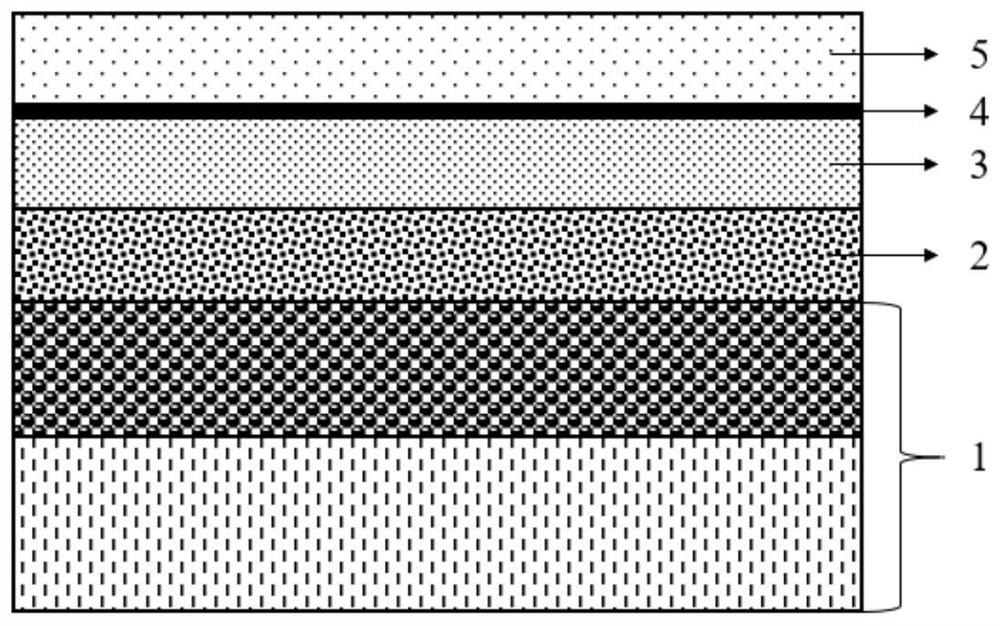

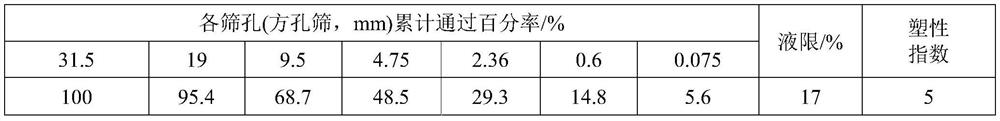

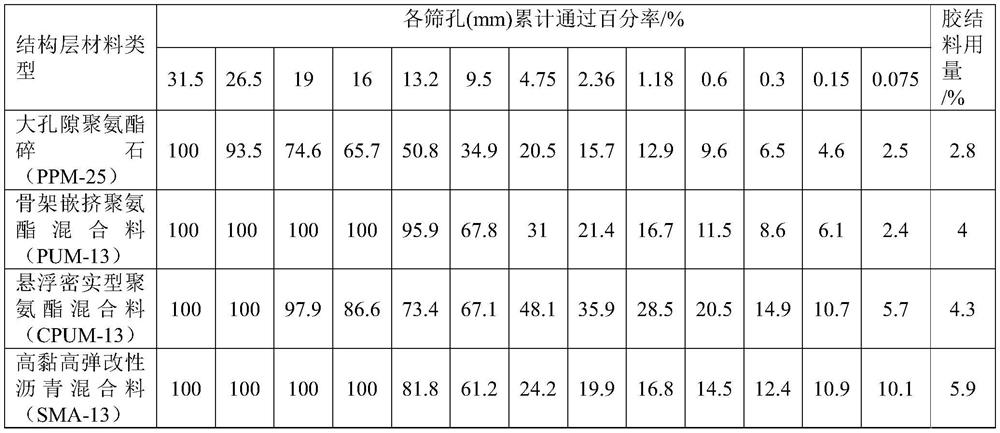

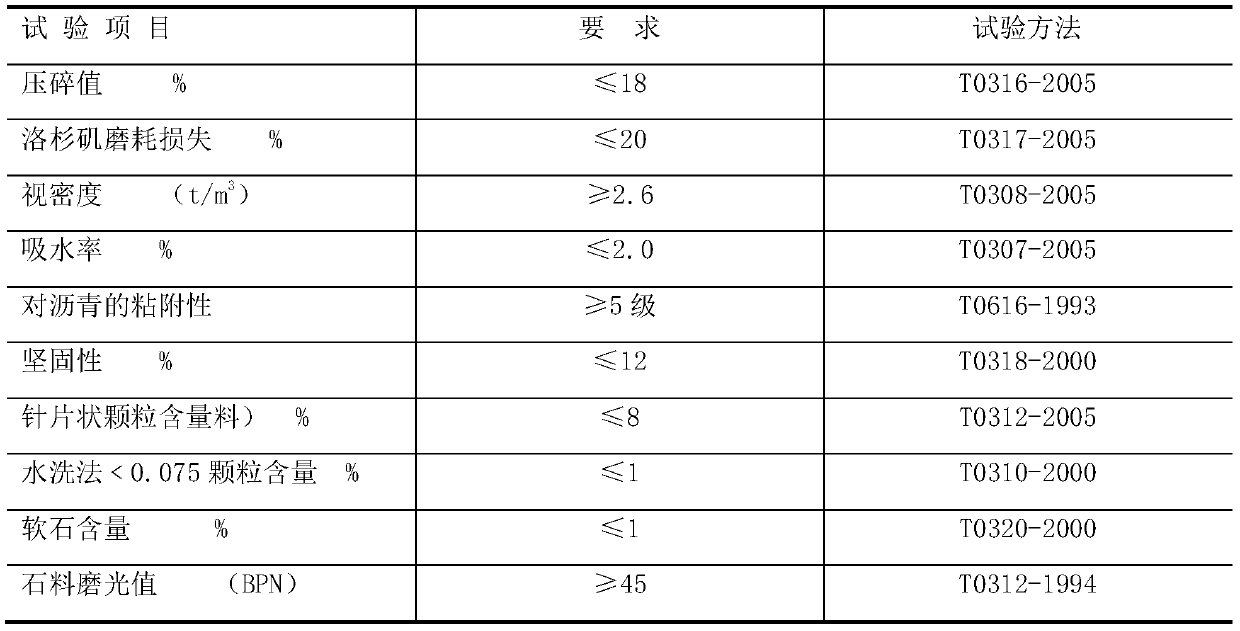

Full-thickness ultrathin long-service-life pavement structure and construction method thereof

ActiveCN112726321AImprove stabilityExtended service lifeIn situ pavingsRoads maintainenceStructural engineeringRoad surface

The invention discloses a full-thickness ultrathin long-service-life pavement structure and a construction method thereof. According to the method, a pavement structure layer with different functions is prepared by matching a polyurethane material with different mineral aggregates, and the full-thickness ultrathin long-service-life pavement structure is synthesized according to the functional difference of the structure layer; the pavement structure is good in overall stability, high in interlayer bonding strength, high in fatigue load resistance, small in structural layer number and small in structural layer thickness, and the service life of the pavement structure can be effectively prolonged.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

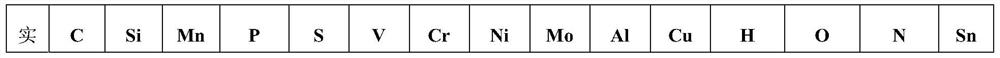

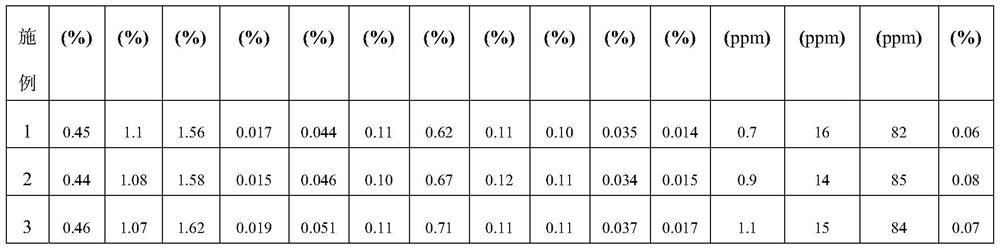

Fatigue-resistant and corrosion-resistant round steel for forging and pressing and preparation method thereof

ActiveCN112899571AImprove fatigue resistanceImprove mechanical propertiesCrankshaftCorrosion resistant

The invention discloses fatigue-resistant and corrosion-resistant round steel for forging and pressing and a preparation method thereof.The fatigue-resistant and corrosion-resistant round steel comprises the following chemical components in percentage by mass: 0.42 to 0.49 percent of C, 1.00 to 1.20 percent of Si, 1.50 to 1.70 percent of Mn, 0.1 to 0.13 percent of V, 0.50 to 1.20 percent of Cr, 0.1 to 0.30 percent of Ni, 0.10 to 0.30 percent of Mo, 0.035 to 0.075 percent of S, less than or equal to 0.035 percent of P, 0.033 to 0.058 percent of Al, less than or equal to 0.02 percent of Cu, less than or equal to 20 * 10 <-4 > percent of O, less than or equal to 1.5 * 10 <-4 > percent of H, 80 * 10 <-4 > to 100 * 10 <-4 > percent of N, 0.05 to 0.10 percent of Sn and the balance of iron and inevitable impurities. The prepared steel has the advantages of being good in mechanical performance, fatigue resistance and corrosion resistance, low in manufacturing cost, short in manufacturing period, capable of being directly used for the forging and pressing procedure without thermal refining and the like, and can be used for hot forging of automobile parts such as crankshafts and connecting rods.

Owner:SHANDONG IRON & STEEL CO LTD

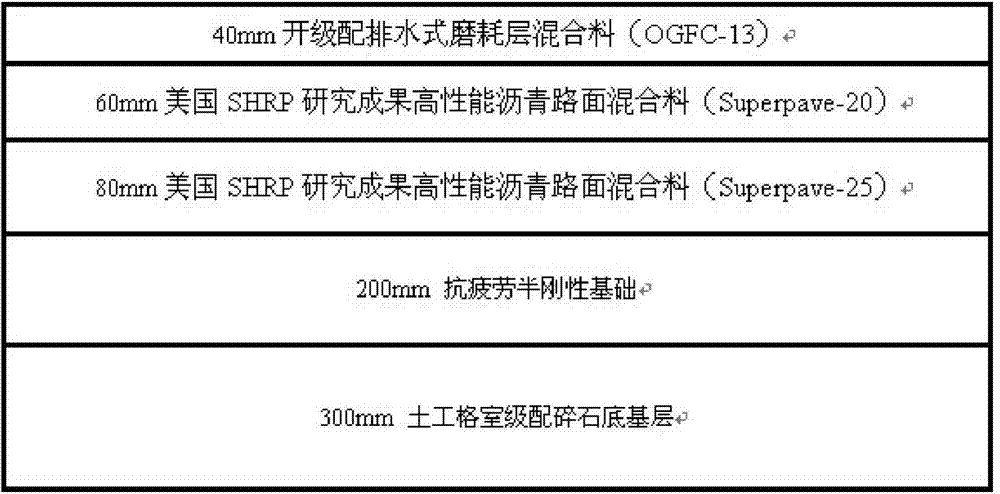

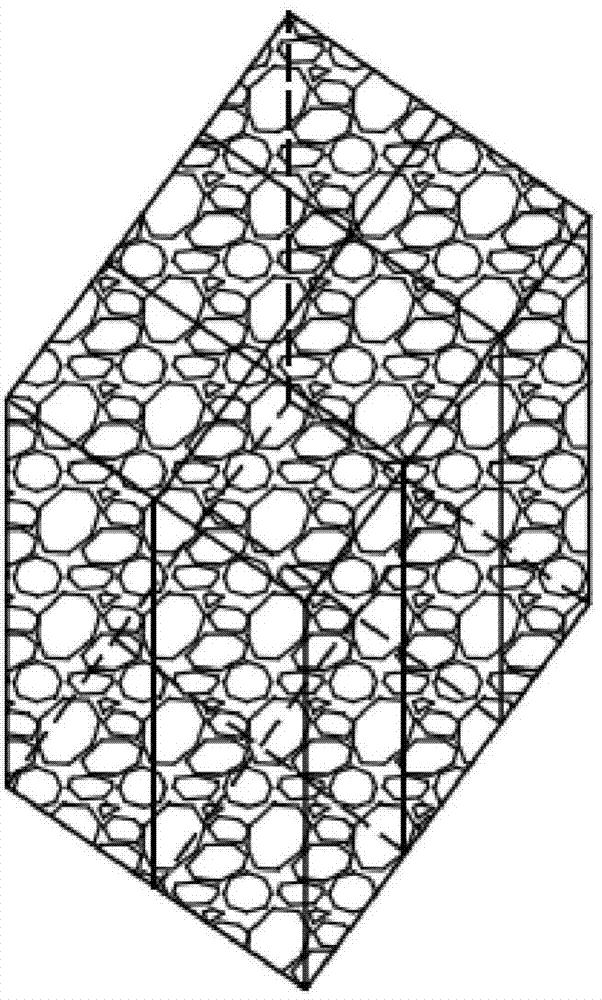

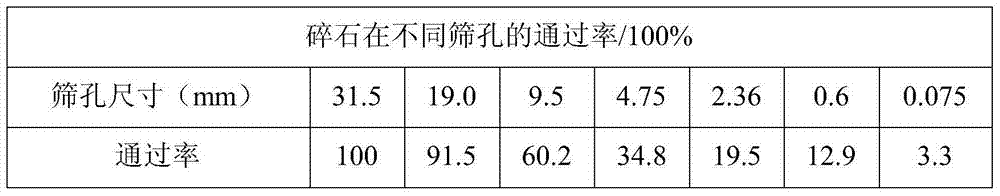

Asphalt pavement structure based on coordination of deformation of subgrade and pavement

The invention provides an asphalt pavement structure based on the coordination of the deformation of a subgrade and a pavement. The pavement structure comprises an asphalt pavement layer, an anti-fatigue semi-rigid base layer and a sub-base layer in sequence from top to bottom, wherein the asphalt surface layer comprises a surface layer, a middle surface layer and a lower surface layer; the surface layer is located on the upper surface of the asphalt pavement layer; the middle surface layer is paved under the surface layer; the lower surface layer is paved under the middle surface layer; sticking layer oil is sprayed among the surface layer, the middle surface layer and the lower surface layer respectively; the anti-fatigue semi-rigid base layer is paved under the lower surface layer; prime coat oil is sprayed between the anti-fatigue semi-rigid base layer and the lower surface layer; and the sub-base layer is paved on the subgrade. The influences on the pavement structure, caused by the non-uniform deformation of the subgrade, can be effectively alleviated.

Owner:SOUTHEAST UNIV

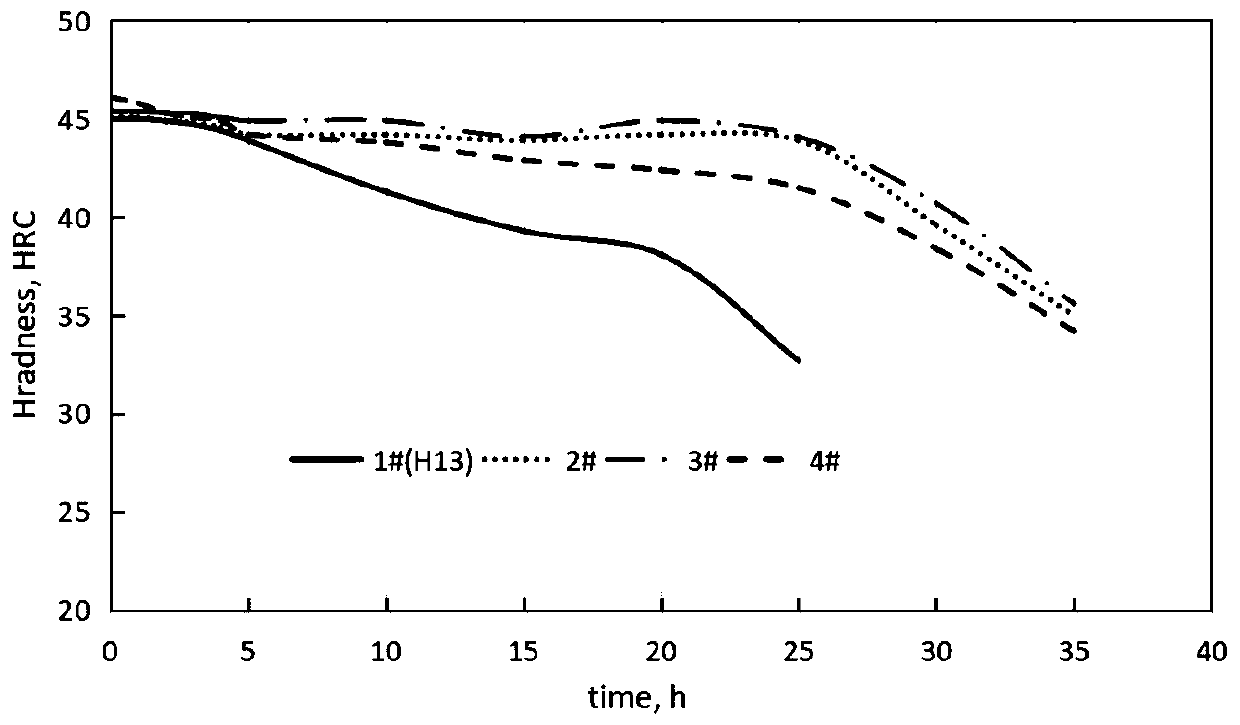

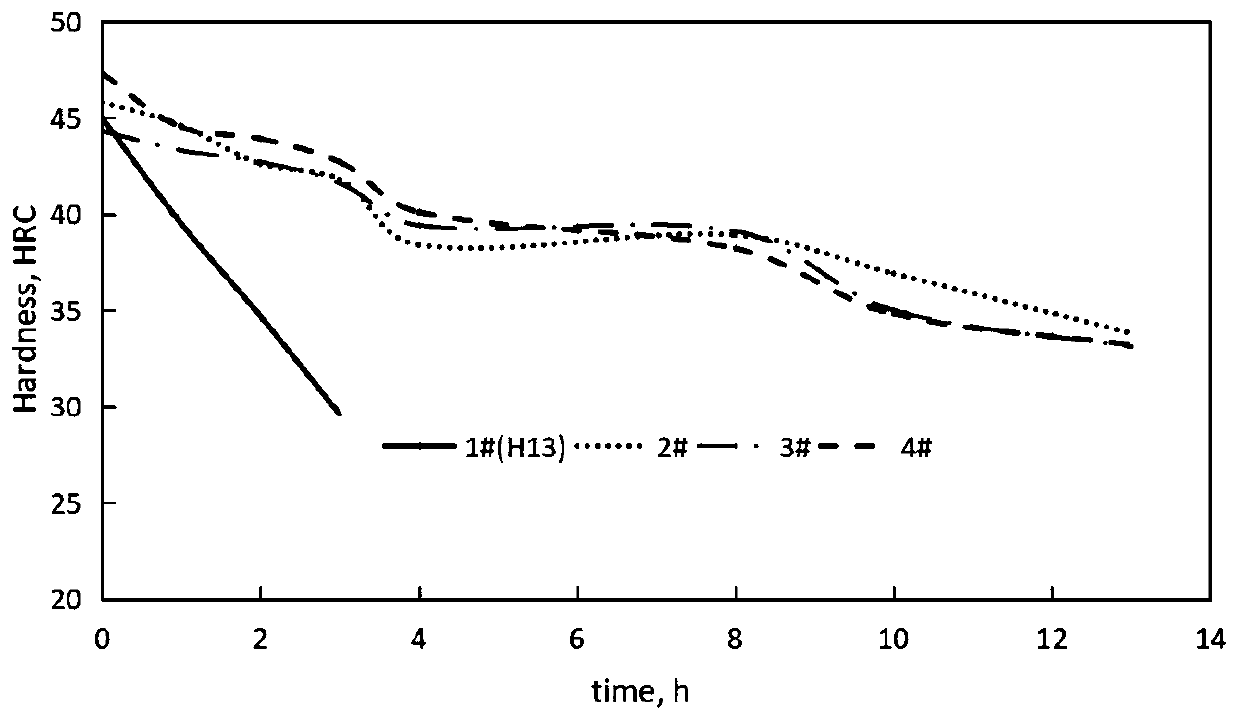

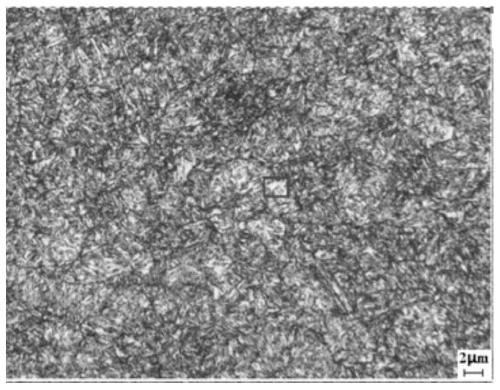

H13 matrix steel and preparation method thereof

ActiveCN111549284AImprove temper stabilityImprove thermal stabilityFurnace typesHeat treatment furnacesMaterials processingRound bar

The invention relates to H13 matrix steel and a preparation method thereof, belongs to the technical field of material processing, and solves the problems of low strength and toughness, poor thermal stability and poor fatigue resistance of existing H13 steel. The H13 matrix steel comprises the following chemical components of, in percentage by mass, 0.30%-0.45% of C, 1.0%-2.0% of Si, 0.50%-1.0% ofMn, 3.0%-4.0% of Cr, 2.5%-3.5% of Mo, 0.7%-1.2% of V, 0.001%-0.05% of Al, 0.004%-0.03% of N, and the balance iron element. The preparation method of the H13 matrix steel comprises the following stepsthat 1, raw materials are prepared according to the composition of each element of the H13 matrix steel, and smelting is carried out in a vacuum furnace to obtain a steel ingot; 2, the steel ingot issubjected to free forging; 3, after free forging is conducted, isothermal spheroidizing annealing is conducted on a round bar; and 4, after spheroidizing annealing, the round bar is subjected to heattreatment, and a product with the specified size is obtained through machining. According to the preparation method, the strength and toughness, the thermal stability and the fatigue resistance of the H13 matrix steel are improved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

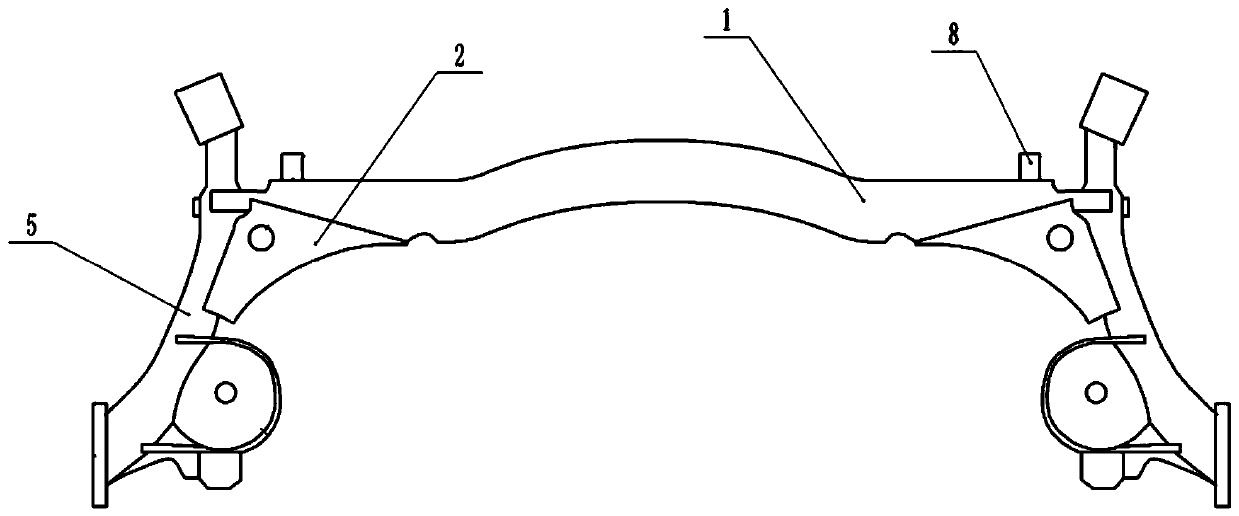

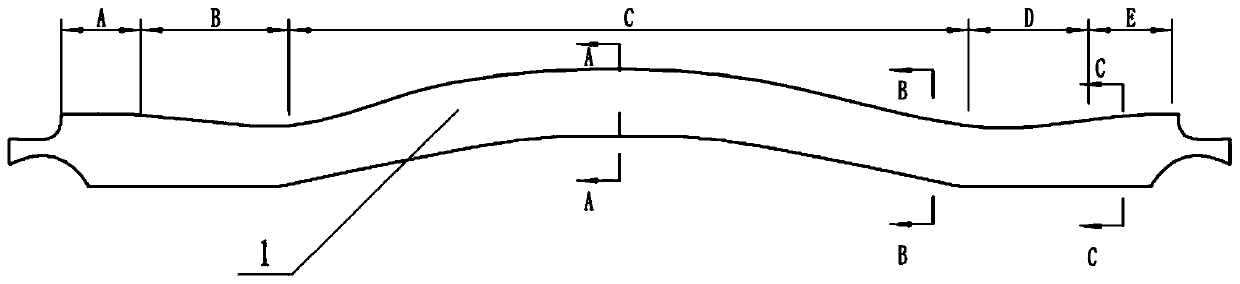

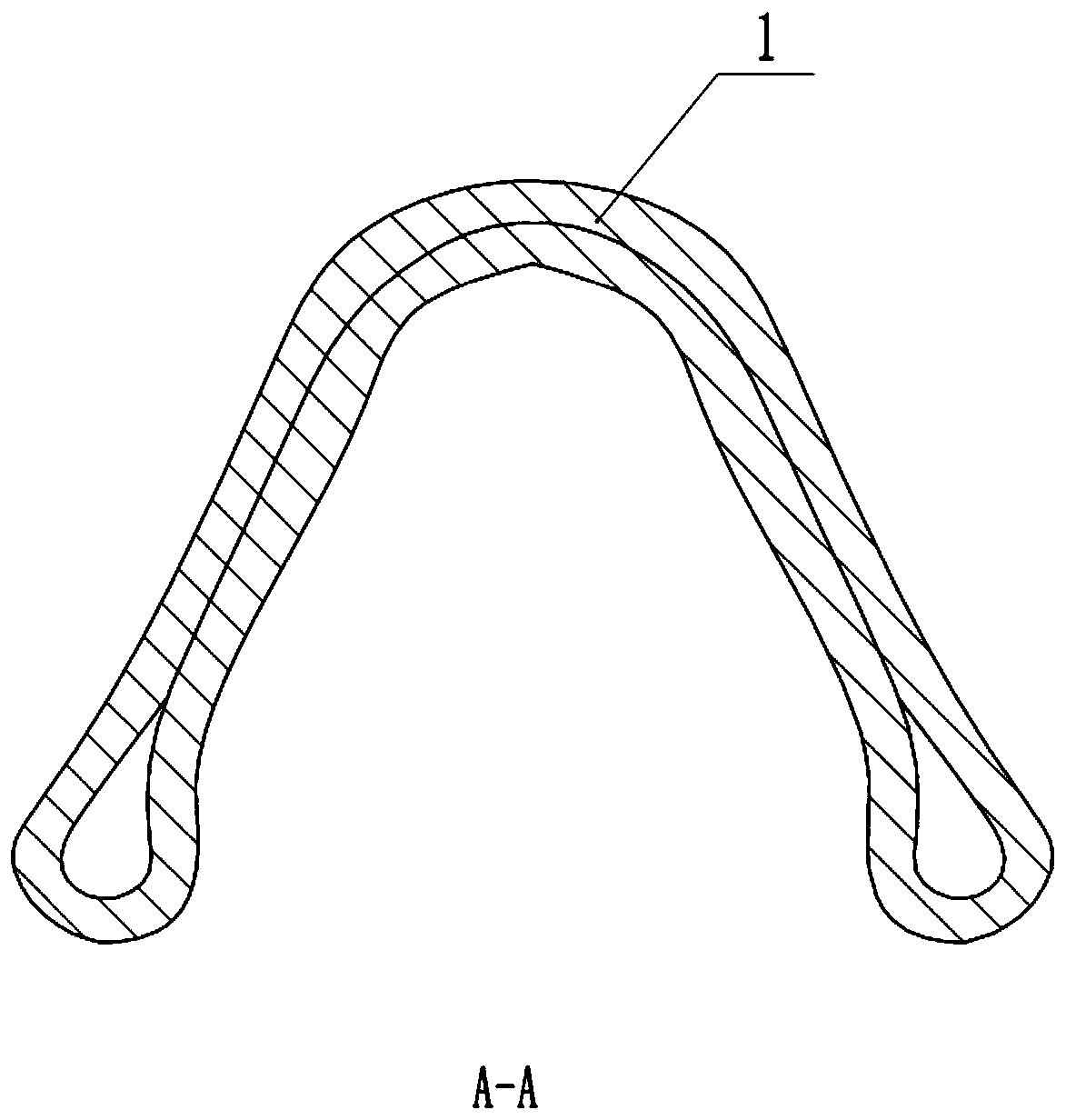

Antifatigue torsion beam for plate formation

PendingCN110385955AImprove toughnessAvoid breakingOptical signallingInterconnection systemsEngineeringMiddle segment

The invention relates to the field of automobile parts, in particular to an antifatigue torsion beam for plate formation. The beam comprises a beam body which is processed through a plate, and a firstclamping unit and a second clamping unit are arranged at the two ends of the plate respectively and integrally clamped in the formation step; the beam body is divided to two flaring segments, two transition segments and one middle segment, the middle segment is bent and is in an arch shape, the two transition segments are located at the two ends of the middle segment respectively, the two flaringsegments are located at the two ends of the transition segments respectively, the cross sections of the transition segments and the middle segment are in a V shape, and the depths of the V-shaped cross section shapes, from the middle of the middle segment to the transition segments, of the beam body are gradually reduced. The antifatigue capacity of the beam is improved.

Owner:天人汽车底盘(芜湖)股份有限公司

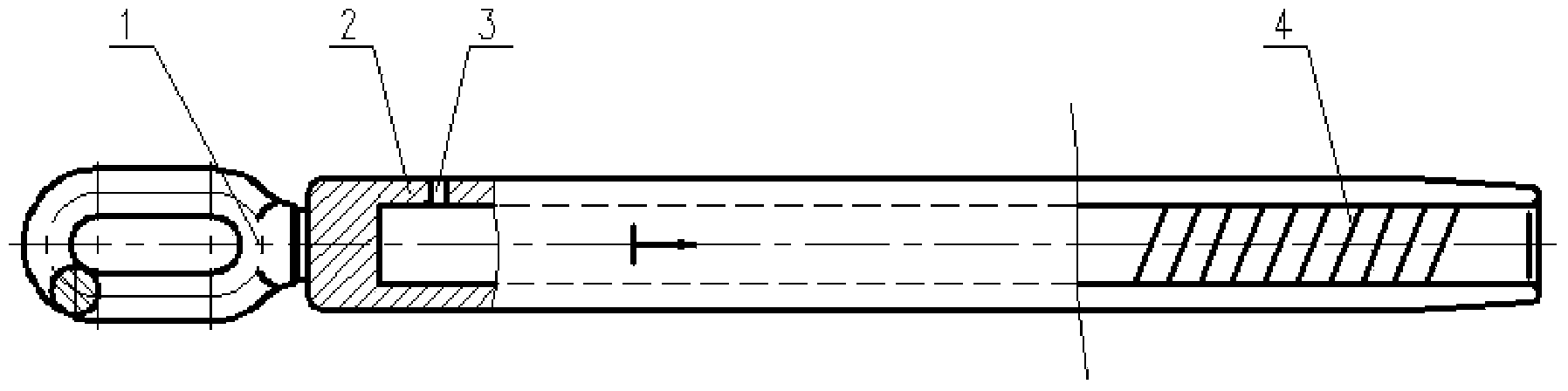

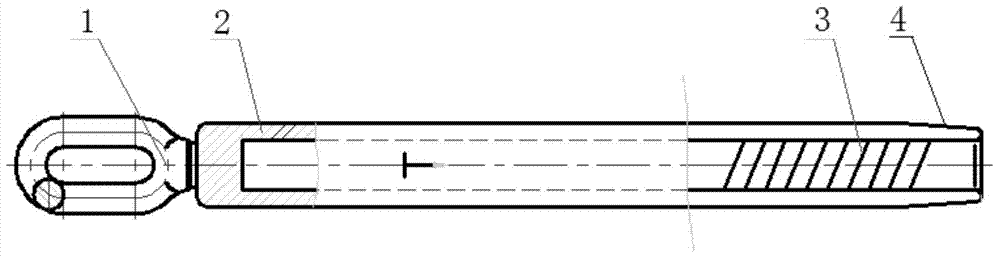

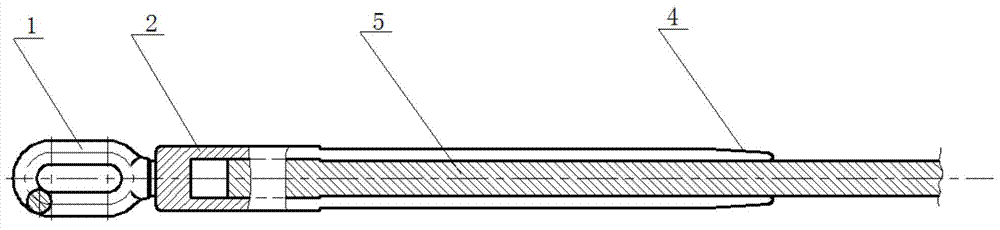

Forging integrated type oiling strain clamp for aluminum alloy stranded wire

InactiveCN104348123AAffect normal operationGuaranteed StrengthAdjusting/maintaining mechanical tensionEngineeringUltimate tensile strength

The invention provides a forging integrated type oiling strain clamp for an aluminum alloy stranded wire. A strain clamp is arranged on an overhead transmission line terminal and is used for anchoring a wire and keeping the electric and mechanical properties of the wire; the strain clamp is characterized in that the strain clamp comprises a pull ring, a connecting pipe and a drainage wire clamp; the connecting pipe and the pull ring are integrally formed along an axial direction; a fixing component and a pulling pin are respectively arranged on the inner wall and the outer wall at one end of the connecting pipe; an oiling hole is arranged in the side wall of the connecting pipe at a joint of the connecting pipe and the pull ring. Compared with the prior art, the forging integrated type oiling strain clamp for the aluminum alloy stranded wire provided by the invention has the advantages that the strain clamp is prevented from being damaged by inner frozen accumulated water, the strength of the strain clamp is increased, the holding capability of the strain clamp for the wire is increased, and a mature crimping technique is adopted so that the crimping quality is excellently ensured.

Owner:STATE GRID CORP OF CHINA +1

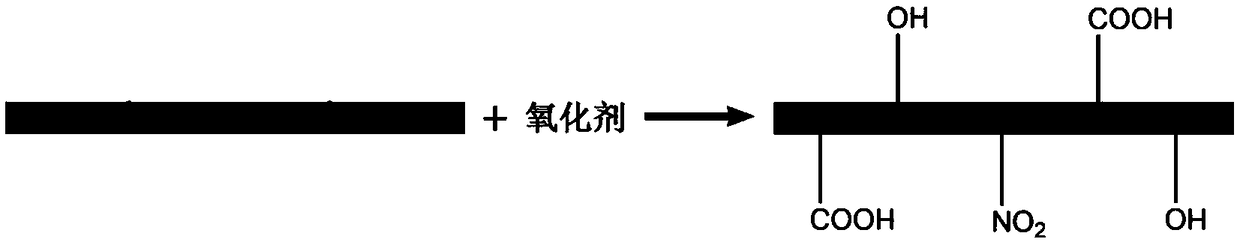

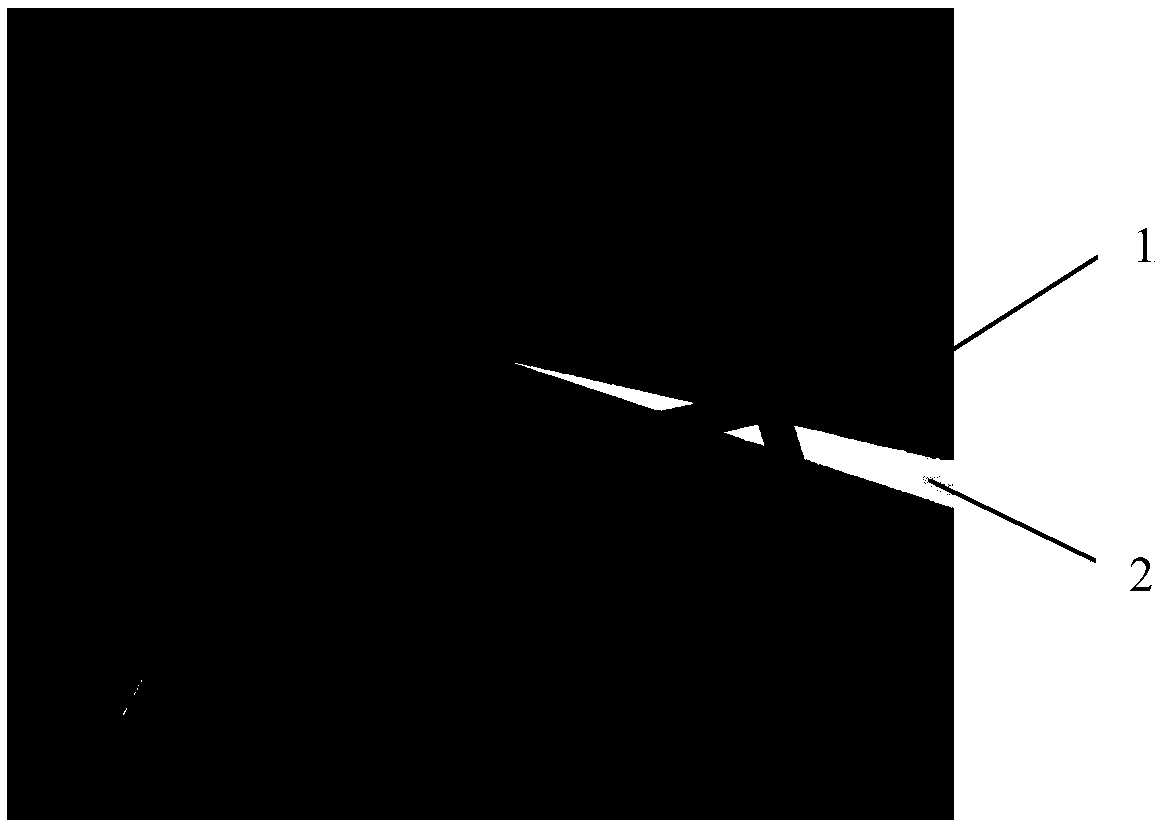

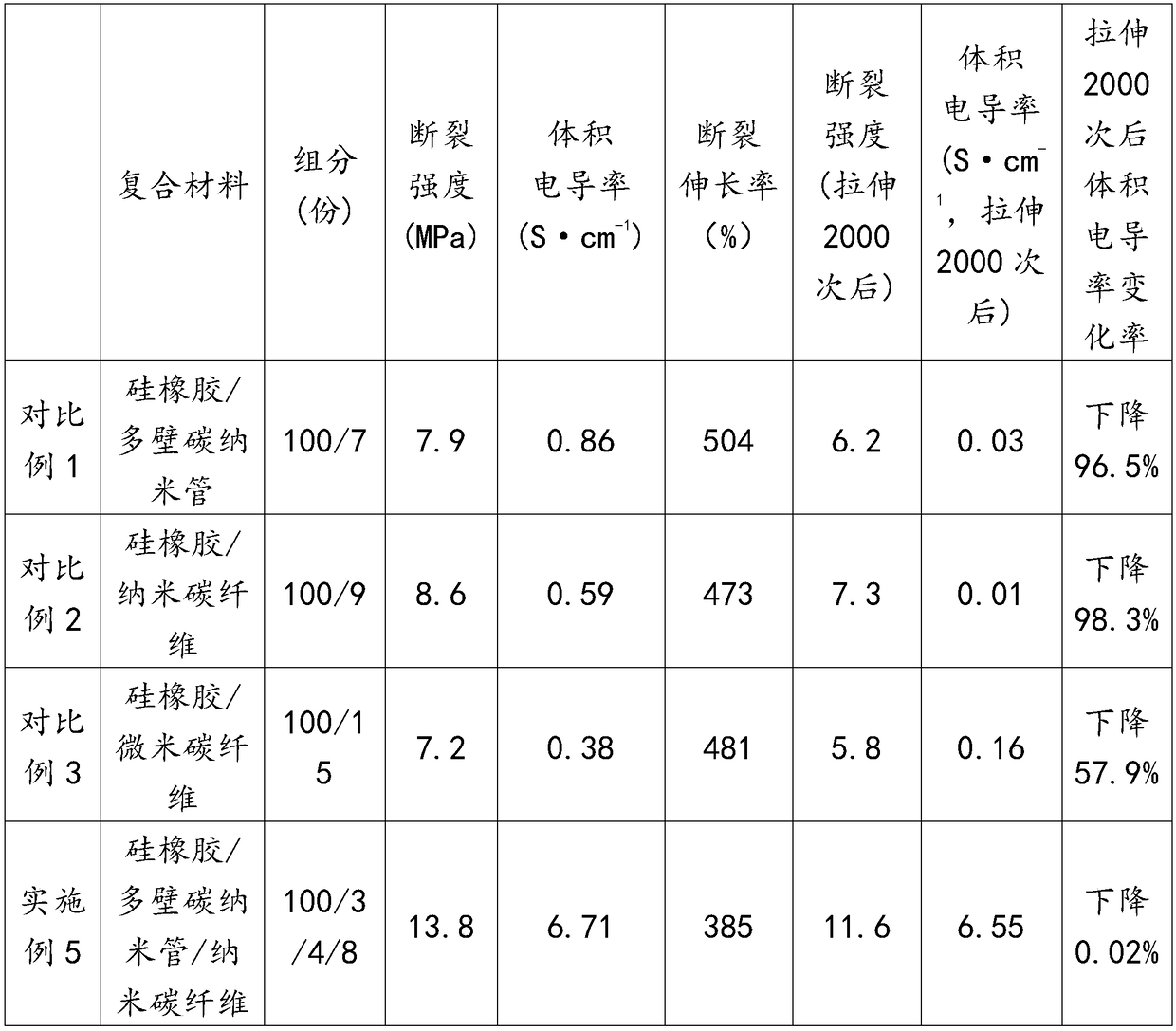

Anti-fatigue conductive composite material and preparation method thereof

ActiveCN108735346AImprove fatigue resistanceImprove electrical stabilityMaterial nanotechnologyNon-conductive material with dispersed conductive materialFiberCarbon fibers

The invention relates to an anti-fatigue conductive composite material and a preparation method thereof. The composite material comprises silicone rubber and vulcanizing agent, and further comprises,by 100 mass parts of the silicone rubber, 2-6 mass parts of carbon nano tube, 2-8 mass parts of carbon nanofibers and 5-15 mass parts of micron carbon fibers; the carbon nanofibers and the micron carbon fibers are obtained through acid oxidation treatment; diameter of the carbon nanofibers is at nanoscale; and diameter of the micron carbon fibers is at micron order and length of the micron carbonfibers is at millimeter level. The preparation method comprises steps of acid oxidation treatment, mixing and vulcanizing. The anti-fatigue conductive composite material provided by the invention hasexcellent anti-fatigue performance and conductive stability, and is suitable for wearable type electronic products, such as smart shoes.

Owner:ZHUHAI ADVANPRO TECH

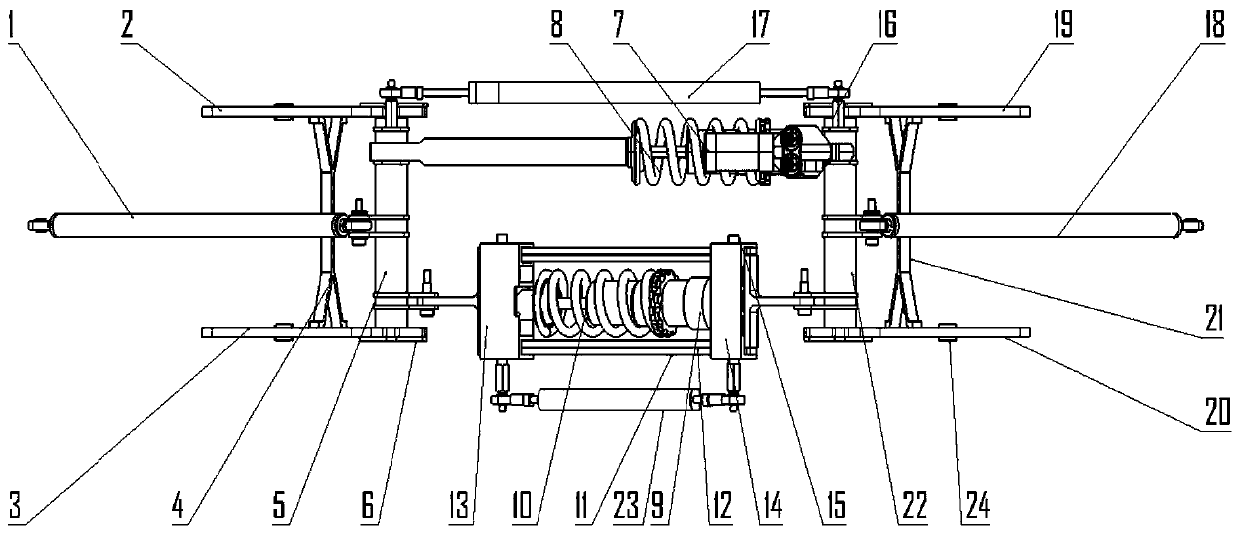

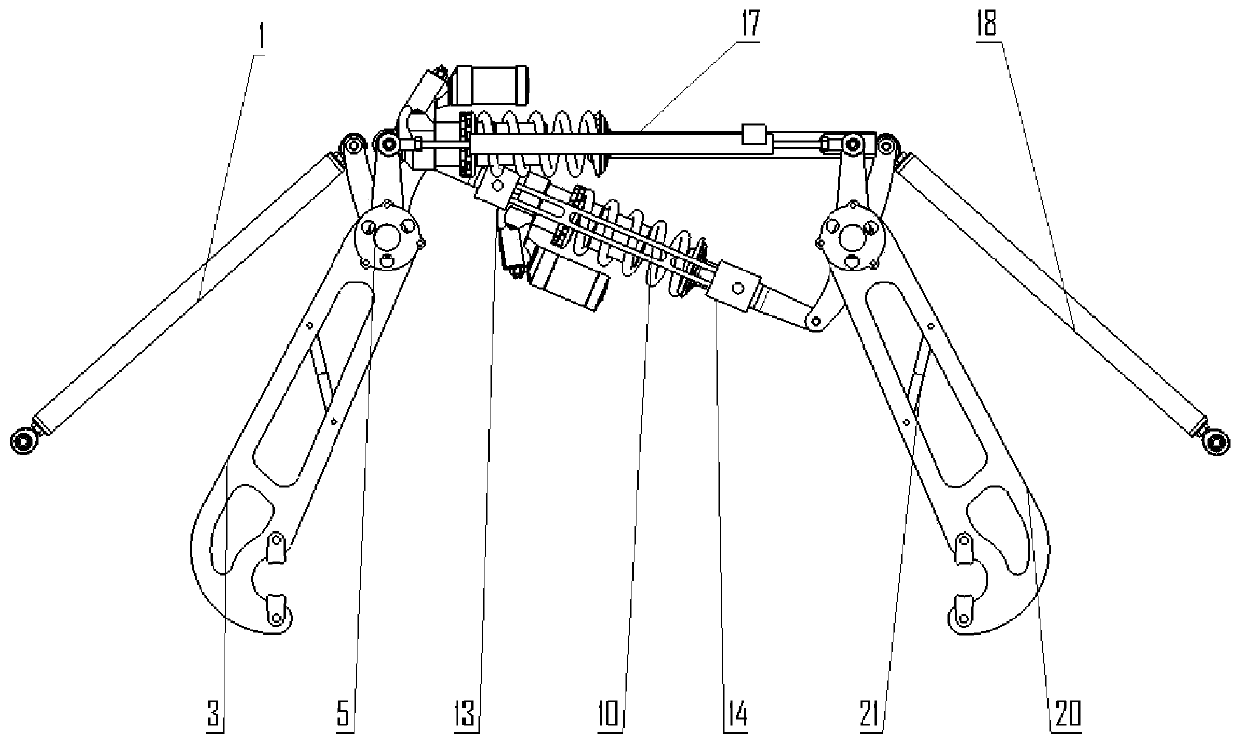

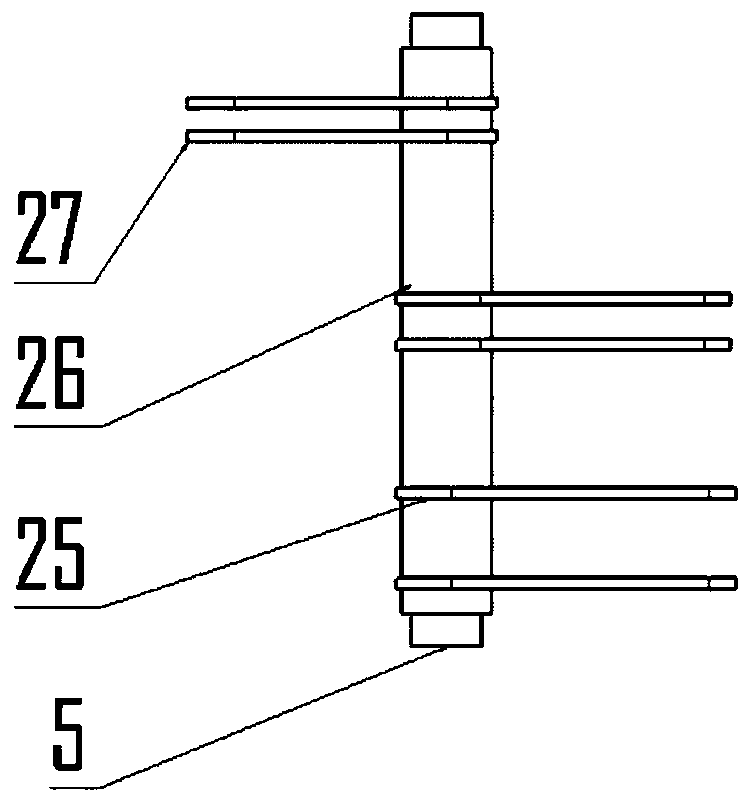

Racing car decoupling type longitudinal inclination and lateral inclination adjusting device

InactiveCN111559213ARealize regulationEasy to debugResilient suspensionsPivoted suspension armsSuspension (vehicle)Control theory

The invention belongs to the field of vehicle engineering, and discloses a racing car decoupling type longitudinal inclination and lateral inclination adjusting device. The device comprises a first rocker arm shaft, a second rocker arm shaft, a reversing mechanism, a first push rod, a second push rod, a longitudinal inclination restraining shock absorber, a lateral inclination restraining shock absorber, a first support, a second support, a third support and a fourth support, wherein the first rocker arm shaft is provided with a first lateral inclination shock absorber lifting lug, a first longitudinal inclination shock absorber lifting lug and a first push rod lifting lug, the second rocker arm shaft is provided with a second lateral inclination shock absorber lifting lug, a second longitudinal inclination shock absorber lifting lug and a second push rod lifting lug, the longitudinal inclination restraining shock absorber is provided with a longitudinal inclination restraining spring,and the lateral inclination restraining shock absorber is provided with a lateral inclination restraining spring; and the reversing mechanism comprises a first guide piece, a second guide piece, a first fixing frame and a second fixing frame. Accurate control over the posture of a vehicle body is achieved, longitudinal inclination adjustment and lateral inclination adjustment are independent anddecoupled from each other, the operation stability and smoothness of the racing car are improved, accurate adjustment of a racing car suspension is achieved, and the overall performance of a suspension system is improved.

Owner:CHANGAN UNIV

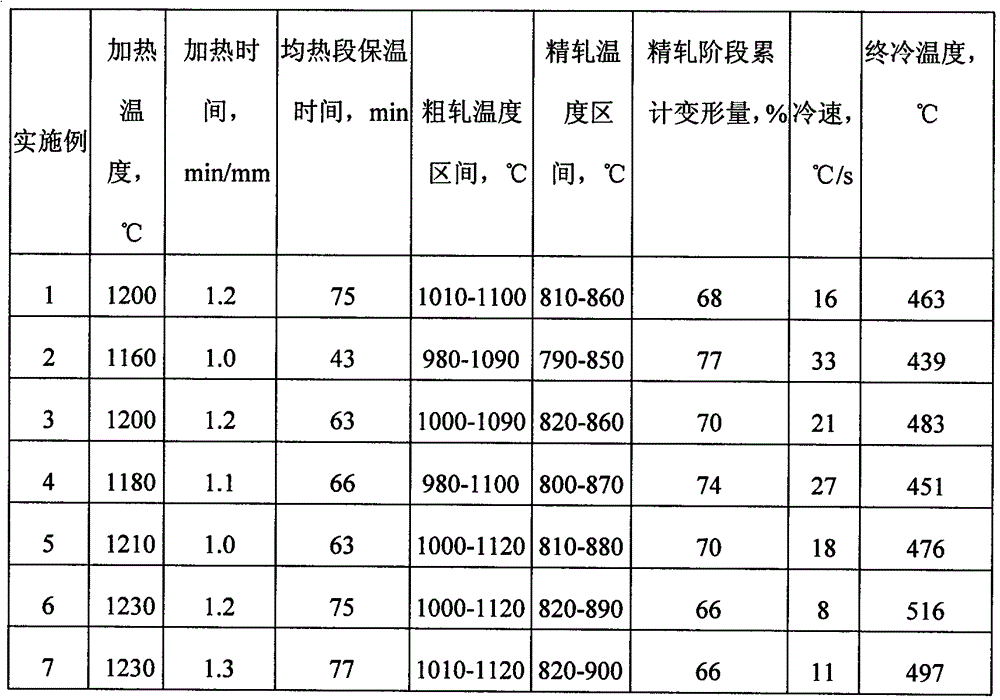

A low-cost high-performance marine riser hot-rolled steel plate and its production method

ActiveCN102851613BGood anti-collapse abilityImprove low temperature toughnessRoll mill control devicesMetal rolling arrangementsImpurityCooling temperature

The invention discloses a hot-rolled steel plate for an ocean riser with low cost and high performance and a production method thereof. The chemical components of the steel plate comprise C 0.04-0.10%, Si 0.10-0.35%, Mn 1.55-1.85%, Nb 0.02-0.08%, Ti 0.008-0.020%, Al 0.010-0.040%, P less than or equal to 0.020%, S less than or equal to 0.003%, Mo less than 0.20%, Cu less than or equal to 0.25%, Ni less than or equal to 0.30%, Cr less than or equal to 0.25%, N less than or equal to 0.008%, and the balance being Fe and unavoidable impurities, wherein Al / N is greater than or equal to 3, Ni+Cu+Mo+Cr is less than or equal to 0.70%, Nb+Ti is less than or equal to 0.09%, and Ti / N is equal to 2.5-5. CEIIW is 0.40-0.45%, CEPCM is 0.16-0.21%, casting blank heating temperature is 1,160-1,230 DEG C, four-stage heating is adopted, rough rolling temperature is 980-1,120 DEG C, fine rolling temperature is 790-900 DEG C, cooling temperature after rolling is 750-800 DEG C, cooling speed is 5-35 DEG C / s, and final cooling temperature is 430-520 DEG C. The steel plate of the invention has yield strength above 555 MPa, endwise tensile strength above 630 MPa, good cracking resistance, corrosion resistance and fatigue resistance, good comprehensive property, and low cost.

Owner:ANGANG STEEL CO LTD

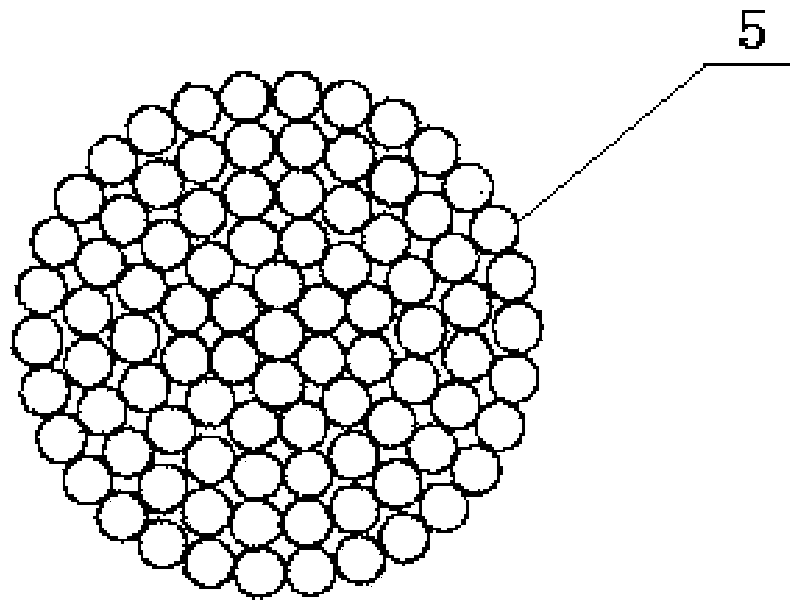

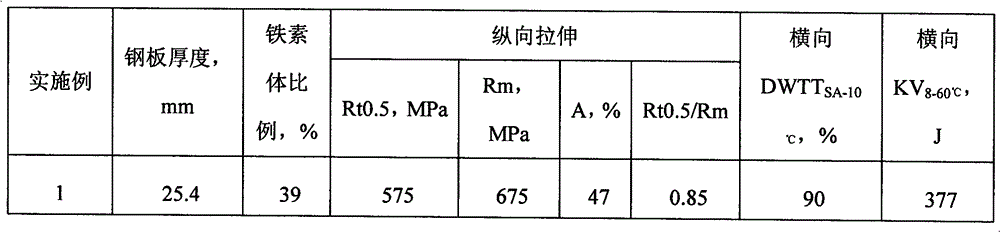

High-speed rail bogie integral force bearing structure of three-dimensional woven composite material, and application thereof

PendingCN111301469AGuaranteed fatigue resistanceGuaranteed structural strengthBogiesBogieUltimate tensile strength

The invention relates to a high-speed rail bogie integral force bearing structure adopting a three-dimensional woven composite material, and an application thereof. The high-speed rail bogie integralforce bearing structure comprises a front side plate, a rear side plate and a middle cross beam. The structure is characterized in that the front side plate, the rear side plate and the middle cross beam are integrally formed by the hybrid fiber three-dimensional woven composite material, wherein the front side plate and the rear side plate adopt variable-thickness V-shaped structural design, endinstallation bases for installing springs are arranged at the two ends of the front side plate and the rear side plate, middle installation bases for installing the springs are arranged in the middlesof the front side plate and the rear side plate, the end installation bases and the middle installation bases are designed to be of a special transition type three-dimensional woven composite transition structure, and metal reinforcing parts are embedded in the end installation bases and the middle installation bases. A barrier plate is designed in the middle of the middle cross beam and is reinforced by the pre-embedded metal parts, so that the overall anti-fatigue performance of the bearing structure is guaranteed, and the structural strength and the integrity of the connecting process of the bearing structure and other parts are guaranteed.

Owner:SHANDONG JIANZHU UNIV +1

Glued laminated bamboo floor and manufacturing method thereof

ActiveCN101891047BReduce consumptionMeet the use requirementsBio-packagingLarge containersBamboo floorUltimate tensile strength

The invention discloses a method for manufacturing glued laminated bamboo floors. The bamboo is applied to containers, so the consumption of wood resources in inland container floors is reduced, the use requirement of the container floors is better met, and the manufacturing cost of the container floors is reduced; meanwhile, an intermittent continuous production method is adopted, so the method for manufacturing the glued laminated bamboo floors can produce various specifications of inland container floors, and better meets the requirements on the strength and fatigue resistance of the inland container floors.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

Wear-proof anti-ageing heat reserving brick and preparation method thereof

The invention discloses a wear-proof anti-ageing heat reserving brick and a preparation method thereof, and relates to the technical field of heat reserving bricks. The heat reserving brick is prepared from the following raw materials: 85-95 parts of portland cement, 25-35 parts of modified carbon fiber, 15-17 parts of modified coal ash, 12-13 parts of mixed fiber, 7-9 parts of modified perlite, 14-16 parts of auxiliary agent and 95-105 parts of water. The preparation method of the wear-proof anti-ageing heat reserving brick comprises the following steps: (1) mixing the raw materials; (2) pressing forming and the like. The wear-proof anti-ageing heat reserving brick has good wear-proof performance and anti-ageing performance.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

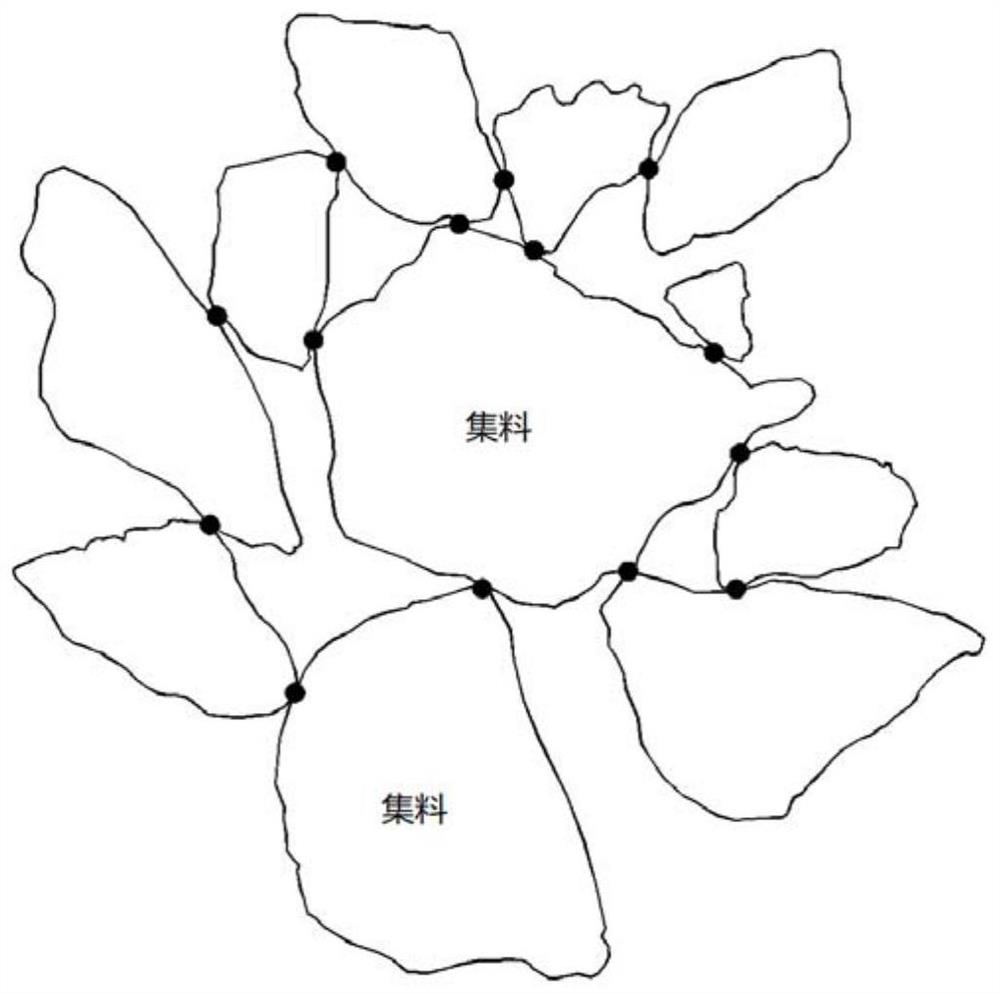

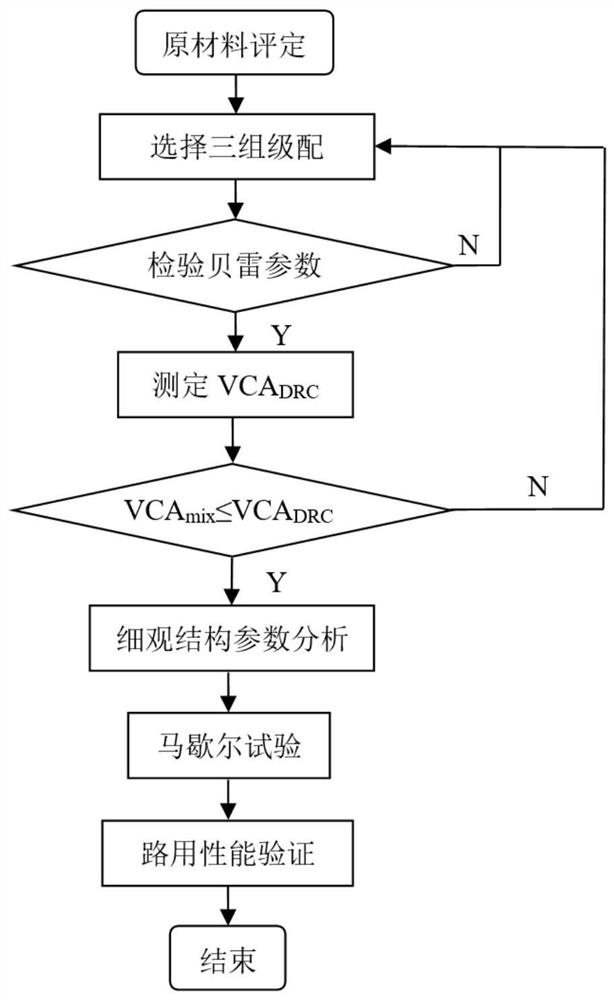

Design method of high-performance ultrathin asphalt wearing layer

ActiveCN112765782AExcellent road performanceLow costSolid waste managementDesign optimisation/simulationRoad engineeringRoad surface

The invention provides a design method of a high-performance ultrathin asphalt wearing layer, and relates to the technical field of road engineering. According to the design method, the double design principle of the high-performance ultrathin asphalt wearing layer with macroscopic and microscopic control indexes is provided. The macroscopic indexes are improved Bailey method parameters [CA] ratio, [FAc] ratio and [FAf] range, VCAmix is less than or equal to VCADRC, and the microscopic index is that the average coordination number is greater than or equal to 1.3, so that the use performance of the asphalt pavement is ensured on the basis of reducing the thickness of the wearing layer of the asphalt mixture and reducing the construction cost. The ultrathin asphalt wearing layer obtained by the design method has the advantages of low construction cost, dense skeleton, watertight pavement and no pollution to the environment, and the pavement performance of the wearing layer, such as rutting resistance, skid resistance, watertightness and durability of the skeleton of the pavement, is obviously improved.

Owner:广州市市政工程试验检测有限公司 +1

Forged integrated strain clamp applied to aluminum alloy stranded conductor

InactiveCN104332921AGuaranteed StrengthEasy to organizeAdjusting/maintaining mechanical tensionEngineeringUltimate tensile strength

The invention provides a forged integrated strain clamp applied to an aluminum alloy stranded conductor. The strain clamp is arranged at the end of an overhead transmission line and used for anchoring a conductor as well as maintaining the electrical and mechanical performances. The device is characterized in that the strain clamp comprises a pulling ring, a connecting tube and a flow guide clamp; the connecting tube and the pulling ring are axially integrally formed; a fixing part and a drawing pin are respectively arranged on the inner wall and the outer wall of one end of the connecting tube. Compared with the prior art, the forged integrated strain clamp applied to aluminum alloy stranded conductor has the advantages that the intensity of the strain clamp is improved; in addition, the holding capacity of the strain clamp to the conductor is improved; meanwhile, the sealing performance of a cavity formed by the strain clamp and the conductor after pressure welding is improved; the matured pressure welding process is adopted, so that the pressure welding quality can be ensured well.

Owner:STATE GRID CORP OF CHINA +2

Ultraviolet-resistant woven bag yarn

InactiveCN107513201AIncrease stressImprove creep resistanceConjugated synthetic polymer artificial filamentsArtifical filament manufactureLow-density polyethylenePolyester

The invention provides an ultraviolet-resistant woven bag yarn. The ultraviolet-resistant woven bag yarn contains the following components in parts by weight: 77-105 parts of low density polyethylene resin, 11-15 parts of polyester imide resin, 1-5 parts of an ultraviolet light absorber, 2-5 parts of sorbitol, 2-4 parts of dioctyl sebacate, 33-45 parts of filler and 2-7 parts of an aid, wherein the aid contains following components in parts by weight: 3-5 parts of a lubricating agent, 2-5 parts of a coupling agent, 1-2 parts of a stabilizer, 1-2 parts of a crosslinking agent and 1-3 parts of an antioxidant. The ultraviolet-resistant woven bag yarn has the beneficial effects that the constitution components and the proportion are unique, and meanwhile, a production method is simple and rapid; when the excellent ultraviolet resistance is guaranteed, the ultraviolet-resistant woven bag yarn further has excellent temperature resistance and weather resistance and is capable of remarkably maintaining each mechanical performance of a woven bag body and the ultraviolet resistance; and the components are easily available, and the ultraviolet-resistant woven bag yarn is relatively low in cost and suitable for being popularized in small and medium-sized enterprises.

Owner:盐城华和再生物资有限公司

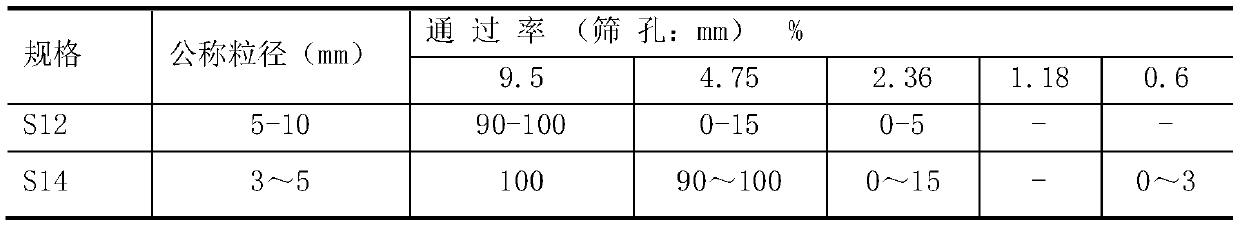

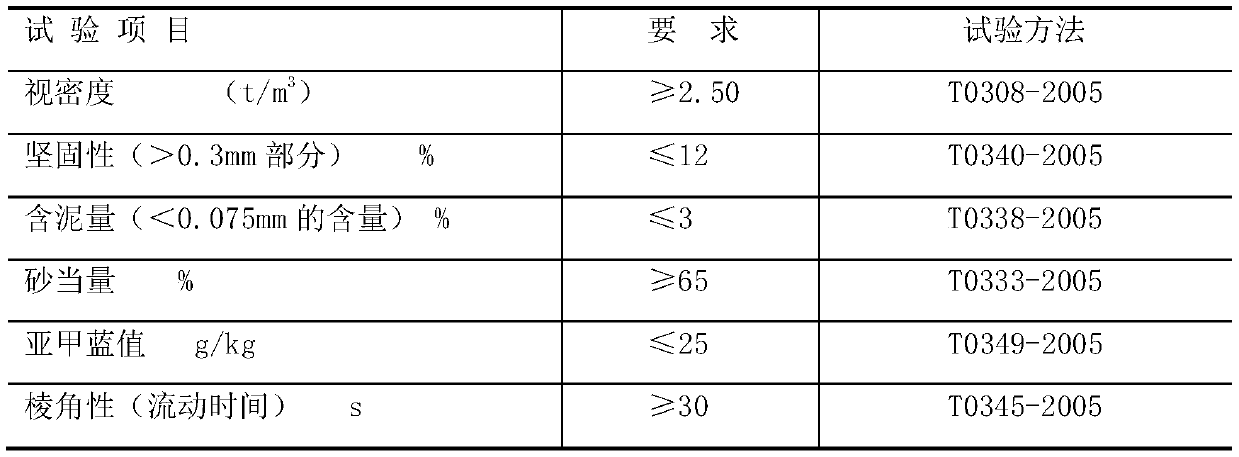

Ultrathin asphalt mixed material and preparation method thereof

InactiveCN110590235AImprove high temperature stabilityGuaranteed fatigue resistancePolyesterFatigue damage

The invention provides an ultrathin asphalt mixed material and a preparation method thereof. The ultrathin asphalt mixed material comprises the following components: 10-50 parts of an aggregate of 5-10mm, 20-50 parts of an aggregate of 3-5mm, 15-35 parts of an aggregate of 0-3mm, 4-10 parts of mineral powder, 5-8 parts of modified asphalt, 0.2-0.5 part of a special ultrathin asphalt mixed materialadditive and 0.2-0.4 part of polyester fiber. Compared with common SMA (stone mastic asphalt) and AC (asphalt concrete) asphalt mixed materials, the ultrathin asphalt mixed material has good high temperature stability and low temperature cracking resistance, excellent fatigue damage resistance and outstanding anti-sliding performance.

Owner:上海同沥新材料科技有限公司

Temperature-resisting type self-repairing coating used for casting mold

InactiveCN108555229AImprove mechanical propertiesImprove high temperature resistanceFoundry mouldsFoundry coresPolyesterFiber

The invention provides a temperature-resisting type self-repairing coating used for a casting mold. The coating comprises carrier resin, blending stock, polyvinyl alcohol and an assistant; the carrierresin comprises linseed oil water soluble alkyd resin, polyester imide resin and organic silicon resin; the blending stock comprises composite fiber powder, ceramic powder and silicon dioxide silicaaerogel; the assistant comprises a tetraethoxysilane acid aqueous solution, repair liquid, an activation solution and a nucleating agent; the coating has the excellent temperature resistance and wearresistance, during use, a flat, continuous and smooth coating thin film is formed on the mold surface, meanwhile, the coating thin film has a certain restoration function, use of the coating is reduced, and the casting cost is reduced; and components are simple and easily obtained, the cost is moderate, the coating is suitable for being used and popularized in small and medium enterprises, and thewide market prospects are achieved.

Owner:SUZHOU HAOYAN PRECISION MOLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com