High-speed rail bogie integral force bearing structure of three-dimensional woven composite material, and application thereof

A technology of three-dimensional weaving and composite materials, which is applied to bogies, railway car body parts, transportation and packaging, etc., can solve the problems of large load-bearing hidden dangers, and achieve the effects of strong practicability, structural strength and integrity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

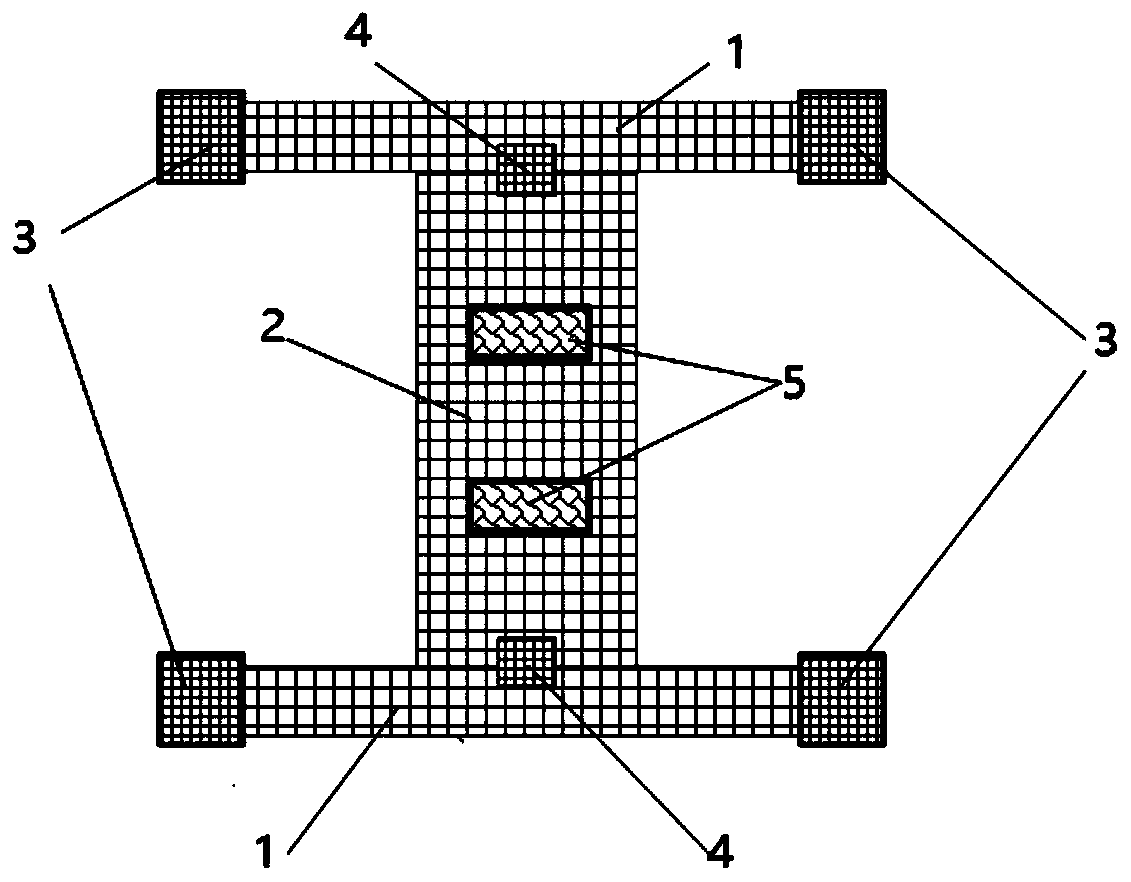

[0026] A high-speed rail bogie load-bearing structure with an integral three-dimensional braided composite material structure, using T800 high-strength carbon fiber and Kevlar49 aramid fiber with a mixing ratio of 5:1 for hybrid prefabricated body weaving design. The prefabricated body adopts a three-dimensional four-way integral braided structure . In the process of processing the front and rear side panels of the load-bearing structure of the bogie, a V-shaped structural design with variable section thickness is adopted. The end of the V-shaped side panel is braided with three-dimensional and four-way hybrid fibers. When it is close to the connection between the side panel and the middle beam The part adopts a three-dimensional seven-direction hybrid fiber weaving structure, and the transitional weaving structure from the end of the side plate to the middle beam connection of the side plate is: three-dimensional four-direction, three-dimensional five-direction, three-dimensio...

Embodiment 2

[0030] A high-speed rail bogie load-bearing structure with an integral three-dimensional braided composite material structure, using T1000 high-strength carbon fiber and Kevlar29 aramid fiber with a mixing ratio of 4:1 for hybrid prefabricated body weaving design. The prefabricated body adopts a three-dimensional four-way integral braided structure . In the process of processing the front and rear side panels of the load-bearing structure of the bogie, a V-shaped structural design with variable section thickness is adopted. The end of the V-shaped side panel is braided with three-dimensional and four-way hybrid fibers. When it is close to the connection between the side panel and the middle beam The part adopts a three-dimensional seven-direction hybrid fiber weaving structure, and the transitional weaving structure from the end of the side plate to the middle beam connection of the side plate is: three-dimensional four-way, three-dimensional six-way, three-dimensional seven-wa...

Embodiment 3

[0034]A high-speed rail bogie load-bearing structure with an integral three-dimensional braided composite material structure, using T800 high-strength carbon fiber and UHMWPE fiber with a mixing ratio of 5:2 for hybrid prefabricated body weaving design. The prefabricated body adopts a three-dimensional five-directional overall braided structure. In the process of processing the front and rear side panels of the load-bearing structure of the bogie, a V-shaped structural design with variable section thickness is adopted. The end of the V-shaped side panel is braided with three-dimensional and four-way hybrid fibers. When it is close to the connection between the side panel and the middle beam The part adopts a three-dimensional seven-direction hybrid fiber weaving structure, and the transitional weaving structure from the end of the side plate to the middle beam connection of the side plate is: three-dimensional four-way, three-dimensional five-way, three-dimensional six-way, thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com