Design method of high-performance ultrathin asphalt wearing layer

A design method and high-performance technology, applied in computer-aided design, design optimization/simulation, calculation, etc., to achieve good economic effect, excellent road performance, and durability against water damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

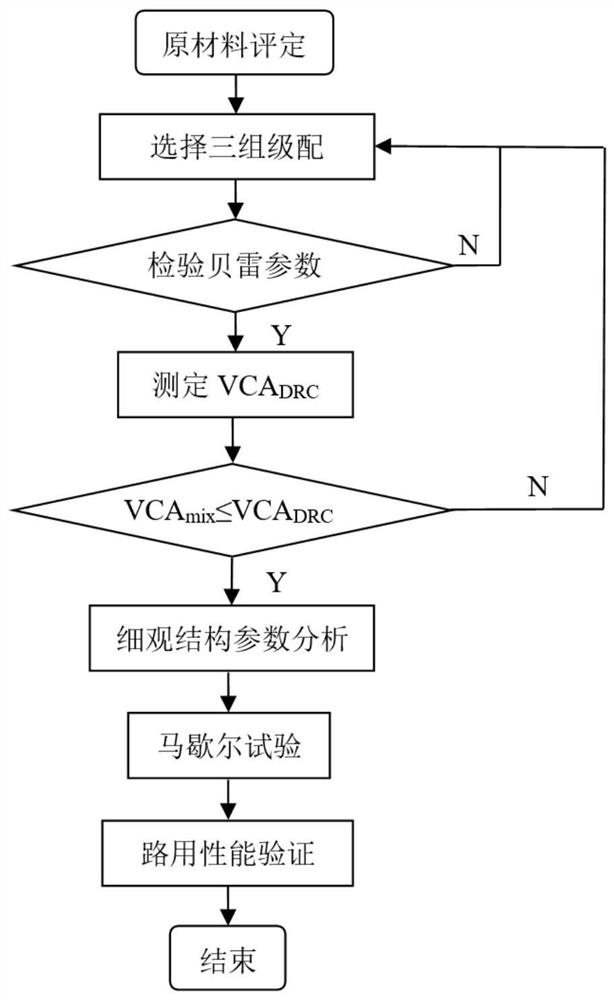

[0060] To design a HPUT-10 wear layer for general roads, with a thickness of 2cm, the main steps are as follows, and the flow chart is as follows figure 2 Shown:

[0061] S1: Raw material performance testing

[0062] The asphalt mix design uses high-viscosity and high-elasticity modified asphalt, and its technical indicators are shown in Table 4, which meets the technical requirements of Class I-D and PG76-28 stipulated in the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0063] Table 4 Test results of high-viscosity and high-elasticity modified asphalt

[0064]

[0065]

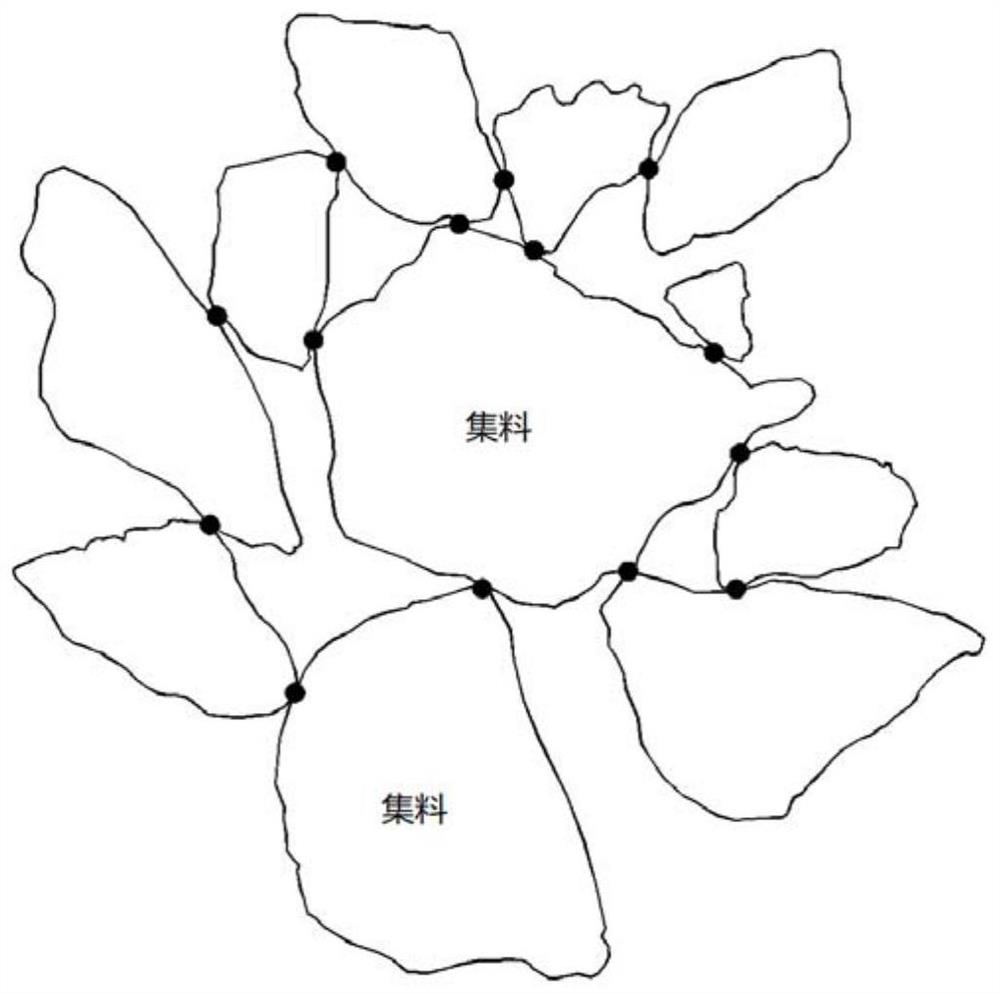

[0066] The asphalt mix design uses coarse aggregate particle size specifications of 5-10mm and 3-5mm respectively; fine aggregate is 0-3mm stone chips, and the aggregate test is strictly in accordance with the "Highway Engineering Aggregate Test Regulations" (JTG E42-2005 ) requirements and methods for testing, see Table 5 for aggregate density and Table 6...

Embodiment 2

[0110] To design a HPUT-10 wearing layer for tunnel pavement and bridge deck pavement, with a thickness of 2cm, the main steps are as follows:

[0111] S1: Raw material performance testing

[0112] The asphalt is mainly Shell SBS (I-D) modified asphalt, and the test results are shown in Table 12.

[0113] Table 12 Test results of SBS(I-D) modified asphalt

[0114]

[0115] Coarse aggregate and fine aggregate are both made of diabase; mineral powder is limestone; anti-stripping agent uses 1.5% P.O.42.5 cement to improve the adhesion between asphalt and aggregate; flocculent wood fiber and flame retardant are added. The aggregate test results are shown in Table 13.

[0116] Table 13 aggregate test results

[0117]

[0118] S2: Select the initial grading

[0119] Select a grading curve this time. If a certain technical index does not meet the requirements during the design process, return to this step for corresponding adjustments. See Table 14 for aggregate screening res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com