Fatigue-resistant and corrosion-resistant round steel for forging and pressing and preparation method thereof

A corrosion-resistant and fatigue-resistant technology, which is applied in the field of fatigue-resistant and corrosion-resistant forging round steel and its preparation, can solve the problem of unsatisfactory yield strength, tensile strength, unmentioned hardness, fatigue resistance and corrosion resistance, unfavorable When it comes to issues such as fatigue resistance and corrosion resistance, it achieves the effects of short manufacturing cycle, low manufacturing cost and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0026] A method for producing round steel for fatigue-resistant and corrosion-resistant forging comprises the following steps:

[0027] 1) Batching process: melted composition target: melted carbon 0.51-0.53%, melted phosphorus 0.021-0.024%, and the content of residual elements meets the standard requirements. The baking temperature of the alloy meets the technical requirements, and the moisture content of the metallurgical auxiliary material is 0.35-0.41%.

[0028] 2) Electric furnace smelting: endpoint C: 0.21-0.22%, P: 0.022-0.024%, the content of residual elements meets the standard requirements; tapping temperature is 1635-1641°C.

[0029] 3) Continuous casting process: the billet enters the drawing and leveling machine at a temperature of 925-926°C, enters the pit for slow cooling for 24-25 hours, and exits the pit at a temperature of 240-245°C.

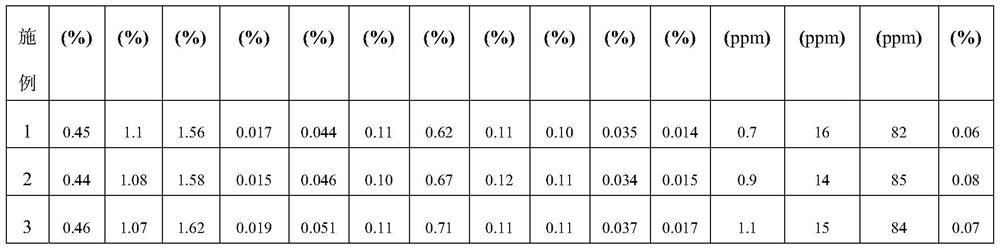

[0030] The chemical composition of table 1 embodiment 1-3 round steel forms

[0031]

[0032]

[0033] The batching p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com