High-strength open-cell micro-porous plastic as well as preparation method and application thereof

A technology of microporous plastics and open cells, applied in the field of microporous plastics, can solve the problems of difficult control of micropore diameter and porosity, low mechanical strength of plastics, complicated process, etc., and achieve simple and fast preparation method and high water absorption rate , Good breathability and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

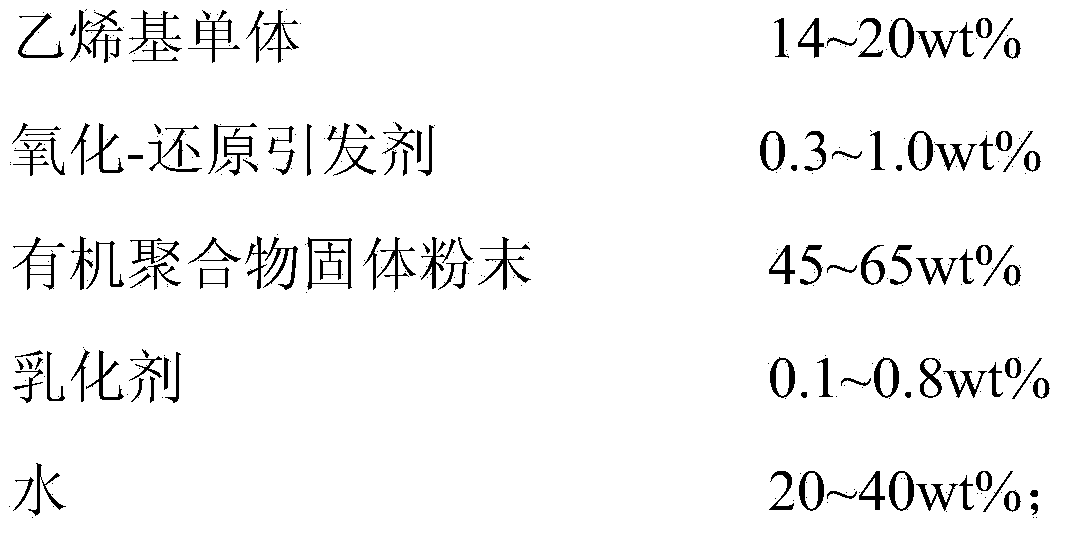

Method used

Image

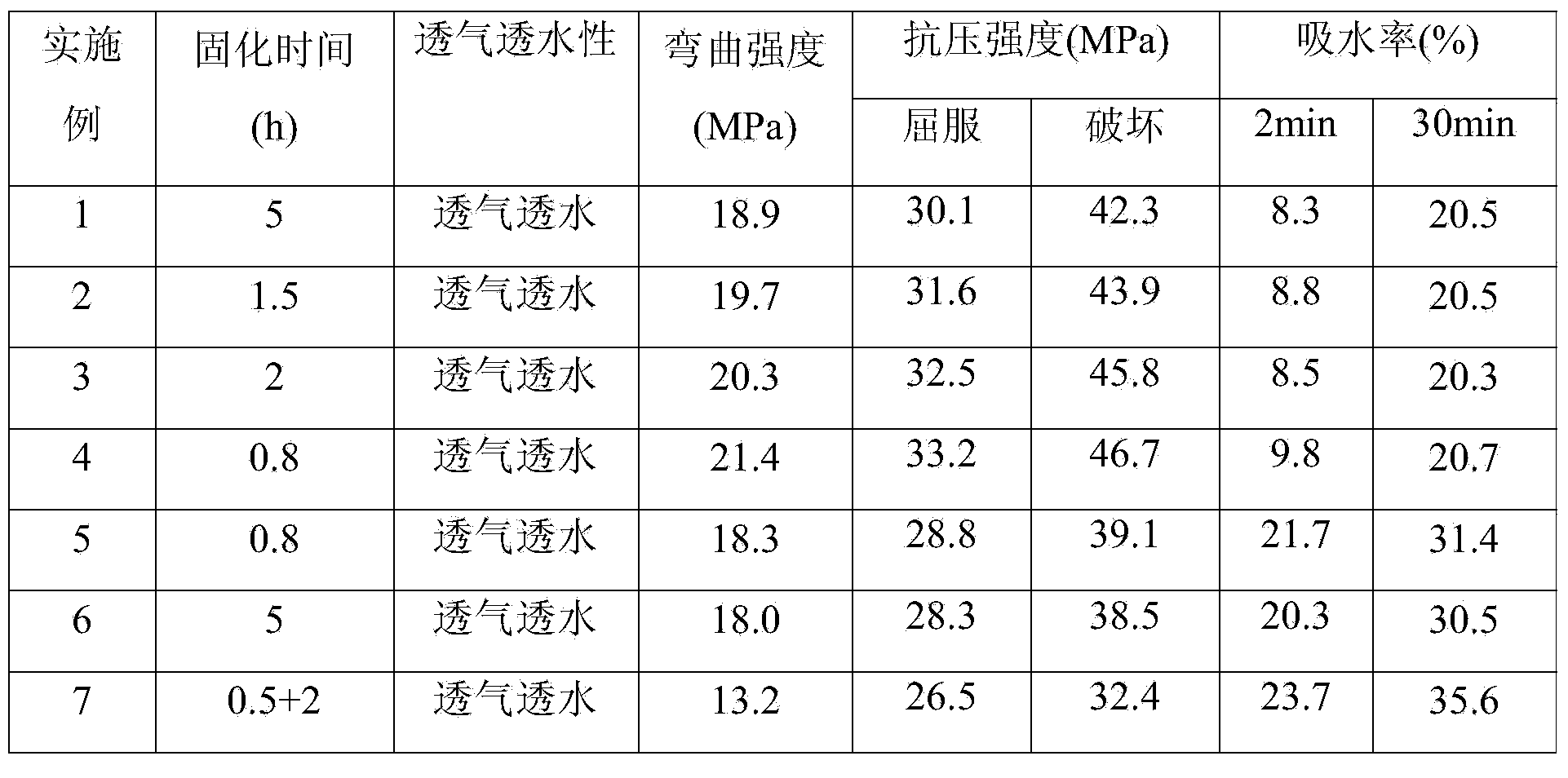

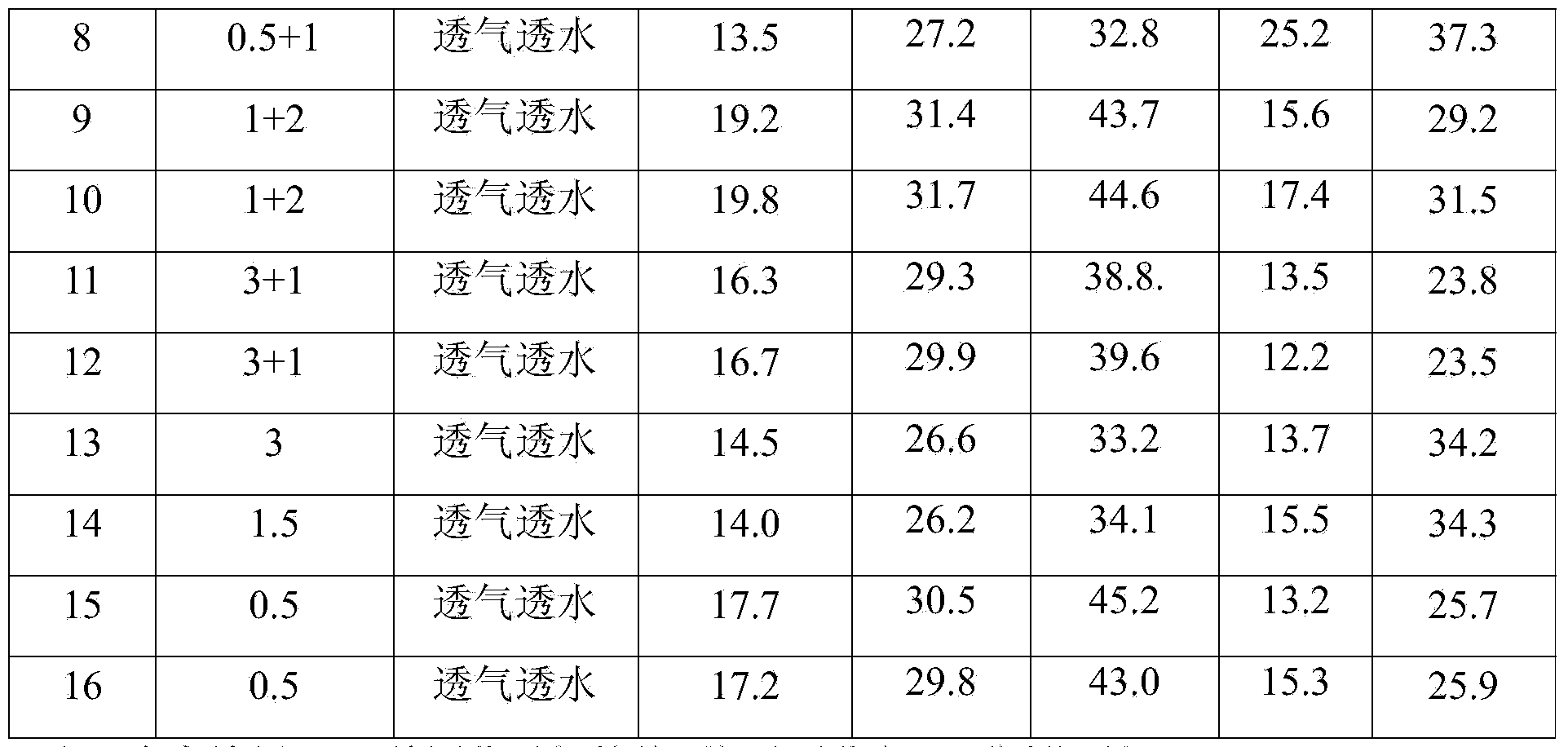

Examples

Embodiment 1

[0038] A preparation of high-strength open-cell microporous plastics, the specific steps are as follows:

[0039] 7g styrene, 133g methyl methacrylate, 600g methyl methacrylate-butyl methacrylate copolymer PMMA-BMA (18-200 mesh), 50g polycarbonate PC (100 ~200 mesh), 5.0g Tween T-20, 4.7g di-(3,5,5-trimethylhexanoyl) peroxide (TMHP), 0.3g N,N-dimethylaniline (DMA) After mixing with 200g of water uniformly within 3 minutes to obtain the mixed solution, pour the mixed solution into the corresponding mold within 3 minutes, then place the mold in a room temperature of 5°C for curing, observe and record the curing time, and demould after curing to obtain High-strength open-cell microporous plastic sample 1. The compressive strength, bending strength, water absorption and air permeability of the samples were tested according to the corresponding test methods, and the test results are listed in Table 1.

Embodiment 2

[0041] A preparation of high-strength open-cell microporous plastics, the specific steps are as follows:

[0042] In a low temperature environment of 5°C, 7g styrene, 133g methyl methacrylate, 600g methyl methacrylate-isobutyl methacrylate copolymer PMMA-IBMA (18-200 mesh), 50g polycarbonate PC ( 100~200 mesh), 5.0g Tween T-20, 4.7g di-(3,5,5-trimethylhexanoyl) peroxide (TMHP), 0.3g N,N-dimethylaniline (DMA ) and 200g of water within 3 minutes to obtain a mixed solution, pour the mixed solution into the corresponding mold within 3 minutes, then place the mold in a room temperature of 20°C for curing, observe and record the curing time, and release the mold after curing. A high-strength open-cell microporous plastic sample 2 was obtained. The compressive strength, bending strength, water absorption and air permeability of the samples were tested according to the corresponding test methods, and the test results are listed in Table 1.

Embodiment 3

[0044] A preparation of high-strength open-cell microporous plastics, the specific steps are as follows:

[0045] 70g styrene, 42g methyl methacrylate, 28g methyl acrylate, 400g polymethyl methacrylate solid PMMA (18-500 mesh), 242g PMMA-BMA (18-200 mesh) in a low temperature environment of 15°C , 6.0g Tween T-60, 2.0g Span S-20, 8.0g dilauroyl peroxide (LPO), 2.0g DMA and 200g water were mixed uniformly within 3 minutes to obtain a mixed solution, and the mixed solution was mixed for 3 minutes Pour it into a corresponding mold, then place the mold in an environment with a room temperature of 15°C for curing, observe and record the curing time, and release the mold after curing to obtain a high-strength open-cell microporous plastic sample 3. The compressive strength, bending strength, water absorption and air permeability of the samples were tested according to the corresponding test methods, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com