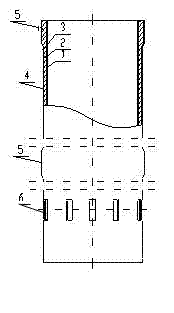

Glass fiber reinforced plastic flue gas jetting pipe used in desulphurization technology, and manufacturing method thereof

A desulfurization process, FRP technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as poor corrosion resistance to chloride ions, high engineering cost, and low resin content in structural layers, so as to ensure anti-fatigue performance, increase the content of resin, and ensure the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Mold preparation: select the outer diameter of the mold to be the same as the inner diameter of the air nozzle, both being 200 mm, clean the surface of the mold, control its surface roughness to 0.8 μm, and the slope of the diameter at both ends of the mold to be 1:1000. Then apply release wax evenly on the surface of the mold for 2 times, and install the mold on the winding machine.

[0037] (2) Making the inner anti-corrosion layer: the innermost layer uses 30g / m 2 One layer of glass fiber surface felt, and then use two layers of 450g / m 2 Chopped glass fiber felt; Weigh 10kg of bisphenol A vinyl resin, add 0.5Kg of 300-mesh silicon carbide wear-resistant filler to the resin, add 200g of conductive carbon powder, stir well, and then add cobalt ion content Be 0.6wt% 2wt% promotor (promptly add 200g promotor in 10Kg resin), stir evenly, dress with small container before use, add active oxygen content in small container and be 2.5wt of ketone peroxide solidifying age...

Embodiment 2

[0044] (1) Mold preparation: select the outer diameter of the mold to be the same as the inner diameter of the air nozzle, both being 200 mm, clean the surface of the mold, control its surface roughness to 0.8 μm, and the slope of the diameter at both ends of the mold to be 1:1000. Then apply release wax evenly on the surface of the mold for 2 times, and install the mold on the winding machine.

[0045] (2) Making the inner anti-corrosion layer: the innermost layer uses 30g / m 2 One layer of glass fiber surface felt, and then use two layers of 450g / m 2 Chopped glass fiber felt; Weigh 10kg of bisphenol A vinyl resin, add 0.2Kg of 300 mesh silicon carbide wear-resistant filler to the resin, add 100g of conductive carbon powder, stir well, and then add cobalt ion content Be 0.6wt% 2wt% promotor (promptly add 200g promotor in 10Kg resin), stir evenly, dress with small container before use, add active oxygen content in small container and be 1.5wt of ketone peroxide curing agent 10...

Embodiment 3

[0052] (1) Mold preparation: select the outer diameter of the mold to be the same as the inner diameter of the air nozzle, both being 200 mm, clean the surface of the mold, control its surface roughness to 0.8 μm, and the slope of the diameter at both ends of the mold to be 1:1000. Then apply release wax evenly on the surface of the mold for 2 times, and install the mold on the winding machine.

[0053] (2) Making the inner anti-corrosion layer: the innermost layer uses 30g / m 2 One layer of glass fiber surface felt, and then use two layers of 450g / m 2 Chopped glass fiber felt; weigh 10kg of phenolic epoxy vinyl resin, add 0.8Kg of 300 purpose silicon carbide wear-resistant fillers in the resin, add 180g conductive carbon powder, fully stir, then add cobalt ion content wherein The accelerator of 2wt% of 0.6wt% (promptly adds 200g accelerator in 10Kg resin), stirs evenly, dresses up with small container before use, adds the ketone peroxide solidifying agent 2.5wt% that active o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com