Anti-fatigue conductive composite material and preparation method thereof

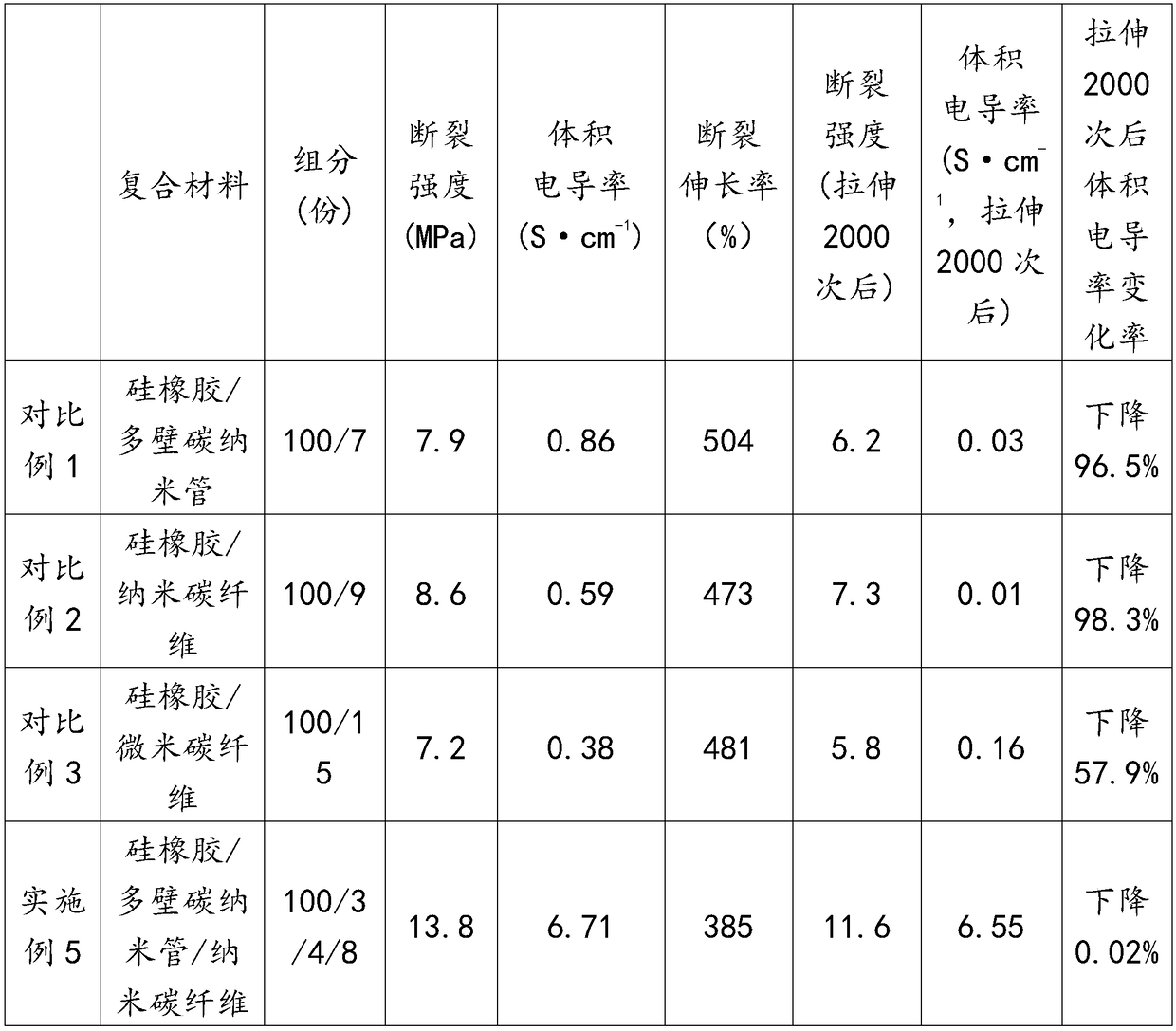

A conductive composite material, fatigue-resistant technology, used in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, nanotechnology for materials and surface science, etc. , The mechanical properties of composite materials are decreased, easy to stick and agglomerate, etc., to achieve the effect of high fatigue resistance, good electrical stability, and improved electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the fatigue-resistant conductive composite material of the present embodiment is as follows:

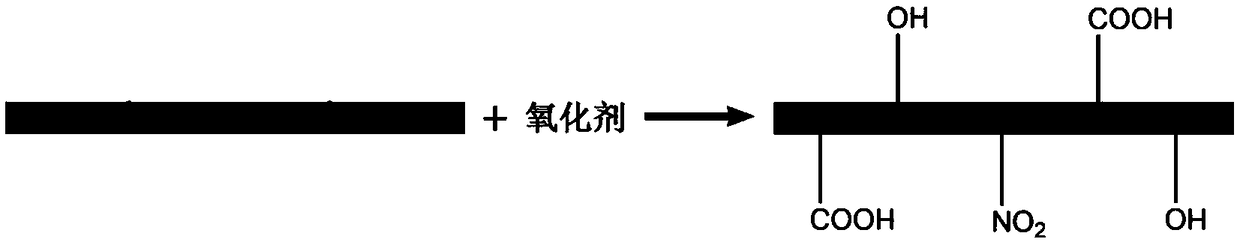

[0036] (1) Carry out acid oxidation treatment on the carbon nanofibers and carbon microfibers respectively, the acid oxidation treatment process is as follows: disperse the carbon nanofibers or carbon microfibers in an oxidizing acid solution. The mass ratio of concentrated nitric acid and concentrated sulfuric acid in the acid solution is 1:1, and the mass ratio of nano-carbon fiber or micron carbon fiber to the acid solution is 1:10. Magnetic stirring is performed at 60°C for 3 hours, and the acid-oxidized carbon fiber is repeatedly mixed with deionized water. Wash until the pH is 6 to 7, and dry at 120° C. for 3 hours to obtain nano-carbon fibers or micro-carbon fibers after acid oxidation treatment.

[0037] (2) Weighing raw materials, wherein the mass parts of silicone rubber, multi-walled carbon nanotubes, nano-carbon fibers and micro-carbon fib...

Embodiment 2

[0042] The preparation method of the fatigue-resistant conductive composite material of the present embodiment is as follows:

[0043] (1) Carry out acid oxidation treatment on the carbon nanofibers and carbon microfibers respectively, the acid oxidation treatment process is as follows: disperse the carbon nanofibers or carbon microfibers in an oxidizing acid solution. The mass ratio of concentrated nitric acid to concentrated sulfuric acid in the acid solution is 1:1, and the mass ratio of nano-carbon fiber or micron carbon fiber to the acid solution is 1:10. Magnetic stirring at 60°C for 3 hours, the carbon fiber after acid oxidation treatment is repeatedly mixed with deionized water. Wash until the pH is 6 to 7, and dry at 120° C. for 3 hours to obtain acid-treated nano-carbon fibers or micro-carbon fibers.

[0044] (2) Weighing raw materials, wherein the mass parts of silicone rubber, multi-walled carbon nanotubes, nano-carbon fibers and micro-carbon fibers are 100 parts, ...

Embodiment 3

[0049] The fatigue-resistant conductive composite material of this embodiment is prepared through the following steps:

[0050] (1) Carry out acid oxidation treatment on the carbon nanofibers and carbon microfibers respectively, the acid oxidation treatment process is as follows: disperse the carbon nanofibers or carbon microfibers in an oxidizing acid solution. The mass ratio of concentrated nitric acid to concentrated sulfuric acid in the acid solution is 1:1, and the mass ratio of nano-carbon fiber or micron carbon fiber to the acid solution is 1:10. Magnetic stirring at 60°C for 3 hours, the carbon fiber after acid oxidation treatment is repeatedly mixed with deionized water. Wash until the pH is 6 to 7, and dry at 120° C. for 3 hours to obtain acid-treated nano-carbon fibers or micro-carbon fibers.

[0051] (2) Weighing raw materials, wherein the mass parts of silicone rubber, multi-walled carbon nanotubes, nano-carbon fibers and micro-carbon fibers are 100 parts, 1 part,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com