Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Good vulcanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene propylene diene monomer and preparation method thereof

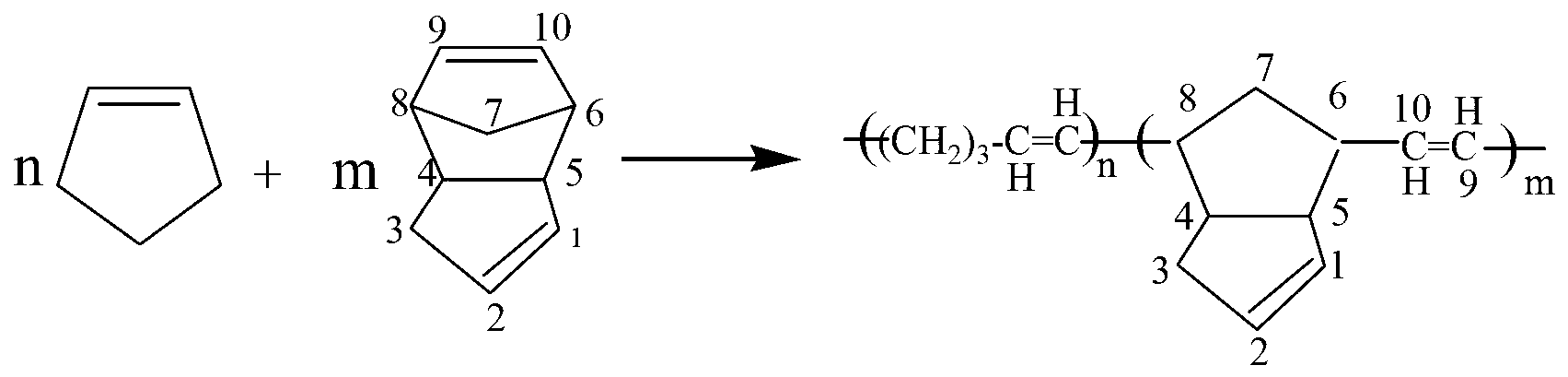

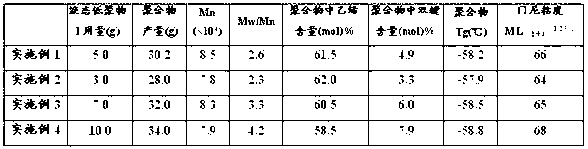

The invention relates to ethylene propylene diene monomer and a preparation method thereof. The ethylene propylene diene monomer comprises 30 to 70%(mol) of ethylene. A third monomer is a liquid low-molecular weight copolymer obtained by copolymerization of cyclopentene and dicyclopentadiene. The ethylene propylene diene monomer comprises 0.5 to 12%(mol) of the third monomer. The third monomer liquid low-molecular weight copolymer of cyclopentene and dicyclopentadiene is a liquid low-molecular weight copolymer containing different double bond structures and having different double bond contents and comprises 3 to 30%(wt) of dicyclopentadiene. The preparation method of the liquid low-molecular weight copolymer has simple processes and a low cost. The liquid low-molecular weight copolymer has no pollution on the environment, an adjustable molecular weight and good dissolvability in a hydrocarbon solvent. The ethylene propylene diene monomer obtained by the preparation method has good sulfuration performances, can be sulfurated by sulphur, has a sulfuration rate close to a sulfuration rate of butadiene styrene rubber, and has good processing performances. The ethylene propylene diene monomer can be widely used for automobile parts, building materials, wires and cables, heat-resistant rubber pipes, high-grade seal pipes and polyolefin modification.

Owner:FUYANG JINGLUE CHEM TECH

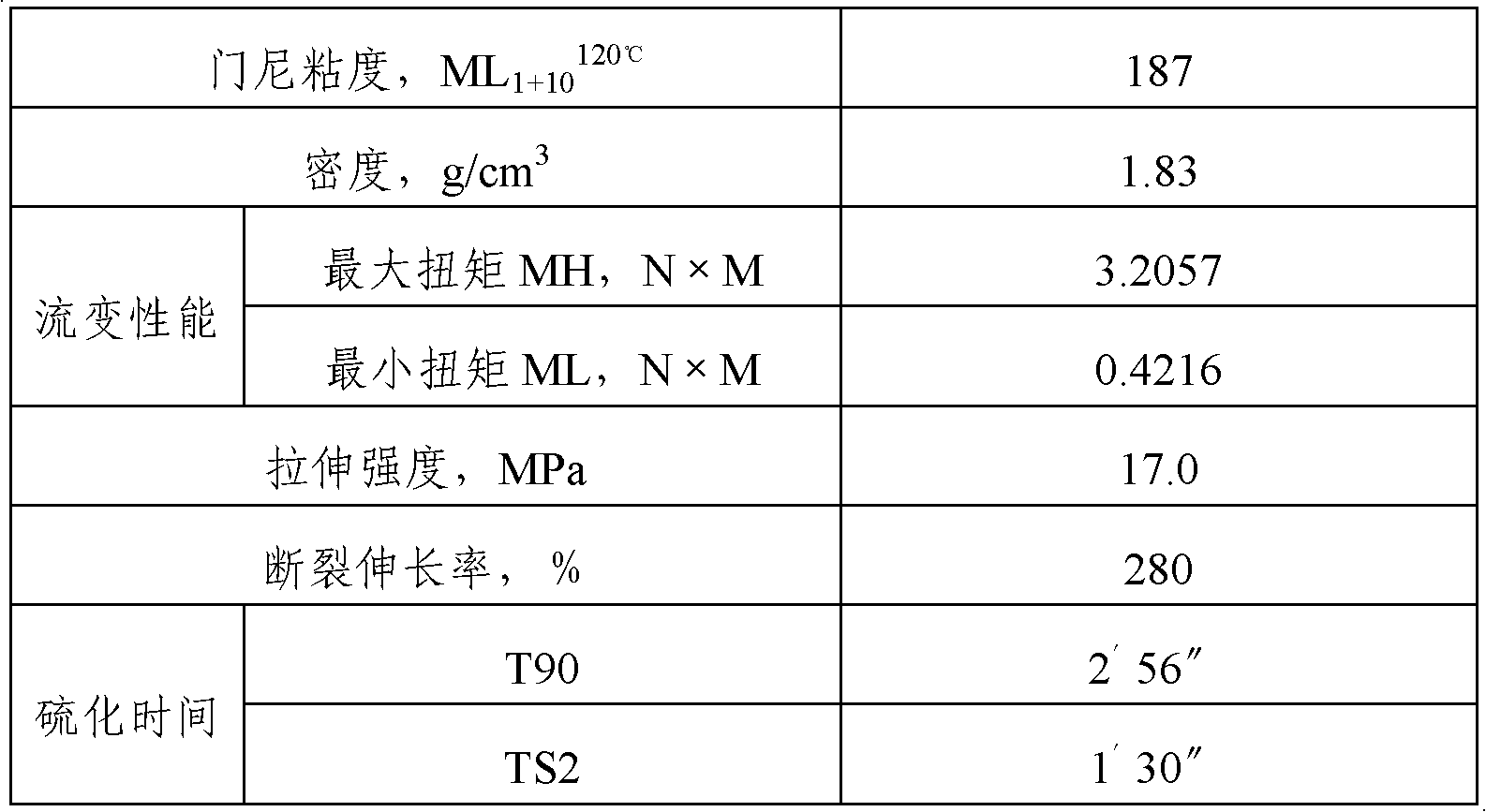

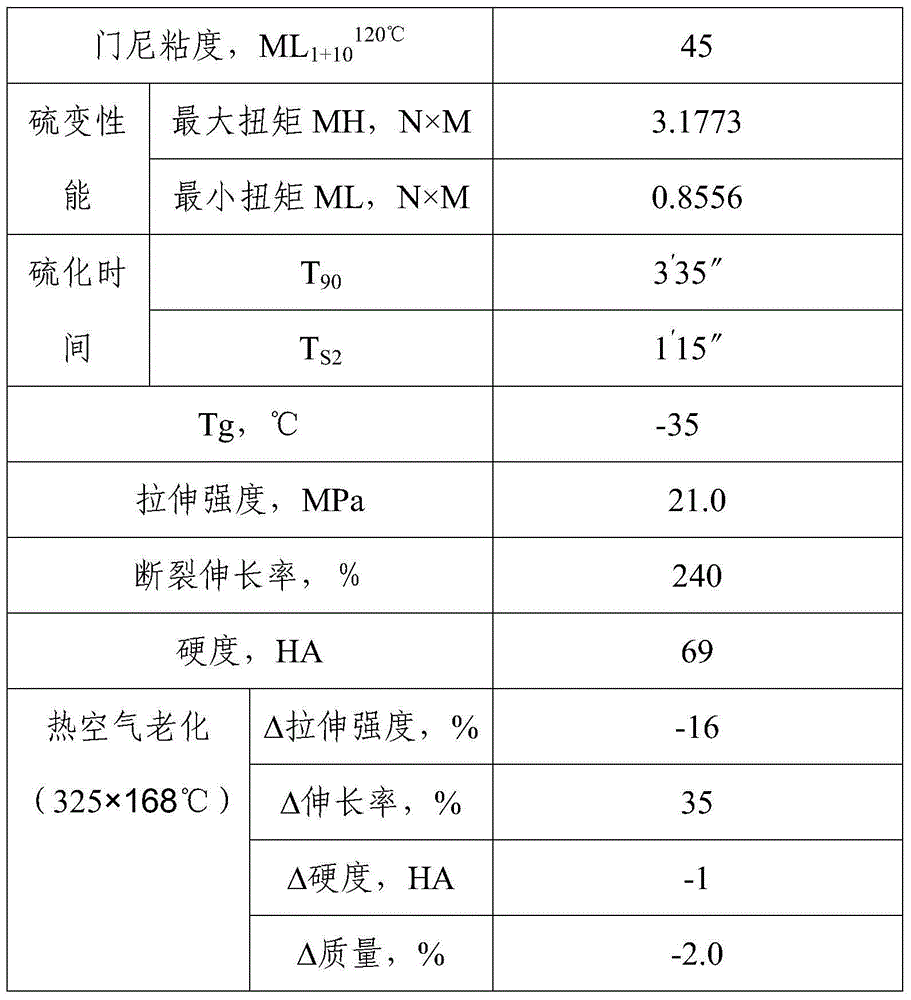

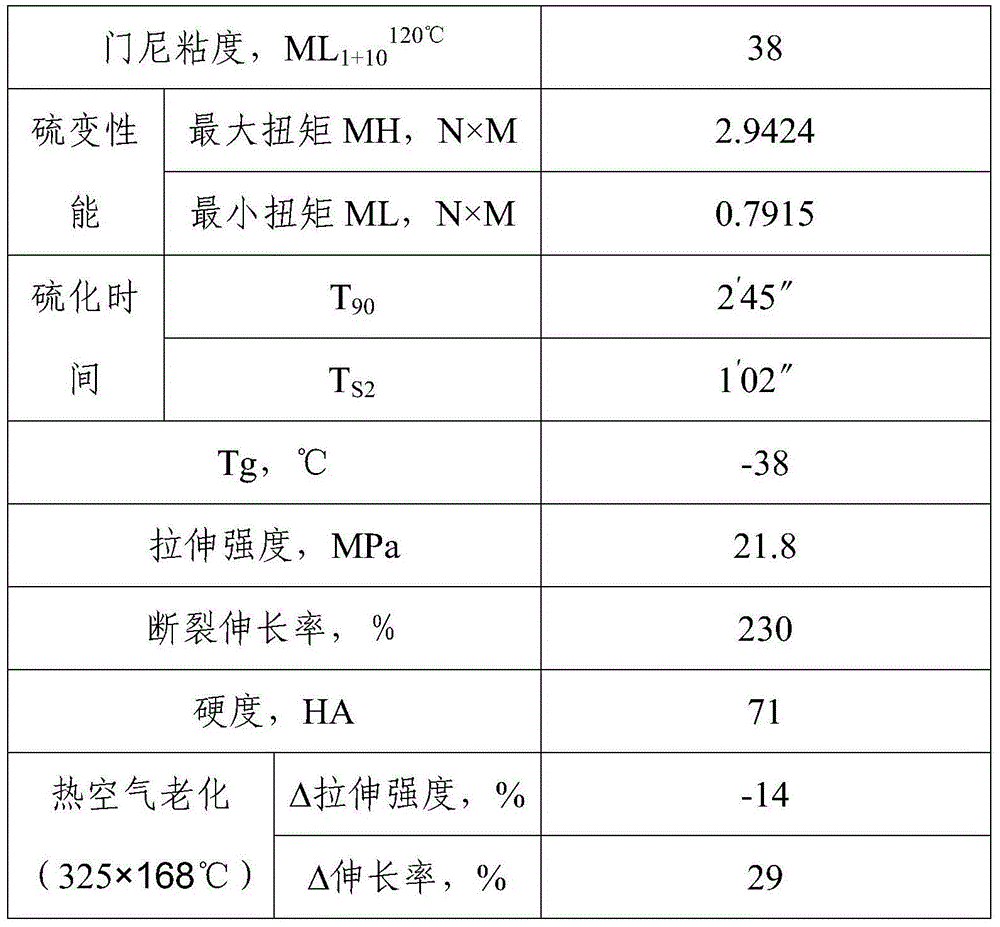

Preparation method of alkali-proof vulcanized fluororubber

The invention provides a preparation method of alkali-proof vulcanized fluororubber. The preparation method includes steps of (1), adding water, emulsifiers and pH (potential of hydrogen) modifiers in a reactor; (2), adding polymerized monomers; (3), starting a stirring device, increasing temperature to be 70-120 DEG C, and adding initiators and chain transfer agents so as to start polymerization reaction; (4), adding residual polymerized monomers in batches, and stopping reaction after all the polymerized monomers are added so as to obtain polymerized emulsion; (5), coagulating, washing and drying the polymerized emulsion to obtain fluororubber; and (6), vulcanizing the fluororubber obtained in the step (5) so as to obtain the vulcanized fluororubber. The preparation method is simple in operation and requires mild reaction conditions. The structure of the fluororubber is controlled effectively by means of regulating structures of the monomers, changing reaction temperatures and the like, so that peroxide, namely the alkali-proof vulcanized fluororubber, is prepared. The prepared vulcanized fluororubber with high Mooney viscosity also has good curability and good oil resistance and can be applied to various industrial fields.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

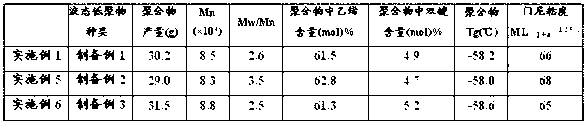

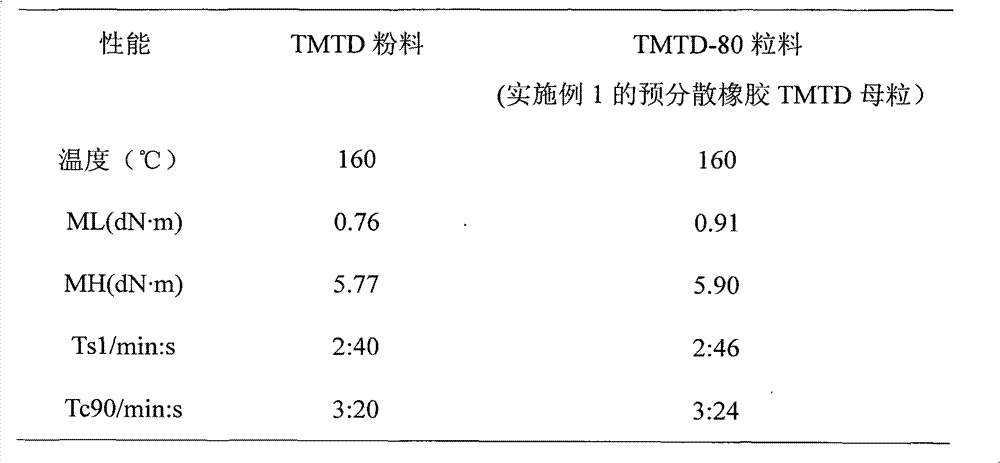

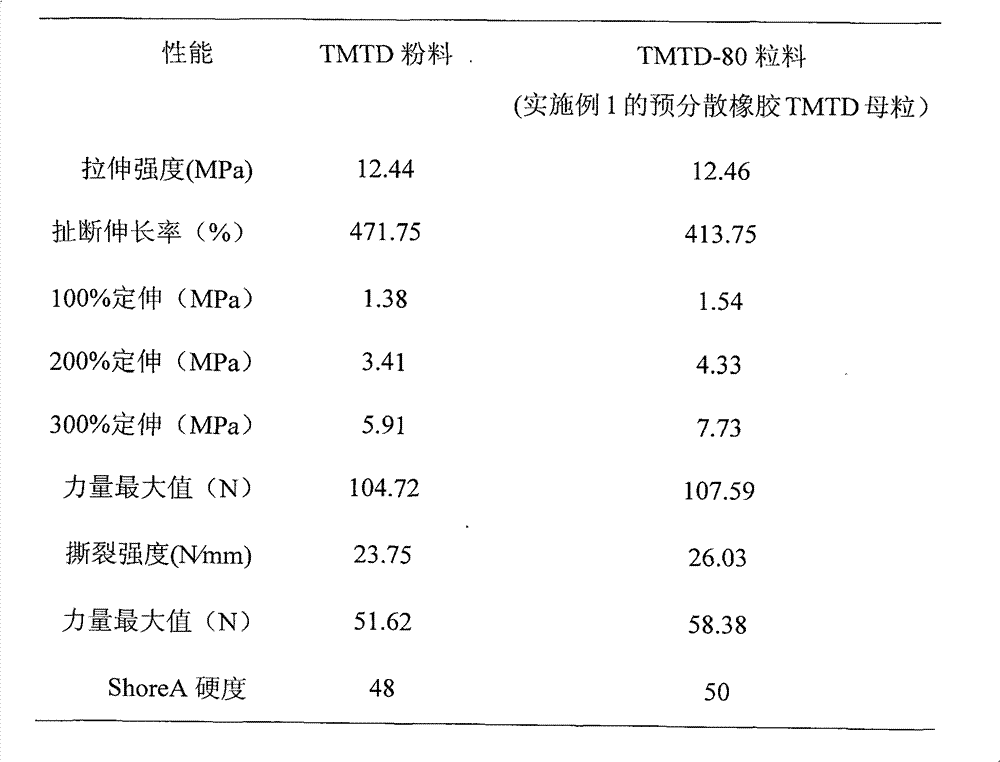

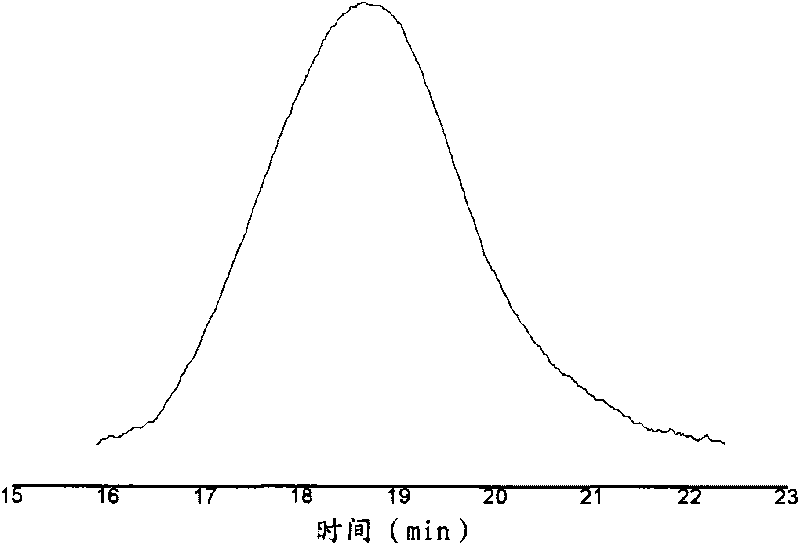

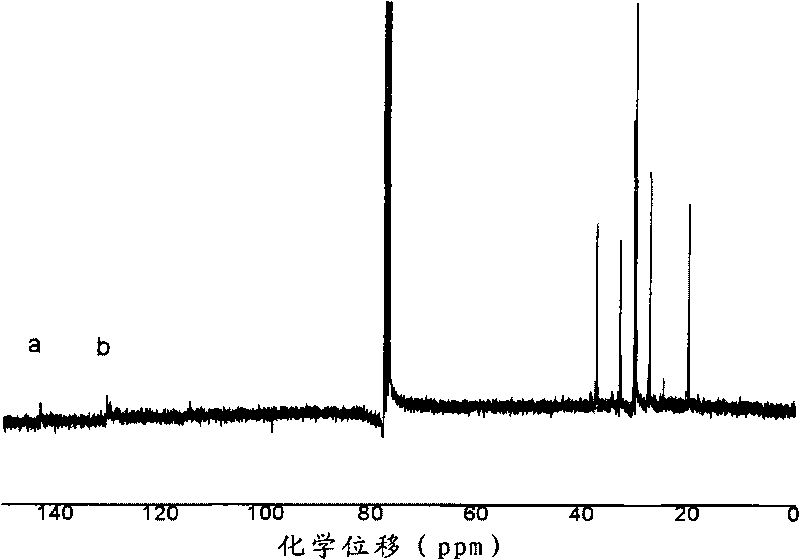

Pre-dispersing rubber accelerator master batch and preparation method thereof

The invention provides pre-dispersing rubber accelerator master batch and a preparation method thereof in order to overcome the defects in the prior art. The pre-dispersing rubber accelerator master batch is characterized in that styrene thermoplastic polymer is adopted as main binder, rubber is used as modifier, and pre-dispersing rubber accelerator master batch comprises, by weight, 10-90% of accelerant, 10-90% of main binder, 0-30% of modifier, preferably 60-90% of accelerator, 10-30% of main binder, 0-20% of modifier and 0-20% of processing oil. The preparation method includes: at the processing temperature of 60-120 DEG C, mixing the accelerator with the main binder and the modifier, adding auxiliaries such as processing oil, and mixing on an open mill or an internal mixer to obtain the pre-dispersing rubber accelerator master batch; and then extruding granules on a single-screw or double-screw extruder to obtain the pre-dispersing rubber accelerator master batch. The pre-dispersing rubber accelerator master batch is good in vulcanization performance and processability and capable of achieving continuous operation and reducing production cost.

Owner:QINGDAO UNIV OF SCI & TECH

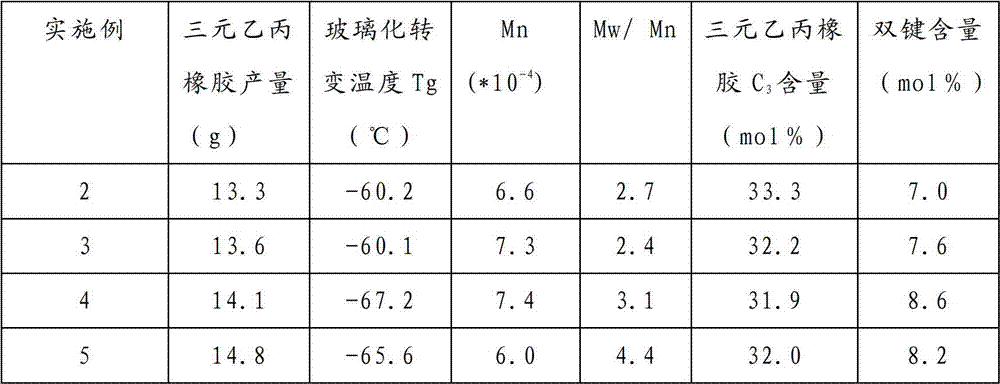

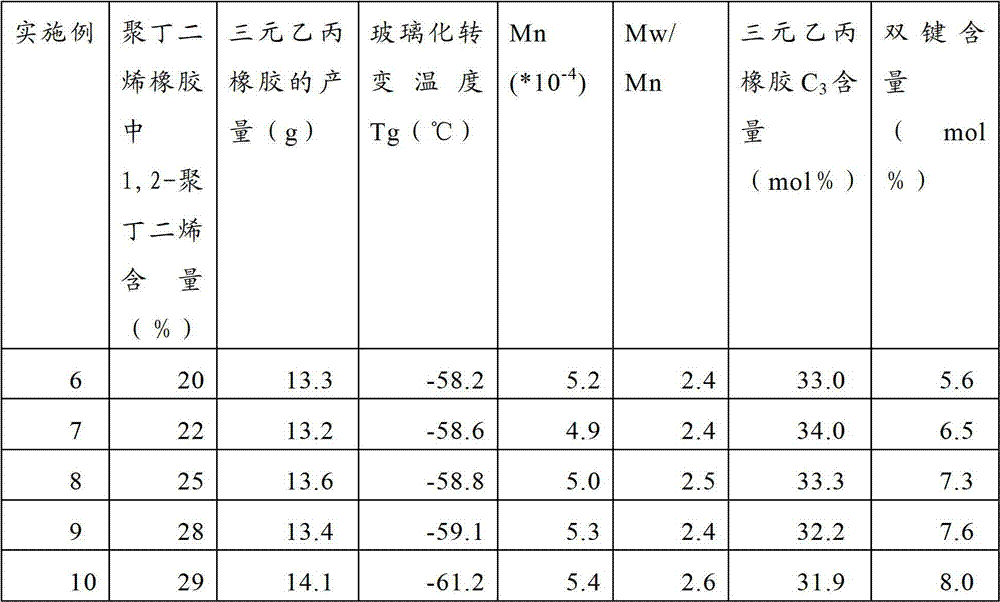

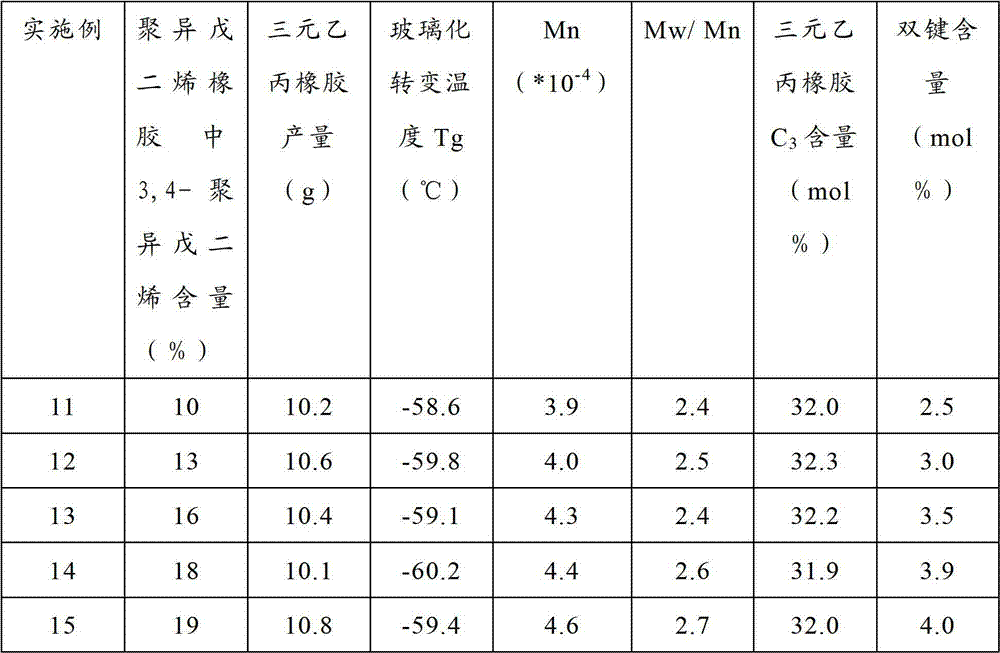

Ethylene-propylene-diene methylene using liquid-state oligomers of diolefin as third monomer and method for preparing same

The invention provides ethylene-propylene-diene methylene taking liquid-state oligomers of diolefin as a third monomer and a method for preparing same. Combined propylene cells account for 20 to 45 molar percent of the ethylene-propylene-diene methylene, the third monomer which is a liquid-state oligomer of diolefin accounts for 0.5 to 15 molar percent of the ethylene-propylene-diene methylene, and the total molar percentage of the combined cells of ethylene, propylene and the third monomer is 100 percent; and the liquid-state oligomer of diolefin of the third monomer is selected from liquid-state oligomers with different double-bond structures and double-bond contents, including the liquid polybutadiene containing 20 to 80 percent of 1,2-strucutres and liquid polyisoprene containing over 90 percent of 1,4-strucutres. Because the side chains contain more double bonds, the ethylene-propylene-diene methylene has good curing and processing properties, and can vulcanize sulfur; the polymer has the molecular weight distribution indexes from 2 to 10; the ethylene-propylene-diene methylene can be used for manufacturing industrial rubber products of automobile parts, waterproof materials, telecom cables and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Synthetic method for fluororubber

ActiveCN102443090AEffective control of Mooney valueGood vulcanizationTetrafluoroethylenePolymer science

The invention relates to a synthetic method for fluororubber. According to the invention, polymeric monomers comprise, by molar weight, 45 to 70% of vinylidene fluoride, 30 to 55% of hexafluoropropene and 0 to 20% of tetrafluoroethene, and are polymerized by using an intermittent emulsion polymerization method, and obtained polymerized emulsion is subjected to coacervation, rinsing, drying and plastication molding so as to obtain the fluororubber. The synthetic method provided in the invention is simple to operate, needs mild reaction conditions, effectively controls a Mooney point of the fluororubber through the measures of adjusting the structure of the monomers, changing reaction temperature, changing addition time of a chain transferring agent, etc., and prepares the fluororubber with a high Mooney point; the prepared fluororubber with a high Mooney point has good curability and excellent oil resistance and can be applied in a plurality of industries, especially in the industry of automobiles.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Preparation method of EPDM (Ethylene-Propylene-Diene Monomer) rubber

The invention provides a preparation method of an EPDM (Ethylene-Propylene-Diene Monomer) rubber. The method comprises the steps of polymerizing an ethylene, a propylene and a third monomer in an organic solvent under the action of a catalyst system to obtain the EPDM rubber. The third monomer is polybutadiene rubber with the content of over 9% of 1, 2-polybutadiene or polyisoprene rubber with the content of over 9% of 3, 4-polyisoprene, and the weight-average molecular weight of the third monomer is 200000-1000000; The catalyst system comprises a vanadium catalyst, an alkyl aluminum compound and an activation promoter. The obtained EPDM rubber has appropriate double bonds, so that sulfonation of the rubber can be carried out by using sulfur, and the EPDM rubber has good vulcanizing property and good processability. The experimental result shows that in the prepared EPDM rubber, the mole percentage of the double bond is 2%-10.5%, and the molecular weight distribution index is 2-5.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

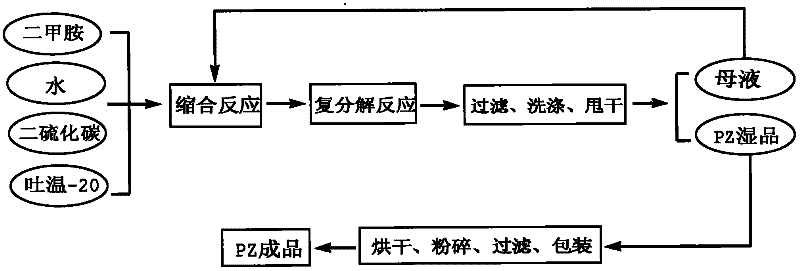

Preparation method of rubber vulcanization accelerator zinc dimethyl dithiocarbamate

InactiveCN102295592AReduce environmental pollutionShort production cycleOrganic chemistryCarbon disulfideSurface-active agents

The invention provides a method for preparing rubber vulcanization accelerator zinc dimethyl dithiocarbamate (PZ), wherein the raw materials used are dimethylamine, carbon disulfide, nonionic surfactant and zinc oxide, and the stoichiometric ratio is two Methylamine: carbon disulfide: non-ionic surfactant: zinc oxide=1: 0.95-1.25: 0.02-0.025: 0.52-0.58; the concrete process of the inventive method is: in the reactor that fills pure water, under stirring state successively Add specified amount of dimethylamine, non-ionic surfactant, zinc oxide, stir for 30-50min, then add carbon disulfide liquid dropwise, dropwise time is 2-2.5h, temperature is controlled at 20°C-25°C; then stir for 1 hour, Carry out solid-liquid separation, discard the liquid, dry the solid, crush, sieve, and pack.

Owner:WILLING NEW MATERIALS TECH CO LTD

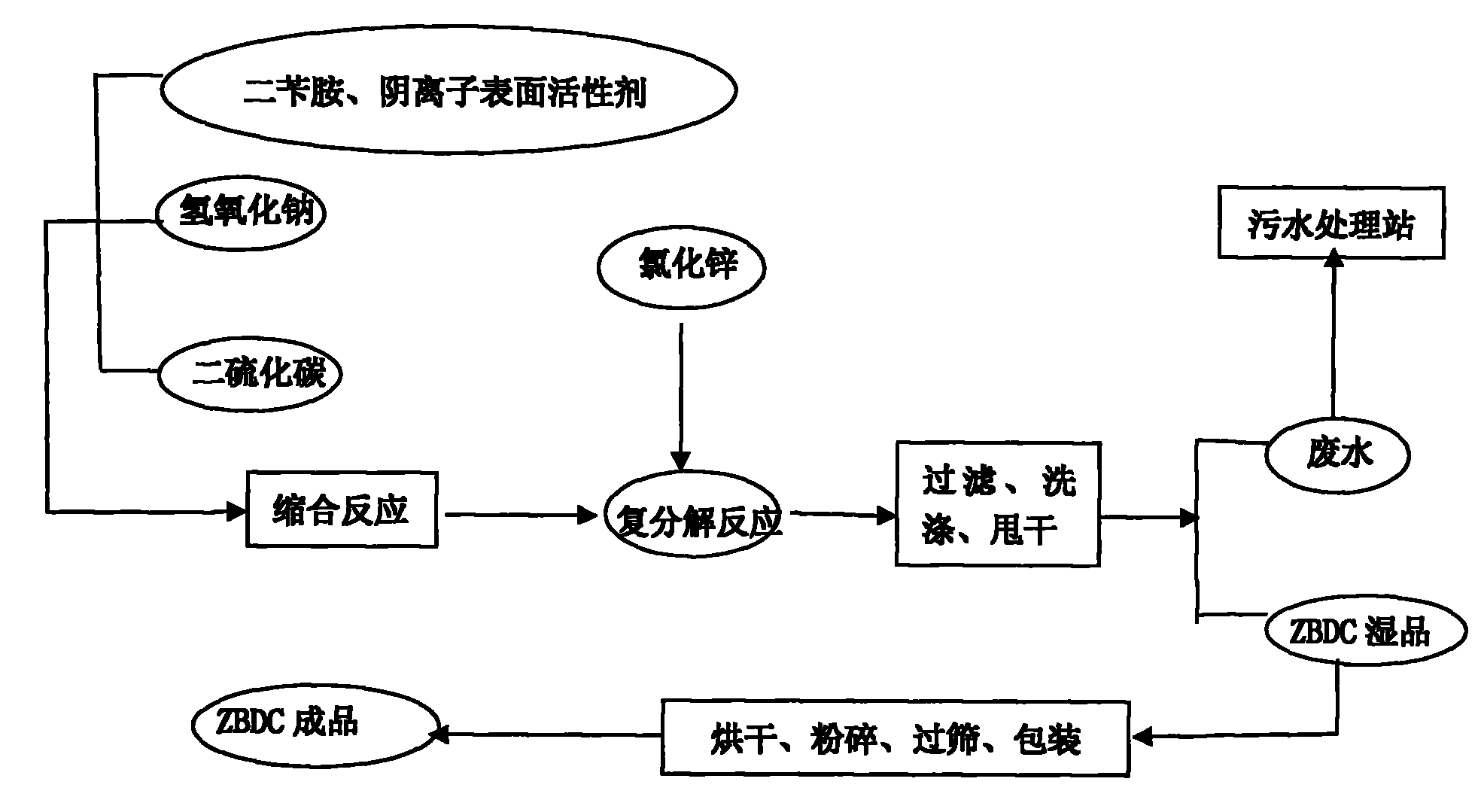

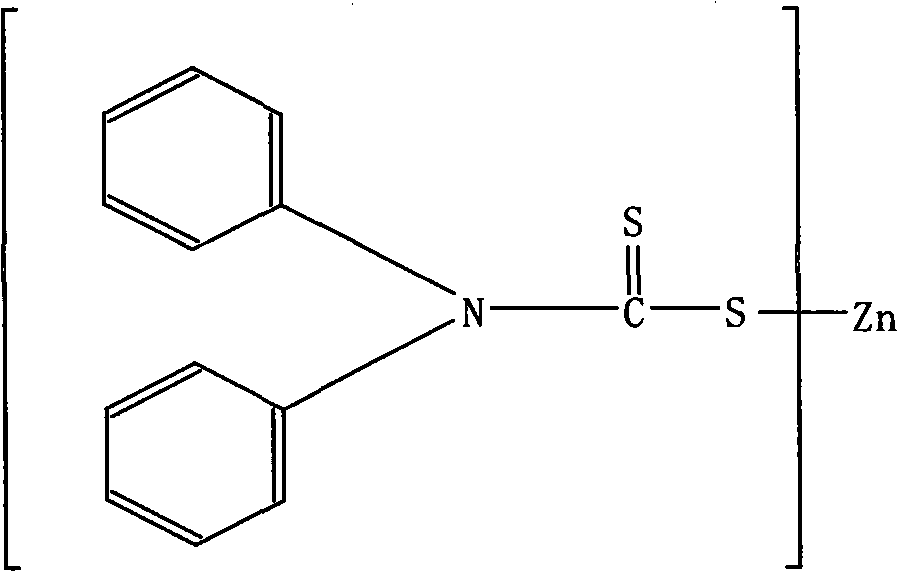

Method for preparing zinc dibenzyl dithiocarbamate (ZBDC) thiofide

ActiveCN101955452AReduce pollutionLess waste waterOrganic chemistryZinc dibenzyldithiocarbamateDodecylsulfonic acid

The invention provides a method for preparing zinc dibenzyl dithiocarbamate (ZBDC) thiofide, which comprises that: the raw materials used are dibenzylamine, carbon disulfide, sodium hydroxide and anionic surfactant, wherein the stoichiometric molar ratio of dibenzylamine to carbon disulfide to sodium hydroxide and anionic surfactant to zinc chloride to sulfuric acid is 1:1.05-1.2:1.05-1.2:0.020-0.025:0.53-0.58:0.005-0.015; and the process comprises: adding dibenzylamine, carbon disulfide, sodium hydroxide and anionic surfactant in a given amount into a reaction kettle holding purified water with stirring in turn, lower the temperature by 10 to 20 DEG C totally, dripping carbon disulfide liquid in a given amount within 6 to 7 hours, stirring for 0.5 to 1 hours after the dripping is finished, keeping the temperature at 30 to 38 DEG C constantly, dripping solution of zinc chloride, performing replacement reaction, regulating the pH value of the reaction liquid to 7 to 9 with sulfuric acid after the replacement reaction is finished, finishing the reaction, stirring for 1 to 2 hours, performing solid-liquid separation, discarding liquid and drying, crushing, sieving and packaging the solid. The anionic surfactant is sodium dodecyl sulfate.

Owner:WILLING NEW MATERIALS TECH CO LTD

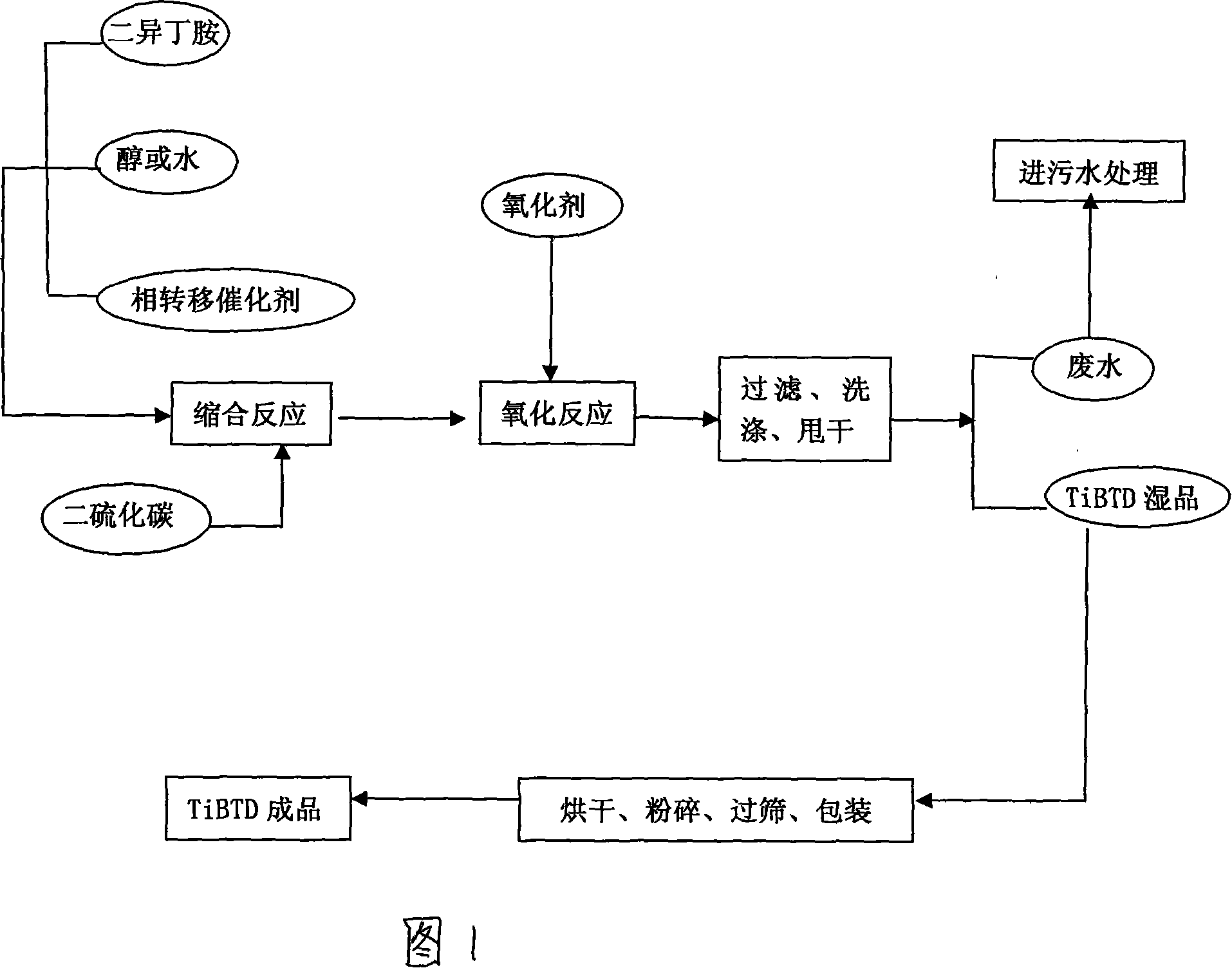

Process for producing vulcanization of rubber accelerant disulfide diisobutyl thiuram

A production method of the diisobutylthiuram disulfide-accelerant of the vulcanization of rubber is provided, which is the production method of the accelerant of the vulcanization of rubber. The method overcomes the defects existing when others produce the product. The raw materials and the mixture ratio of the invention are diisobutylamine : carbon disulfide : oxidant equals to 1 : 1-1.3 : 0.35-0.55; the production method is that enamel reaction axe with volume of 2000L is added with the diisobutylamine, alcohols or water and phase transfer catalyst with specified amount in turns; the cooling water is turned on with temperature reduced to the preferential temperature and is added with carbon disulfide liquid measured accurately by drops, and the time is controlled; after added by drops, the pH value of the reaction liquid is measured to the specialized range; after the pH value is stable, the preferential temperature is controlled and the oxidant is added by drops to carry out oxidation reaction. After the oxidation reaction, the insulation temperature is kept for 1h and solid-liquid separation is conducted to abandon the liquid and dry, crush, sieve and pack the solid.

Owner:WILLING NEW MATERIALS TECH CO LTD

Method for increasing drying efficiency of natural rubber

A method to enhance drying efficiency of natural rubber, which is, in the process of acid coagulated natural rubber and micro-organism coagulated natural rubber, adding nanometer silicon dioxide suspension, coagulating, drying. A plurality of polar ''aqueous channel'' is formed in hydrophobic natural rubber, which can enhance quality of natural rubber. Drying efficiency of the inventive natural rubber is improved by about 20%, energy consumption is reduced by about 20%. The obtained natural rubber is in golden color and very dry. The quality thereof meets quality criterion of fifth Chinese standard natural rubber, with initial drawability P0 between 35 and 42, plasticity retention PR1 equal to or more than 75, content of nitrogen equal to or less than 0.54%, content of volatile equal to or less than 0.70%, content of ash equal to or less than 0.54%, Mooney viscosity of raw rubber between 75 and 79. The product has good vulcanizing property, and vulcanization thereof has good physical properties, high mechanical strength, great tear resistance.

Owner:GUANGDONG OCEAN UNIVERSITY

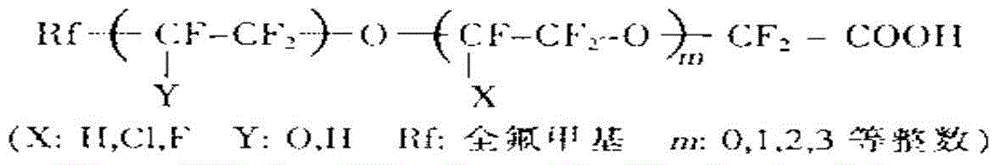

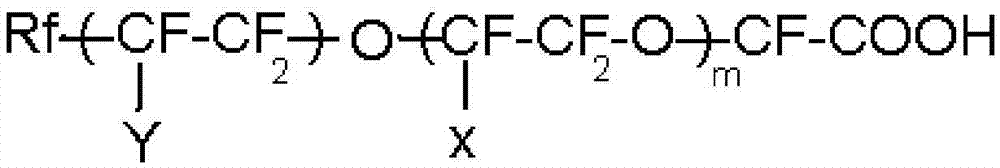

Low-temperature-resistant perfluoroether rubber and synthesis method thereof

The invention relates to a synthesis method of a low temperature-resistant perfluoroether rubber. The synthesis method comprises the following steps: 1) evenly mixing an emulsifier, fluoroether oil and water together and heating until 40 DEG C to form a microemulsion, and adding a comonomer A and a comonomer B to the microemulsion to obtain a mixed liquor; 2) adding deionized water and a pH regulator to a reaction kettle, adjusting the content of oxygen in the reaction kettle to be lower than 20ppm, increasing the temperature in the reaction kettle to the range of 70-120 DEG C, and adding the mixture of tetrafluoroethylene and perfluoromethyl vinyl ether to the reaction kettle; 3) adding the mixed liquor to the reaction kettle and adding the initiator potassium peroxodisulfate to start reacting, and adding a vulcanization point monomer and a chain transfer agent until the reaction ends, thereby obtaining a polymer; 4) performing electrolyte coagulation on the polymer and then washing, drying in vacuum and molding by plastifying to obtain the perfluoroether rubber. The synthesis method is simple to operate and mild in reaction conditions, and is capable of preparing the low-temperature-resistant perfluoroether rubber by adjusting the monomer structure.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Anti-flaming aging-resistant rubber material

The invention discloses an anti-flaming aging-resistant rubber material which comprises the following constituents in parts by weight: 40 parts to 45 parts of butadiene styrene rubber, 30 parts to 36 parts of polyurethane elastomer, 10 parts to 15 parts of chlorinated butyl rubber, 2 parts to 3 parts of vulcanizing agent BPO, 1.2 parts to 1.8 parts of sulphur, 2 parts to 4 parts of divinyl carboxylic acid sodium, 20 parts to 30 parts of calcite powder, 9 parts to 11 parts of kieselguhr, 5 parts to 7 parts of aluminum silicate, 14 parts to 15 parts of carbon black N660, 14 parts to 15 parts of carbon black N330, 10 parts to 12 parts of magnesium hydroxide, 3 parts to 5 parts of quartz powder, 5 parts to 7 parts of zinc oxide, 2 parts to 4 parts of calcium stearate, 5 parts to 8 parts of barium stearate, 5 parts to 7 parts of diphenyl phosphate ester, 2 parts to 4 parts of melamine, and 1.5 parts to 2.5 parts of silane coupling agent KH450. The anti-flaming aging-resistant rubber material has an excellent anti-flaming aging-resistant performance, so that smog is effectively prevented from generating during a combustion process; besides, the ozone resistance and the weather resistance of the anti-flaming aging-resistant rubber material are excellent; moreover, the anti-flaming aging-resistant rubber material further has the advantages of high elasticity, high hardness and high strength.

Owner:南通鹏达体育用品有限公司

High-performance fluorine rubber gasket and manufacturing method thereof

The invention discloses a high-performance fluorine rubber gasket. The high-performance fluorine rubber gasket comprises, by weight, 40-80 parts of binary fluorine rubber, 20-30 parts of silane-modified fluororubber, 12-20 parts of atomized carbon black, 5-10 parts of barium sulfate, 5-15 parts of calcium hydroxide, 1-5 parts of calcium titanate, 1-3 parts of chelate titanate coupling agents, 2-6 parts of molybdenum disulfide, 2-6 parts of phenyl methylpolysilicone resin, 1-2 parts of magnesium oxide, 1-3 parts of dicumyl peroxide, 0.5-1.2 parts of dibenzothiazyl disulfide, 0.5-1.2 parts of triallyl isocyanurate, 1-1.8 parts of bisphenol A, 1-3 parts of hexafluoride isopropylidene diphenol, 1-3 parts of benzyl triphenyl phosphoric chloride, 1-2 parts of sodium stearate, 1-3 parts of palm wax, 1-3 parts of fluorinated polyamide and 1-2 parts of fatty alcohol. The invention further discloses a manufacturing method of the high-performance fluorine rubber gasket. The compression deformation and high-temperature steam resistance of the fluorine rubber gasket are excellent, and the manufacturing method is simple.

Owner:ANHUI JINYANG FLUORINE CHEM

Asymmetric latent polyurethane curing agent and preparation method thereof

ActiveCN107043447ARapid responseGood vulcanizationImino compound preparationBenzoic acidReaction temperature

The invention discloses an asymmetric latent polyurethane curing agent and a preparation method thereof. A molecular structure of the asymmetric latent polyurethane curing agent has an oxazolidine group and an imine group, and has oxazolidine and imine dual function groups effect, and the asymmetric latent polyurethane curing agent has the characteristics of low viscosity, convenient operation, moderate reaction speed, and no odor after being released. The synthesis is characterized in that in a reaction vessel, ethanolamine cyclization, primary amino aldehyde (ketone) amination, and carboxyl and hydroxy esterification reaction are completed, process such as purification separating of an intermediate is not required, the process condition is mild, discharge of exhaust gas and waste residue is not generated, and a catalyst can be reused. The main raw materials are para amino benzoic acid (or ester), diethanolamine and aldehyde or ketone with 1-13 carbons. The reaction temperature is 40-150 DEG C, and the product can be used as the latent curing agent of a polyurethane material and as an active diluent.

Owner:江苏湘园化工有限公司

Anti-aging modified natural rubber composite material

The invention discloses an anti-aging modified natural rubber composite material. The anti-aging modified natural rubber composite material is prepared from natural rubber, butadiene rubber, butadiene styrene rubber, butadiene-acrylonitrile rubber, epoxidized natural rubber, nano-zinc oxide, stearic acid, sulfur, dicumyl peroxide, triallyl trimellitate, p-tert-butyl-phenolic resin, nano calcium carbonate, precipitated silica, carbon black purple, nano-microcrystalline cellulose, nano-silicon dioxide, an anti-aging agent, potassium iso-propyl xanthate, dibenzylamine, tetrahydrofurfurylamine, isopropyl trioleoyl titanate, vinyltris(beta-methoxyethoxy)silane, diethylene glycol distearate and polyethyl dialcohol adipate. The anti-aging modified natural rubber composite material is high in strength, good in heat resistance and aging resistance and capable of meeting the usage requirements of multiple fields of cables, rubber pipes and the like.

Owner:苏州技佳橡塑有限公司

Rapidly vulcanized fluoroelastomer and preparation method thereof

The invention relates to a rapidly vulcanized fluoroelastomer and a preparation method thereof. The rapidly vulcanized fluoroelastomer comprises comonomers. The comonomers comprise two or more of vinylidene fluoride, chlorotrifluoroethylene, tetrafluoroethylene, 3, 3, 3-trifluoropropene, hexafluoropropylene and a perfluoroalkyl ether monomer, and a vulcanization point monomer, wherein a use amount of the vulcanization point monomer is 2-3% that of the comonomers. The rapidly vulcanized fluoroelastomer has high fuel permeability resistance, short vulcanization time, a fast vulcanization rate, low Mooney viscosity and high mechanical properties. The preparation method controls vulcanization time tc90 of the fluoroelastomer within 80s. The rapidly vulcanized fluoroelastomer has Mooney viscosity [ML(1+10 121 DEG C)] of 50-80 DEG C, tensile strength of greater than or equal to 22MPa and elongation of greater than or equal to 230%.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

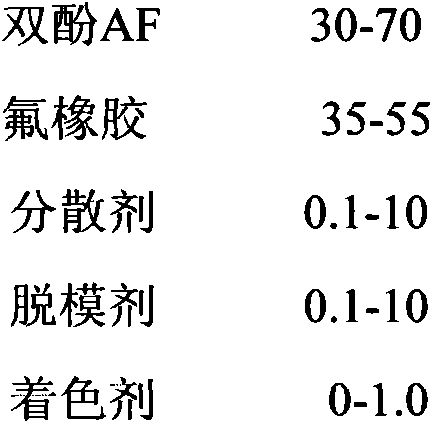

Fluorubber use bisphenol AF pre-dispersion mother colloidal particle formula

The invention discloses a fluorubber use bisphenol AF pre-dispersion mother colloidal particle formula prepared from the following raw materials by mass: 30-70 parts of bisphenol AF; 35-55 parts of fluorubber; 0.1-10 parts of a dispersant; 0.1-10 parts of a release agent; and 0-1 parts of a colorant. The fluorubber as a carrier is cooperated with the dispersant and the release agent, the bisphenol AF curing agent is mixed into the fluorubber on an open blending machine, so that the bisphenol AF is fully dispersed uniformly in the fluorubber, the bisphenol AF curing agent has excellent curing properties in the fluorubber, and can meet the use requirements. The fluorubber use bisphenol AF pre-dispersion mother colloidal particle formula can improve the dispersion of the fluorubber curing agent bisphenol AF (2, 2-bis-(4-hydroxy phenyl) hexafluoropropane) and BPP (tri phenyl phosphorus chloride) in the fluorubber, and overcomes the problems of the poor dispersion and mutual smelting of a traditional curing agent in the fluorubber.

Owner:SHANGHAI PINKE RUBBER & PLASTIC MATERIAL

Peroxide vulcanized fluororubber and polymerizing method thereof

The invention relates to peroxide vulcanized fluororubber and a polymerizing method thereof. The polymerizing method comprises the following steps: (1) mixing an emulsifier, hydrofluoroether oil and water and heating to form colorless and transparent microemulsion; (2) adding water and a pH regulator into a reactor until system pH is 8 to 9, firstly utilizing nitrogen to displace air in the reactor, and then introducing mixed gas to displace nitrogen; (3) adding the microemulsion into the reactor, continuing introducing mixed monomer, adding an initiator and a chain transfer agent and starting polymerization reaction; (4) adding a vulcanization point monomer to react continuously when the mixed monomer reacts and reaches certain accumulative reacting weight; (5) agglomerating, washing and drying obtained polymerized emulsion, plastifying and shaping, and packaging to obtain the fluororubber. The polymerizing method disclosed by the invention improves a reaction rate by improving a configuring mode of the emulsifier, adjusting adding time and an adding mode of the vulcanization point monomer and the like, and improves vulcanizing performance of the peroxide vulcanized fluororubber.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

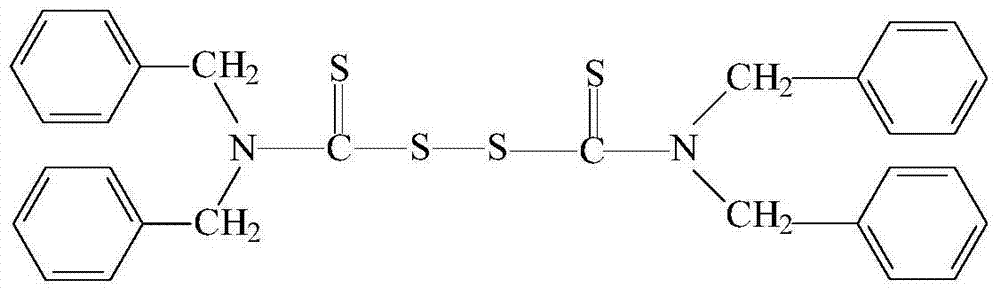

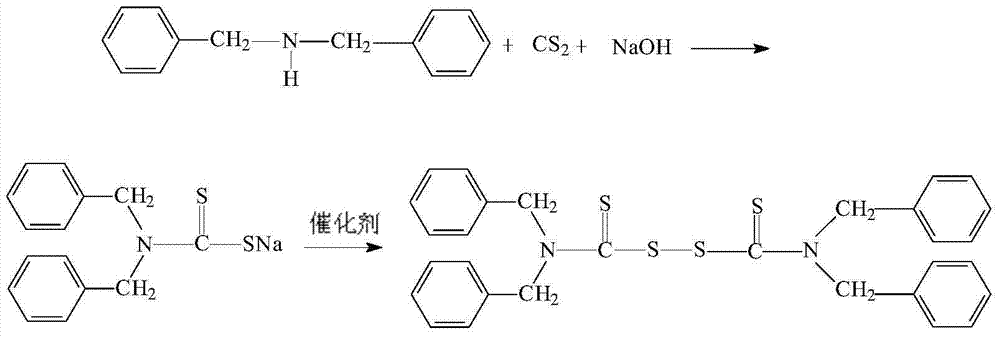

Preparation method of tetrabutylthiuram disulfide used as rubber vulcanization accelerator

ActiveCN104326956AIncrease the rate of oxidation reactionsIncrease concentrationOrganic chemistrySulfonateVulcanization

The invention relates to a preparation method of tetrabutylthiuram disulfide used as a rubber vulcanization accelerator. By virtue of the preparation method, tetrabutylthiuram disulfide is prepared by a two-step process, namely sodium dibenzyl amino sulfonate is prepared from dibenzylamine, carbon disulfide and sodium hydroxide and then oxidized by a hydrogen peroxide oxidant to prepare tetrabutylthiuram disulfide. According to the preparation method, carbon disulfide is excessive, so that dibenzylamine is fully reacted; excessive unreacted carbon disulfide is separated and recycled in time; the production cost is reduced; the pollution to the environment is low; low-concentration hydrogen peroxide with a concentration of 5-20wt% is used as the oxidant and applied to the oxidation reaction; hydrogen peroxide has the characteristics of being low in cost, stable in property, small in pollution, easy to store and transport and high in safety; the cost can be effectively reduced; the pollution to workers in the operation process is alleviated; the safety is improved; meanwhile, the oxidization effect is not reduced.

Owner:山东斯递尔化工科技有限公司

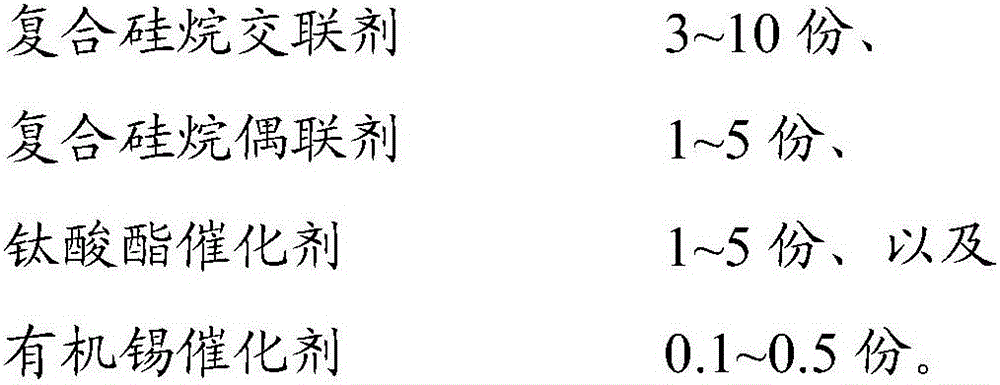

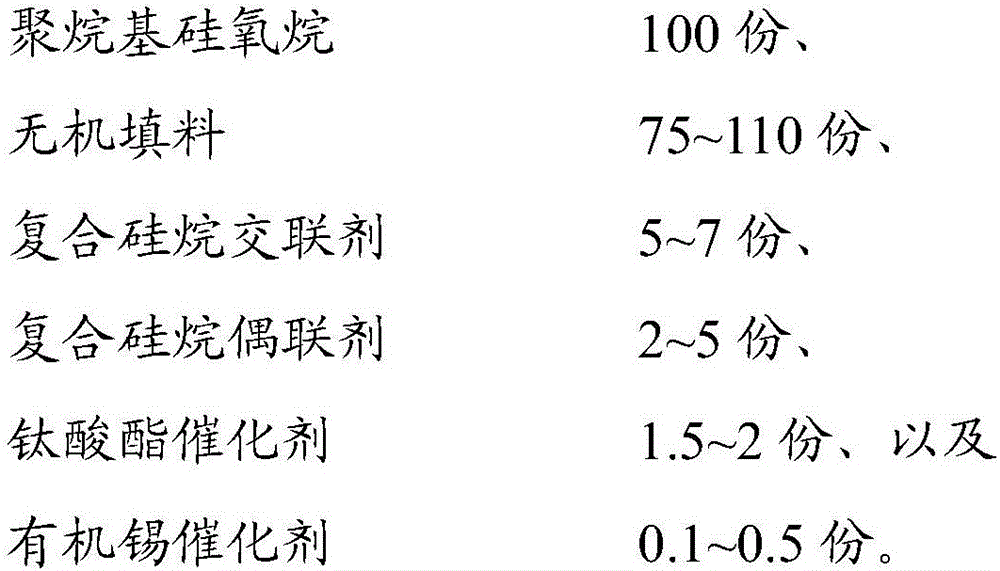

Single-ingredient silicone structural sealant and preparation method thereof

ActiveCN106634806AHigh bonding strengthImprove cohesionNon-macromolecular adhesive additivesCross-linkTin

The invention relates to a single-ingredient silicone structural sealant and a preparation method thereof. The single-ingredient silicone structural sealant is prepared from 100 parts of poly-alkylsiloxane, 70 to 150 parts of inorganic filling materials, 3 to 10 parts of composite silane cross linking agents, 1 to 5 parts of composite silane coupling agents, 1 to 5 parts of titanium ester catalysts and 0.1 to 0.5 part of organic tin catalysts. The single-ingredient silicone structural sealant uses a mode of adding the composite silane cross linking agents into the composite silane coupling agents on the basis of using the poly-alkylsiloxane as a main body raw material; by using a mode of improving the Van der Waals' force and the hydrogen-bond interaction on the polarity base material by polarity functional groups on longer polarity long chains in the composite silane coupling agents, the bonding force on the substrates can be further enhanced; on the basis, through the existence of the polarity chain sections, the reinforcing effect of the filling materials can be improved, and the cohesion of the structural sealant is improved; meanwhile, the effect of optimizing the cross linking structure can be achieved by the composite silane cross linking agents; therefore the stretch intensity of the structural sealant is improved.

Owner:GUANGZHOU BAIYUN CHEM IND

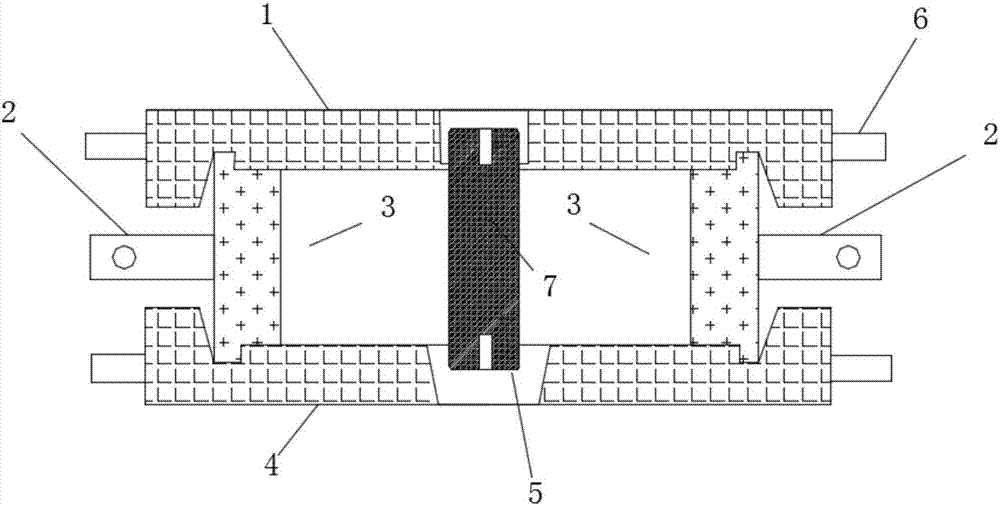

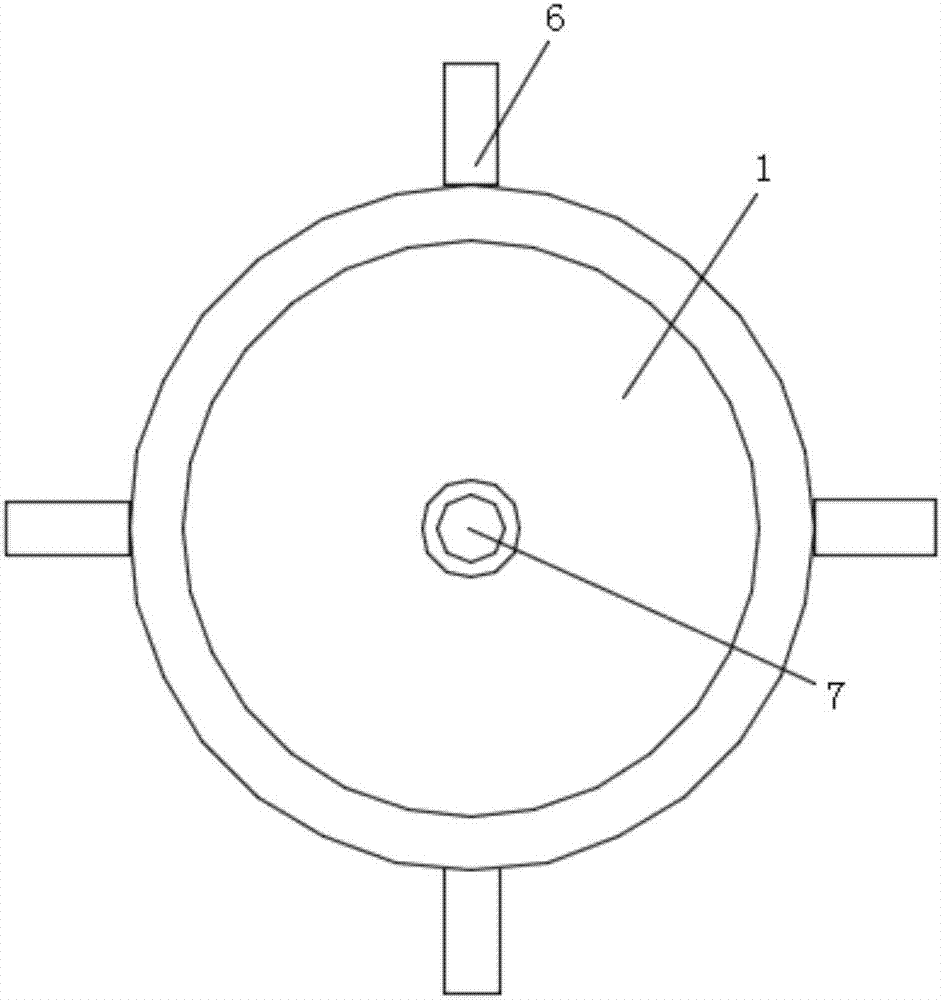

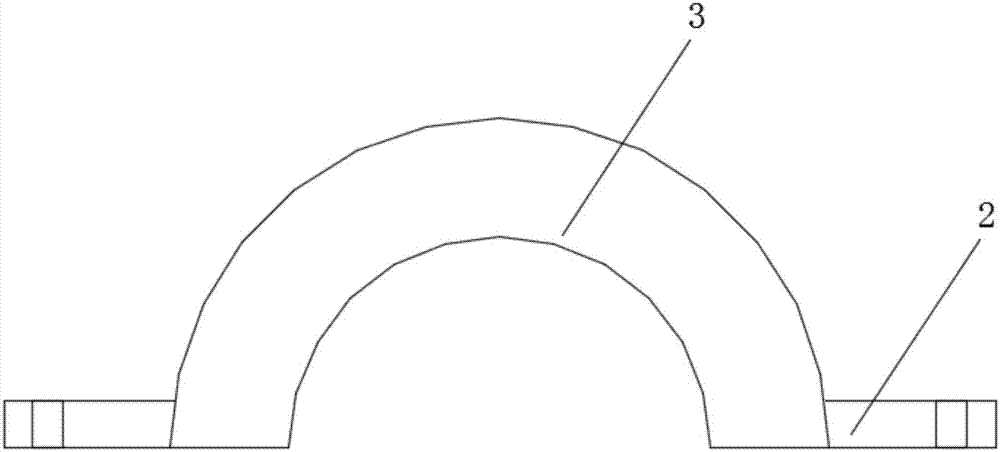

Vulcanized mould for secondary-class building seismic isolation support

The invention discloses a vulcanized mould for a secondary-class building seismic isolation support. The mould comprises an upper mould, a lower mould, two molding blocks, rubber discharging blocks, hoisting blocks and a mandrel, wherein the hoisting blocks are arranged surrounding the outer parts of the upper mould and the lower mould; the upper mould and the lower mould are connected through the molding blocks; the two molding blocks are connected through a bolt rod; the rubber discharging blocks are arranged on the upper mould and the lower mould; and the two ends of the mandrel are respectively connected with the rubber discharging block of the upper mould and the rubber discharging block of the lower mould. The mould has a simple structure, is reasonable in design, is simple and convenient to operate, has good vulcanizing property, has good integrity and use security, is attractive in appearance, is convenient to separate and replace, costs less time and saves materials; the mould is high in repeating utilization ratio, low in using cost, and long in service life; and the manufactured support has higher quality and can meet production demands of people.

Owner:SHAANXI YONGAN DAMPING TECH

Method for preparing zinc diphenyl dithiocarbamate

The invention relates to a method for preparing zinc diphenyl dithiocarbamate, belonging to the technical field of chemical synthesis. The method comprises the steps of: firstly, reacting carbon disulfide with diphenylamine under the condition that water is used as solvent and sodium hydroxide is used as a catalyst, and then carrying out replacement reaction with zinc chloride. The synthesis can be finished in two steps in the reaction process and is free of complicated processing processes, three wastes are not generated basically, and products have high purity and good color. The invention has the advantages that the sodium hydroxide is cheap and common and is easy to purchase, the method has short production cycle and high safety coefficient, basically no waste gas is discharged, the products have high melting point and white appearance, the total product yield is 80-92% and the comprehensive cost is low.

Owner:JIANGSU FEIYA CHEM IND

Rubber sealing sleeve material of soft sealing gate valve with low compression deformation and preparation method

The invention provides a rubber sealing sleeve material of a soft sealing gate valve with low compression and deformation. The rubber sealing sleeve material is prepared from the following raw materials in parts by weight: 45 to 55 parts of ethylene propylene diene methylene rubber, 10 to 20 parts of butadiene rubber, 1 to 3 parts of maleic anhydride, 2 to 6 parts of light-weight magnesium oxide, 3 to 6 parts of terpene resin, 5 to 10 parts of cashew nut oil modified phenolic resin, 2 to 5 parts of 1-di-(tert-butylperoxy)cyclohexane, 1 to 3 parts of triallyl isocyanurate, 2 to 4 parts of accelerant, 20 to 30 parts of reinforcing agent and 2 to 5 parts of vulcanizing agent. The invention also discloses a preparation method of the rubber sealing sleeve material. The prepared rubber sealing sleeve material has the advantages that the compression deformation is very low, the anti-aging property is good, the material is not easily deformed and aged after being used for a long time, the service life is prolonged by more than two times, the preparation technology is simple, the vulcanizing property is excellent, the sticking to a die in the vulcanizing process is avoided, and the rate of finished products is high.

Owner:ANHUI SRILL VALVE CO LTD

Sound-insulation heat-preservation rubber product and preparation method thereof

The invention relates to the field of rubber, and particularly discloses a sound-insulation heat-preservation rubber product and a preparation method thereof. The formula comprises at least the following components: an ethylene-propylene-diene monomer, silicon dioxide aerogel, a filler, sulfur, an activator, a plasticizer, an anti-aging agent, an organic foaming agent and paraffin oil. According to the rubber product and method provided by the invention, the modified silicon dioxide aerogel is used, so that mechanical properties of silicon dioxide aerogel are improved, and mechanical properties and vulcanization properties of a rubber compound are further improved by controlling a usage amount ratio of the silicon dioxide aerogel; in addition, filler light weight calcium carbonate is modified, so that dispersibility of light weight calcium carbonate is improved, the vulcanization properties of the rubber compound are improved; and the modified silicon dioxide aerogel and the modified light weight calcium carbonate are comprehensively coordinated, so that the prepared rubber product has more excellent tensile strength, elongation at break and vulcanization properties.

Owner:南京大毛牛环保科技有限公司

Carbon-nanotube-modified chlorosulfonated polyethylene composite material

InactiveCN105585786AImprove the defect of large compression setImprove heat resistancePhosphateCarbon nanotube

The invention discloses a carbon-nanotube-modified chlorosulfonated polyethylene composite material which is prepared from the following raw materials in parts by weight: 100 parts of chlorosulfonated polyethylene, 5-15 parts of styrene-butadiene-styrene block copolymer, 3-10 parts of divinylbenzene, 0.5-2 parts of peroxidated succinic acid, 1-2.5 parts of magnesium oxide, 3-10 parts of pentaerythritol, 2-5 parts of accelerator, 10-25 parts of carbon black, 10-30 parts of carbon nanotube, 1-3 parts of anti-aging agent, 0.1-0.5 part of anti-scorching agent, 3-10 parts of trioctyl trimellitate, 1-3 parts of tolyldiphenyl phosphate, 2-5 parts of N-hydroxymethylpropanamide methyl phosphonate and 1-3 parts of vinyl-terminated silicon oil. The carbon-nanotube-modified chlorosulfonated polyethylene composite material disclosed by the invention has the advantages of excellent flame retardancy, excellent heat resistance, favorable curability and high mechanical strength.

Owner:合肥市再德高分子材料有限公司

Preparation method for plastic base of refrigerator

The invention discloses a preparation method for a plastic base of a refrigerator. The preparation method comprises the following steps: heating and plasticizing polycarbonate, an ethylene-vinyl acetate copolymer and an acrylonitrile-butadiene-styrene copolymer so as to obtain a first material; adding disproportionated rosin and polyethylene wax into the first material, carrying out plasticization, adding diatomite, talcum powder, aluminum hydroxide, calcium sulfate whiskers, a silane coupling agent, carbon fibers, acetic anhydride, stearyl alcohol, 1,1-bis-(tert-amylperoxy)cyclohexane and an accelerator TMTM and carrying out plasticization so as to obtain a second material; and subjecting the second material to heating and plasticizing, thin-passing, and sheet production successively so as to obtain the plastic base of the refrigerator. The plastic base of the refrigerator prepared in the invention has good resistance to permanent compression deformation, good toughness and excellent resistance to impact and tearing, reduces the damage of the refrigerator to floors, and can ensure safe use of the refrigerator for at least 20 years.

Owner:无为县大江橡塑制品有限公司

Process for producing rubber vulcanization accelerant penta-methylene thiuram tetrasulfide

The present invention relates to a kind of preparation method of rubber vulcanization accelerator bispentamethylene thiuram tetrasulfide, wherein said method uses water as solvent, and the raw materials used and their molar ratio are: hexahydropyridine: carbon disulfide: sulfur: hydrogen peroxide =1: 1~1.3: 1.8~2.5: 0.4~0.7, the specific process of the method is: under normal pressure, add hexahydropyridine and sulfur successively in the reaction kettle filled with water under stirring state, after adding Finally, control the temperature within the range of 20°C to 30°C, then add carbon disulfide liquid dropwise, and control the dropwise addition time for 2 to 3 hours. After the dropwise addition, measure the pH value of the reaction solution. After the temperature is stable within the range, control the temperature of the reaction solution at 30°C to 40°C, and start to add hydrogen peroxide dropwise to carry out the oxidation reaction. The oxidation reaction time is 3 to 4 hours; The liquid is separated, and the obtained solid is dried, crushed, sieved, and packaged to obtain the product. The method of the present invention has short production cycle, high safety factor, almost no waste gas emission, high melting point, good appearance and high yield of the obtained product, which is obviously superior to other preparation methods, and the comprehensive cost is low. Adopting the method of the present invention can improve the product Quality, energy saving and consumption reduction, reducing "three wastes" pollution.

Owner:WILLING NEW MATERIALS TECH CO LTD

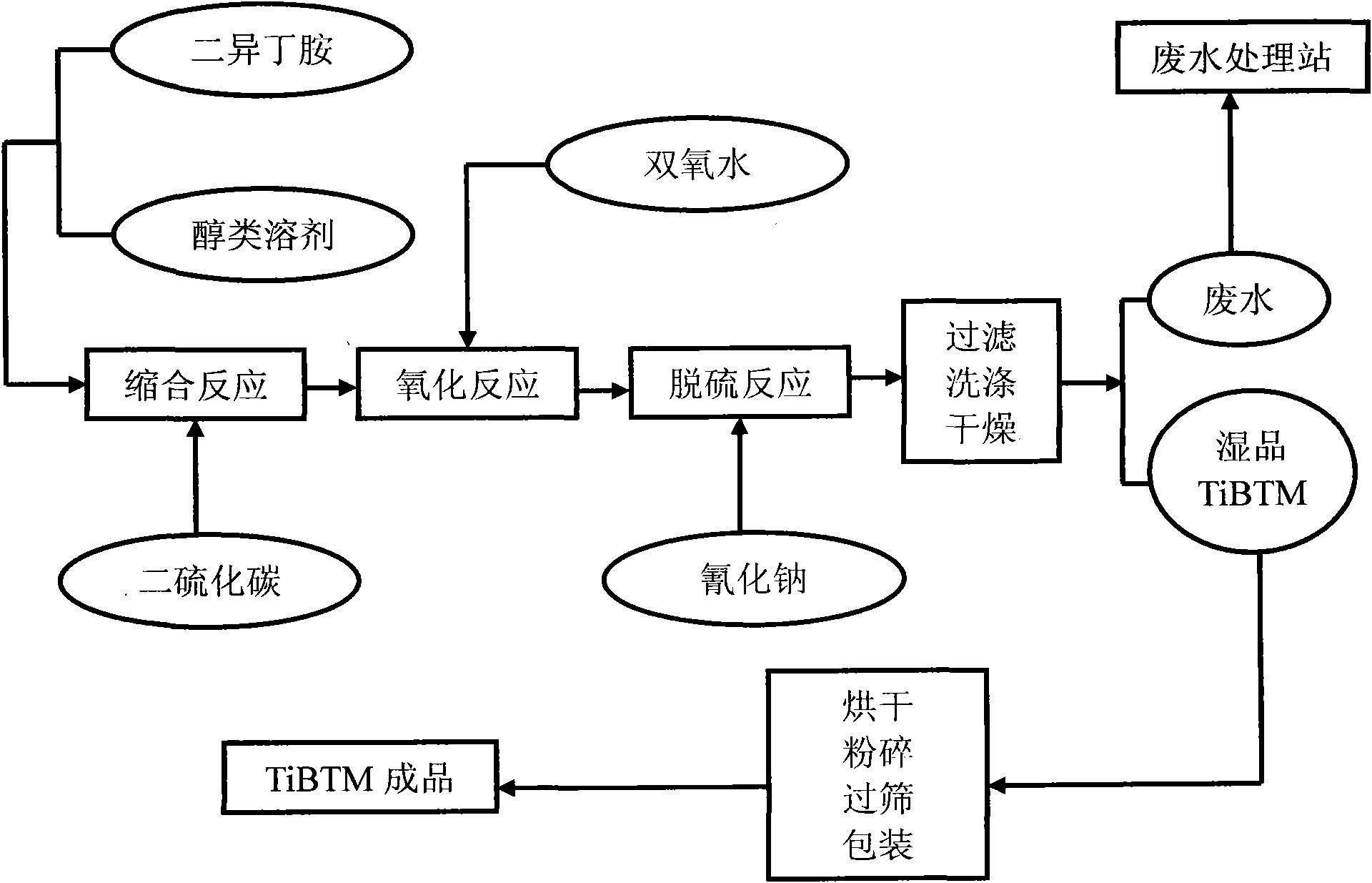

Preparation method of thiofide TiBTM (Tetraisobutylethiuram Monosulfide)

The invention relates to a preparation method of thiofide TiBTM (Tetraisobutylethiuram Monosulfide). The raw materials include diisobutylamine, carbon disulfide, hydrogen peroxide and sodium cyanide; the raw materials contain the following components according to stoichiometric molar ratio: 1 diisobutylamine, 1.1-1.3 carbon disulfide, 0.50-0.60 hydrogen peroxide and 0.60 sodium cyanide. The specific technique of the preparation method comprises the following steps of sequentially adding an amount of diisobutylamine liquid to a reaction kettle containing 100-200 ml alcohol (methanol, ethanol, isopropyl alcohol and the like) with the mass percentage of 70-80% under the condition that the rotation speed of a stirring device is 200-1200rpm; controlling the temperature within 10-35 DEG C, synchronously dripping the needed carbon disulfide liquid and the hydrogen peroxide, wherein the dripping of the hydrogen peroxide is a little earlier than that of the hydrogen peroxide to carry out condensation and oxidation reactions, and controlling the time of the reactions within 4-6h; reacting till a pH value is within 7 to 8, adding NaCN, and controlling the reaction temperature within 40-50 DEG C; after the reactions are finished, holding the temperature for 0.5-1.5h, and carrying out the solid-liquid centrifugal separation; and drying, crushing, sieving and packing the solid to obtain thethiofide TiBTM.

Owner:WILLING NEW MATERIALS TECH CO LTD

Synthetic method for fluororubber

The invention relates to a synthetic method for fluororubber. According to the invention, polymeric monomers comprise, by molar weight, 45 to 70% of vinylidene fluoride, 30 to 55% of hexafluoropropene and 0 to 20% of tetrafluoroethene, and are polymerized by using an intermittent emulsion polymerization method, and obtained polymerized emulsion is subjected to coacervation, rinsing, drying and plastication molding so as to obtain the fluororubber. The synthetic method provided in the invention is simple to operate, needs mild reaction conditions, effectively controls a Mooney point of the fluororubber through the measures of adjusting the structure of the monomers, changing reaction temperature, changing addition time of a chain transferring agent, etc., and prepares the fluororubber with a high Mooney point; the prepared fluororubber with a high Mooney point has good curability and excellent oil resistance and can be applied in a plurality of industries, especially in the industry of automobiles.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Method for increasing drying efficiency of natural rubber

A method for improving the drying efficiency of natural rubber. During the coagulation process of acid coagulated natural rubber and microbial coagulated natural rubber, nano silicon dioxide suspension is added, coagulated and dried. Form a lot of polar "moisture channels" in hydrophobic natural rubber to improve the quality of natural rubber. The drying efficiency of the natural rubber in the invention is increased by about 20%, and the energy consumption is reduced by about 20%. The color of the obtained natural rubber is golden yellow and very dry, and its quality meets the quality standard of Chinese standard natural rubber No. 5 rubber. The initial value of plasticity P0 is between 35 and 42, the plasticity retention rate PRI is ≥ 75, and the nitrogen content is lower than ≤ 0.54 %, volatile content ≤ 0.70%, ash content ≤ 0.54%; Mooney viscosity of raw rubber is between 75-79. The product has excellent vulcanization performance, good physical properties of vulcanized rubber, high mechanical strength and high tear resistance.

Owner:GUANGDONG OCEAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com