Vulcanized mould for secondary-class building seismic isolation support

A technology for vibration isolation bearings and vulcanization molds, which is applied in the field of molds, can solve problems affecting the quality of rubber seismic bearings, difficulty in ensuring the shape of bearings, uneven vulcanization, etc. The effect of less and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

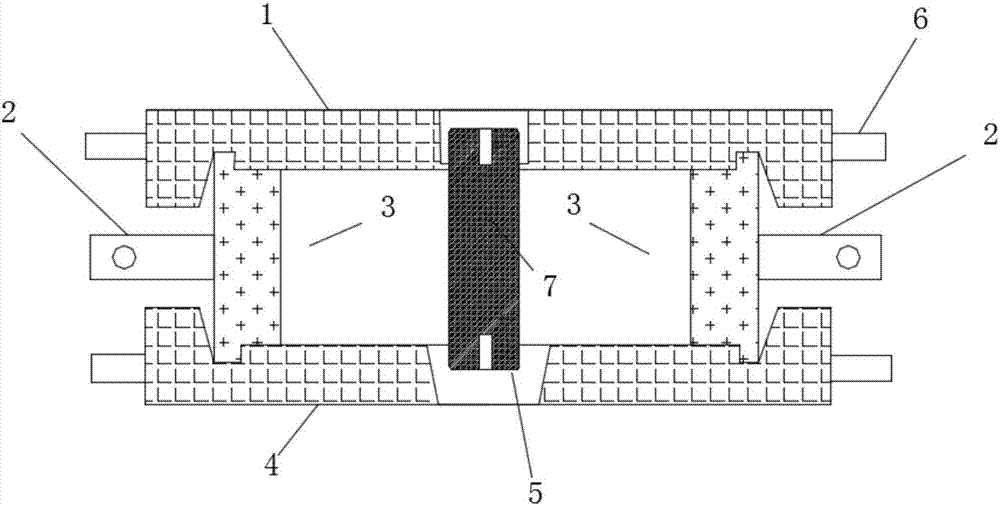

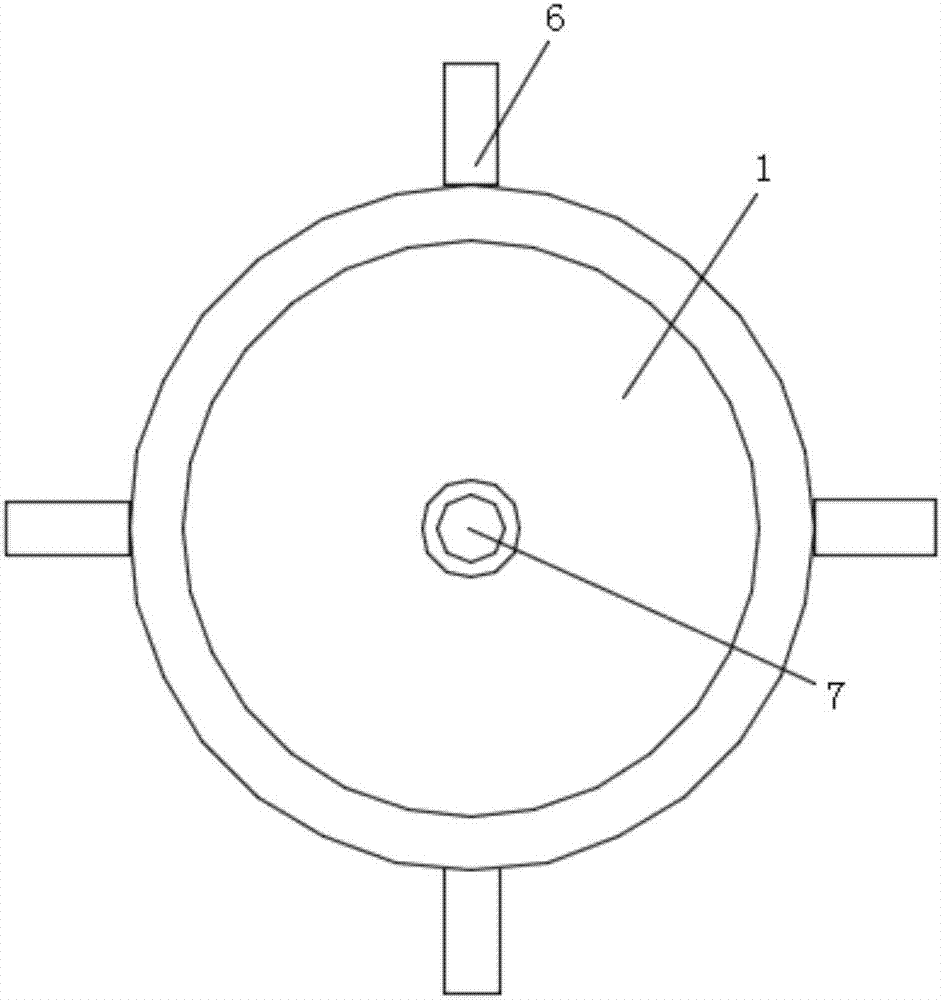

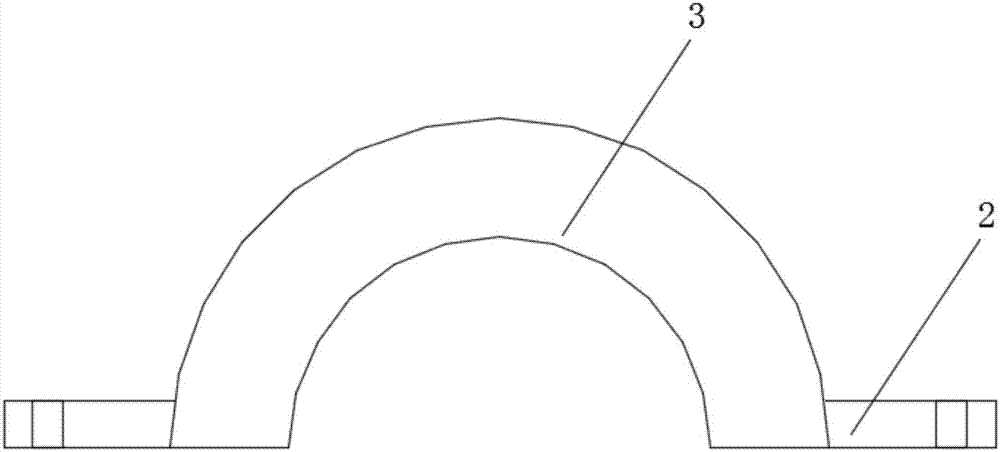

[0016] see Figure 1-4 , a vulcanization mold for second-class building isolation bearings, including an upper mold 1, a lower mold 4, a forming block 3, a rubber removal block 5, a lifting block 6 and a mandrel 7, and the upper mold 1 and the lower mold 4 are externally Lifting blocks 6 are arranged around the surroundings, and the number of forming blocks 3 is two. The upper mold 1 and the lower mold 4 are connected by forming blocks 3, and the two forming blocks 3 are connected by bolt rods 2. The upper mold 1 and the The lower mold 4 is provided with a rubber removal block 5 , and the two ends of the mandrel 7 are respectively connected with the rubber removal block 5 of the upper mold 1 and the lower mold 4 . The quantity of lifting block 6 is eight, and four lifting blocks 6 are positioned at upper mold 1 periphery, and other four lifting bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com