Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228results about How to "Improve copolymerization performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous emulsion polymerization of fluorinated monomers in the presence of a partially fluorinated oligomer as an emulsifier

InactiveUS20070004848A1Increase speedSmall particle sizeTransportation and packagingFibre treatmentPolymer scienceOligomer

The present invention relates to a method for making a fluoropolymer comprising an aqueous emulsion polymerization of one or more fluorinated monomers wherein said aqueous emulsion polymerization is carried out in the presence of an oligomer that comprises one or more ionic groups, has a partially fluorinated backbone, a number average molecular weight of not more than 2000 g / mol and that has a combination of repeating units different from that of the fluoropolymer that is being produced by the polymerization of said one or more fluorinated monomers. Since the polymerization of the one or more fluorinated monomers to produce the desired fluoropolymer is carried out in the presence of the oligomer, the resulting dispersion will contain the oligomer in addition to the fluoropolymer. Thus, in a further aspect, the invention relates to an aqueous dispersion of a fluoropolymer comprising the oligomer.

Owner:3M INNOVATIVE PROPERTIES CO

Water and oil repellent composition and treatment method

InactiveUS20070088141A1Improve performanceImprove copolymerization performanceFibre treatmentEmulsion paintsCarbon atomStereochemistry

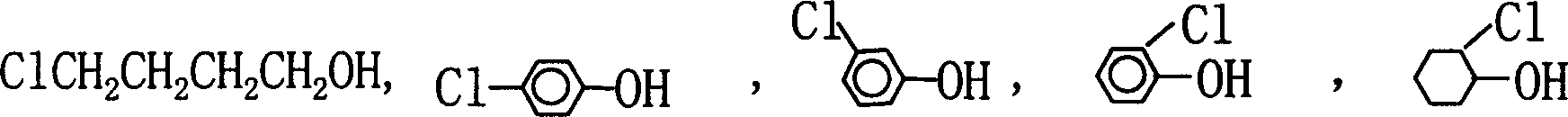

Disclosed is a water- and oil-repellent agent comprising the following fluorine-containing copolymer (A). The fluorine-containing copolymer (A) comprises: (a1) a fluoroalkyl group-containing polymerizable monomer of the formula: wherein Y is a divalent organic group [for example, an aliphatic group having 1 to 10 carbon atoms, an aromatic or cycloaliphatic group having 6 to 10 carbon atoms, a —SO2N(R1)R2— group (in which R1 is a hydrogen atom or an alkyl group having 1 to 4 carbon atoms, and R2 is an alkylene group having 1 to 10 carbon atoms), a —CON(R1)R2— group (in which R1 is a hydrogen atom or an alkyl group having 1 to 4 carbon atoms, and R2 is an alkylene group having 1 to 10 carbon atoms), or a —CH2CH(OY1)CH2— group (in which Y1 is a hydrogen atom or an acyl group having 1 to 4 carbon atoms)]; and Rf is a linear or branched fluoroalkyl or fluoroalkenyl group having 1 to 6 carbon atoms; and (a2) vinylidene chloride.

Owner:DAIKIN IND LTD

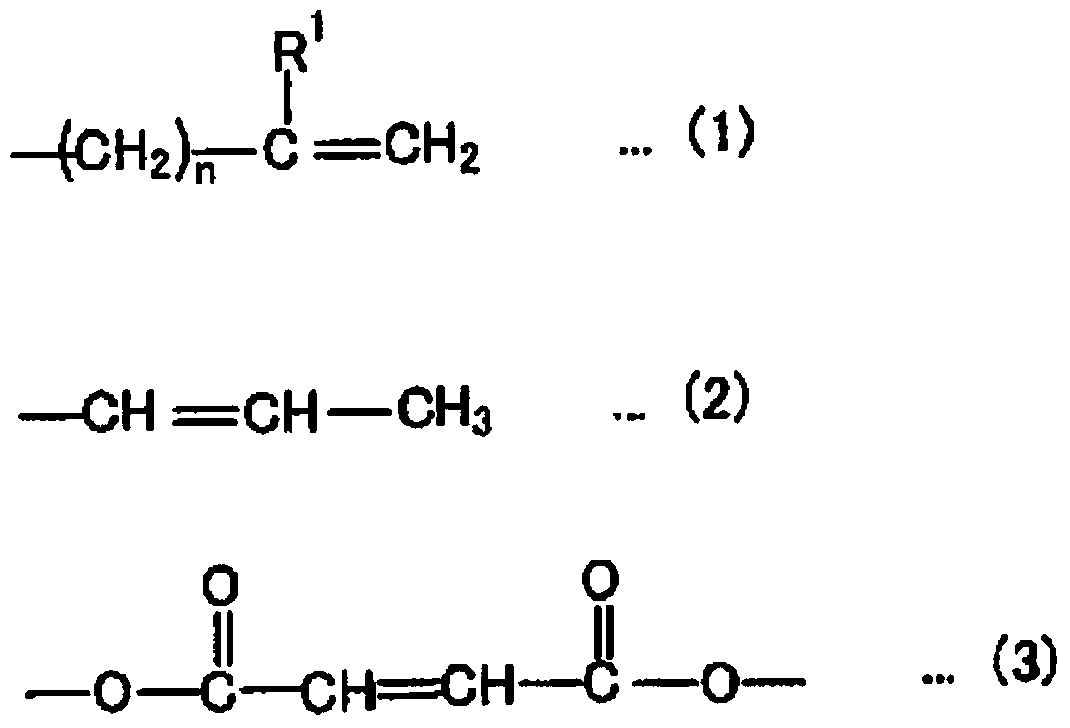

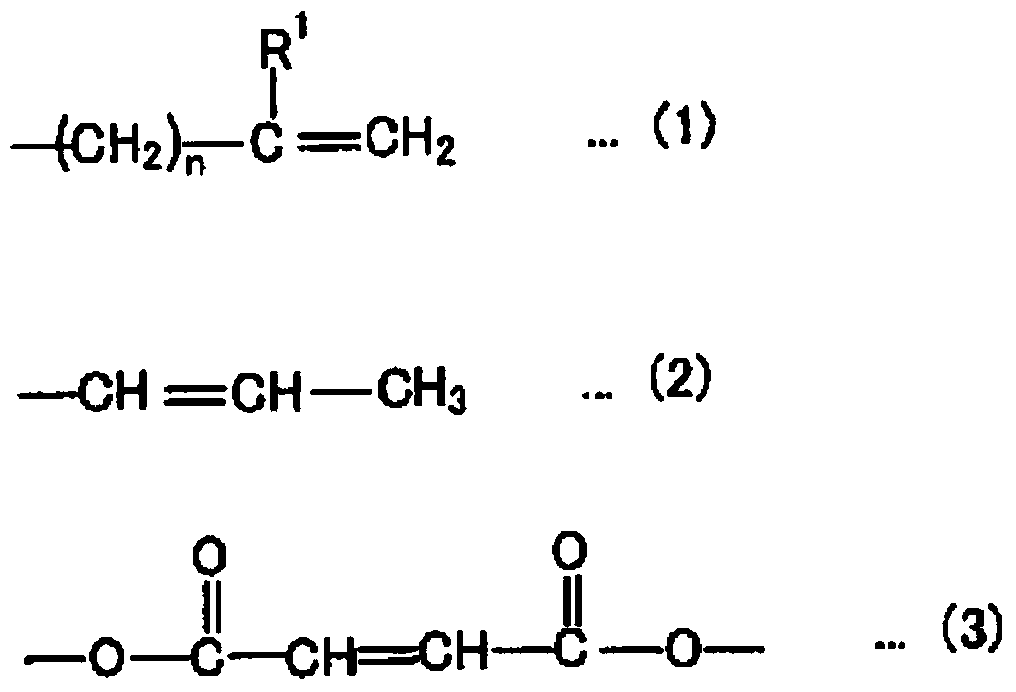

Cement additive

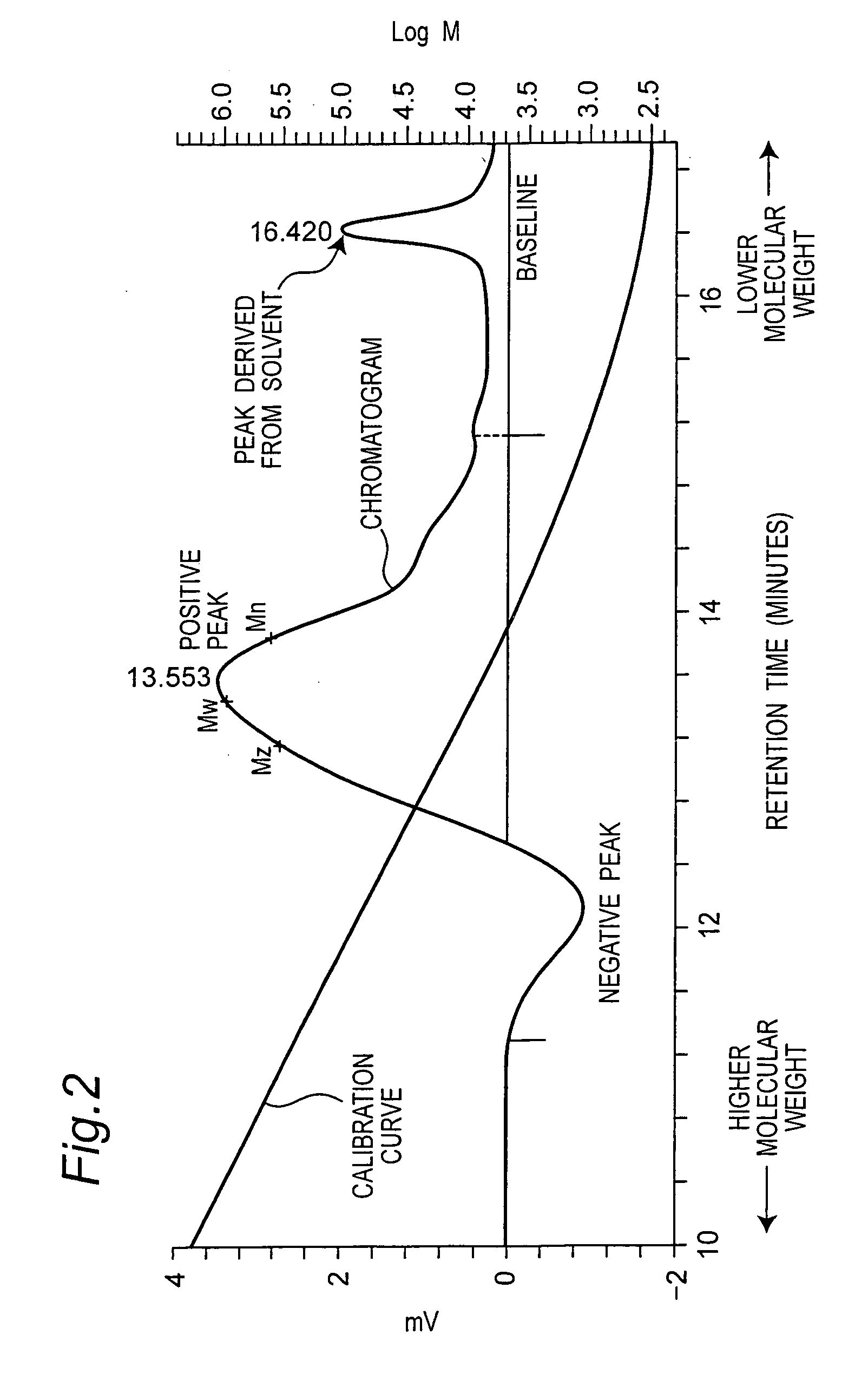

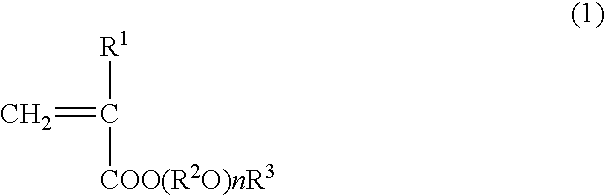

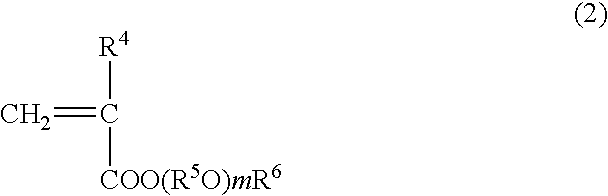

The present invention is thus directed to a cement additive which comprises a copolymer (A) obtained by polymerizing a monomer mixture (K), wherein;said monomer mixture (K) comprises a polyalkylene glycol ester monomer (I) represented by the general formula (1): a polyalkylene glycol ester monomer (II) represented by the general formula (2): and a carboxylic acid monomer (III) represented by the general formula (3):

Owner:NIPPON SHOKUBAI CO LTD

Catalyst for ethene polymerization or multipolymer, preparing method thereof

A catalyst for polymerization or copolymerization of ethylene is prepared through dissolving magnesium halide in organic epoxy compound, organic phosphorus compound or inertial diluent, adding alkane educing aid, porous inertial carrier and halide of Ti, and educing. It is possible to add alcohol compound and / or electron donor. Its advantages are high activity and copolymerizing performance, and high sensitivity to hydrogen regulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

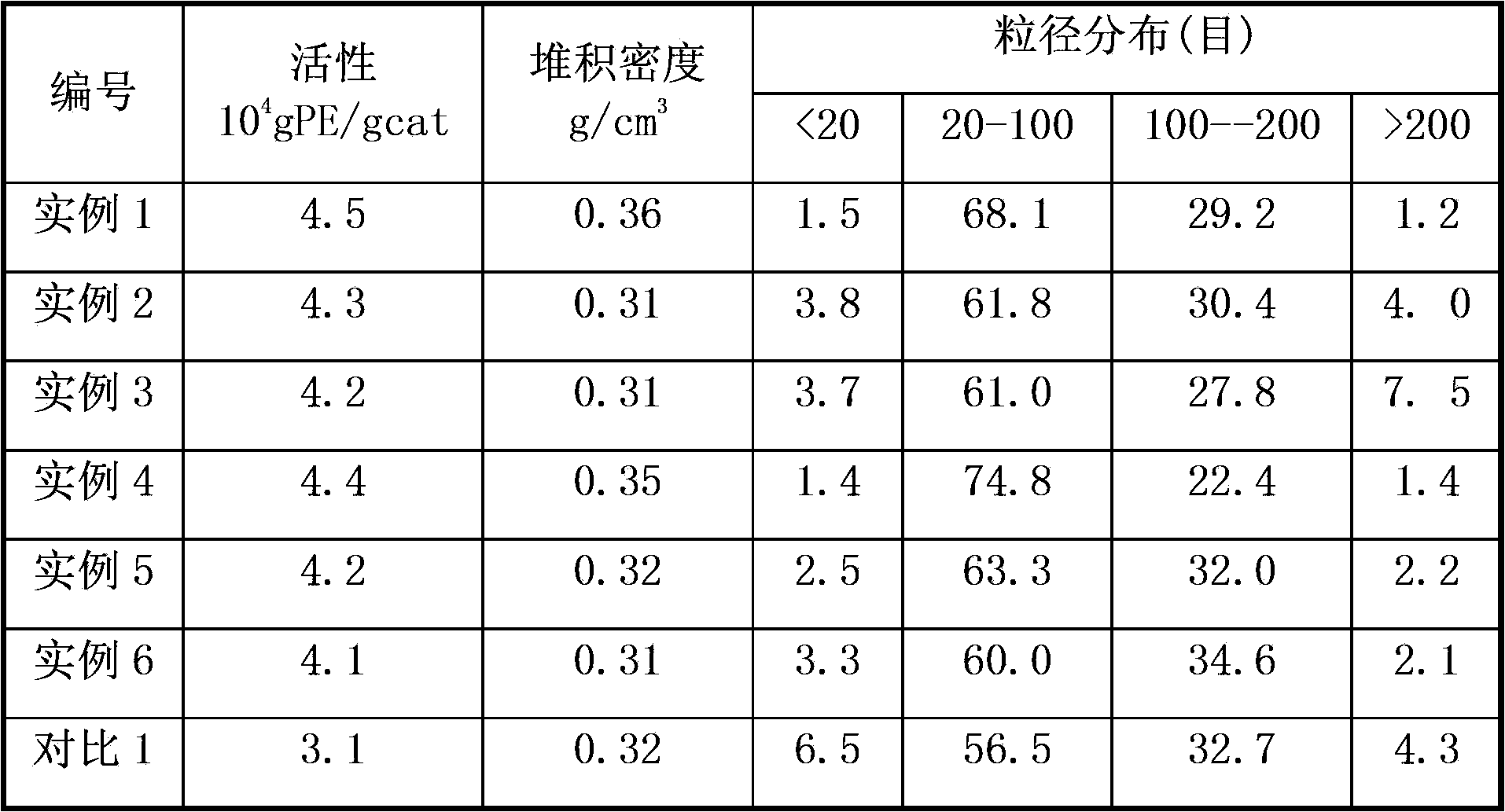

Catalyst active component for ethylene polymerization or copolymerization and catalyst precursor comprising the active component and preparation method thereof

ActiveCN101139407ANot easy to produceImprove copolymerization performanceBulk chemical productionElectron donorAccelerant

The present invention provides catalyst active components used in ethylene polymerization or polymerization, the catalyst precursors as well as the preparation method of the catalyst active components. The catalyst active components in the present invention comprise: magnesium compounds; titanium compounds Ti (OR) 4-n X n , where X is halogen, R is alkyl, n is O or an integer less than or equals 4; catalytic accelerant which is of chelate function and is of matching iron of [O,O] or[O,N]; Electron donor with silicon; Organic ester R'OH, where R' represents alkyl; and halogenated hydrocarbon. The catalyst precursors provided in the present invention are firm particles with high catalytic activity, stable dynamics and good polymerization and hydrogen-sensitive performance. The polyethylene products obtained from the catalyst precursors are particles of good shape, with the particle diameter evenly distributed. The density of the particles is high.

Owner:BEIJING JINDINGKE CHEM TECH

Copolymerization flotation-sedimentation tank and water purification method

ActiveCN105502549AExtended collision stick timeEnhanced interactionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationEngineeringEnvironmental geology

The invention relates to a copolymerization flotation-sedimentation tank. The copolymerization flotation-sedimentation tank comprises a multi-channel folded plate copolymerization flocculation basin, a flotation-sedimentation tank and an air dissolving system, wherein the multi-channel folded plate copolymerization flocculation basin is used for realizing the coagulation and the copolymerization of flocculates and microbubbles; the flotation-sedimentation tank is connected to the rear end of the multi-channel folded plate copolymerization flocculation basin and is used for separating foamed flocculates from water flow and precipitating settleable flocculates which cannot float; and the air dissolving system is connected with a water outlet end of the flotation-sedimentation tank and is connected with the multi-channel folded plate copolymerization flocculation basin and the flotation-sedimentation tank to supply high-pressure backflow gas dissolved water to the multi-channel folded plate copolymerization flocculation basin and the flotation-sedimentation tank. According to the copolymerization flotation-sedimentation tank, the high-pressure backflow gas dissolved water is fed for three times, by virtue of organic combination with a flocculation process, a microbubble and flocculate copolymerized environment is created, and the produced foamed flocculates are stable and are not easily separated, so that the problems that the adhesion efficiency of particles is low, the trapping effect is not ideal, the adhesion of the foamed flocculates is instable, and the like of a traditional dissolved air flotation process are solved, and the coagulation, air floatation and sedimentation processes are organically combined and integrated; and the copolymerization flotation-sedimentation tank has prominent superiority in the treatment of water quality in high-algae, low-turbidity and burst high-turbidity reservoirs.

Owner:SHANDONG JIANZHU UNIV

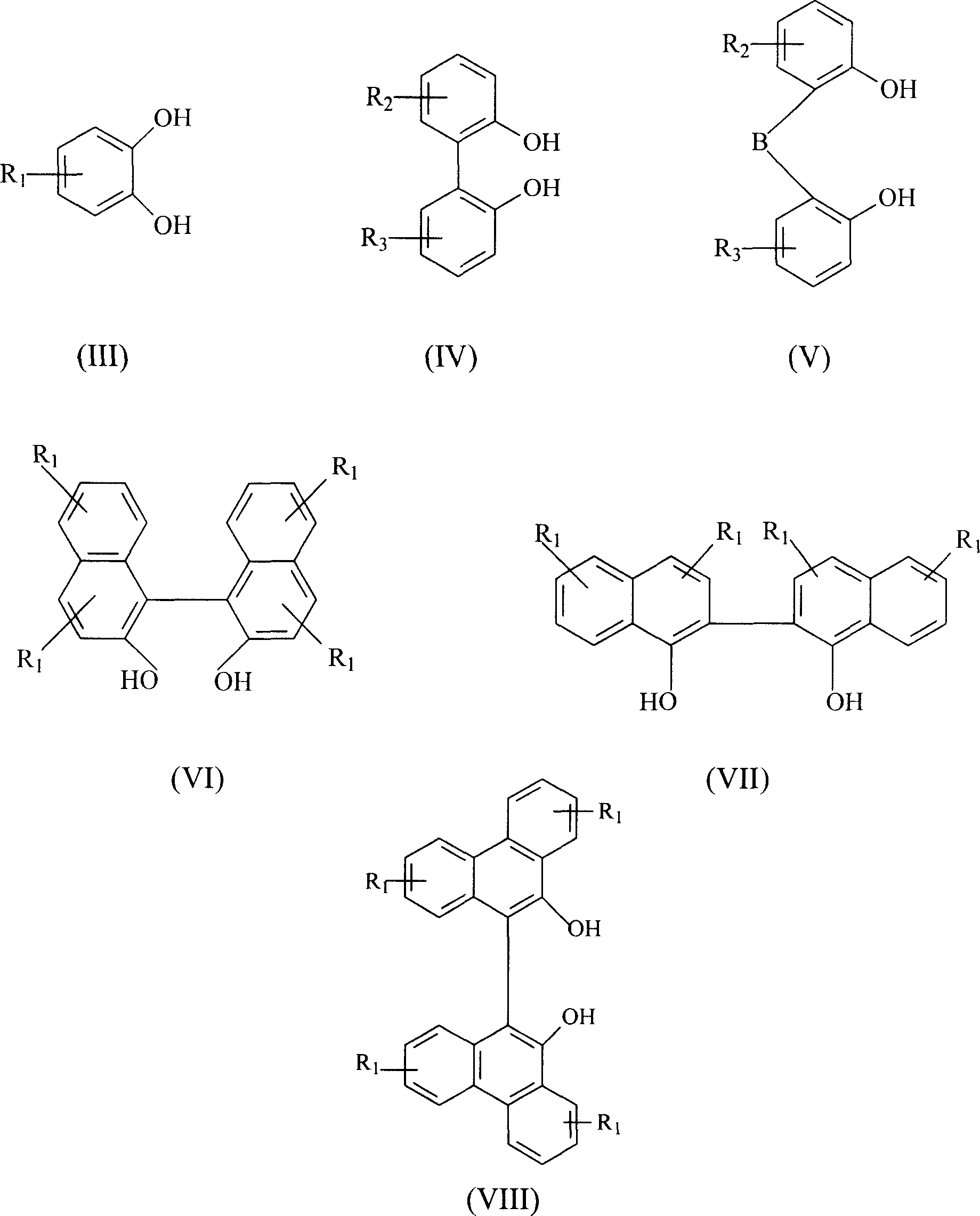

Catalyst activity component for polymerization of propylene or combined polymerization, catalyst precursor containing the same and preparation thereof

ActiveCN101412775AHigh selectivityImprove copolymerization performanceBulk chemical productionElectron donorSolid particle

The invention provides a catalyst active ingredient used for propylene polymerization or copolymerization, a catalyst precursor containing the active ingredient, and a preparation method thereof. The catalyst active ingredient comprises a magnesium compound, a titanium compound Ti(OR)4-nXn, a chelated corrdination type electron donor, a selectively added diester electron donor, a siliceous electron donor, organic alcohol R'OH and halogenated hydrocarbons, wherein X is halogen; R is alkyl; n is 0 or an integer which is less than or equal to 4; and R' is alkyl. The catalyst precursor provided by the invention has the advantages of solid particles, high catalytic activity, stable dynamic curve, strong copolymerization performance, high hydrogen regulation sensitivity and so on, and a polypropylene product prepared by utilizing the catalyst precursor has the advantages of good particle shape, uniform particle size distribution, high fusion index of polymers, high bulk density and a small quantity of powder.

Owner:BEIJING JINDINGKE CHEM TECH

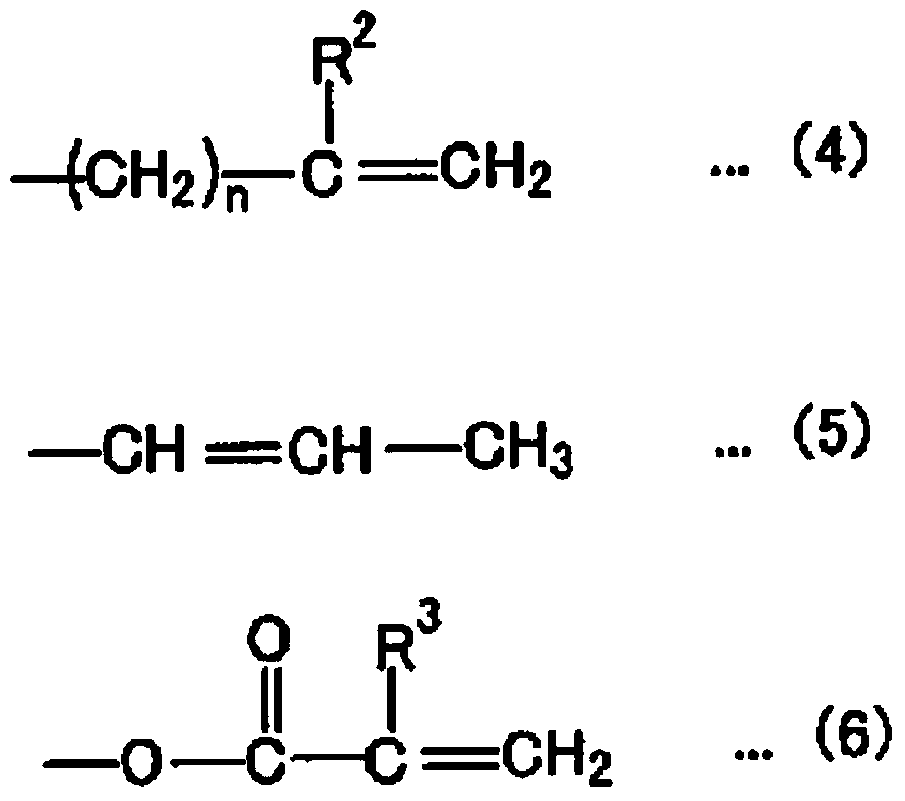

Emulsifying agent for emulsion polymerization

ActiveUS20140243552A1Improve copolymerization performanceGood dispersionGroup 5/15 element organic compoundsTransportation and packagingHydrogen atomEmulsion polymerization

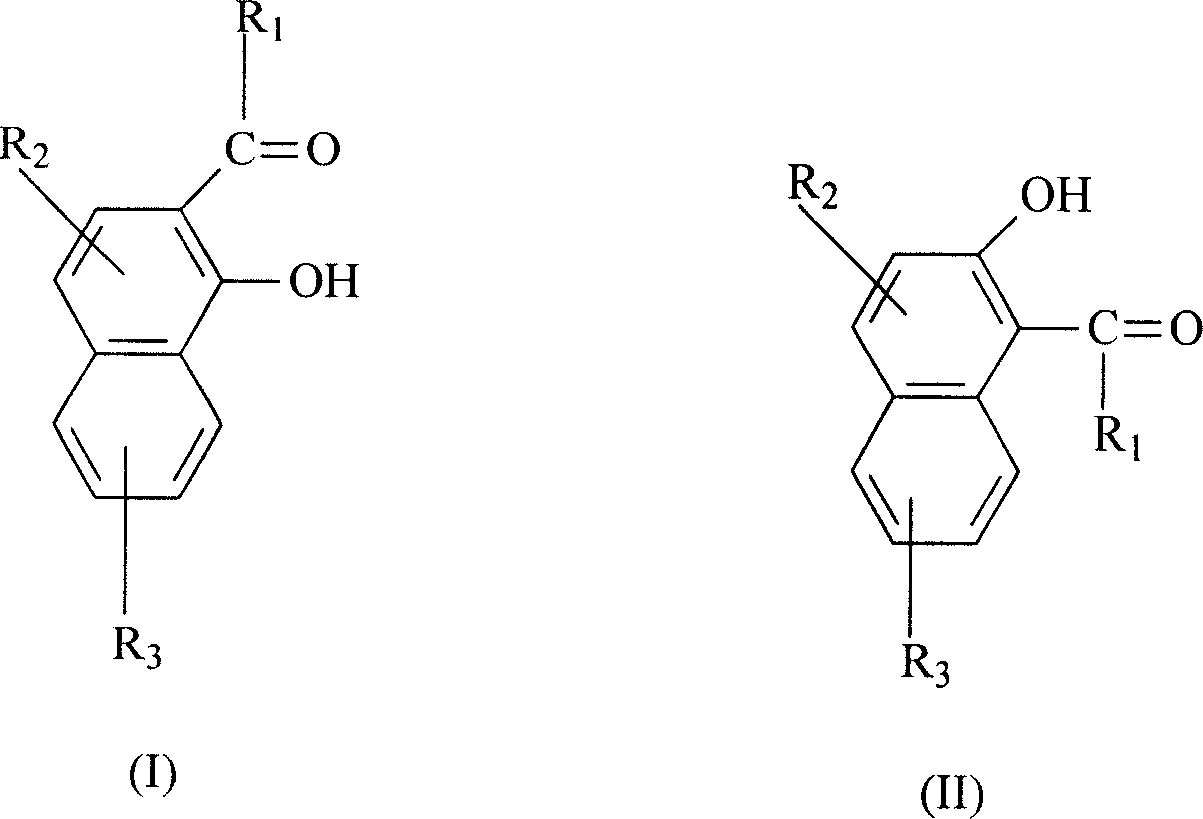

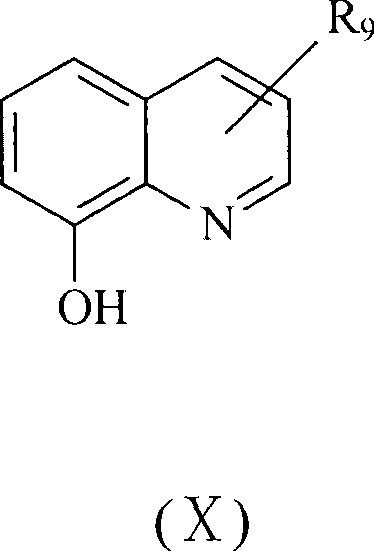

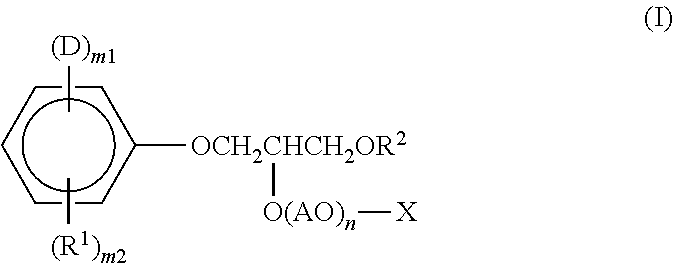

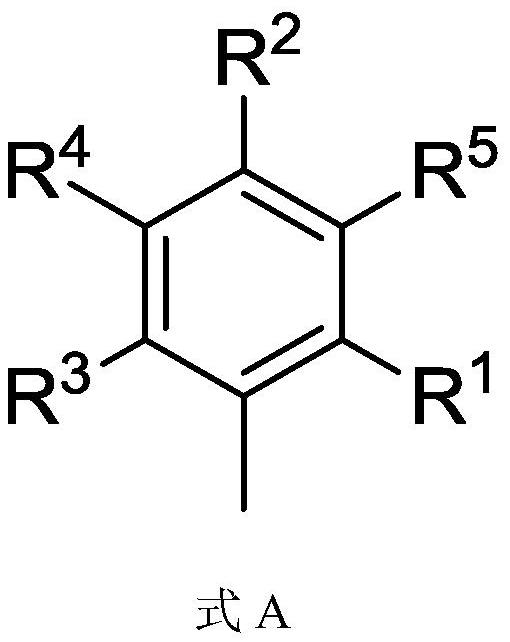

A reactive emulsifier comprising a compound of formula (I), which makes polymerization stability satisfactory and is capable of improving the water resistance etc. of the polymer film to be obtained.In the formula (I), D represents a polymerizable unsaturated group represented by the chemical formula D-1 or D-2; m1 represents a number of 1 or larger; R1 represents an alkyl group having 1 to 12 carbon atoms; m2 represents a number of 0 to 4; and the sum of m1 and m2 is 1 to 5. R2 represents a hydrocarbon group having 6 to 30 carbon atoms; A represents either an alkylene group or a substituted alkylene group which has 2 to 4 carbon atoms; and n is in the range of 0 to 1,000. X represents a hydrogen atom or an anionic hydrophilic group which is —(CH2)a—SO3M etc.R3 represents a hydrogen atom or methyl.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Ethylene-propylene-diene methylene using liquid-state oligomers of diolefin as third monomer and method for preparing same

The invention provides ethylene-propylene-diene methylene taking liquid-state oligomers of diolefin as a third monomer and a method for preparing same. Combined propylene cells account for 20 to 45 molar percent of the ethylene-propylene-diene methylene, the third monomer which is a liquid-state oligomer of diolefin accounts for 0.5 to 15 molar percent of the ethylene-propylene-diene methylene, and the total molar percentage of the combined cells of ethylene, propylene and the third monomer is 100 percent; and the liquid-state oligomer of diolefin of the third monomer is selected from liquid-state oligomers with different double-bond structures and double-bond contents, including the liquid polybutadiene containing 20 to 80 percent of 1,2-strucutres and liquid polyisoprene containing over 90 percent of 1,4-strucutres. Because the side chains contain more double bonds, the ethylene-propylene-diene methylene has good curing and processing properties, and can vulcanize sulfur; the polymer has the molecular weight distribution indexes from 2 to 10; the ethylene-propylene-diene methylene can be used for manufacturing industrial rubber products of automobile parts, waterproof materials, telecom cables and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Catalyst used for ethylene polymerization or copolymerization and its preparation method

A catalyst for the polymerizing and copolymerizing of ethene and its preparing process is disclosed. The active component of said catalyst is prepared through dissolving magnesium halide in organic epoxy compound, organic P compound, organic alcohol, or inertial deluent to obtain uniform solution, educing out the solid deposition contain Mg / Ti by adding educing assistant and Ti halide or its derivative, and treating the Ti contained component by hydrogenating improver. Its advantages are high activity, high hydrogenating sensitivity and good granular form.

Owner:CHINA PETROLEUM & CHEM CORP +1

Emulsion polymerization method using reactive emulsifying agent, aqueous polymer dispersion obtained by same, and polymer film

InactiveCN103906768ASolve the problem of adverse effects caused by copolymerizationImprove copolymerization performanceHydrophilic monomerFunctional monomer

Provided is an emulsion polymerization method for carrying out emulsion polymerization of monomers using a reactive emulsifier in an aqueous medium in the presence of a polymerization initiator, the emulsion polymerization method being capable of solving problems such as an enhancement of a rate of copolymerization of the reactive emulsifier with the monomer, dissolution of a bubbling trouble, a more improvement of water resistance of a coating film, etc. The emulsion polymerization is carried out using one or two or more kinds of polymerizable unsaturated monomers X having at least one carbon-carbon double bond in a molecule, one or two or more kinds of reactive emulsifiers Y having at least one polymerizable group in a molecule, and one or two or more kinds of polyfunctional monomers Z1 having two or more polymerizable unsaturated groups in a molecule and having a molecular weight per functional group of less than 150, or one or two or more kinds of hydrophilic monomers Z2 having one polymerizable unsaturated group and a hydrophilic group in a molecule and having an average molecular weight of less than 250, with a proportion of the total use amount of the polyfunctional monomer Z1 or hydrophilic monomer Z2 to the total use amount of the reactive emulsifier Y being in the range of Z1 / Y = 1 / 3 to 1 / 30 or Z2 / Y = 1 / 1 to 1 / 30 in terms of a mass ratio.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Ingredients of catalyst for vinyl polymerization and catalyst

The invention relates to ingredients of a catalyst for vinyl polymerization. The ingredients comprise the following reaction products: (1) a magnesium compound, (2) an organic alcoholic compound, (3) an organic silicon compound, (4) a non-ionic surfactant, and (5) a titanium compound, wherein the structural formula of the organic silicon compound is at least one of R<1>xR<2>ySi(OR<3>)z, wherein R<1> and R<2> are respectively alkyl or halogen of which the carbon numbers are 1 to 10; R<3> is alkyl of which the carbon number is 1 to 10; x, y and z are integral numbers; x is larger than or equal to 0 and smaller than or equal to 2; y is larger than or equal to 0 and smaller than or equal to 2; z is larger than or equal to 0 and smaller than or equal to 4; x+y+z=4; the non-ionic surfactant is at least one of the periodic copolymers of a poly-oxyethylene ether compound, a carbon oxo alcohol ethoxy compound and an epoxy compound. The catalyst is relatively high in catalytic activity and copolymerization performance; a polymer prepared with the catalyst is relatively high in bulk density and relatively small in size distribution; the catalyst is suitable for homopolymerization of ethylene or copolymerization of ethylene and other Alpha-olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst active constituent and catalyst containing same

ActiveCN1814627ACatalyst particles are largeSettling fastOlefin polymerizationPolymerization catalysts

This invention provides an olefin polymerization catalyst active component suitable for ethene polymerization or copolymerization reaction of ethene and alpha-olefin and a catalyst containing said active component, which introduces electronic compound and halohydrocarbon into an active component containing Ti to get a high-active olefin polymerized catalyst. When carrying out olefin polymerrization by the catalyst prepared in such method, one can get the polymer in large density and resin in good size.

Owner:BEIJING JINDINGKE CHEM TECH

Ball shape catalyst for ethylene polymerization and preparation process thereof

InactiveCN1861645AHigh polymerization activityGood hydrogen sensitivityZiegler–Natta catalystPolymer science

A spherical Ziegler-Natta catalyst used for sludge or gas-phase polymerization of ethene and its preparing process are disclosed. Said catalyst along with organoaluminum cocatalyst can be used for the homopolymerization of ethene or copolymerization of ethene and alpha-olefin to obtain spherical products.

Owner:北京燕化高新催化剂有限公司

Catalyst active component, its preparation and catalyst containing it

Owner:BEIJING JINDINGKE CHEM TECH

Supported vanadium alkene polymerization catalyst, preparation method and applications thereof

The invention relates to a supported vanadium alkene polymerization catalyst, which comprises a porous inorganic carrier, a catalyst composite modifying component, a vanadium containing component, and a catalyst activating component; wherein the catalyst composite modifying component is the product of high temperature burning of a first soluble compound and / or a second soluble compound, and the vanadium containing component is the product of high temperature burning of a third compound. Compared with the conventional Ziegler-Natta vanadium catalysts, the provided supported vanadium alkene polymerization catalyst has the advantages of higher and more stable activity, wider range of polymerization temperature, and excellent copolymerization performance.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst for olefin polymerization, method for producing olefin polymer, method for producing propylene copolymer, propylene polymer, propylene polymer composition, and use of those

Disclosed is a catalyst for olefin polymerization composed of a crosslinked metallocene compound (A-1) represented by the general formula [1-1] below and at least one or more compounds (b) selected from organic aluminum oxy compounds (b-1), compounds (b-2) forming an ion pair, and organic aluminum compounds (b-3). [1-1] (In the general formula [1-1], R<1>, R<2>, R<3>, R<4>, R<5>, R<8>, R<9> and R<12> respectively represent one selected from a hydrogen atom, a hydrocarbon group and a silicon-containing group; R<6>, R<7>, R<10> and R<11> are not hydrogen atoms and respectively represent one selected from a hydrocarbon group and a silicon-containing group; R<13> and R<14> respectively represent a hydrogen atom, a hydrocarbon group other than a methyl group or the like; M represents Ti, Zr or the like; Y represents carbon or the like; Q represents a halogen or the like; and j represents an integer of 1-4.

Owner:MITSUI CHEM INC

Catalyst component for ethene polymerization, preparing method and catalyst thereof

InactiveCN1490343AImprove copolymerization performanceHigh polymerization activityOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

A catalyst for the ethylene polymerization and its preparing process and application are disclosed. Said catalyst contains an inorganic oxide as carrier, and several active components, carried by said carrier, which are alkyl metal compound, halide, dual-function compound able to react with dihydroxy magnesium, Mg compound, and Ti compound. Its advantages are better hydrogen regulating performance and balanced activity, and low static electricity.

Owner:CHINA PETROLEUM & CHEM CORP +1

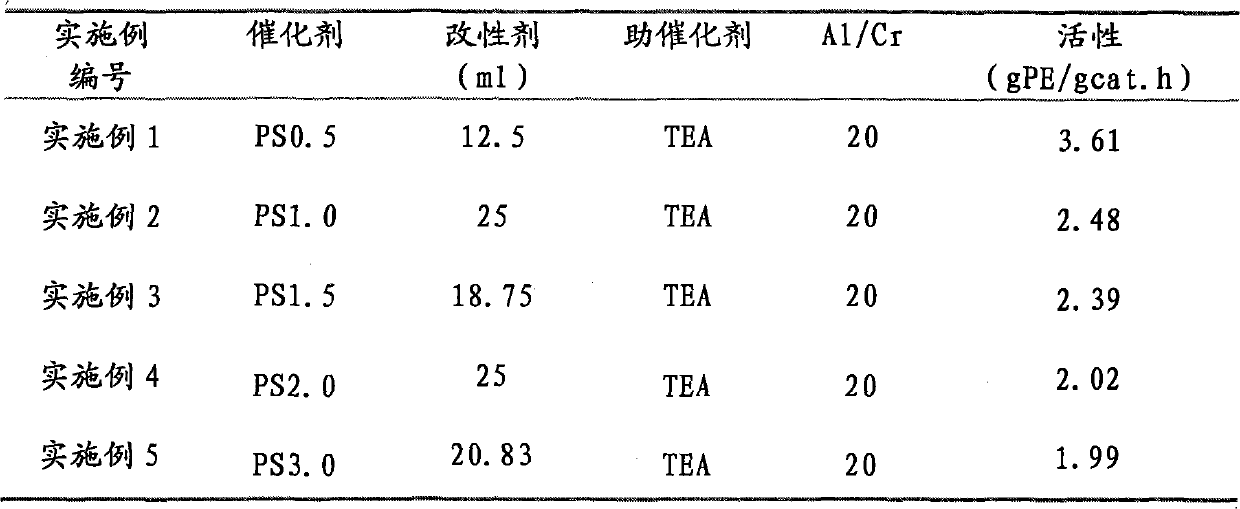

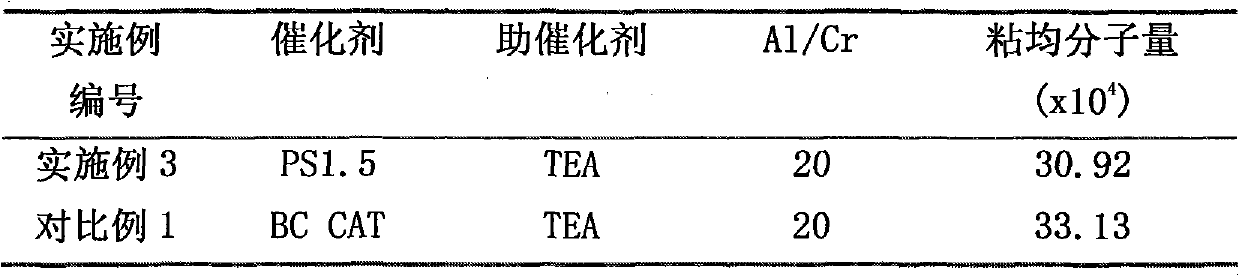

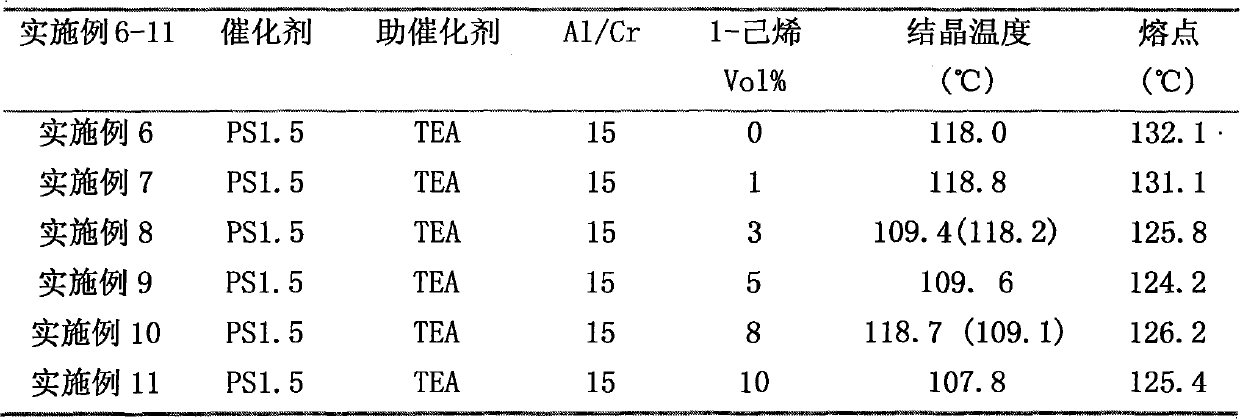

Organic chromium catalyst for ethylene polymerization and preparation method thereof

ActiveCN102453154AHigh activityInduction time is suitableChemical recyclingBulk chemical productionHigh activityInorganic oxide

The invention provides an organic chromium catalyst for ethylene polymerization and a preparation method thereof. The catalyst comprises a main active catalyst, an inorganic oxide carrier, a modifier and a cocatalyst, wherein the main active catalyst is a chromium salt, and the content of the main active catalyst in the catalyst is 0.01-5% by mass; technical requirements of the carrier inorganic oxide comprise that the surface area is about 200-700m<2> / g, the pore volume is about 1-4cc / g, the aperture is about 60-700 and the particle dimension is about 10-200mum; the modifier is a recovery liquid for the preparation of an alkylsilane chromate catalyst; and the cocatalyst is an alkyl compound of Al, Li, B and Zn. The organic chromium catalyst for the ethylene polymerization provided in theinvention has the advantages of high activity, proper induction time, and suitableness of the production of wide molecular weight distribution range polyethylene products; and the preparation method provided in the invention has the advantages of simple synthetic technology and low preparation cost.

Owner:CHINA PETROLEUM & CHEM CORP

Titanium fluoride modified load type chrome alum double-active center catalyst and preparation method thereof

InactiveCN105199021AIncrease contentHigh hydrogen sensitivityBulk chemical productionTitanium fluorideHydrogen

The invention belongs to polyethylene catalysts, and particularly relates to a titanium fluoride modified load type chrome alum double-active center catalyst. The titanium fluoride modified load type chrome alum double-active center catalyst comprises an inorganic carrier and loaded active components and modified components. The active components comprise chromium oxides and vanadium oxides, and the modified components comprise fluorine and titanium. According to the catalyst, the content and distribution of comonomers are improved, the number of the comonomers inserted into a low molecular weight end is reduced, the number of the comonomers inserted into a high molecular weight end is increased, and therefore more chalaza molecules can be formed easily, and polyethylene products with better performance are prepared. Meanwhile, the catalyst has the advantages of being high in activity, sensitive in hydrogen regulation response performance and the like. The invention further provides a preparation method of the catalyst. The inorganic carrier is firstly loaded with one of the modified components, and then loaded with the rest of the components, the process is reasonable, and industrial production is easy.

Owner:CHINA PETROLEUM & CHEM CORP

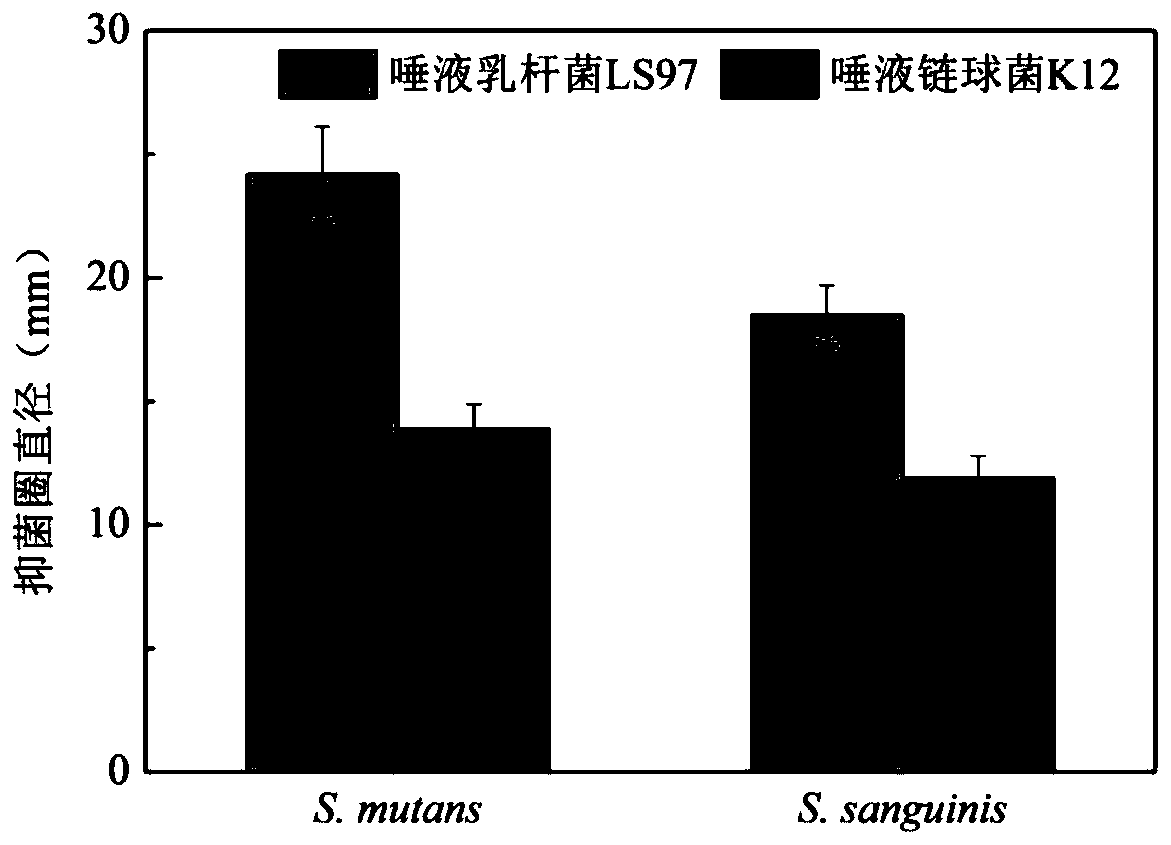

Caries resistant lactobacillus plantarum K41 and application thereof

ActiveCN108486022APromote growthEnhanced inhibitory effectBacteriaMicroorganism based processesBiotechnologyAntibiotic Y

The invention discloses a strain of caries resistant lactobacillus plantarum K41 and application thereof. Lactobacillus plantarum K41 provided by the invention is preserved in Common Microorganism Center of Chinese Microorganism Strain Preservation Management Committee, with preservation number of CGMCC No.15462, and preservation date of March 20, 2018. The strain is separated from farmyard self-made pickles in Yanan Road, Shunqing District, Nanchong, Sichuan, grows well on an MRS agar culture medium, can inhibit growth of streptococcus mutans UA159, forming of exopolysaccharide, degradation of hydroxyapatite, and forming of a biological film, has good auto-agglutination and copolymerization capability, is good in tolerance for antibiotics, salt and acid, and is easy to be planted in the oral cavity. Animal experiment shows that K41 can inhibit rat enamel demineralization and caries degree, can be applied to functional food, and has very important meaning for body health.

Owner:SICHUAN UNIV +1

Phosphate surfactant and method for preparing trifluorochlor oethylene polymer

The invention discloses a phosphate surfactant, of which the chemical formula is: H-(CF2)m-CH2-O-(CH2CH2O)n-PO(OM)2, wherein m is equal to 2, 4, 6 or 8, n is equal to 0 or 1, and M is NH4+ or Na+. The invention also discloses a method for preparing trifluorochlor oethylene polymer emulsion or solid with the phosphate surfactant as an emulsifier. The surfactant can be used for emulsion polymerization of fluoride-containing monomer. Used as the emulsifier, the surfactant can achieve a high polymerization rate, good dispersion stability, high yield, excellent copolymerization performance and / or multiple particle sizes (including small particle size). Besides, the method can realize polymerization by only using conventional equipment, is easy and convenient to operate and has a low cost, and does not cause environmental pollution during and after reaction.

Owner:UNIV OF JINAN

Catalyst containing mono schiff base ligand and its preparation and usage for olefine polymerization

The present invention provides a catalyst containing mono schiff base and monocyclopentadiene gliand. The said catalyst is used in polymerization of olefine and can be used to obtain polymer with high molecular weight and high copolymerized monomer inserting rate.

Owner:CHINA PETROLEUM & CHEM CORP +2

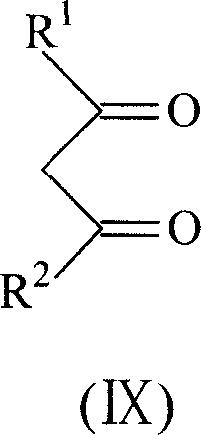

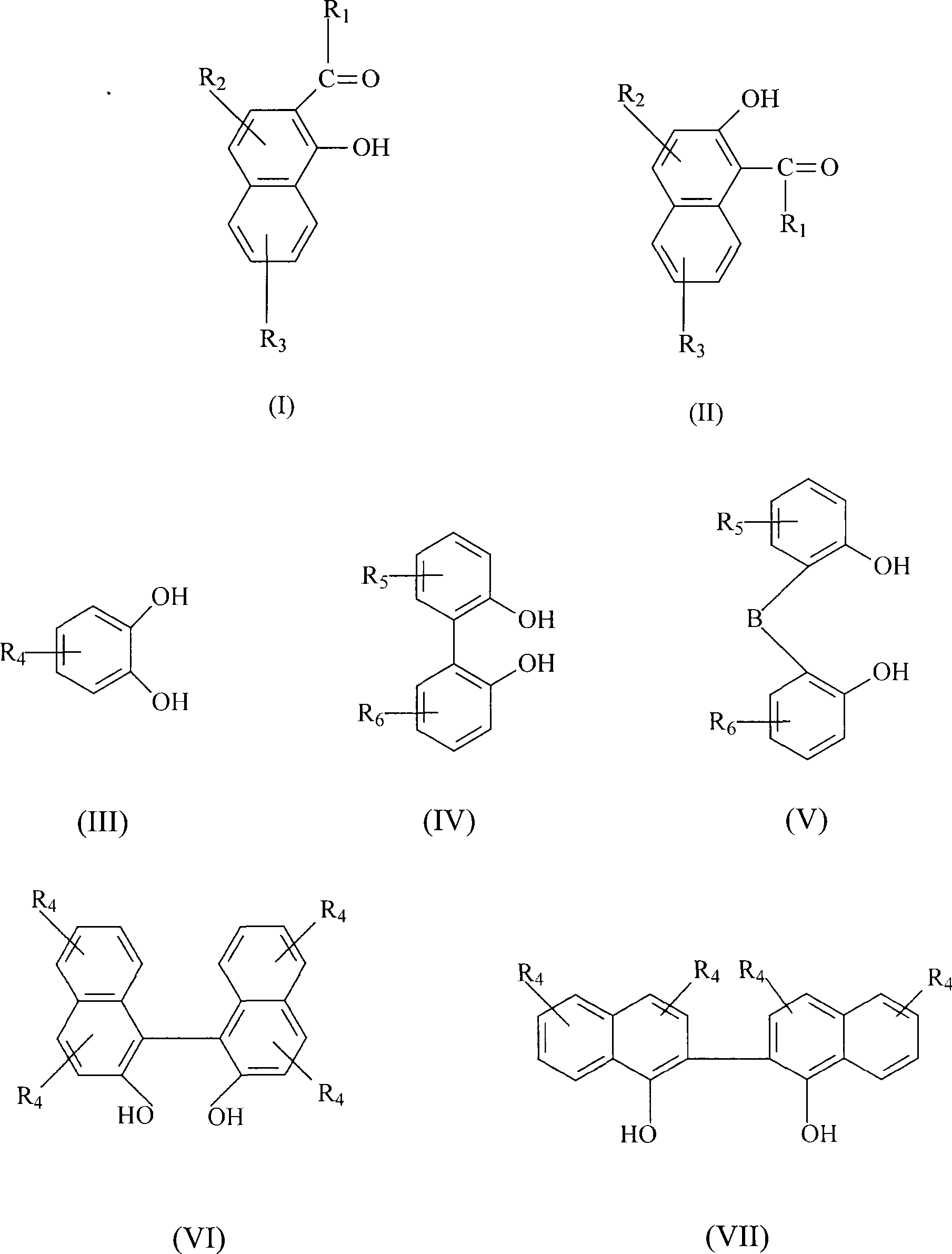

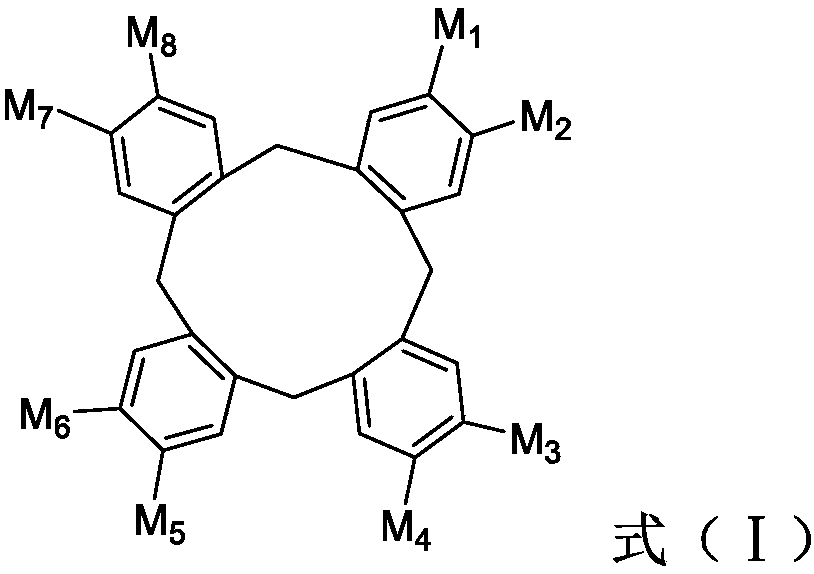

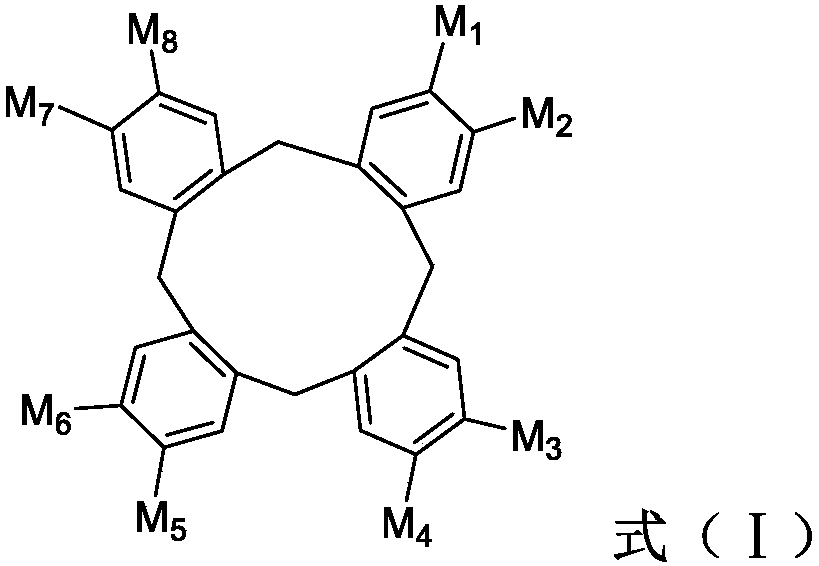

Solid catalyst component and catalyst system for olefin polymerization, and olefin polymerization method

ActiveCN110016094AImprove copolymerization performanceHigh polymerization activityPolyolefinHydrogen

The invention belongs to the field of olefin polymerization catalysts, and particularly provides a solid catalyst component and catalyst system for olefin polymerization, and an olefin polymerizationmethod. The solid catalyst component comprises a reaction product of the following components: 1) an alkoxy magnesium compound; 2) a titanium compound; and 3) an internal electron donor compound, wherein the internal electron donor compound comprises at least one selected from cyclotetraveratrylene represented by a formula (I) and derivatives of the cyclotetraveratrylene. According to the solid catalyst component disclosed by the invention, polymerization activity, hydrogen regulation sensitivity and copolymerization performance of the polyolefin catalyst are improved by introducing the cyclotetraveratrylene and the derivative of the cyclotetraveratrylene as the internal electron donor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Emulsion drying strengthening agent for paper and preparation method thereof

InactiveCN101086148ASmall particle sizeImprove adsorption capacityReinforcing agents additionPaper/cardboardSolubilityEmulsion

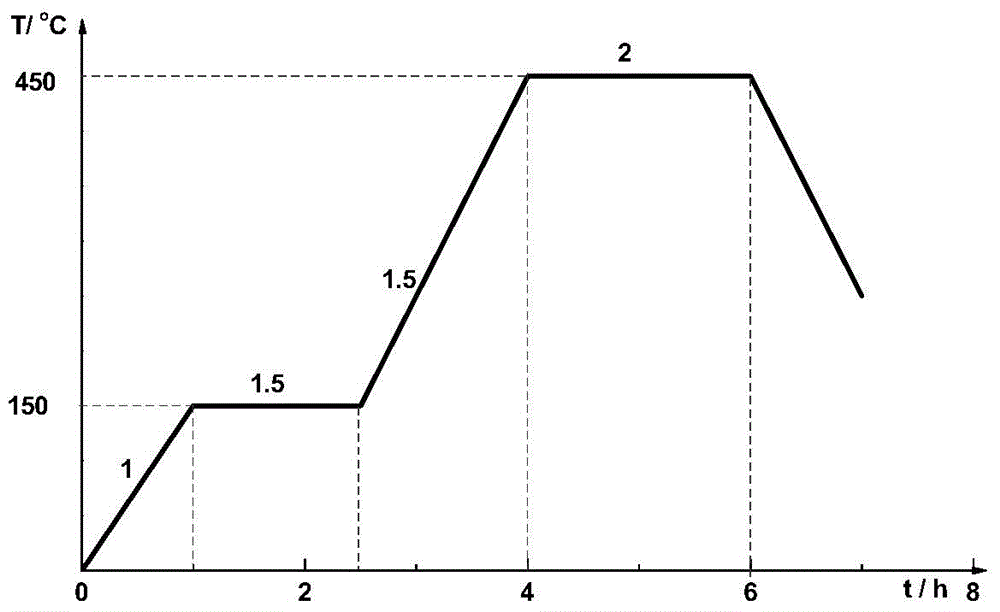

The invention discloses an emulsion strength-increasing agent which is special for papers and its preparation method, the preparation method includes the following steps: reacting the initiating agent, the mixed monomer combined with phenylethene and acrylic ester, water and composite emulsifier 0.5-1.5 hours and under 50-65deg.Cwhich total amount is 0.2-2.0%; drip-adding the excess mixing monomer combined by the initiating agent, acrylic nitrile, water-solubility monomer and basic ion monomer, the drip-adding time is 2-5 hours; heating the body system temperature to 75-90deg.C after the drip-adding is completed, and reacting 1-4 hours under the temperature; adjusting pH valve to 6.5-8.0 and the product is prepared. The emulsion strength-increasing agent in the invention has the advantages of small particle size, easy adsorbing, high effective ingredients, stable performance and etc.; it can be used in the wet part adding when paper making, it can significantly improve the dry strength and tear resistance of paper, at the same time, the ring compression strength and folding resistance of paper is markedly improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

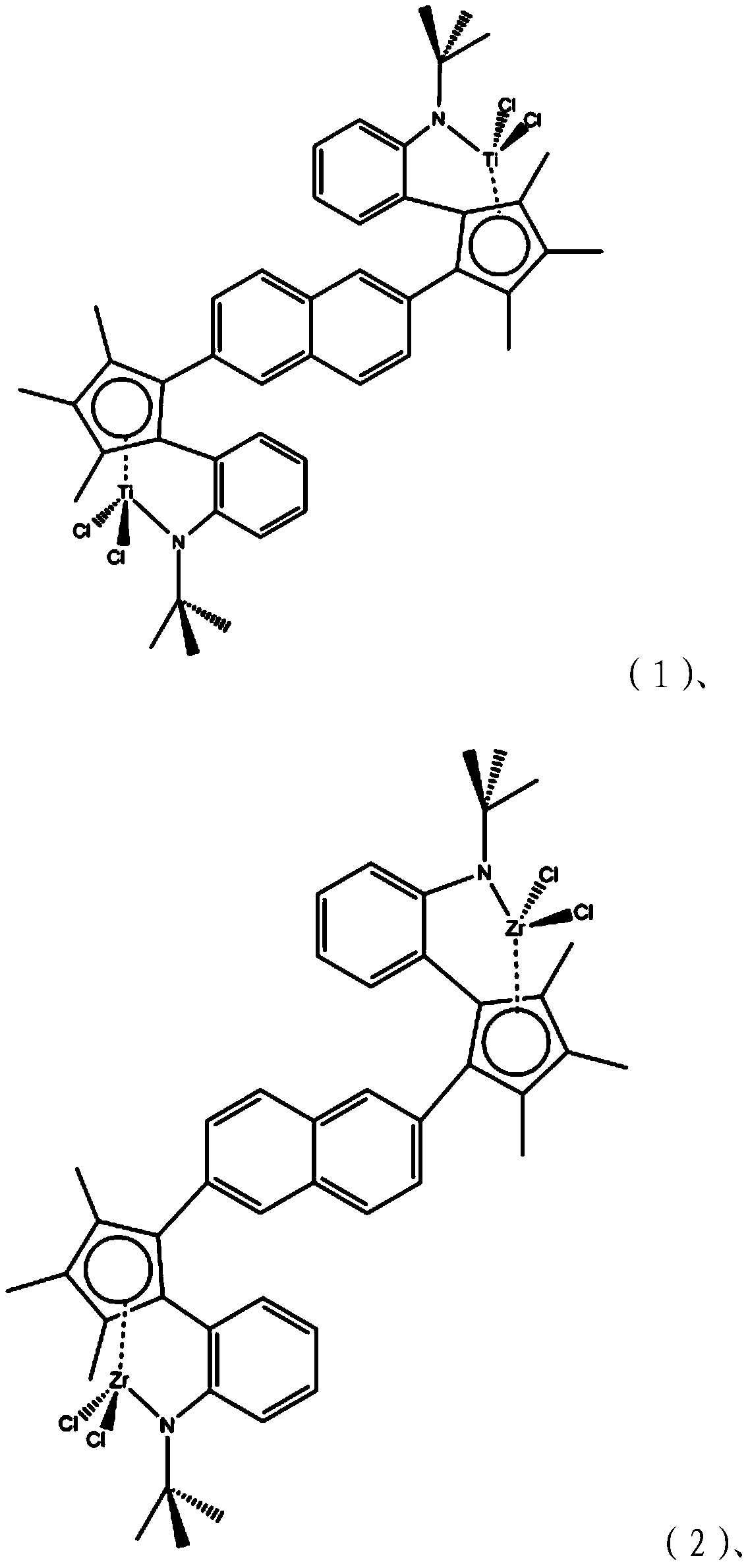

Diimine metal complex and preparation method and application thereof

ActiveCN112745359AThe synthesis method is simpleReduced activityNickel organic compoundsPolymer sciencePtru catalyst

The invention relates to a diimine metal complex as shown in a formula I and a preparation method and application thereof, and the diimine metal complex is used as a main catalyst of a catalyst for olefin polymerization and can catalyze ethylene polymerization at a relatively high temperature to prepare high-molecular-weight branched polyethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Charcoal circulation type co-coagulation flotation tank water purification system and method

ActiveCN107055954AGood removal effectEfficient removalSpecific water treatment objectivesTreatment involving filtrationFlocculationBiological activated carbon

The invention relates to a charcoal circulation type co-coagulation flotation tank water purification system and method. Mechanical flocculation, dissolved air flotation and an inclined plate settling basin are organically combined so as to form copolymerization dissolved air flotation, and mechanical flocculation and dissolved air flotation are organically combined through a copolymerization dissolved air flotation process, so that the stability of bubble floc is improved. Ozone oxidation and biological activated carbon are organically combined, so that the decomposition ability of powder biological activated carbon on organic matters is greatly improved. Air flotation and ozone oxidation are organically combined, so that an ozone oxidation effect is greatly improved. Mechanical flocculation, copolymerization air flotation, the biological activated carbon and inclined plate settling are organically combined, so that under the conditions of effectively controlling the rotate speed, reducing the hydraulic loss and the like, an aquatic organic matter is removed, and the stable bubble floc is formed. The system provided by the invention is flexible in process and operation manner, can be beneficial for effectively reducing the operation cost, has the advantages of high adaptability to water quality change, high efficiency, convenience in operation and the like, and has a wide application prospect.

Owner:SHANDONG JIANZHU UNIV

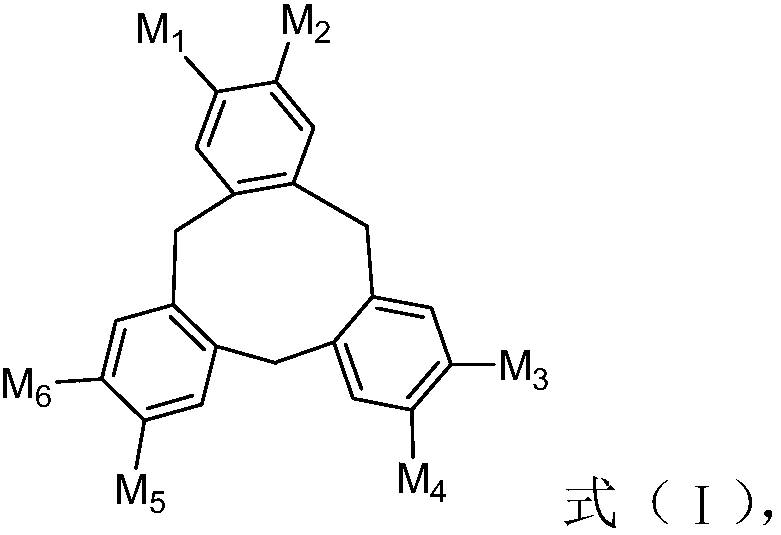

Solid catalyst component and catalyst system used for olefin polymerization, and olefin polymerization method

ActiveCN109280101AImprove copolymerization performanceHigh polymerization activityPolyolefinHydrogen

The invention relates to the field of olefin polymerization catalysts, and specifically relates to a solid catalyst component and catalyst system used for olefin polymerization, and an olefin polymerization method. The solid catalyst component includes reaction products of the following components: 1) a liquid component containing magnesium, 2) a titanium compound, 3) an internal electron donor compound, and optionally selected 4) an assistant precipitating agent. The internal electron donor compound is selected from at least one of cyclotriveratrylene and derivatives thereof shown as a formula (I), and M1-M6 are selected from hydrogen, hydroxy, amino, an aldehyde group, a carboxyl group, an acyl group, halogen atoms. Through the introduction of the cyclotriveratrylene and derivatives thereof as internal electron donors, the polymerization activity, hydrogen response and copolymerization performance of the polyolefin catalyst can be enhanced. The structure of the cyclotriveratrylene and the derivatives thereof is shown as the formula (1).

Owner:CHINA PETROLEUM & CHEM CORP +1

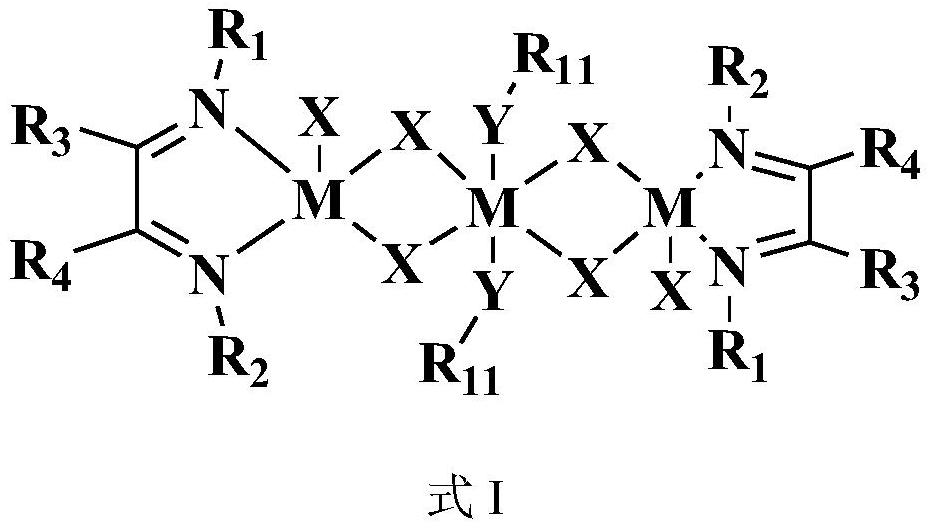

Dual core metallocene catalyst and preparation method and applications thereof

The invention relates to a dual core metallocene catalyst and a preparation method and applications thereof. The catalyst comprises two parts: a main catalyst and a co-catalyst; wherein the main catalyst is formed by bridging two molecules containing IVB-IIB group transition metal atoms with an organic metal complex formed by a cyclopentadienyl group or a substituted cyclopentadienyl group throughrigid groups. The catalyst is applied to ethylene / alpha-olefin solution co-polymerization reactions under the assistance of an activating co-catalyst, has extremely good polymerization activity and copolymerization performance, and can be used to prepare high molecular weight ethylene / alpha-olefin random copolymer with a high alpha-olefin content.

Owner:WANHUA CHEM GRP CO LTD +1

Lactobacillus salivarius LS97 and application thereof

ActiveCN110819569ARelieve dental cariesGood effectBacteriaDigestive systemBiotechnologyMicroorganism

The invention relates to the field of microorganisms, and in particular to lactobacillus salivarius LS97 and an application thereof. The strain is preserved in the China General Microbiological Culture Collection Center on Dec.10, 2018, and the preservation number of the strain is CGMCC NO.16922. The strain is classified and named as Lactobacillus salivarius, and the preservation address of the strain is Institute of Microbiology, Chinese Academy of Sciences on No.3, No.1 Courtyard, Beichen West Road, Chaoyang District, Beijing. The lactobacillus salivarius LS97 can effectively inhibit growthof streptococcus sobrinus.

Owner:JIANGSU WECARE BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com