Supported vanadium alkene polymerization catalyst, preparation method and applications thereof

A technology for olefin polymerization and catalysts, applied in the field of supported vanadium-based olefin polymerization catalysts and their preparation, can solve the problems of unstable activity, high carrier cost, and complicated loading process, and achieve high controllability and good shape and performance The prospect of industrialization and the effect of low raw material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

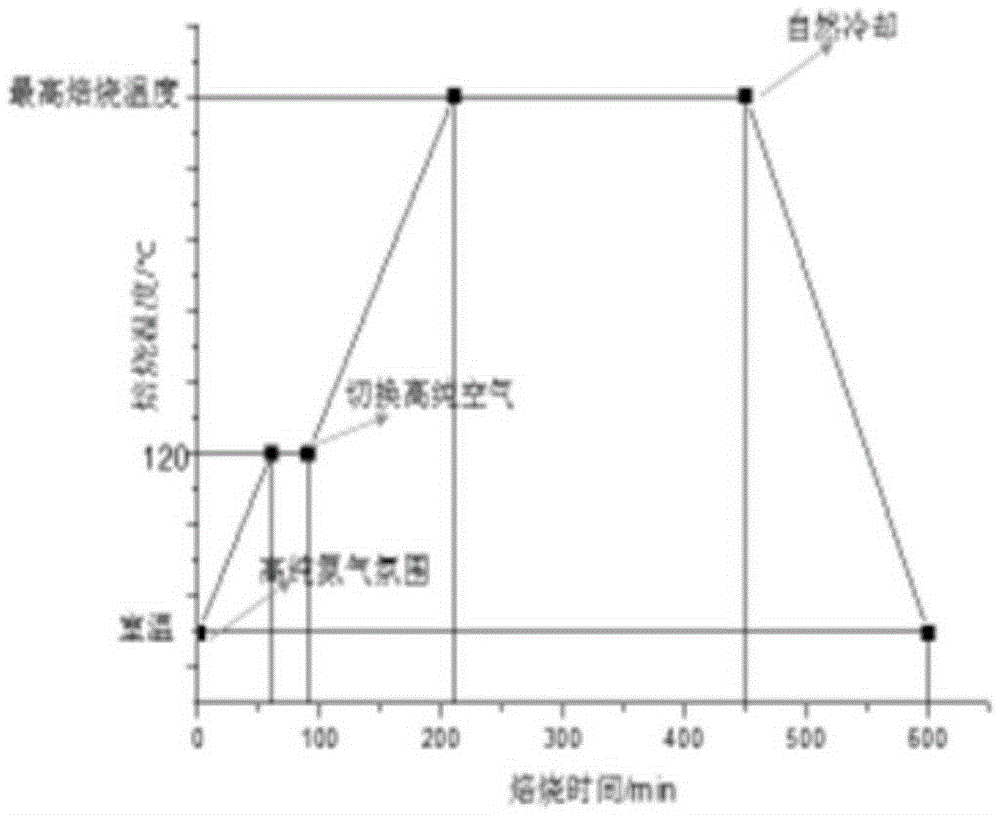

[0122] Embodiment 1: Get 10g silica gel (pore volume is 1.5~1.7cm 3 / g, the surface area is 250~300m 2 / g) impregnated with zirconium nitrate, ammonium sulfate and metavanadic acid aqueous solution at 50°C, wherein the additions of zirconium, sulfur and vanadium were 2%, 2% and 0.5% respectively (according to zirconium, sulfur and vanadium in the catalyst weight fraction in the precursor). After impregnating with continuous stirring for 4 hours, the temperature was raised to 120°C and dried for 12 hours, and then the dried product was placed in a fluidized bed and calcined at 500°C under a high-purity air atmosphere. The roasting procedure is shown in the appendix image 3 , the calcined catalyst precursor was naturally cooled from the calcining temperature to 300 °C in a high-purity air atmosphere, and then switched to a nitrogen atmosphere to naturally cool to room temperature. Finally, the catalyst precursors were collected and stored in a glove box under a nitrogen atmos...

Embodiment 2

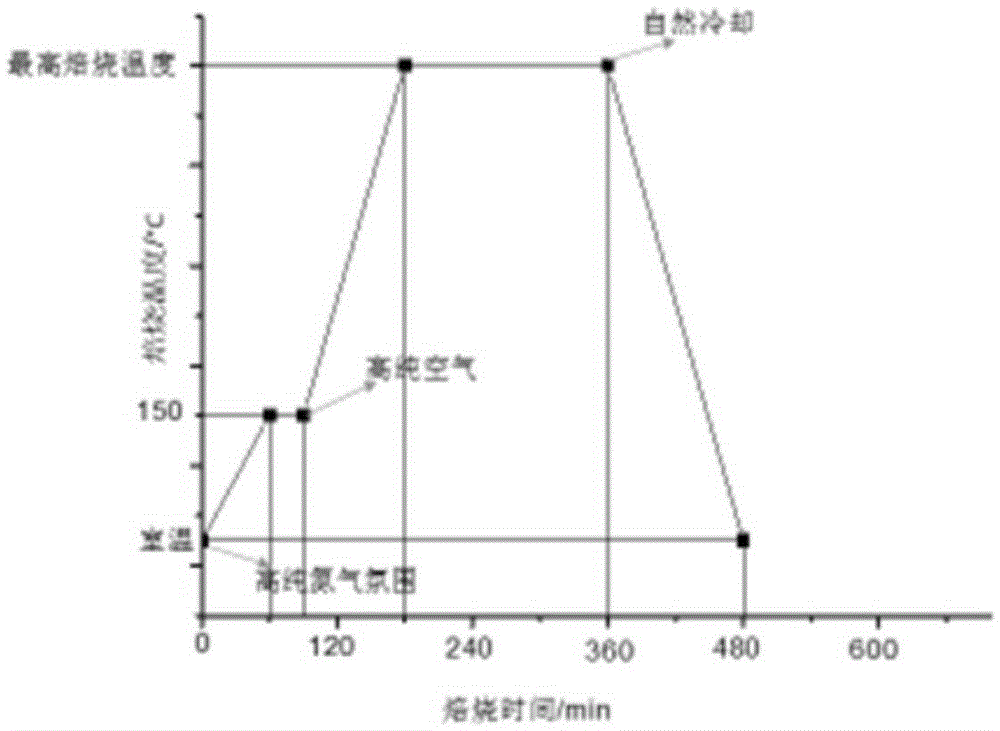

[0123] Embodiment 2: get 10g silica gel (pore volume is 1.5~1.7cm 3 / g, the surface area is 250~300m 2 / g) impregnated with zirconium nitrate aqueous solution at 50° C., wherein the addition of zirconium to the silica gel is 2% (calculated by zirconium weight). After continuous stirring and impregnating for 4 hours, the temperature was raised to 120°C and dried for 12 hours, and then the dried product was placed in a fluidized bed and calcined at 500°C under a high-purity air atmosphere, and the calcined product was naturally cooled from the calcining temperature to room temperature. The roasting procedure is as attached figure 1 shown. Subsequently, the above roasted product was impregnated with an aqueous solution containing ammonium metavanadate and ammonium sulfate at 50° C., wherein the added amounts of vanadium and sulfur were 0.5% and 2% (by weight of vanadium and sulfur) respectively. After continuously stirring and impregnating for 4 hours, the temperature was rais...

Embodiment 3

[0124] Embodiment 3: get 10g silica gel (pore volume is 1.5~1.7cm 3 / g, the surface area is 250~300m 2 / g) impregnation with ammonium sulfate aqueous solution at 50° C., wherein the addition of sulfur to the silica gel is 2% (by weight of sulfur). After continuous stirring and impregnating for 4 hours, the temperature was raised to 120°C and dried for 12 hours, and then the dried product was placed in a fluidized bed and calcined at 500°C under a high-purity air atmosphere, and the calcined product was naturally cooled from the calcining temperature to room temperature. The roasting procedure is as attached figure 1 shown. Then impregnate the above roasted product with an aqueous solution containing ammonium metavanadate and zirconium nitrate at 50° C., wherein the added amounts of vanadium and zirconium are 0.5% and 2% (by weight of vanadium and zirconium) respectively. After continuously stirring and impregnating for 4 hours, the temperature was raised to 120°C for 12 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com