Emulsion polymerization method using reactive emulsifying agent, aqueous polymer dispersion obtained by same, and polymer film

A reactive emulsifier and emulsion polymerization technology, which is applied in the field of water-based polymer dispersion and polymer film, can solve the problems of reduced reaction rate, whitening (white turbidity, increase of by-products, etc.), and achieve the improvement of copolymerization and the elimination of air bubbles , Improve the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] The present invention will be described more specifically by way of examples below, but the present invention is not limited by the following examples. In addition, unless otherwise specified, "parts" or "%" are "parts by weight" or "% by weight", respectively.

[0086] 1. Reactive emulsifier

[0087] The reactive emulsifier that can be used in the present invention may be a commercial product or a trial product as long as it satisfies the conditions defined in the present invention, and the reactive emulsifier shown below was tested for the purpose of illustrating the effect of the present invention. example. In addition, when it was not available as a commercial item, the reactive emulsifier synthesized under the following conditions was used for the test.

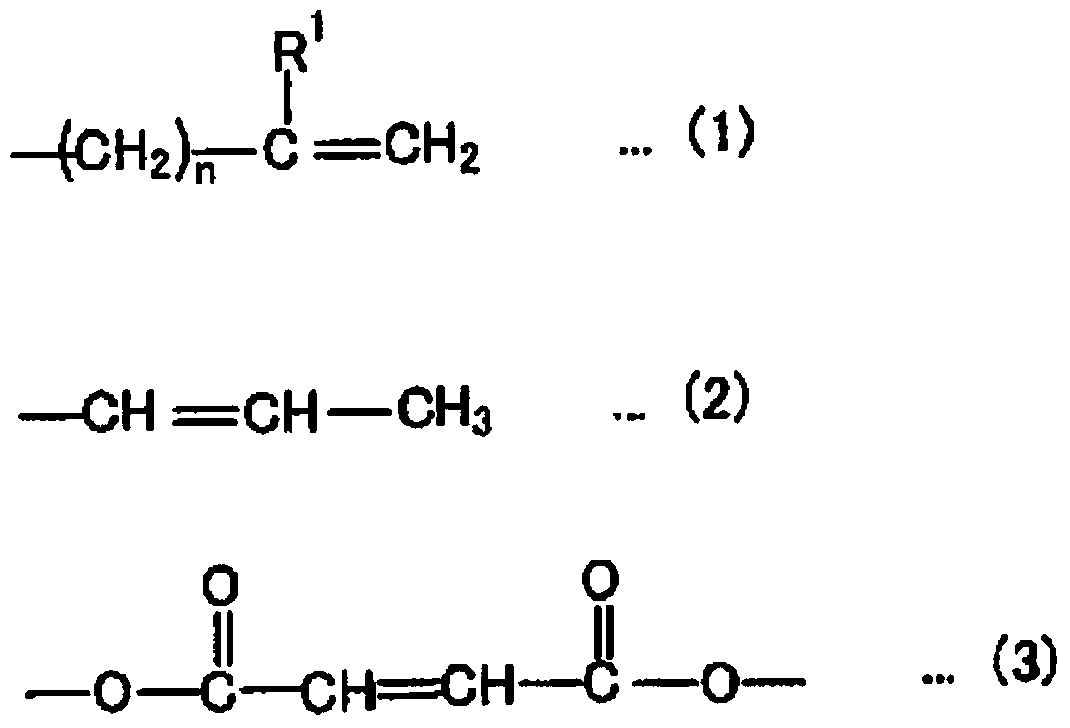

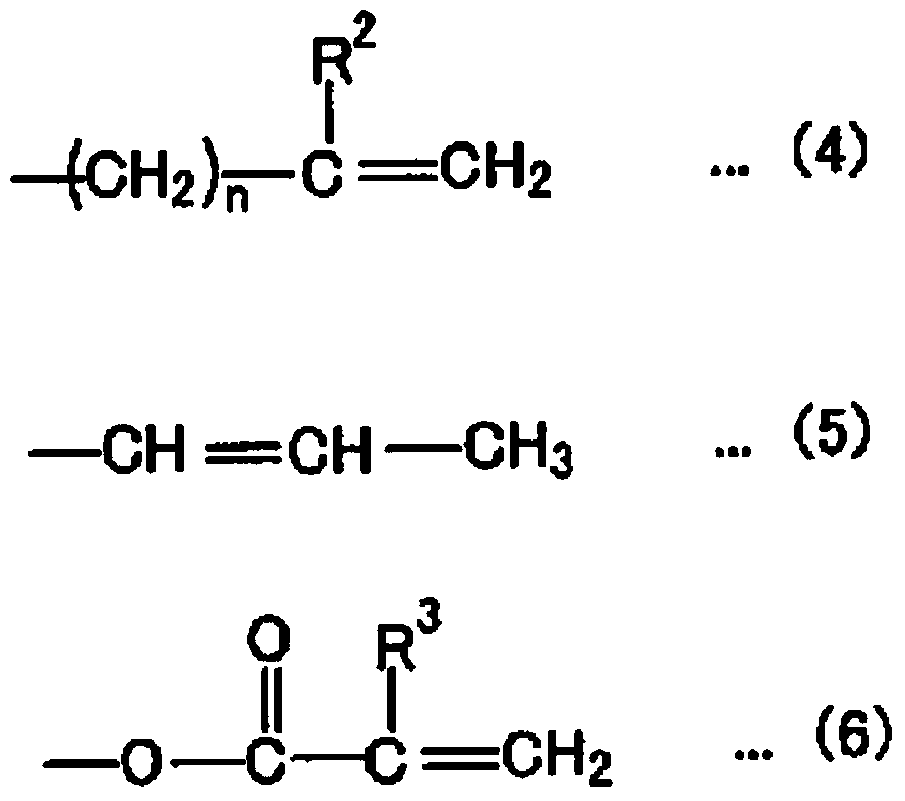

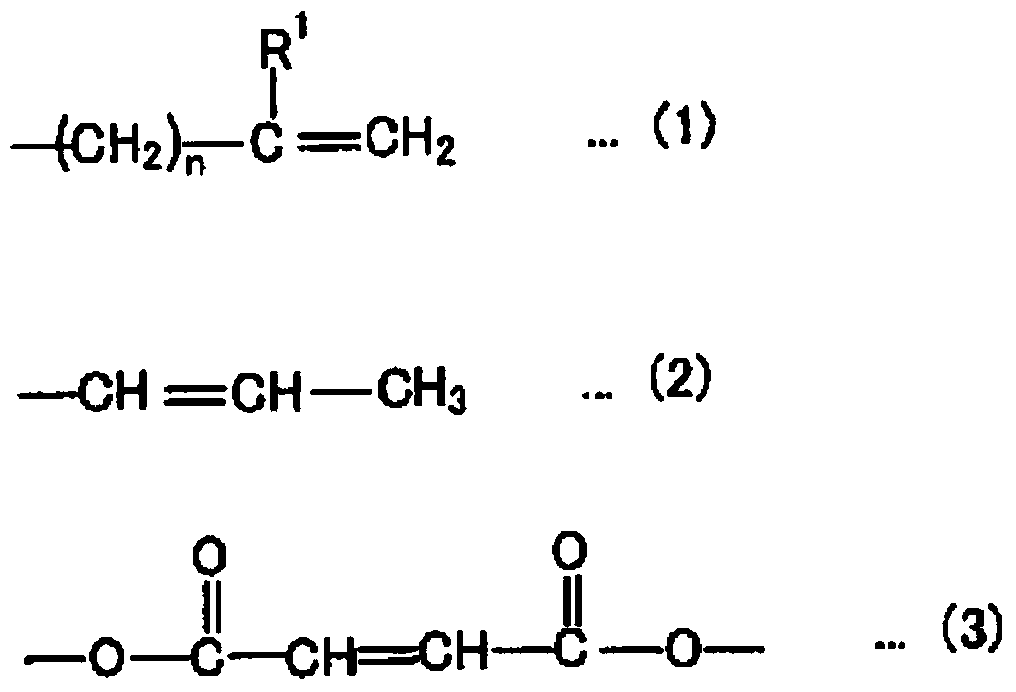

[0088] Reactive emulsifier[1]

[0089] A reactive emulsifier (AQUALON KH-10 manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.) having the following structural formula was tested.

[0090]

[0091] Reac...

Embodiment 5-1~5-8、 comparative example 5-1~5-8

[0176] As monomers, 123.75 g of methyl methacrylate, 123.75 g of butyl acrylate, and 2.5 g of acrylic acid were blended, followed by mixing the emulsifiers described in Table 5 and predetermined amounts of polyfunctional monomers, and further ions using a homomixer. 105 g of water was exchanged to manufacture a mixed monomer emulsion.

[0177] Next, 122 g of ion-exchanged water and 0.25 g of sodium bicarbonate were added to a reactor equipped with a stirrer, a reflux cooler, a thermometer, a nitrogen introduction tube, and a dropping funnel, and stirring was continued while venting with nitrogen, and the previously prepared mixing sheet was added to the reactor. A part of the body emulsion, 36 g, was heated to 80°C. Then, after continuing stirring for 15 minutes, a solution prepared by dissolving 0.5 g of ammonium persulfate as a polymerization initiator in 20 g of ion-exchanged water was added to initiate polymerization. Next, 15 minutes after adding the polymerization initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com