Organic chromium catalyst for ethylene polymerization and preparation method thereof

A technology of ethylene polymerization and catalyst, applied in chemical recycling, bulk chemical production, etc., can solve the problem of high production cost and price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Weigh 0.87 g of a chromium acetate aqueous solution with a concentration of 50% by weight, with a chromium content of 11.5% by weight, and add 56 ml of deionized water. Add the prepared chromium acetate aqueous solution to 20 g of Davison 955 silica gel, mix and immerse for 6 hours, and then dry at 60-120°C for more than 12 hours in an air atmosphere. Then put the dried catalyst matrix into a Φ30×500mm quartz tube activator welded with a sintered quartz distribution plate at the bottom, and pass dehydrated and deoxidized high-purity nitrogen to fluidize the catalyst. Heat up the quartz tube activator at 200°C for 2 hours to further remove moisture from the catalyst. The temperature is raised to 325°C, and then switched to dehydrated dry air. The temperature is raised to 600°C and maintained for 4 hours, and finally switched back to high-purity nitrogen. After the activator is cooled to room temperature, the chromium oxide catalyst is taken out and stored in a nitrogen at...

Embodiment 2

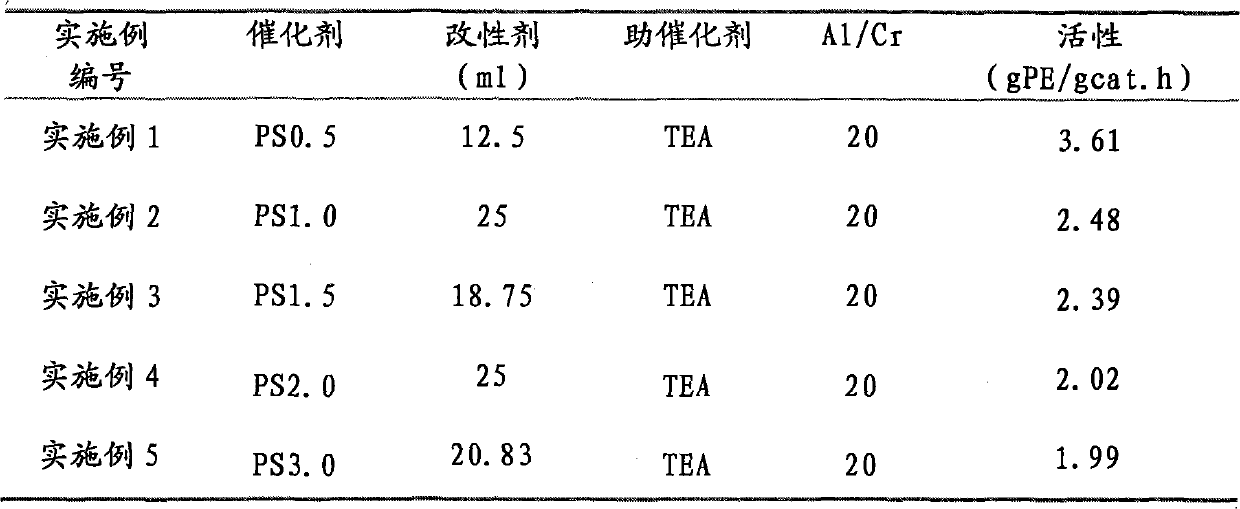

[0083] The process of Examples 2-5 is similar to that of Example 1, except that the PS modifiers are added in different amounts. In Example 2, the amount of PS modifier added was 25ml, TPS:Cr=1.0; in Example 3, the amount of PS modifier added was 18.75ml, TPS:Cr=1.5; in Example 4, the amount of PS modifier added was 25ml, TPS:Cr=2.0; in Example 5, PS modifier 20.83ml, TPS:Cr=3.0.

Embodiment 5

[0092] The modifier concentration in Example 5 is 1.15×10 -2 mol / L.

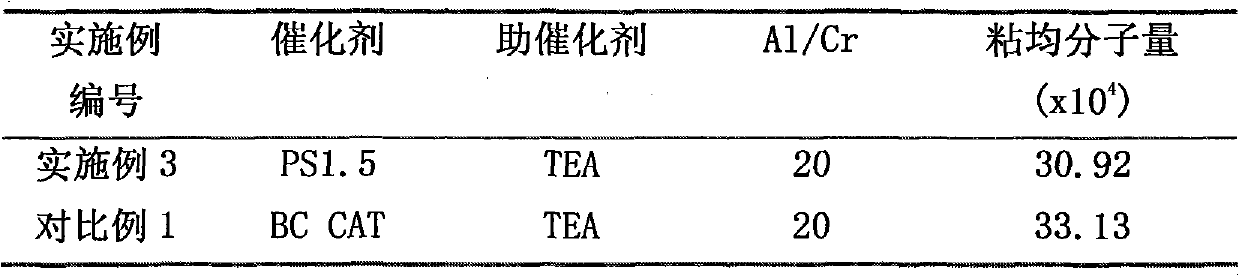

[0093] Table 2 Polymerization conditions: 85°C, pressure: normal pressure, polymerization time: 1 hour

[0094]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com