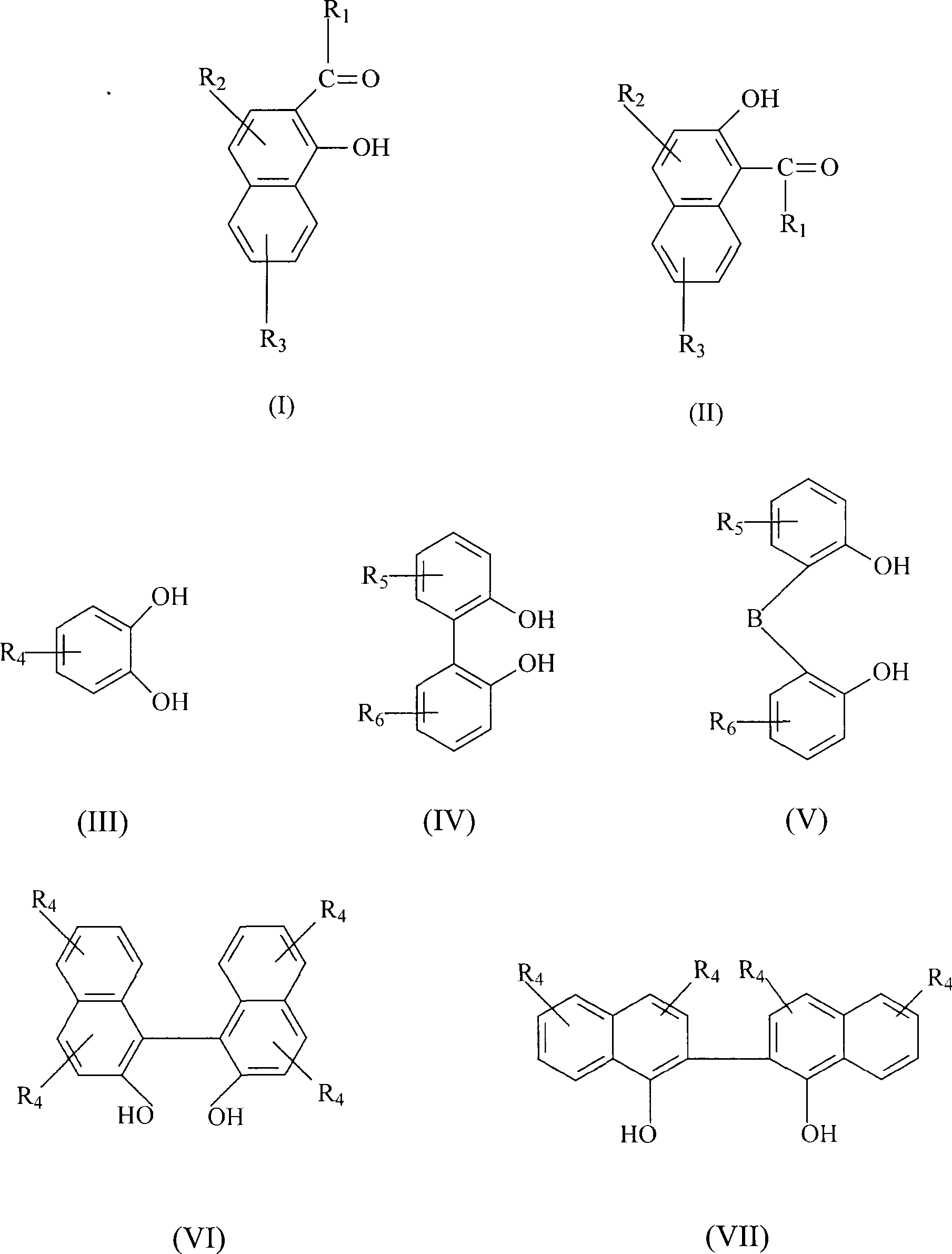

Catalyst activity component for polymerization of propylene or combined polymerization, catalyst precursor containing the same and preparation thereof

An active component, propylene polymerization technology, applied in the production of bulk chemicals, etc., can solve the problem that the metal active center is not modified or the modification is not strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1~18

[0114] Preparation of magnesium composite support

[0115] Under a nitrogen atmosphere, 8 grams of magnesium powder (150 μm) and 360 mL of hexane solvent were added to the reactor, and then 5.0 grams of Davison955 silica gel (produced by Grace, USA), 36 mL of n-chlorobutane, 20 mL of Si(OC 2 h 5 ) 4 , 5mL Ti(OC 4 h 9 ) 4 and 0.4 g I 2 Initiate at 60°C. After initiation, slowly add 110mL of n-chlorobutane and 140mL of hexane mixed solvent dropwise. After the dropwise addition, raise the temperature to 70°C for 2 hours to prepare the magnesium composite carrier.

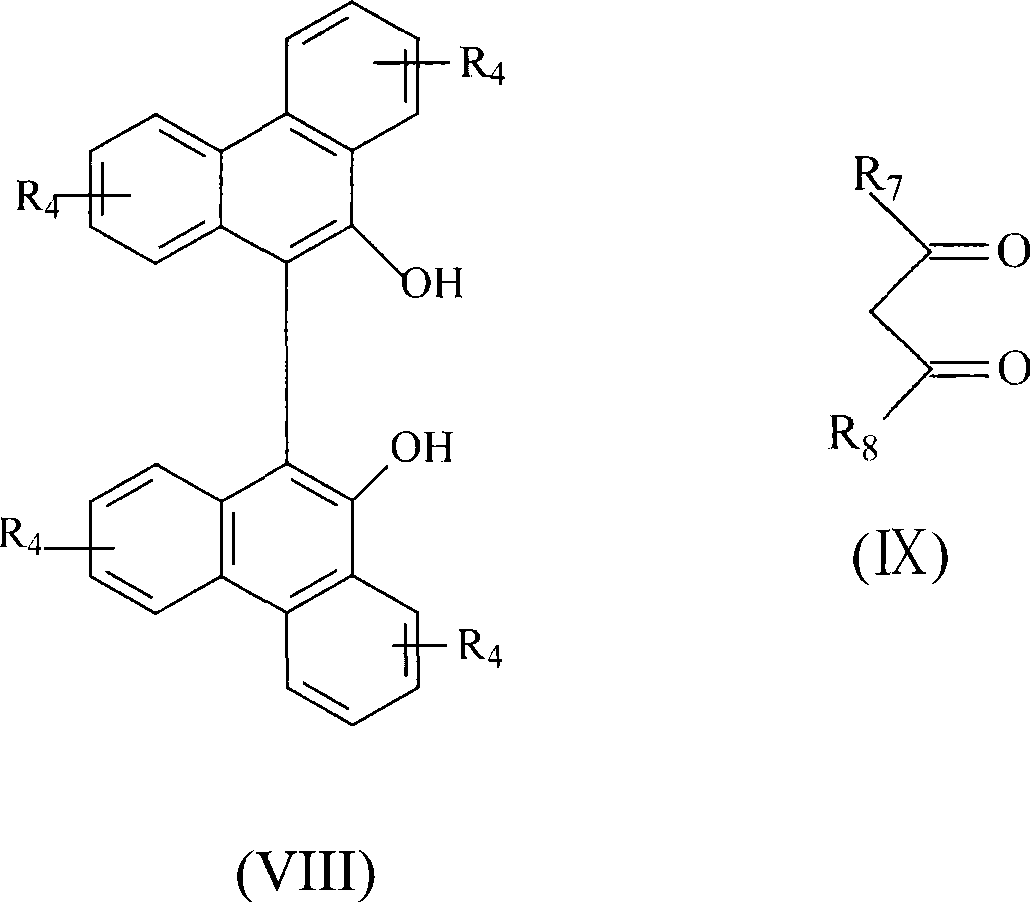

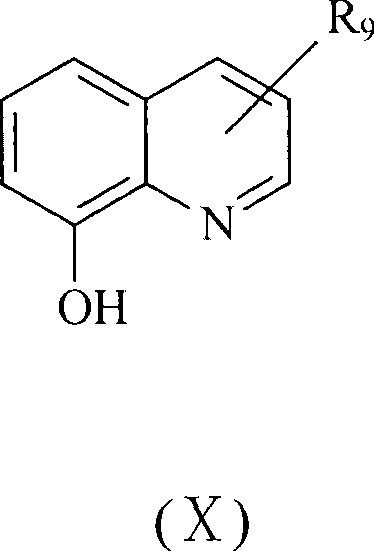

[0116] Preparation of catalyst precursor

[0117] Place 4.76 grams of the prepared magnesium composite carrier in a reaction flask, add 50 mL of n-hexane, and sequentially add 3.1 mL of isooctyl alcohol (0.02 mol), 1.65 mL of γ-chloropropyltrimethoxysilane and 1.65 mL of γ -Chloropropyltriethoxysilane was heated to 50°C for 1 hour reaction, then 10ml of toluene solution containing 4.6mmol chelate coordination el...

preparation example 19

[0122] The catalyst precursor of the present invention was prepared by the same method as Preparation Example 1 except that the amount of α-acetylnaphthol was 2.3 mmol. The Ti content and Mg content of the prepared catalyst precursor were as follows: Ti mass %: 1.98; Mg mass %: 22.02.

preparation example 20

[0124] The catalyst precursor of the present invention was prepared by the same method as Preparation Example 1 except that the amount of α-acetylnaphthol was 6.9 mmol. The Ti content and Mg content of the prepared catalyst precursor were as follows: Ti mass %: 6.2; Mg mass %: 15.31.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com