Pre-dispersing rubber accelerator master batch and preparation method thereof

A rubber accelerator and pre-dispersion technology, which is applied in the field of rubber pre-dispersion accelerator masterbatch and its preparation, can solve problems such as bad odor, unfavorable industrial hygiene and environmental protection, and poor compatibility between chemicals and rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

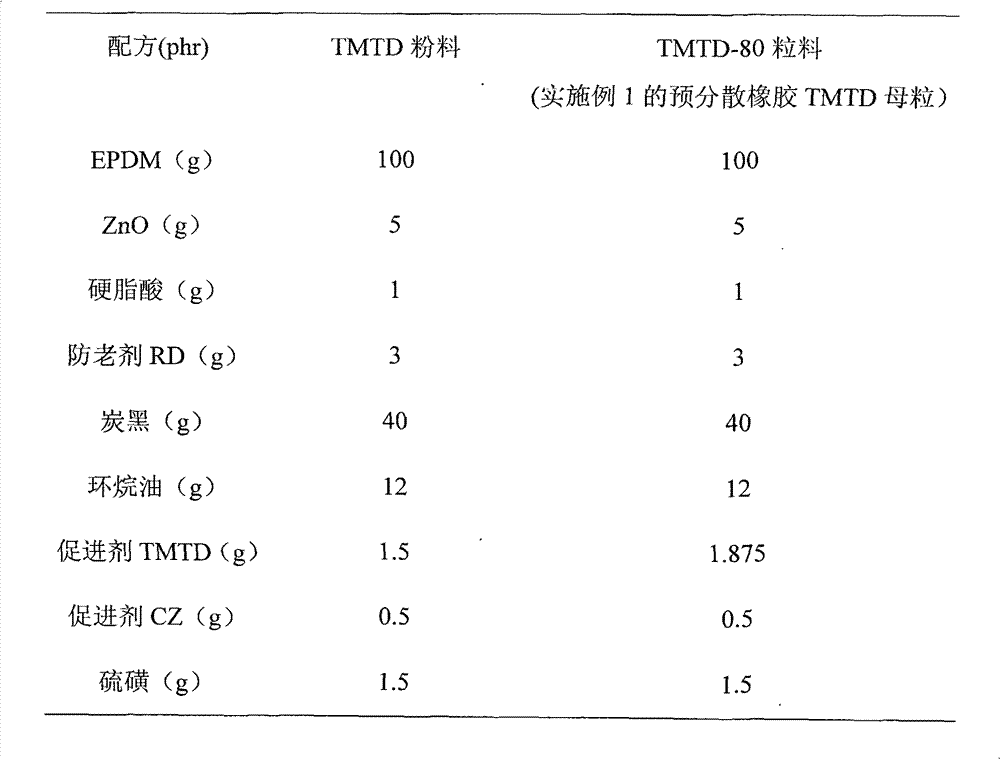

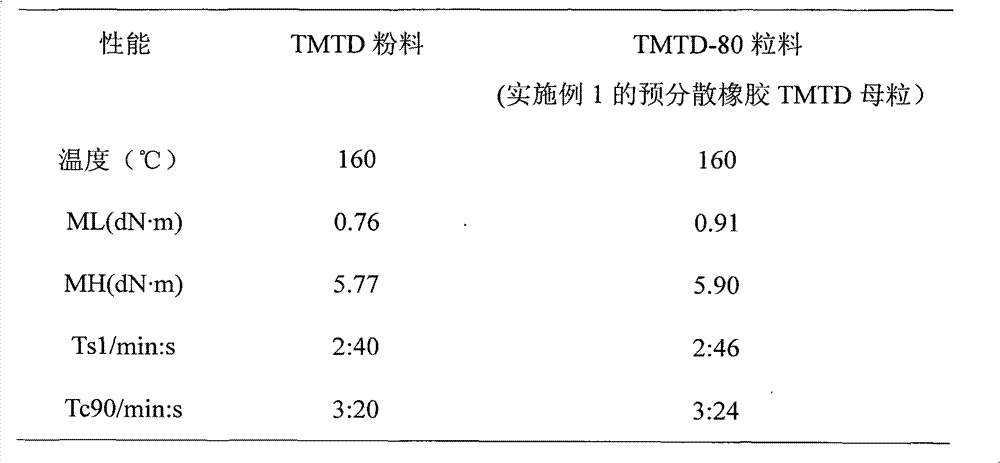

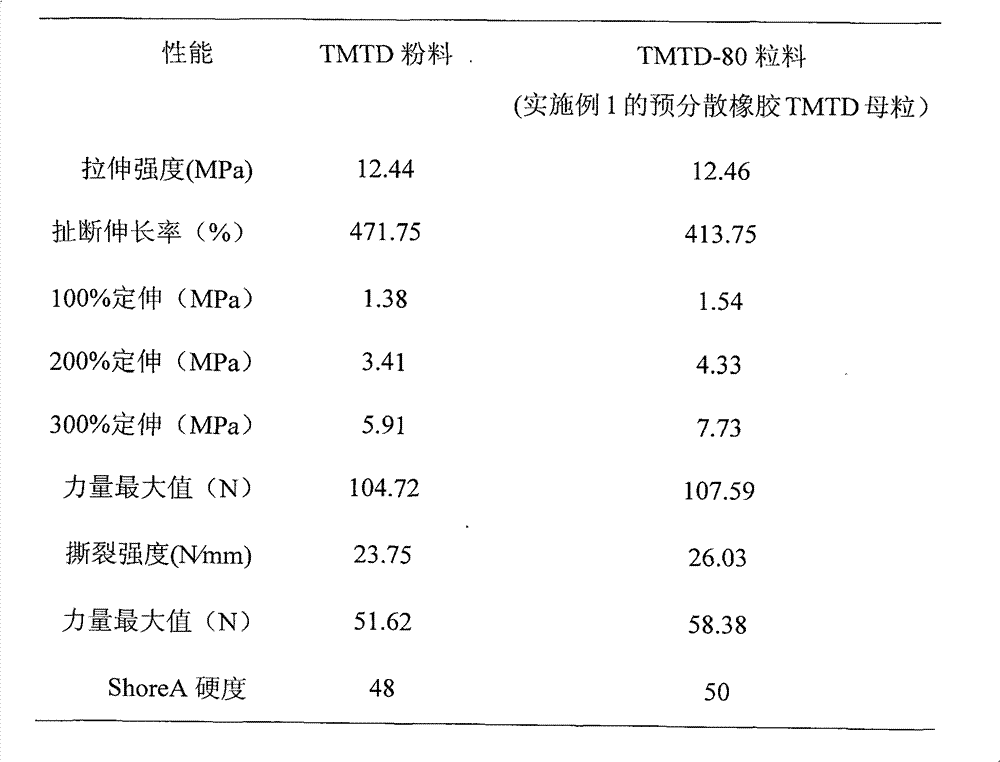

Embodiment 1

[0020] Accurately weigh 70g of styrene thermoplastic elastomer SBS and 30g of EVA rubber. Preheat the rollers of the mill and adjust to a temperature of 80°C. According to the amount of rubber mixing, adjust the roller distance to the specified size, adjust and fix the position of the rubber baffle; put the SBS powder into the roller gap of the open mill along one side of the roller, add EVA, and add 50g of naphthene in batches Base rubber oil and 600g accelerator TMTD, use methods such as tamping, rolling, and triangular bagging to make the rubber evenly and continuously wrapped on the front roller, leaving an appropriate amount of accumulated glue on the top of the roller distance, after 2-3 minutes of rolling, Turn over to form a smooth and gap-free roll wrapping rubber, press the rubber material to the required thickness, weigh the quality of the next piece and place it on a flat, dry rubber storage board. Turn on the single-screw extruder, set the temperature of each hea...

Embodiment 2

[0022] Accurately weigh 24.0g of SBS, 12.0g of EPDM, 12.0g of naphthenic rubber oil and 144.0g of accelerator TBTD, turn on the HAKKE rheometer, adjust the temperature to 75°C, and the speed to 40r / min, first add SBS and EPDM, and add them in batches Accelerator TBTD and naphthenic rubber process oil were pre-mixed in the HAKKE rheometer for 10 minutes, and the Hakke was opened to take out the material to obtain a pre-dispersed rubber additive masterbatch. Turn on the single-screw extruder, set the temperature of each heating zone of the screw as follows: zone 1 80-90°C, zone 2 85-90°C, zone 3 85-90°C, zone 4 85-90°C, speed 40r / min , adding the pre-dispersed rubber accelerator masterbatch, extruding and granulating to obtain the pre-dispersed rubber accelerator TBTD masterbatch with an accelerator content of 75%.

Embodiment 3

[0024] Accurately weigh 90.0g SEBS, 30.0g CR, 30.0g aromatic rubber oil, and 350.0g CZ accelerator. Preheat the mill rolls to a temperature of 85°C. Put the SBS mixed powder and CR into the roll gap of the open mill along one side of the roller, add the accelerator CZ and aromatic rubber oil in batches, and use methods such as pounding, rolling, and triangular bagging to form smooth and gap-free Roller rubber; press the rubber material to the required thickness, weigh the quality of the next piece and place it on a flat, dry rubber storage board. Turn on the single-screw extruder, the first zone is 80-90°C, the second zone is 85-90°C, the third zone is 85-90°C, the fourth zone is 85-90°C, the speed is 50r / min, add the pre-dispersed rubber additive masterbatch , extruded and granulated to obtain a pre-dispersed rubber accelerator CZ masterbatch with an accelerator content of 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com