Preparation method of thiofide TiBTM (Tetraisobutylethiuram Monosulfide)

A technology of tetraisobutylthiuram and rubber vulcanization, which is applied in the direction of organic chemistry, can solve the problems of non-compliance with national environmental protection policies and energy-saving production requirements, difficulty in achieving "green and clean" production, and difficulty in meeting high-end requirements, and achieve reduction Fixed asset investment, superior vulcanization performance, and short vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

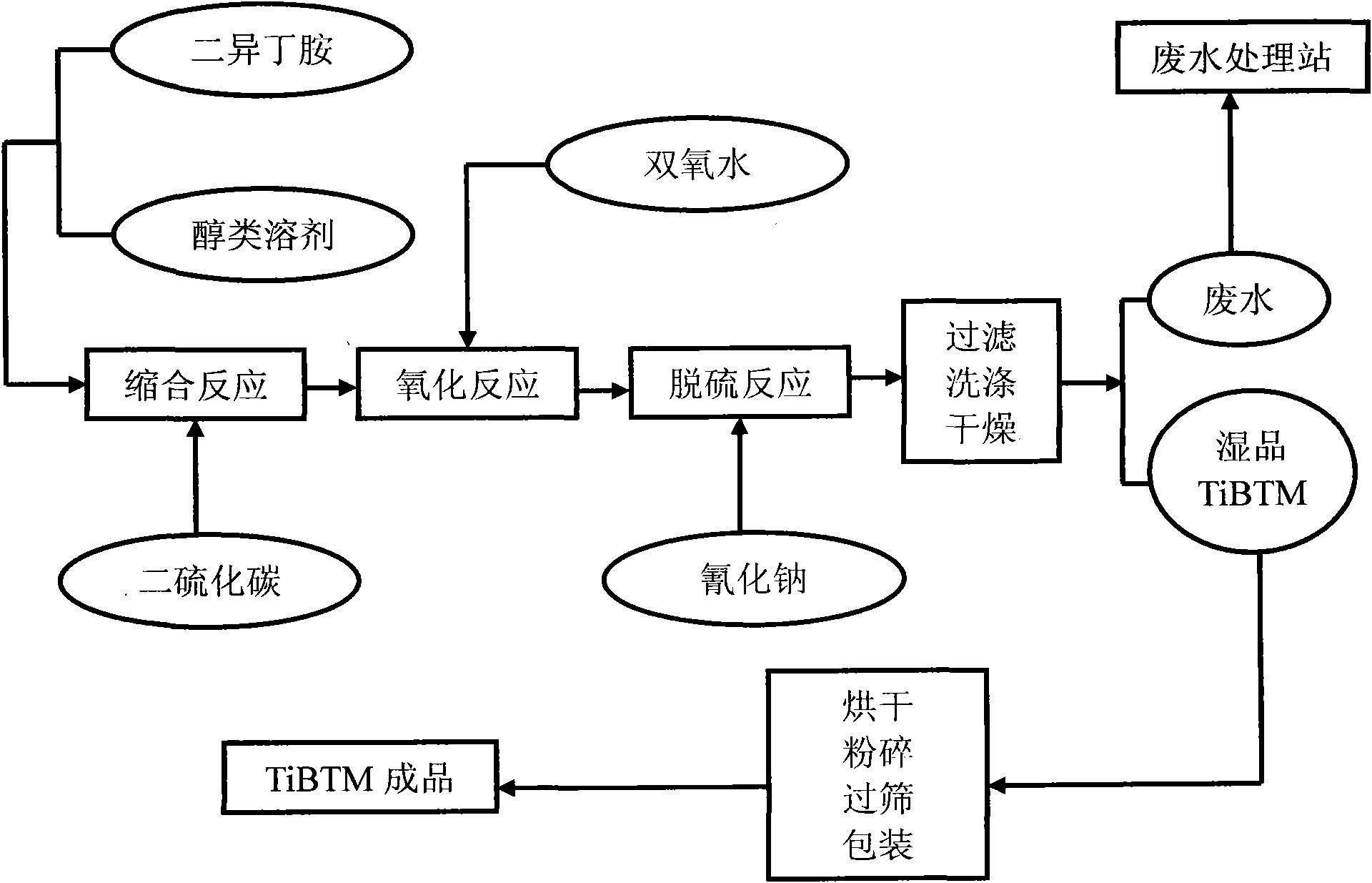

Method used

Image

Examples

Embodiment 1

[0027] The used raw material of the present invention is diisobutylamine, carbon disulfide, hydrogen peroxide, sodium cyanide; The stoichiometric molar ratio of raw material is: diisobutylamine: carbon disulfide: hydrogen peroxide: sodium cyanide=1: 1.1: 0.52: 0.50

[0028] The process is as follows: add a certain amount of diisobutylamine to the reaction kettle containing 100ml of methanol with a mass percentage of 70%, and the stirrer rotates at a speed of 400 rpm; control the temperature at 15°C, and add carbon disulfide dropwise at a uniform speed Liquid and hydrogen peroxide, in which carbon disulfide drops slightly earlier than hydrogen peroxide, carry out condensation reaction and oxidation reaction, control the reaction time for 4 hours; react to pH value 7, put in NaCN, control the reaction temperature 40 ℃, after the reaction is complete, keep warm for 0.5 h, solid-liquid centrifugal separation; solid drying, crushing, sieving, and packaging. It was determined that t...

Embodiment 2

[0030] The used raw material of the present invention is diisobutylamine, carbon disulfide, hydrogen peroxide, sodium cyanide; The stoichiometric molar ratio of raw material is: diisobutylamine: carbon disulfide: hydrogen peroxide: sodium cyanide=1: 1.3: 0.60: 0.60

[0031] The process is as follows: add a certain amount of diisobutylamine to the reaction kettle containing 150ml of ethanol with a mass percentage of 72%, and the stirrer rotates at 800 rpm; control the temperature at 35°C, and dropwise add The required carbon disulfide liquid and hydrogen peroxide, in which carbon disulfide is dropped slightly earlier than hydrogen peroxide, carry out condensation and oxidation reactions, and control the reaction time for 6 hours; react to a pH value of 8, put in NaCN, control the reaction temperature at 50 ° C, after the reaction is complete , keep warm for 1.5h, and carry out solid-liquid centrifugation; solid drying, crushing, sieving, and packaging. After determination, the ...

Embodiment 3

[0033] The used raw material of the present invention is diisobutylamine, carbon disulfide, hydrogen peroxide, sodium cyanide; The stoichiometric molar ratio of raw material is: diisobutylamine: carbon disulfide: hydrogen peroxide: sodium cyanide=1: 1.2: 0.56: 0.52

[0034]The process is as follows: add a certain amount of diisobutylamine sequentially to a reaction kettle filled with 180ml of isopropanol with a mass percentage of 75%, and the stirrer rotates at 1200 rpm; control the temperature at 28°C, and drop Add the required carbon disulfide liquid and hydrogen peroxide, wherein the carbon disulfide drops slightly earlier than the hydrogen peroxide, carry out the condensation and oxidation reaction, control the reaction time for 5 hours; react to a pH value of 7.6, put in NaCN, control the reaction temperature at 45°C, and the reaction is complete Afterwards, keep warm for 1.0h, and carry out solid-liquid centrifugation; the solid can be dried, pulverized, sieved, and packa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com