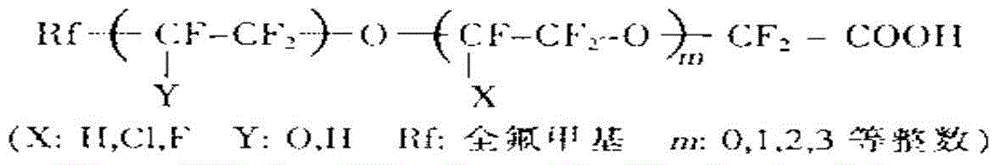

Low-temperature-resistant perfluoroether rubber and synthesis method thereof

A technology of perfluoroether rubber and synthesis method, which is applied in the field of polymer materials, can solve the problems of low reactivity of comonomers, incapable of large-scale commercial production, slow polymerization speed, etc., and achieve good chemical medium resistance and good vulcanization performance, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

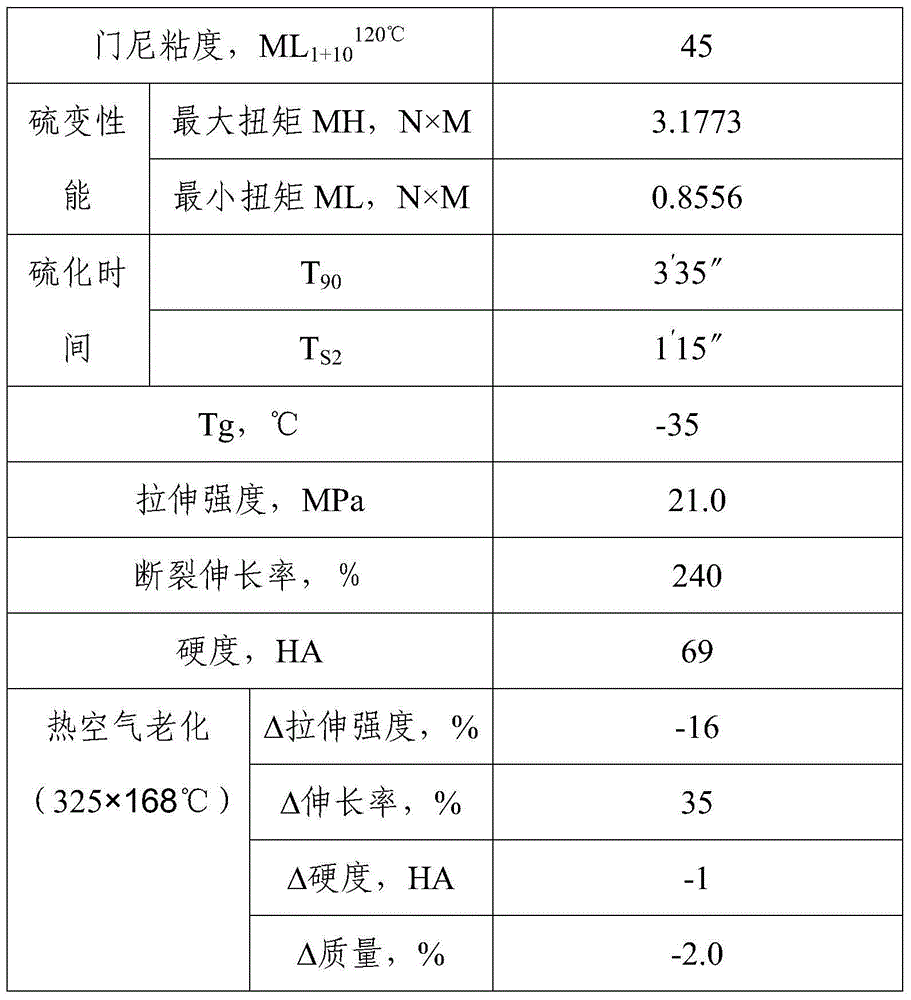

Embodiment 1

[0027] 1) the ionic surfactant CF 3 -CF 2 -CF 2 -O-(CF 2 -CF 2 -O) 2 -CF 2 -COOH, nonionic surfactant (polyoxyethylene oleate), fluoroether oil (CF 3 -CF 2 -CF 2 -O-(CF 2 -CF 2 -O) 2 -CF 3 ), mixed with water according to the weight ratio (18:14:3:65), stirred gently and heated to 40°C and mixed evenly to form a colorless and transparent microemulsion with a weight of 500g. Comonomer A100g (CF 3 CF 2 CF 2 OCF (CF 3 ) CF 2 OF=CF) and comonomer B 2500g CF 3 OCF 2 OCF 2 OCF=CF 2 Add to the above microemulsion and mix well.

[0028] 2) Add 30L deionized water and 45g pH buffer disodium hydrogen phosphate to the reactor, replace the air in the reactor with nitrogen to make the oxygen content less than 20ppm, raise the reactor to 85°C, and use a diaphragm compressor to Mixed monomers (tetrafluoroethylene:perfluoromethyl vinyl ether=65:35mol%) were added into the reactor to raise the pressure to 4.0Mpa, and then the stirring was started to fully mix the mixed mon...

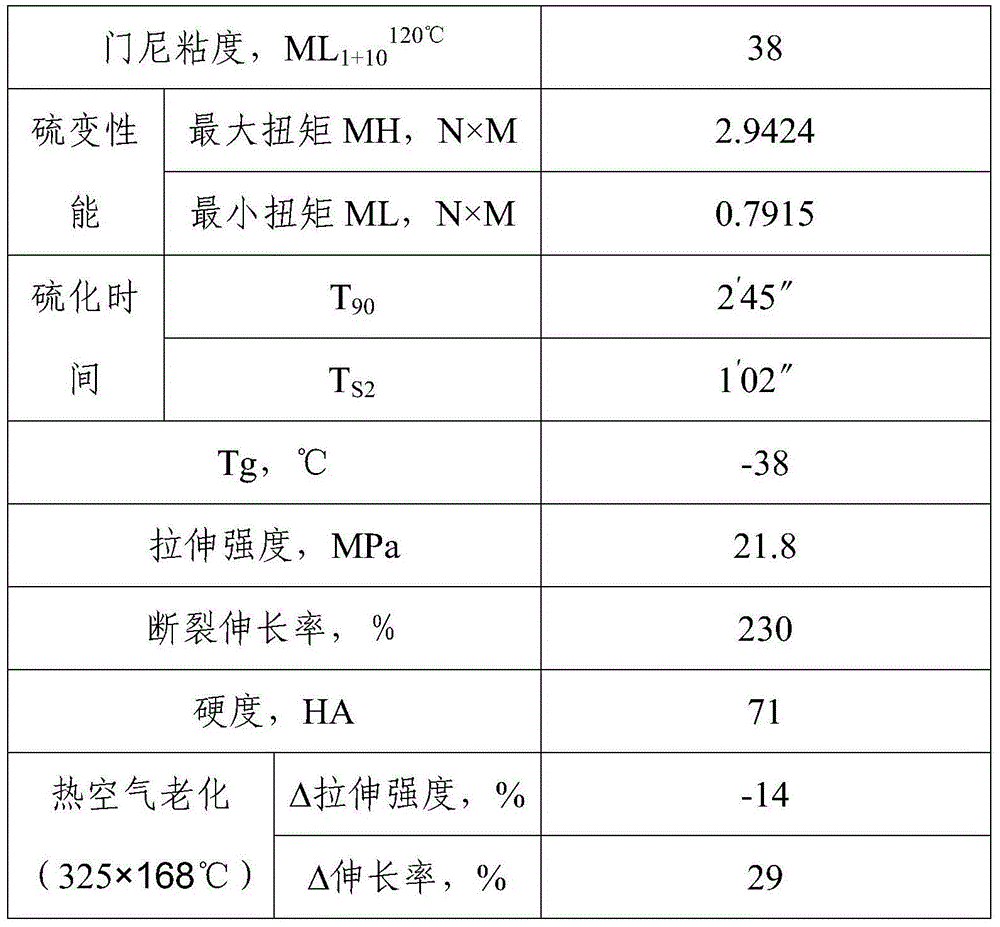

Embodiment 2

[0034] 1) the ionic surfactant CF 3 -CF 2 -CF 2 -O-(CF 2 -CF 2 -O) 2 -CF 2 -COOH, nonionic surfactant (polyoxyethylene oleate), fluoroether oil (CF 3 -CF 2 -CF 2 -O-(CF 2 -CF 2 -O) 2 -CF 3 ), water, etc. according to the weight ratio (18:14:3:65), gently stirred and heated to 40°C and mixed evenly to form a colorless and transparent microemulsion with a weight of 500g. Comonomer A240g (CF 3 CF 2 CF 2 OCF (CF 3 ) CF 2 OF=CF) and comonomer B 3500g CF 3 OCF 2 OCF 2 OCF=CF 2 Add to the above microemulsion and mix well.

[0035] 2) Add 30L deionized water and 45g pH buffer disodium hydrogen phosphate to the reactor, replace the air in the reactor with nitrogen to make the oxygen content less than 20ppm, raise the reactor to 85°C, and use a diaphragm compressor to Mixed monomers (tetrafluoroethylene:perfluoromethyl vinyl ether=65:35mol%) were added into the reactor to raise the pressure to 4.0Mpa, and at this time, the stirring was started to fully mix the mixe...

Embodiment 3

[0042] 1) the ionic surfactant CF 3 -CF 2 -CF 2 -O-(CF 2 -CF 2 -O) 2 -CF 2 -COOH, nonionic surfactant (polyoxyethylene oleate), fluoroether oil (CF 3 -CF 2 -CF 2 -O-(CF 2 -CF 2 -O) 2 -CF 3 ), water, etc. according to the weight ratio (15:10:5:70), gently stirred and heated to 40°C and mixed evenly to form a colorless and transparent microemulsion with a weight of 500g. Comonomer A240g (CF 3 CF 2 CF 2 OCF (CF 3 ) CF 2 OF=CF) and comonomer B3500gCF 3 OCF 2 OCF 2 OCF=CF 2 Add to the above microemulsion and mix well.

[0043] 2) Add 30L deionized water and 45g pH buffer disodium hydrogen phosphate into the reactor, replace the air in the reactor with nitrogen to make the oxygen content less than 20ppm, raise the reactor to 90°C, and use a diaphragm compressor to Mixed monomers (tetrafluoroethylene: perfluoromethyl vinyl ether = 70:30mol%) were added into the reactor to raise the pressure to 4.4Mpa, and then the stirring was started to fully mix the mixed mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com