Single-ingredient silicone structural sealant and preparation method thereof

A one-component, sealant technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of insufficient bonding strength, limited application, etc., to enhance adhesion and improve cohesion. , The effect of optimizing the cross-linking structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

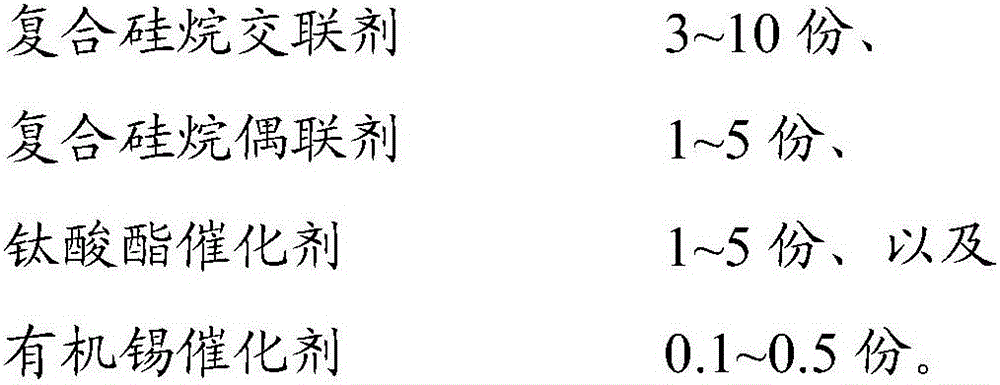

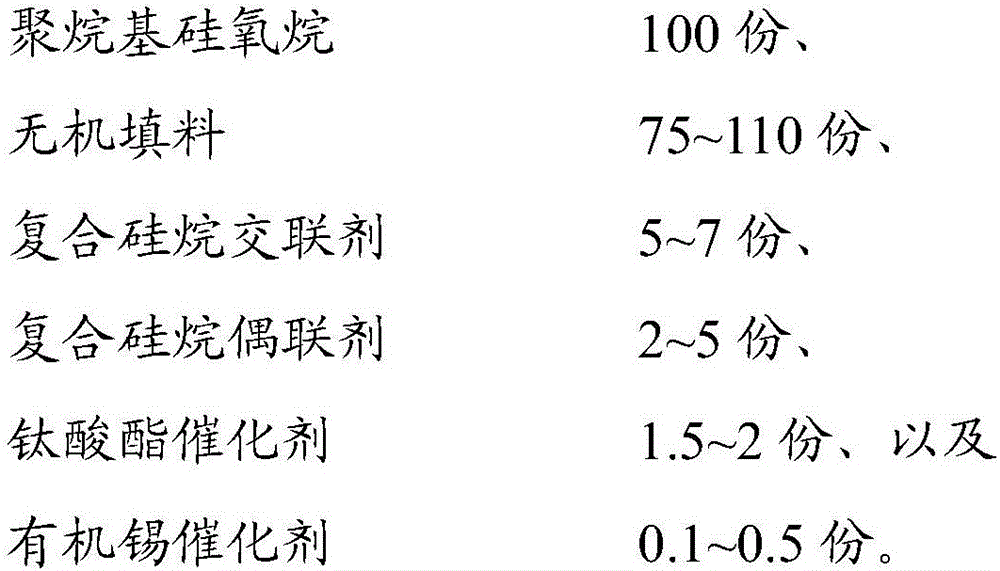

[0028] Example 1 provides a one-component silicone structural sealant with high bonding strength, which is prepared from the following raw material components in parts by weight: α, ω-dihydroxyl with a viscosity of 50000mPa.s Reaction of 100 parts of polydimethylsiloxane, 100 parts of nano-active calcium carbonate, 4 parts of methyltrimethoxysilane, 1 part of dimethyldimethoxysilane, γ-aminopropyltrimethoxysilane and tartaric acid 2.5 parts, 1.5 parts of acetoacetoxytitanium diisopropoxydiacetate and 0.1 part of dibutyltin dilaurate.

[0029] The preparation method of the above-mentioned one-component silicone structural sealant with high bonding strength is as follows:

[0030] Add corresponding parts by weight of α, ω-dihydroxypolydimethylsiloxane and nano-active calcium carbonate into the kneader, and dehydrate and blend for 30 minutes at 50-150°C with a vacuum of -0.06-0.099MPa. ~300min, the base material is obtained after cooling;

[0031] At room temperature, add the a...

Embodiment 2

[0033] Example 2 provides a one-component silicone structural sealant with high bonding strength, which is prepared from the following raw material components in parts by weight: α, ω-dihydroxyl with a viscosity of 50000mPa.s 100 parts of polydimethylsiloxane, 110 parts of nano-active calcium carbonate, 3 parts of methyltriethoxysilane, 2 parts of dimethyldimethoxysilane, γ-aminopropyltrimethoxysilane and hexadiene 2 parts of acid reactants, 2 parts of acetoacetoxytitanium diisopropoxydiacetate, and 0.5 part of dibutyltin dilaurate.

[0034] The preparation method of the above-mentioned one-component silicone structural sealant with high bonding strength is as follows:

[0035]Add corresponding parts by weight of α, ω-dihydroxypolydimethylsiloxane and nano-active calcium carbonate into the kneader, and dehydrate and blend for 30 minutes at 50-150°C with a vacuum of -0.06-0.099MPa. ~300min, the base material is obtained after cooling;

[0036] At room temperature, add the abo...

Embodiment 3

[0038] Example 3 provides a one-component silicone structural sealant with high adhesive strength, which is prepared from the following raw material components in parts by weight: α, ω-dihydroxyl with a viscosity of 80000mPa.s 100 parts of polydimethylsiloxane, 70 parts of nano-active calcium carbonate, 5 parts of hydrophobic fumed silica, 5 parts of methyltrimethoxysilane, 2 parts of dimethyldimethoxysilane, epoxy cyclohexyl 3 parts of reactant of trimethoxysilane and hexamethylenediamine, 1 part of acetoacetoxy titanium diisopropoxydiacetate, 1 part of acetoacetoxy titanium 1,3-dipropoxydiacetate and two 0.3 parts of butyltin bis(β-diketone ester).

[0039] The preparation method of the above-mentioned one-component silicone structural sealant is as follows:

[0040] Add corresponding parts by weight of α, ω-dihydroxypolydimethylsiloxane, nano-active calcium carbonate, and hydrophobic fumed silica into the kneader. Under MPa, dehydrate and blend for 30-300 minutes, and obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com