Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Good industry prospects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing rear passivation double-sided solar cell

InactiveCN102800745AThe process is simpleGood industry prospectsFinal product manufactureSemiconductor devicesEtchingEngineering

The invention discloses a method for producing a rear passivation double-sided solar cell. The method sequentially comprises the following steps of: positive cleaning, making a texture surface, forming a PN junction through diffusion, performing periphery and rear etching, evaporating a positive SiNx anti-reflection film, evaporating a rear passivation film or / and SiNx [11] passivation film or other passivation films, performing screen printing on a back electrode, performing screen printing on a positive electrode, and sintering. The method for producing the rear passivation double-sided solar cell has the advantages that the compounding rate of the rear surface can be greatly reduced, the back reflection is improved, and the more photon-generated carriers are collected. Compared with processes such as photoetching, laser sintering and laser opening, the method is simple in process flow and suitable for mass production. The actual working and generating efficiency can be effectively improved. The used equipment is compatible with the traditional solar cell equipment, the equipment does not need to be increased, the process cost is low, the capacity is high, and the method has good industry prospects.

Owner:TIANWEI NEW ENERGY HLDG +1

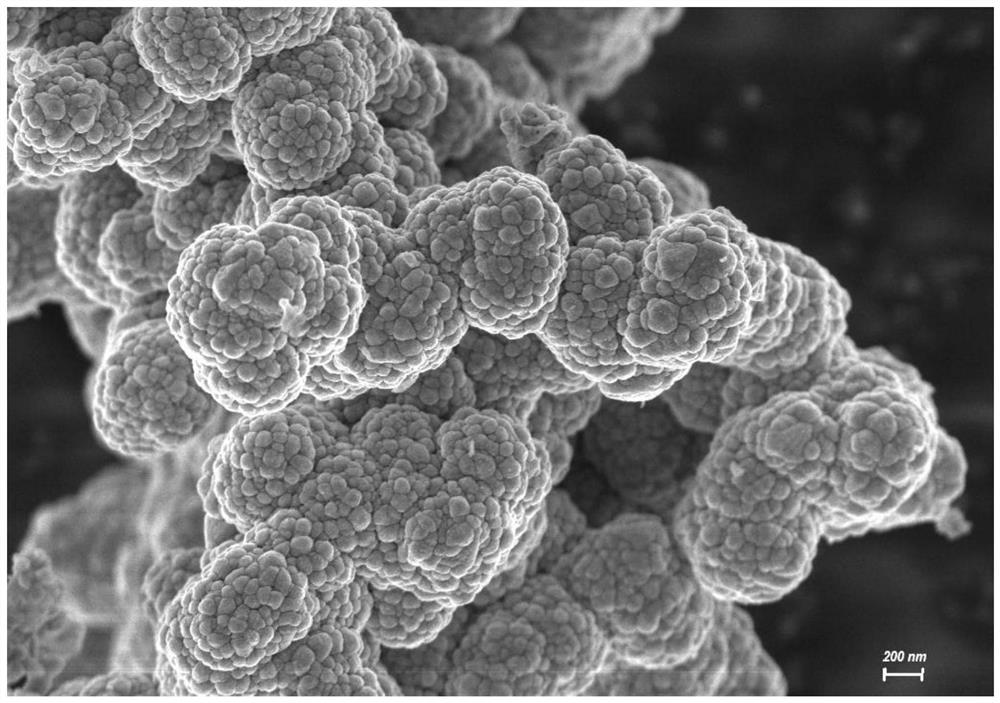

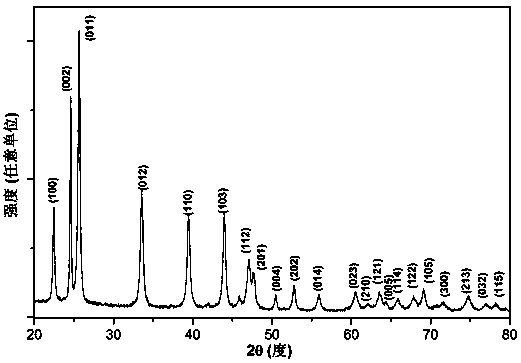

Preparation method and application of graphene/cobalt-nickel-manganese ferrite nano-composite material

ActiveCN109021919AImprove performanceShort synthesis timeOther chemical processesMagnetic/electric field screeningFerrite nanoparticlesCobalt

The invention discloses a preparation method and application of a graphene / cobalt-nickel-manganese ferrite nano-composite material. The preparation method comprises: adding a solution containing an iron source, a cobalt source, a nickel source and a manganese source into a dispersion containing graphene oxide drop by drop to obtain a mixed solution, adjusting pH of the mixed solution to greater than or equal to 8, adding a reducing agent into the mixed solution to obtain a precursor solution, transferring the precursor solution into a reactor, and carrying out microwave synthesis to obtain thegraphene / cobalt-nickel-manganese ferrite nano-composite material. The graphene / cobalt-nickel-manganese ferrite nano-composite material is composed of layered graphene and spherical cobalt-nickel-manganese ferrite nanoparticles. The spherical cobalt-nickel-manganese ferrite nanoparticles are uniformly dispersed on the layered graphene surface and between the layers. The graphene / cobalt-nickel-manganese ferrite nano-composite material has the characteristics of strong absorption intensity, effective absorption frequency bandwidth, thin thickness and light weight.

Owner:CENT SOUTH UNIV

Preparation method of aluminum oxide-carbon nano tube composite powder material

InactiveCN105198447AIncrease profitEvenly dispersedMaterial nanotechnologyDecompositionReaction temperature

The invention discloses a preparation method of an aluminum oxide-carbon nano tube composite powder material. The preparation method comprises the steps of through a chemical vapor deposition method, taking a metal organic precursor as a raw material, under the temperature condition of 400 to 800 DEG C, taking metal nano particles formed on the surface of aluminum oxide powder as a catalyst, simultaneously pumping carbon-rich gases such as methane and acetylene, and enabling carbon nano tubes to grow in situ, so as to obtain an aluminum oxide-metal nano particle-carbon nano tube composite powder material. Through changing various parameters such as the weight of the organic raw material, the flow or constituent of a reactant gas and reaction temperature, the decomposition of the raw material and the generation of the metal nano particles and the carbon nano tubes are adjusted, and the size and the microstructure of the powder is controlled. The method has the characteristics of being simple, short in preparation period and the like, and the prepared aluminum oxide-metal nano particle-carbon nano tubes are uniformly distributed, and have wide application prospect in multiple fields such as conductive ceramics and catalytic materials.

Owner:HOHAI UNIV

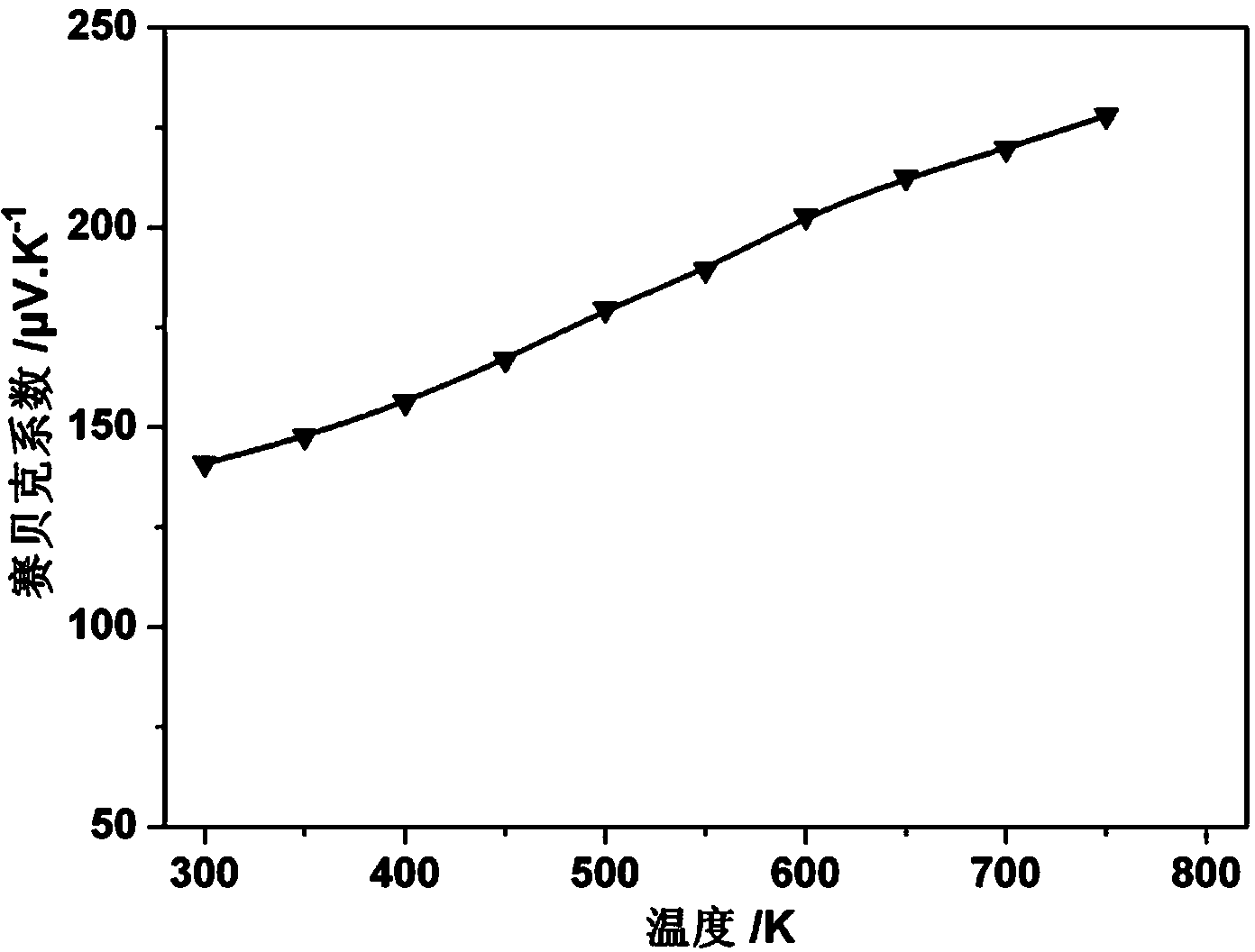

Graphene/Cu2AX3 type thermoelectric composite material and preparation method thereof

InactiveCN104046876AImprove thermoelectric performanceSimple preparation processThermoelectric device manufacture/treatmentThermoelectric device junction materialsHigh volume manufacturingGraphite

The invention relates to a graphene / Cu2AX3 type thermoelectric composite material and a preparation method thereof. The chemical formula of the material is graphene / Cu2AX3, wherein the composite phase is grapheme of which the content is 0.5-5%, the matrix is Cu2AX3-type thermoelectric material with a diamond-like structure, A is Sn or Ge and X is Se or Te. The preparation method disclosed by the invention comprises the steps of preparing raw materials, and carrying out mechanical alloying, spark plasma sintering and the like. The method has the advantages of simple preparation process and good repeatability, can be put into the mass production and has good industrial prospects, and p-type graphene / Cu2AX3 type thermoelectric composite material prepared by the method has excellent thermoelectric properties.

Owner:UNIV OF JINAN

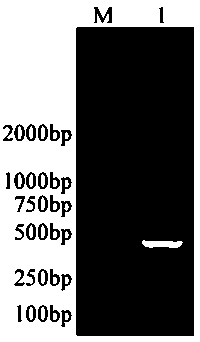

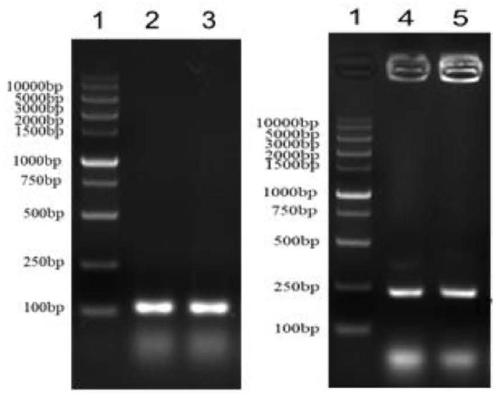

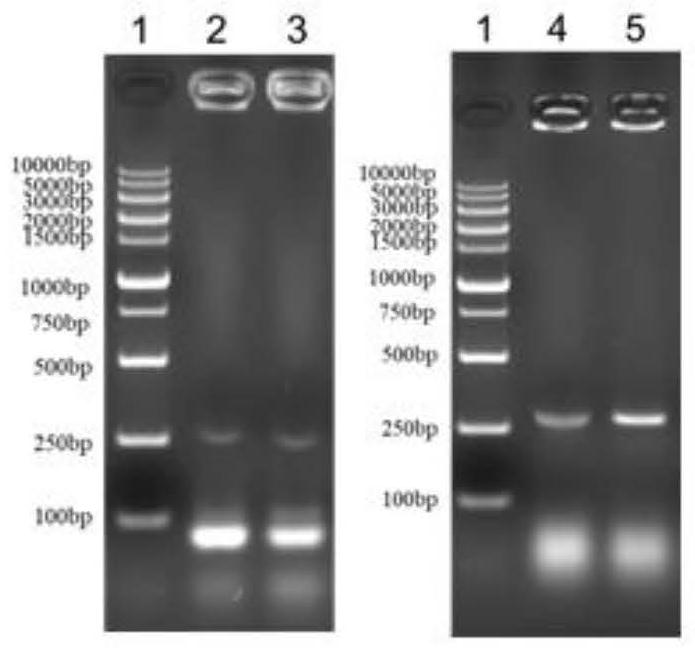

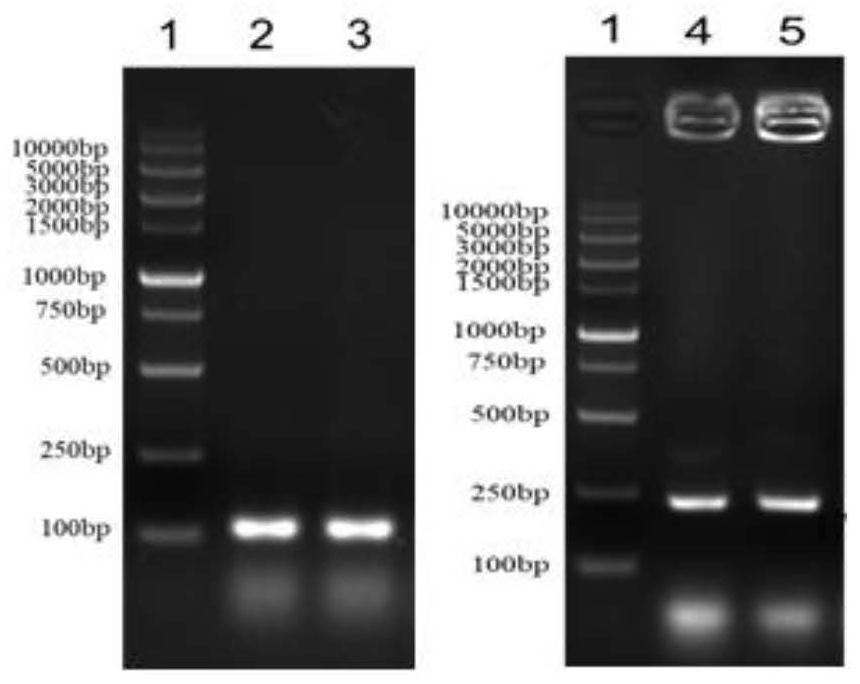

Protein recombinant lactococcus lactis for secretory expression of core antigen COE of PEDV (Porcine Epidemic Diarrhea Virus) as well as preparation method and application of protein recombinant lactococcus lactis

ActiveCN104120142AStrong immune responseGood industry prospectsBacteriaMicroorganism based processesStaphylococcus lactisTGE VACCINE

The invention belongs to the field of animal biomedicine engineering, and in particular discloses protein recombinant lactococcus lactis for secretory expression of a core antigen COE of a PEDV (Porcine Epidemic Diarrhea Virus) as well as a preparation method and an application of the protein recombinant lactococcus lactis. The method comprises the following steps: connecting a signal peptide and other sequences onto a gene of the core antigen COE of the PEDV via an overlap extension PCR method by designing multiple primers, connecting the gene to a lactococcus lactis expression vector pNZ8048 and introducing the vector with the gene into a cell of the lactococcus lactis NZ9000 in an electrotransformation manner so as to obtain recombinant bacteria; and inducing the recombinant bacteria with nisin so as to obtain an expression, and directly taking all induced cultures as oral vaccines capable of stimulating mice and inducing strong cellular immune responses. Thus, the protein recombinant lactococcus lactis can serve as a novel oral vaccine product with a good industrial prospect and has a positive effect for reducing harms of the PEDV to pig industry, thereby playing a great practical significance for promoting the healthy development of the pig industry.

Owner:SOUTH CHINA AGRI UNIV

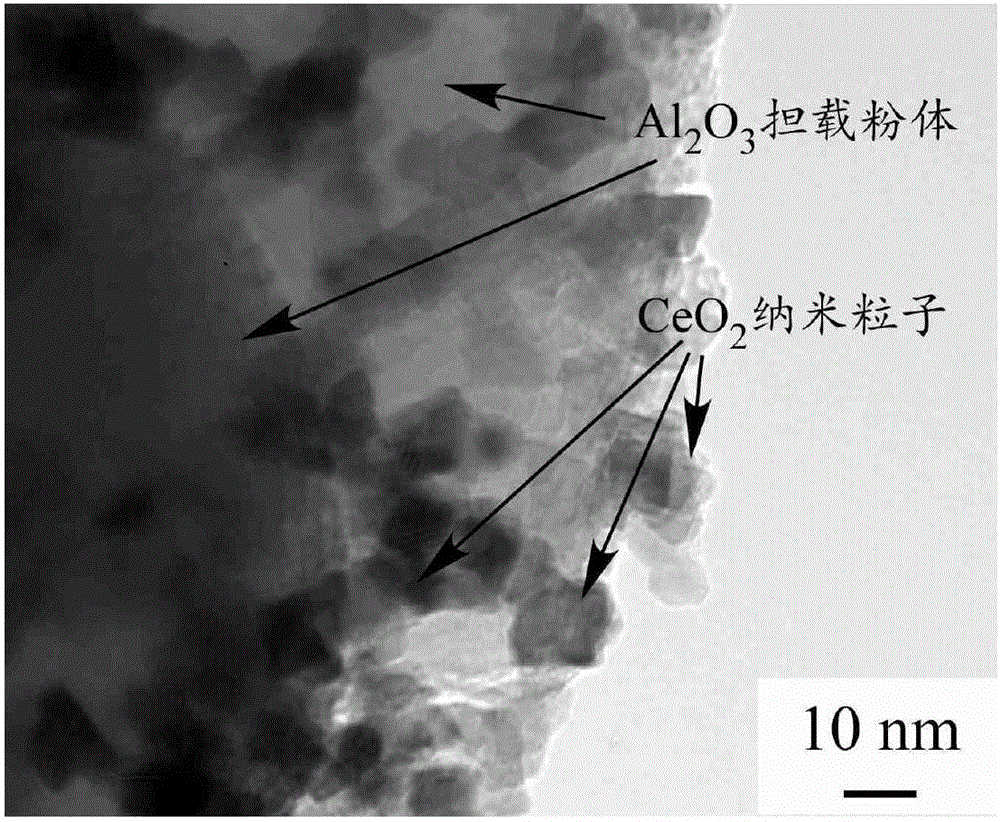

Alumina supported type cerium oxide powder material preparation method

InactiveCN105126808AEvenly dispersedIncrease profitCatalyst activation/preparationChemical vapor deposition coatingCerium(IV) oxideDecomposition

The invention discloses an alumina supported type cerium oxide powder material preparation method which comprises: chemical vapor deposition method is adopted, a cerium metal organic precursor is effectively decomposed in an oxygen atmosphere and in a temperature range of 500-700 DEG C, and CeO<2> nano particles are generated and uniformly dispersed on the support alumina. Experiment parameters of reaction of organic materials and oxygen are changed to accelerate the CeO<2> precursor decomposition, powder size and microstructure are controlled, then cerium oxide nanoparticles are prepared and uniformly dispersed, and toxic waste liquid is prevented from being created. The alumina supported type cerium oxide powder material of the invention has a simple preparation method and short preparation cycle; the produced cerium oxide nanoparticle are uniformly dispersed and widely used as catalytic materials and functional materials in a plurality of fields.

Owner:HOHAI UNIV

Touch control display module

ActiveCN105204674AGood light transmissionGood optical performanceNon-linear opticsInput/output processes for data processingPolarizerComputer science

The invention provides a touch control display module. The touch control display module comprises a cover plate, an upper polarizer, a lower polarizer, an upper substrate and a lower substrate, the upper substrate and the lower substrate are located between the upper polarizer and the lower polarizer, a liquid crystal layer is clamped between the upper substrate and the lower substrate, the touch control display module further comprises a first electrode layer and a second electrode layer, and a first conducting unit located on a first electrode string and a second conducting unit located on a second electrode string are arranged in a mutually-complementary mode. By means of the touch control display module, the haze problem caused by nanometer silver wires can be effectively lowered. The touch control display module has the advantages of being simple in process, good in display effect and the like.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Method for coating surface of oxide ceramic powder with metal nanoparticles

The invention discloses a method for uniformly coating the surface of oxide ceramic powder with carbon impurity-free metal nanoparticles. The method comprises the following steps: grinding and mixing a metal organic raw material and the oxide ceramic powder, and putting the mixture into a rotary reaction chamber; under a rotary heating condition, introducing oxidizing gas to oxidize the metal organic raw material into a metal oxide; and introducing reductive gas to reduce the metal oxide into metal-state nanoparticles. Through adoption of the method, uniform coating of the metal-state nanoparticles is realized, and the problems of roughening and growing of the nanoparticles caused by a long-term coating reaction at a high temperature are solved. The method disclosed by the invention is simple, and is short in the preparation period. The prepared metal nanoparticles are dispersed uniformly, and the oxide ceramic powder coated by the metal nanoparticles have wide application prospects in a plurality of fields as a catalytic material, conductive ceramics and the like.

Owner:HOHAI UNIV

Travelling wave driven prezoelectric ceramic pump capable of realizing forward-reverse fluid flow

InactiveCN1710280AEasy to operateReduce mechanical wearPumpsPositive-displacement liquid enginesElectricityBack pressure

The invention relates to flow pump technique field in precise machine which features that the circle edge of pump body is processed with slots on both upper and lower side, and with several through holes in slots; the slot is sealed by upper and lower pump cover forming a flow channel; upper and lower piezoelectric ceramic plate pasted respectively on the upper and lower side of the pump body, moreover the upper and lower pieces is one fourth wavelength different along the circle, generating a needed traveling wave fluctuate in upper and lower slots while working; flow inlet port and outlet port placed on the same or different sides of the ceramic pump, and block is just between the two port ensuring the flow enters from the inlet port and leaves from the outlet port. The flow direction is controlled by the phase difference of the two exterior power source while the flow amount, speed and back pressure with width, frequency and phase position. It is of low sealing requirement, high reliability, fine flow block performance, handily operation and the working frequency is above 10 KHz.

Owner:TSINGHUA UNIV +1

Standing wave driven piezoelectric ceramic pump capable of realizing positive and negative directional flow of liquid

InactiveCN1959109AMeet the use requirementsEasy to operateFlexible member pumpsPositive-displacement liquid enginesElectricityUltrasonic vibration

A piezoelectric ceramic pump of stationary wave driving mode enabling to flow fluid in forward and backward directions is prepared as enclosing pump cavity by two parallel pump shells, two pump covers and piezoelectric vibrator, forming piezoelectric vibrator by sticking piezoelectric ceramics on metal plate, setting equally divided electrode regions uniformly on front surface of piezoelectric ceramic plate, generating stationary wave ultrasonic vibration by said vibrator under action of electric field, setting polarization direction of each said region along thickness direction of said plate and making polarization direction be alternatively revered.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

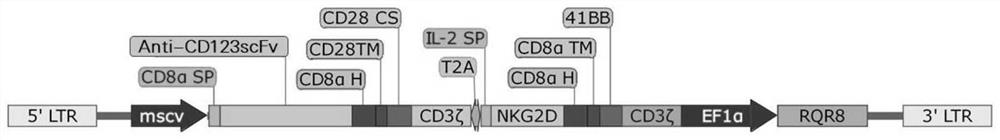

Bispecific chimeric antigen receptor targeting CD123 and NKG2D ligands and application of bispecific chimeric antigen receptor

PendingCN111995688AEnhance specific killing effectOvercoming immunosuppressionVirusesMicroorganism based processesSingle-Chain AntibodiesNkg2d ligands

The invention discloses a bispecific chimeric antigen receptor targeting CD123 and NKG2D ligands and the application of the bispecific chimeric antigen receptor, and particularly discloses a bispecific chimeric antigen receptor (CAR) amino acid construct or a functional variant thereof, wherein the bispecific chimeric antigen receptor (CAR) amino acid construct can simultaneously expresses an anti-CD123 single-chain antibody and a natural NKG2D extracellular fragment and can target CD123 and NKG2DL; the bispecific chimeric antigen receptor has a parallel connection mode and a series connectionmode; and the invention discloses a CAR (chimeric antigen receptor), a construct structure thereof, a nucleotide sequence of the construct, a recombinant expression vector containing the nucleotide sequence and a construction mode and application of the corresponding expression vector. The CAR structure endows T cells with higher and lasting multiplication capacity and high anti-tumor capacity; and according to the bispecific chimeric antigen receptor, multiple infusions of single-target CAR-T cells can be avoided, so that not only is the harm to a patient reduced, but also the economic pressure of the patient can be reduced, and the bispecific chimeric antigen receptor has relatively great clinical research and application values.

Owner:金鑫

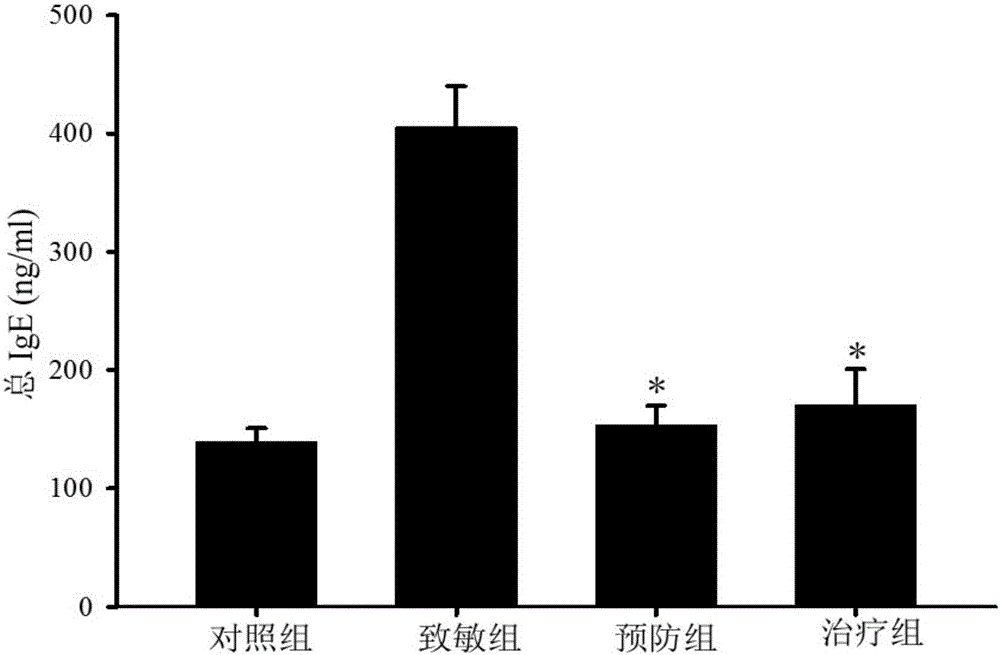

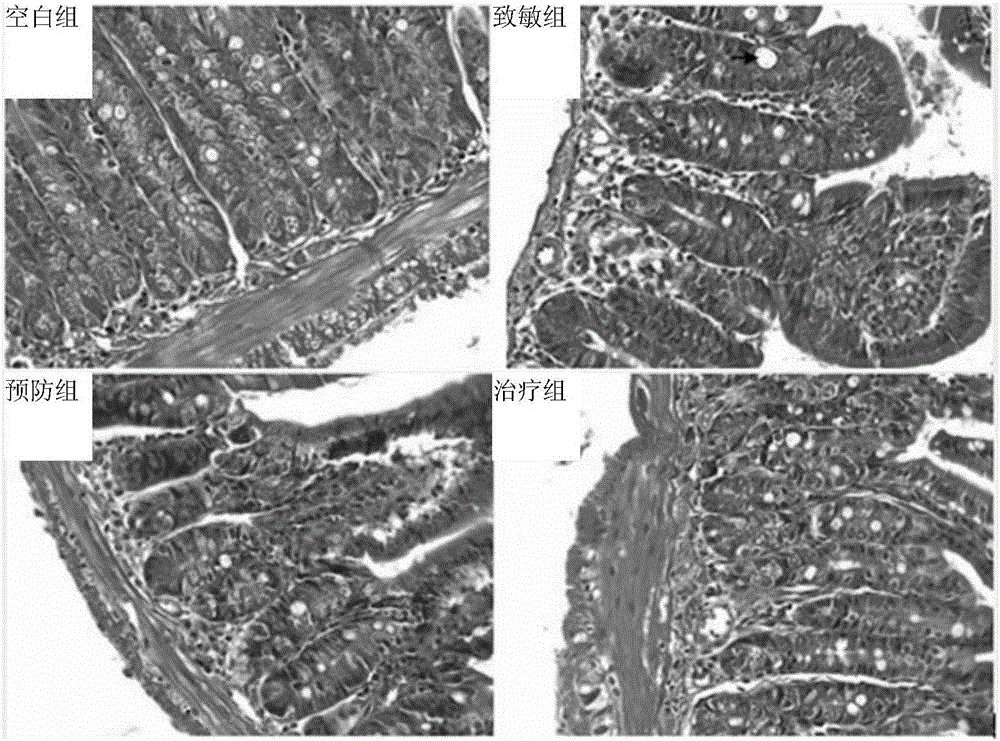

Application of lactobacillus plantarum in preparing antiallergic product

InactiveCN106262931ALow priceEnsure balanceDigestive systemUnknown materialsActive componentGenetics

The invention discloses an application of lactobacillus plantarum in preparing an antiallergic product. The invention provides the application of lactobacillus plantarum in preparing a product for preventing and / or treating allergy; and the lactobacillus plantarum is lactobacillus plantarum SC9 with the collection number of CCTCC NO.M 208150. The invention also protects a product for preventing and / or treating allergy with an active component of lactobacillus plantarum; and the lactobacillus plantarum is lactobacillus plantarum SC9 with the collection number of CCTCC NO.M 208150. The lactobacillus plantarum disclosed by the invention can be applied to the fields of foods, health products and medicines and has very good industrial prospects.

Owner:JILIN ACAD OF AGRI SCI

Preparation method of Se doped skutterudite thermoelectric material

ActiveCN108461619AImprove thermoelectric performanceEvenly dopedThermoelectric device manufacture/treatmentThermoelectric device junction materialsSkutteruditeHigh volume manufacturing

The invention discloses a preparation method of an Se doped skutterudite thermoelectric material. A fusion-annealing method is adopted to prepare Sb-omitted CoSb3-x thermoelectric material powder; thepowder is subjected to selenium permeation treatment; then, quick hot-pressing sintering is carried out to obtain a final product. According to the preparation method, a selenium permeation technology is used for doping the skutterudite thermoelectric material, so as to favorably realize the even doping of the Se element and avoid the uneven doping of a traditional method, and then, Se doped skutterudite thermoelectric material blocks are prepared through a quick hot-pressing sintering technology. The preparation method has the advantages of convenient and simple technology, good repeatability, high controllability and convenience in operation, the accurate control on an Se doping amount is realized through controlling technical parameters of Se permeation, and the preparation method canbe used for large batch production and has a good industrial prospect. The prepared Se doped skutterudite thermoelectric material has excellent thermoelectric properties and is suitable for mass production.

Owner:UNIV OF JINAN

Lactobacillus rhamnosus and application in the preparation of antidepressant products

ActiveCN108715822AHas antidepressant propertiesGood industry prospectsNervous disorderBacteriaLactobacillus rhamnosusGenetics

The invention discloses a lactobacillus rhamnosus and an application in the preparation of antidepressant products. The invention provides a lactobacillus rhamnosus TF318 of which the CCTCC No. is 2018113. The invention also provides the application of lactobacillus rhamnosus TF318 in the preparation of antidepressant products. The invention also provides an antidepressant product of which the active ingredient is lactobacillus rhamnosus TF318. The product is food, health food or drug. The lactobacillus rhamnosus TF318 has antidepressant effect and can be used as a functional probiotic bacteria which is capable of treating and preventing depression. The lactobacillus rhamnosus provides new idea for clinically preventing and controlling spiritual diseases relative to depression.

Owner:JILIN ACAD OF AGRI SCI

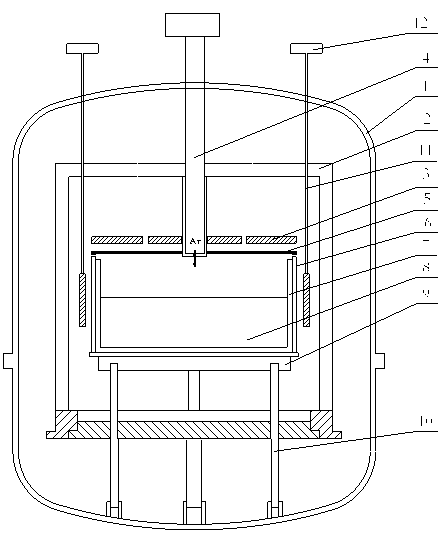

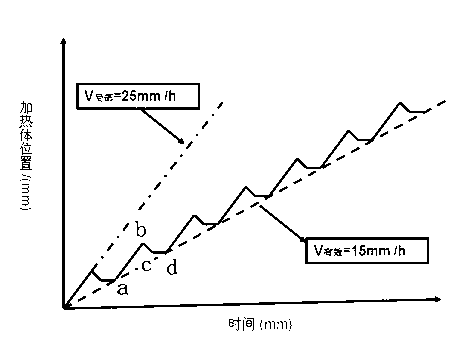

Low-carbon quasi-single crystal ingot furnace and method for adopting low-carbon quasi-single crystal ingot furnace for ingot casting

InactiveCN102703969AReduce carbon contentEliminate latencyPolycrystalline material growthFinal product manufactureMetallurgyIngot casting

The invention discloses a low-carbon quasi-single crystal ingot furnace and a method for adopting the low-carbon quasi-single crystal ingot furnace for ingot casting. The low-carbon quasi-single crystal ingot furnace comprises a furnace body (1), a heat insulation cage (2) and a heat exchange table (9), wherein a crucible (7) is placed on the heat exchange table (9), the top of the crucible (7) is provided with heaters A (3), and heaters B (8) are distributed at the circumference of the crucible (7) and are connected with traction devices (12) through heater lifting rods (11). The method comprises five steps including material charging, heating melting, crystal growth, annealing and cooling. The low-carbon quasi-single crystal ingot furnace and the method have the advantages that the ingredient supercooling phenomenon caused by carbon content enriching in a solute boundary layer can be effectively inhibited, so the influence on the growth speed of quasi-single crystals caused by impurity enriching is reduced, and meanwhile, the content of carbon in quasi-single crystal ingots can be effectively reduced; and the generation and the growth of the fine crystal regions near the crucible wall can be effectively inhibited, so the quality of the quasi-single crystal ingots can be obviously improved, and the utilization rate of the ingots is improved.

Owner:TIANWEI NEW ENERGY HLDG +1

Lactobacillus plantarum for expressing mouse antibacterial peptide gene

ActiveCN111333713AHigh expressionPromote healthy developmentAntibacterial agentsBacterial antigen ingredientsNucleotideIntestinal inflammation

The invention provides lactobacillus plantarum for expressing a mouse antibacterial peptide gene, and belongs to the technical field of genetic engineering. The lactobacillus plantarum optimizes the nucleotide sequence of CRAMP protein, and can promote the secretory expression of the CRAMP gene in combination with Usp45 signal peptide, so that a lactobacillus expression system becomes a food-gradeexpression system, and can be taken together with thalli. The recombinant lactobacillus plantarum can be used as a novel oral vaccine product with a good industrial prospect, plays a positive role inrelieving intestinal inflammation, and has important practical significance for promoting the healthy development of intestinal tracts.

Owner:JIANGNAN UNIV

Nano-copper powder and application thereof to preparation of automobile decorative cloth

PendingCN112296327AUniform particle sizeImprove the bactericidal effectTransportation and packagingMetal-working apparatusMetallurgyCopper chloride

The invention discloses nano-copper powder. The particle size of the nano-copper powder is 100-200 nm, the copper content is not lower than 98 wt%, raw materials of the nano-copper powder comprise copper chloride, copper sulfate and other copper salt, a reducing agent, a dispersing agent and the like, and a high-speed shearing dispersion assisted ultrasonic reduction method is adopted to reduce the bivalent copper salt into nanoscale elemental copper powder. The nano-copper powder is good in dispersity, prepared nano-copper is in a nano-cluster shape, and good antibacterial and mildew-proof performance and excellent peculiar smell removing capacity are achieved. The invention also discloses application of the nano-copper powder to preparation of automobile decorative cloth. Based on preparation of the nano-copper powder, an automobile interior decorative cloth material with good antibacterial, mildew-proof and deodorizing performance can be obtained through composite processing of thenano-copper powder and polymers.

Owner:上海沪正实业有限公司

Method for opening passivation layer on back surface of solar cell

InactiveCN102437242ALow priceExcellent opening widthFinal product manufactureSemiconductor devicesScreen printingSlurry

The invention discloses a method for opening a passivation layer on the back surface of a solar cell. In the method, the opening operation is performed by adopting the conventional equipment; the width of the opening obtained by using the method is equal to the width of the opening obtained by using an improved corrosive slurry opening technology, namely a better opening width can be obtained without changing the equipment, so that the utilization value of the old equipment is increased; meanwhile, by adopting the opening technology, the price of the used acidic liquid and the price of the later-stage cleaning solution are low; screen printing is not required, so damages to the equipment is avoided; therefore, the production cost is reduced; and the method has a good industrial prospect.

Owner:TIANWEI NEW ENERGY HLDG +1

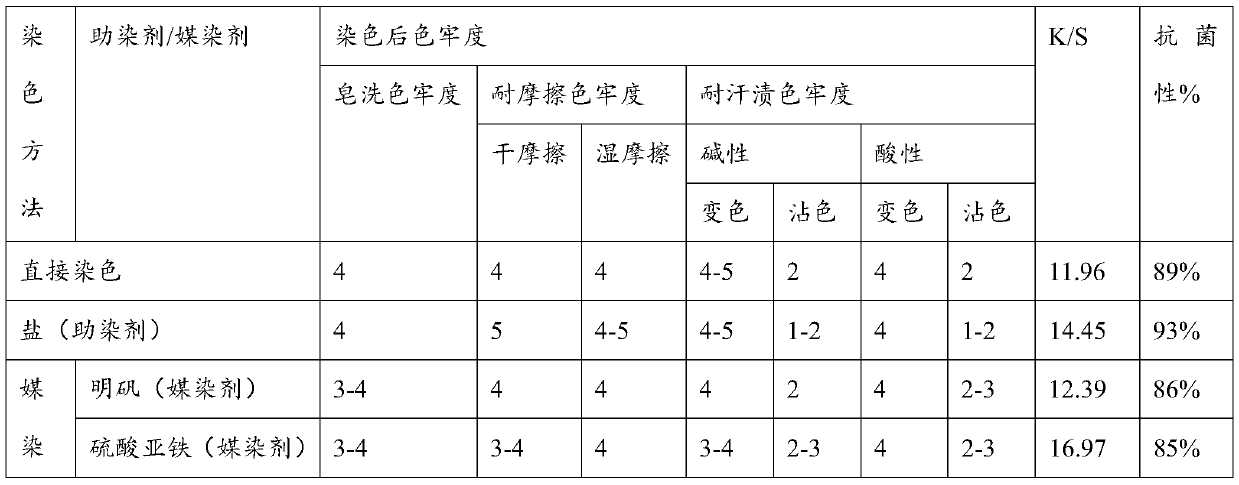

Dyeing method of bamboo fiber fabric based on mahonia bealei plant dye

ActiveCN111235915ASimple dyeing processEasy to transportDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsFiberPulp and paper industry

The invention belongs to the technical field of fabric dyeing methods, and particularly relates to a dyeing method of a bamboo fiber fabric based on a mahonia bealei plant dye. When mahonia bealei, used as a natural plant dye, is applied to the bamboo fiber for dyeing, a fabric with the antibacterial property can be obtained to be more applicable to manufacturing of home clothes. The dyeing methodprovided by the invention comprises the following steps of carrying out desizing and scouring treatment on the fabric by adopting starch biological enzyme and scouring enzyme respectively, and performing bleaching by using hydrogen peroxide and hydrogen peroxide biological enzyme; and obtaining a mahonia bealei dyeing solution through alcohol extraction, carrying out dyeing by taking a salt as aco-dyeing agent, and then carrying out soaping. The color of the dyed fabric is soft and elegant, the dyeing process is simple, the mahonia bealei dye obtained through the alcohol extraction mode canbe freeze-dried and stored, and transport and use are facilitated. The scheme is applied to practical production and has high economic significance.

Owner:DEZHOU UNIV

Combined guard board for preparing pseudo-single crystal with high utilization rate and method for preparing pseudo-single crystal

InactiveCN102787348ASimple designLow costPolycrystalline material growthFrom frozen solutionsHeat currentCrucible

The invention discloses a combined guard board for preparing a pseudo-single crystal with high utilization rate and a method for preparing the pseudo-single crystal, wherein the guard board is improved to realize different heat radiation intensities in different areas of a crucible, so as to improve a growth condition of the single crystal. The combined guard board for preparing the pseudo-single crystal with high utilization rate comprises a lateral crucible graphite guard board which is attached onto the outer wall of the crucible; the lateral crucible graphite guard board comprises an inner guard board attached onto the outer wall of the crucible, and an outer guard board attached onto one side of the inner guard board; the outer guard board is located on one side of the inner guard board far away from the crucible; a plurality of strip-shaped inner guard board holes with the axes being in parallel with one another are formed on the inner guard board; a plurality of strip-shaped outer guard board holes with the axes being in parallel with one another are formed on the outer guard board; and the axes of the strip-shaped inner guard board holes are in parallel with the axes of the strip-shaped outer guard board holes. With the adoption of the combined guard board, the ratio of the radial transmission to the vertical transmission of the heat from the crucible is greatly decreased so as to effectively inhibit the radial heat current of the crucible, and the formation proportion of polycrystal around a cast ingot is decreased, so that the utilization rate of the cast ingot is increased.

Owner:TIANWEI NEW ENERGY HLDG

Method for preparing supported nickel oxide nano-particles

ActiveCN107010677AEvenly dispersedIncrease profitMaterial nanotechnologyNickel oxides/hydroxidesNitrateBoron nitride

The invention discloses a method for preparing supported nickel oxide. The method includes effectively decomposing a precursor NiCp2 under oxygen atmosphere conditions at the temperatures of 500-600 DEG C, carrying out reaction, generating nickel oxide nano-particles and uniformly dispersing the nickel oxide nano-particles on cubic boron nitride powder carriers. The method has the advantages that experimental parameters such as the precursor NiCp2 content and the oxygen content are changed, accordingly, the NiCp2 can be quickly decomposed and coated, the size and microscopic structures of powder are controlled, the cubic boron nitrate powder keeps in stirred states, the nickel oxide nano-particles can be prepared and uniformly dispersed on the surfaces of the cubic boron nitride powder carriers, and carbon pollution in reaction procedures can be prevented; the method is simple and is short in preparation cycle, and the nickel oxide nano-particles prepared by the aid of the method are uniformly dispersed and can have broad application prospects in diversified field when used as catalytic materials, functional materials and the like.

Owner:HOHAI UNIV

Composite base material for drinking water biological treatment and method for using the same

InactiveCN1654349AGood removal effectHigh removal rateWater/sewage treatment by flocculation/precipitationComposite mediaPhosphate

The present invention discloses one kind of composite medium for the biotreatment of drinking water and its usage. The composite medium contains glucose, acetate and phosphate in the mass proportion determined on whether the limiting nutritious elements in the water to be treated are organic matter or phosphate. The usage includes determining whether the limiting nutritious elements in the water to be treated are organic matter or phosphate in the BGP process; determining the DOC and BDOC of the water into the reactor; compounding medium based on the determined results; and throwing the composite medium. The present invention has high organic matter eliminating rate and other advantages.

Owner:NANJING UNIV

Interplanting method for lemongrass and okra

The invention discloses an interplanting method for lemongrass and okra. The method comprises the following steps: pre-processing seeds and disinfecting for further use; transplanting seeds in a nursery seedling plate after germination and transplanting seeds to the field when seeds grow up at the heights of 10-18 cm; burning chicken manures on the soil that needs to be sowed and turning over soil for 2 to 5 times, planting an okra seedling each two plants of lemongrass, keeping the distance between lemongrass seeds and okra plants for 5-8 cm and watering once per day to ensure the water content in the soil ranges from 30%-45%; picking off tops after lemongrass flower and carrying out daily management and picking after flowers wither 8-12 days. The interplanting method for lemongrass and okra has the following beneficial effects: steps are simple; the lemongrass and okra are planted together so that usage of arable areas is reduced and yield of okra is improved; quality of okra is improved; insect pests are reduced; and the interplanting method has a good industry prospect.

Owner:江苏东方绿洲环境建设有限公司

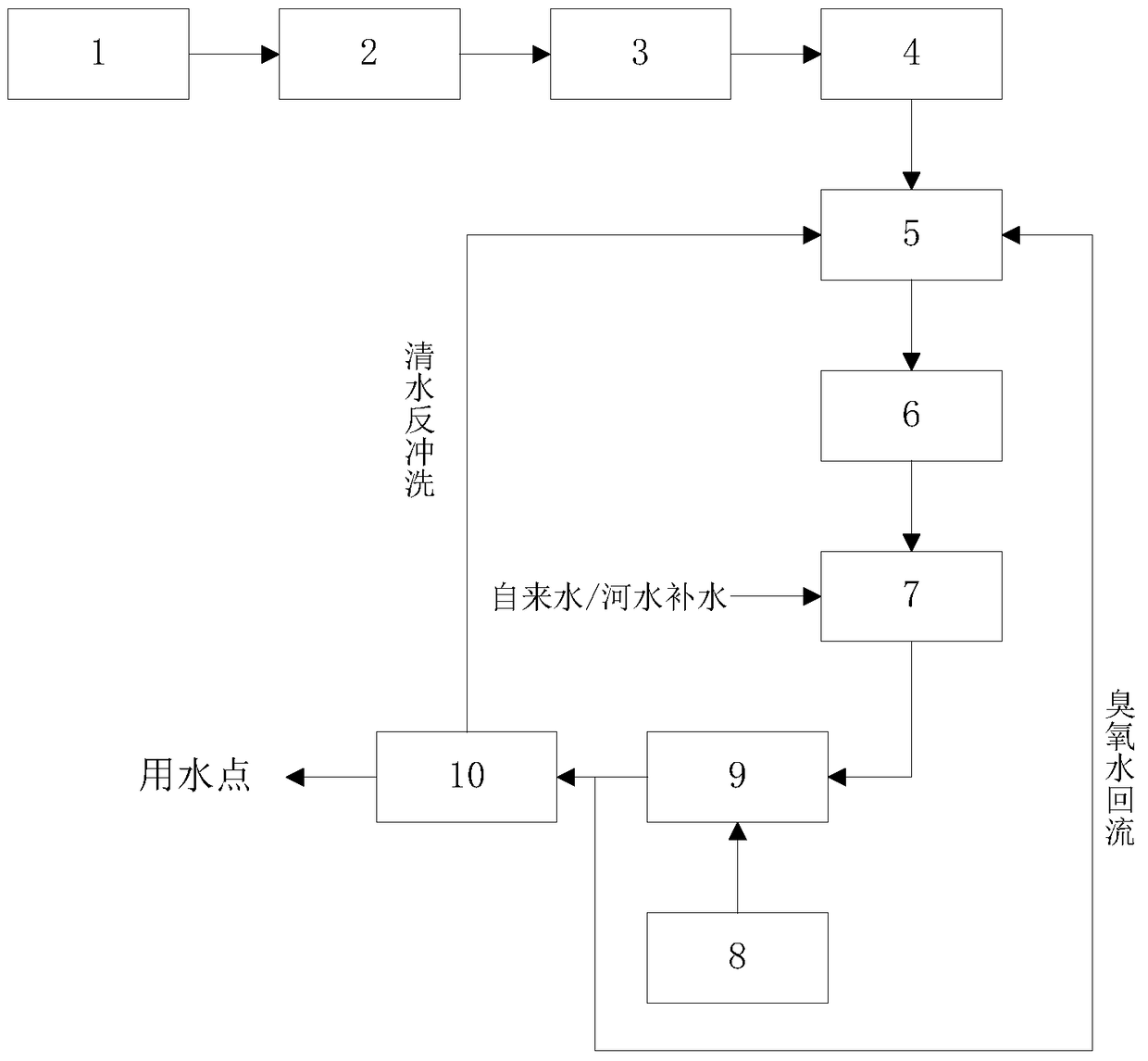

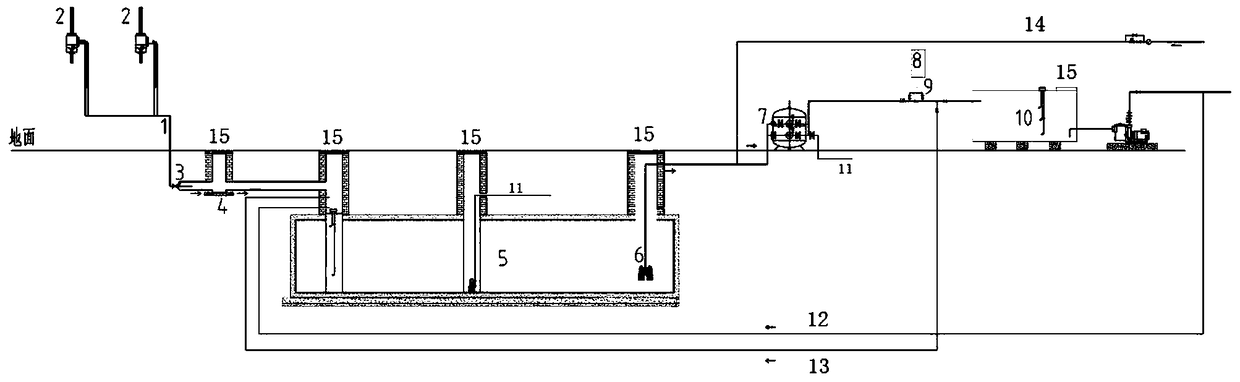

Device and method for rainwater collection, treatment and reuse in multi-span greenhouses

ActiveCN105293749BSmall footprintFlexible space arrangementGeneral water supply conservationEnergy based wastewater treatmentOzone generatorEcological environment

The invention discloses a multi-span greenhouse rainwater collecting and treating reusing device which comprises a water gathering pipe, initial rainwater filtering devices, a double power supply programming controller, a safety diverting well, a modular water storage pond, a pressurizing pump, a multi-medium filter, an ozone generator, a Venturi ejector and a clean water pond, wherein the initial rainwater filtering devices are used for initially realizing filtration of rainwater of 2-5mm; the double power supply programming controller is used for controlling the liquid level of the water storage pond and switching of the initial rainwater filtering devices; the safety diverting well is used for precisely filtering rainwater and controlling the water quantity; the ozone generator and the Venturi ejector are used for generating ozone water. The invention further discloses a rainwater collecting and treating reusing method based on the device. According to the device and method disclosed by the invention, the collected rainwater is disinfected and sterilized by using the ozone water so as to solve the problem that the water quality in the water storage pond is deteriorated, so that the rainwater is recycled, and therefore, the utilization efficiency of a water resource is improved, the regional ecological environment is improved, and an extra economical benefit is further generated.

Owner:拜森生物环保科技(上海)有限公司

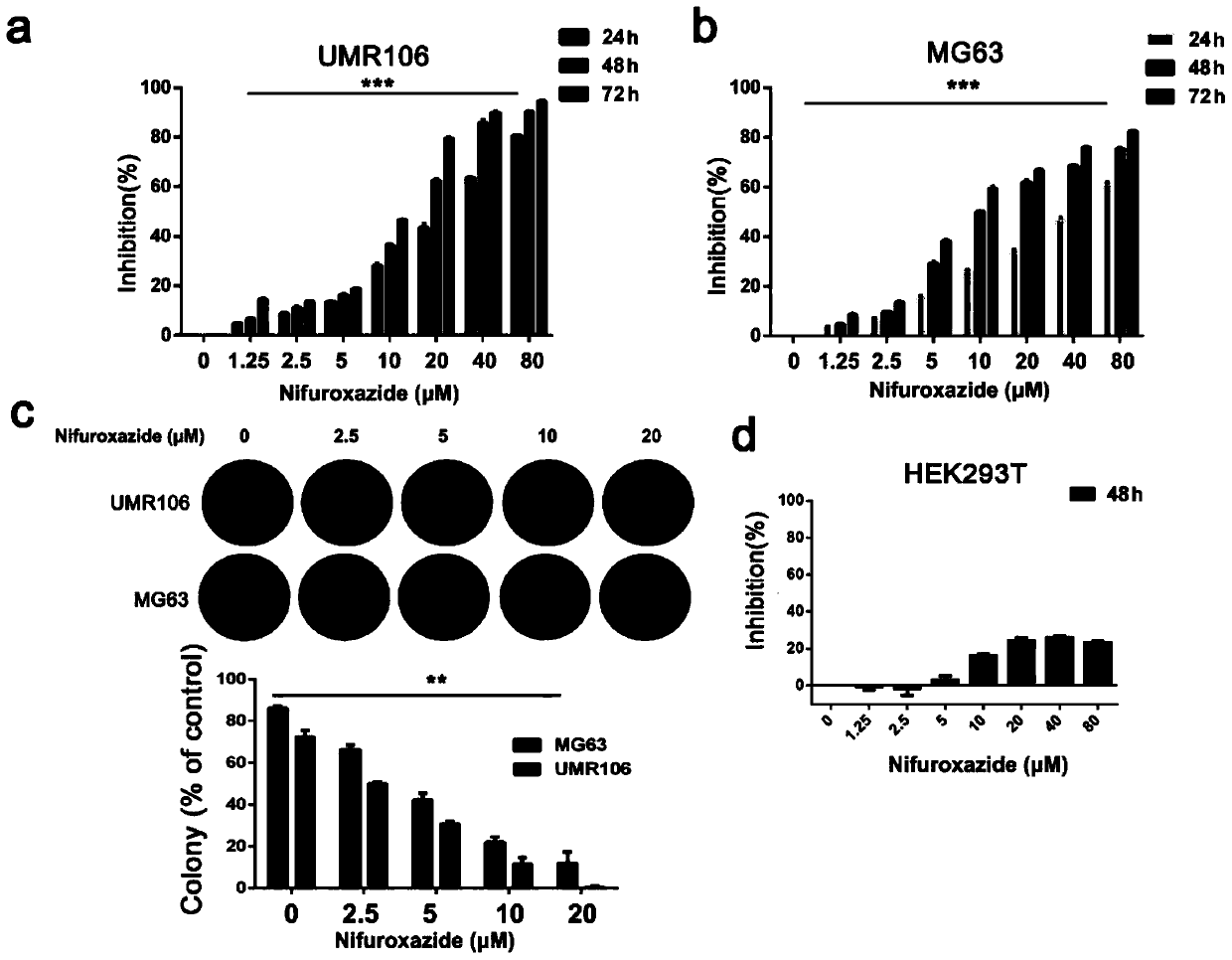

Application of nifuroxazide or salt thereof to treating osteosarcoma

InactiveCN109793729AGood industry prospectsOrganic active ingredientsAntineoplastic agentsDrugAnti-Tumor Drugs

The invention provides an antitumor medicine. Nifuroxazide and / or salt of the nifuroxazide are used as active components of the antitumor medicine, and pharmaceutically acceptable auxiliary componentsare added into the nifuroxazide and / or the salt to prepare the antitumor medicine. The invention further provides application of the nifuroxazide to preparing antitumor medicines. Preferably, tumor is osteosarcoma. The antitumor medicine and the application have the advantages that apoptosis of osteosarcoma cells can be effectively induced by the nifuroxazide and the salt of the nifuroxazide, osteosarcoma cell proliferation, migration and invasion can be inhibited by the nifuroxazide and the salt of the nifuroxazide, and obvious antitumor effects can be realized in an in-vivo manner; the nifuroxazide and / or the salt of the nifuroxazide can be used for preparing osteosarcoma medicines, and accordingly the antitumor medicine and the application have excellent industrial prospects.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

A biochar-containing composite iron ore pellet for microwave reduction and its preparation and application

The invention relates to the technical field of metallurgy, and particularly discloses a biochar-containing composite iron ore pellet for microwave reduction. The composite iron ore pellet comprises apellet core and a pellet shell wrapping the pellet core; the pellet core comprises iron ore powder 1, iron ore powder 2 and biochar; the pellet shell comprises iron ore powder 1; the specific surfacearea of the iron ore powder 1 is greater than or equal to 1656.0 cm<2> / g; and the specific surface area of the iron ore powder 2 is greater than or equal to 853.0 cm<2> / g. Preparation and applicationmethods of the pellet are also disclosed. The composite iron ore pellet has a core-shell structure, the biochar is only distributed on the pellet core, the two kinds of iron ore powder meet the particle size grading requirement in the pellet core, the ubiquitous problem that the performance indexes of a biochar-containing composite iron ore pellet green pellet are relatively poor can be synergistically solved, the microwave reduction performance of the pellet can be improved, and the iron grade, the metallization rate and the reducibility of the reduced metallized pellet are improved.

Owner:CENT SOUTH UNIV

Biochar-containing composite iron ore pellet for microwave reduction as well as preparation and application thereof

The invention relates to the technical field of metallurgy, and particularly discloses a biochar-containing composite iron ore pellet for microwave reduction. The composite iron ore pellet comprises apellet core and a pellet shell wrapping the pellet core; the pellet core comprises iron ore powder 1, iron ore powder 2 and biochar; the pellet shell comprises iron ore powder 1; the specific surfacearea of the iron ore powder 1 is greater than or equal to 1656.0 cm<2> / g; and the specific surface area of the iron ore powder 2 is greater than or equal to 853.0 cm<2> / g. Preparation and applicationmethods of the pellet are also disclosed. The composite iron ore pellet has a core-shell structure, the biochar is only distributed on the pellet core, the two kinds of iron ore powder meet the particle size grading requirement in the pellet core, the ubiquitous problem that the performance indexes of a biochar-containing composite iron ore pellet green pellet are relatively poor can be synergistically solved, the microwave reduction performance of the pellet can be improved, and the iron grade, the metallization rate and the reducibility of the reduced metallized pellet are improved.

Owner:CENT SOUTH UNIV

A nanocomposite mg2ge/mg3sb2 thermoelectric material and its preparation method

ActiveCN106531879BPrevent oxidationShort processing cycleMaterial nanotechnologyThermoelectric device manufacture/treatmentPhysical chemistryElectric properties

The invention discloses a Mg2Ge / Mg3Sb2 thermoelectric material with a nanocomposite structure and a preparation method thereof. The thermoelectric material is composed of a Mg3Sb2 matrix phase and a Mg2Ge nanophase, wherein the Mg2Ge nanophase is dispersed in the Mg3Sb2 matrix phase, and the size of the Mg2Ge is 10- 20nm. The present invention prepares thermoelectric materials by melting, melt spinning and sintering combined with discharge plasma sintering. The obtained thermoelectric material belongs to p-type thermoelectric material, which increases phonon scattering, greatly reduces thermal conductivity, and improves Seebeck coefficient. It has good thermoelectric performance.

Owner:UNIV OF JINAN

A kind of Lactobacillus plantarum expressing antimicrobial peptide gene

ActiveCN111333713BHigh expressionPromote healthy developmentAntibacterial agentsBacterial antigen ingredientsBiotechnologyNucleotide

Owner:JIANGNAN UNIV

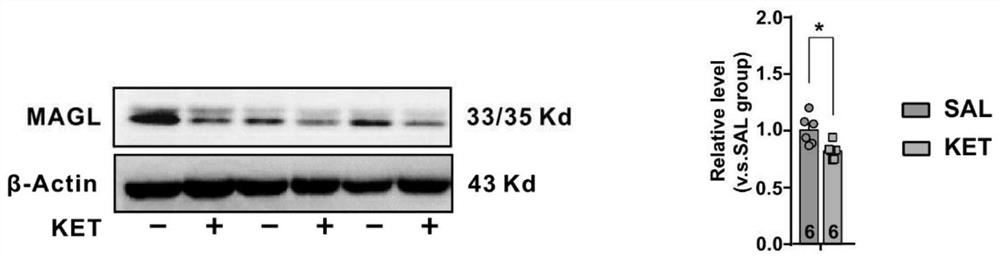

Medicine for treating ketamine addiction

ActiveCN113577311AAddiction reductionGood industry prospectsNervous disorderPharmaceutical delivery mechanismAddiction medicineAddictions drugs

The invention discloses a medicine for treating ketamine addiction, and belongs to the field of anti-addiction medicines. The invention discloses a medicine for treating ketamine addiction. The medicine takes a substance for improving the expression of a Mgll gene as an active ingredient. The invention provides an effective solution for ketamine addiction, and has good industrial prospect and public benefit value.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com