Travelling wave driven prezoelectric ceramic pump capable of realizing forward-reverse fluid flow

A piezoelectric ceramic pump and fluid flow technology, used in pumps, machines/engines, liquid variable capacity machines, etc., can solve problems such as single means, and achieve the effects of safe and reliable work, reduced mechanical wear, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

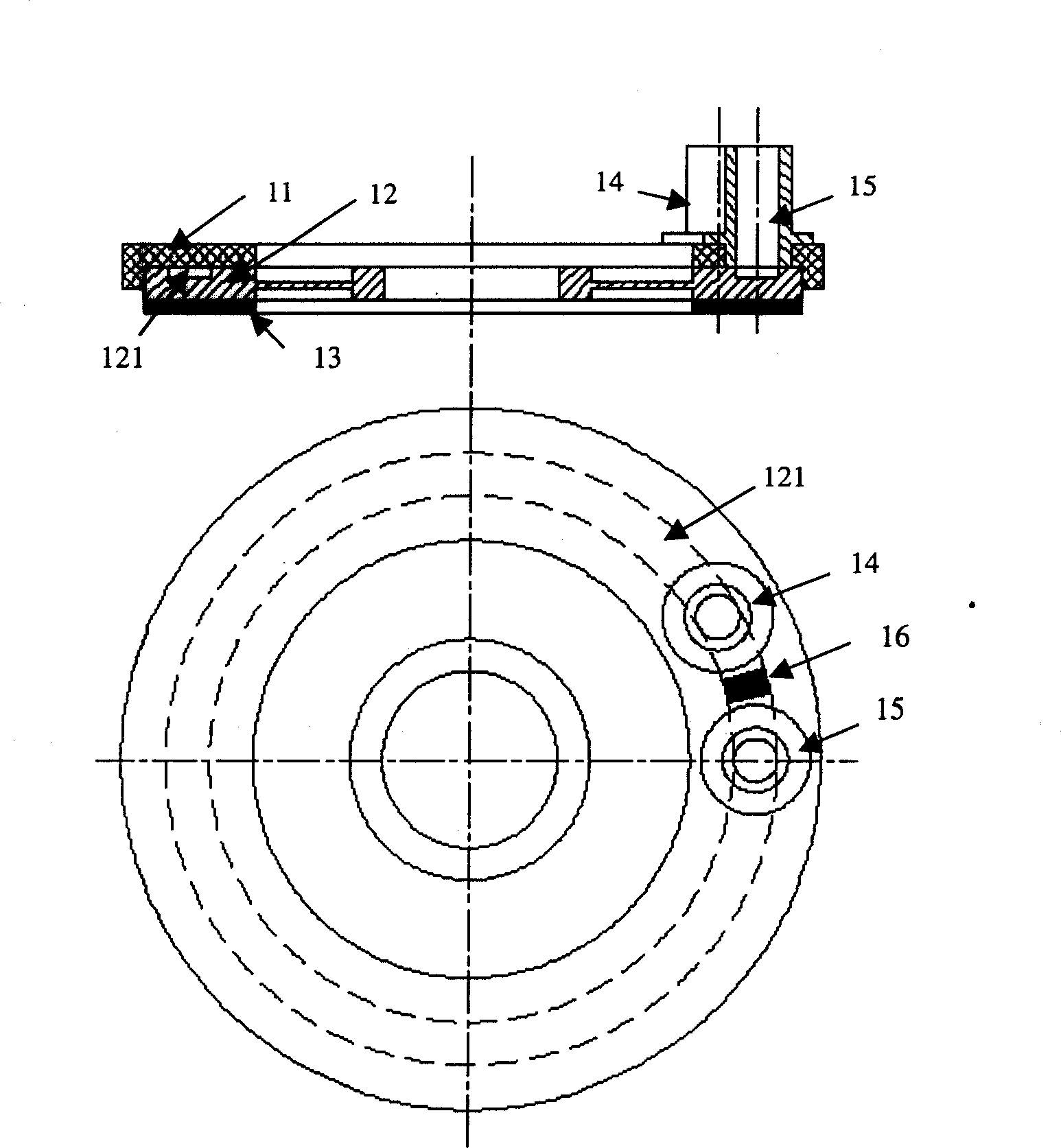

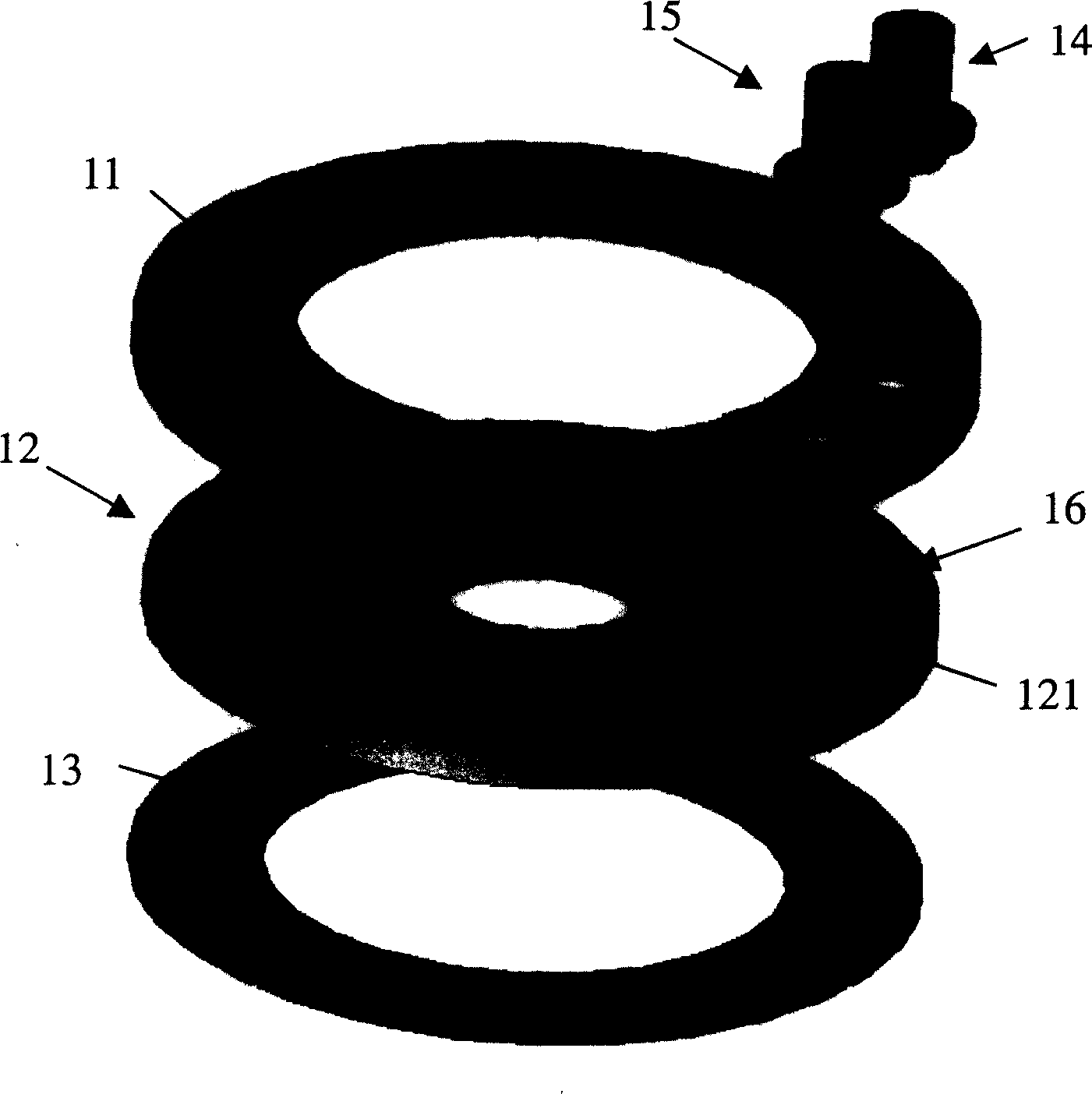

[0056] The present invention has designed the first embodiment of the traveling wave driven piezoelectric ceramic pump, such as Figure 1-6 shown. In this embodiment, the traveling-wave driven fluid piezoelectric pump is connected to the pump body 12 by the pump cover 11 with the inlet port 14 and the outlet port 15, and the bottom end of the pump body 12 is bonded with a piezoceramic ring piece 13. A block 16 is disposed in the groove 121 . It is characterized in that: on the upper side of the outer circumference of the pump body 12, there are circumferentially distributed grooves 121, the cross section of the groove is rectangular, the three end faces of the rectangle rely on the pump body 12, and the upper end faces rely on the pump cover 11 for sealing. On the lower side of the outer circumference of the pump body 12, a piezoelectric ceramic ring piece 13 is adhered. The inlet port 14 and the outlet port 15 are glued and fixed on the same side of the pump cover 11, and t...

Embodiment 2

[0061] The present invention has designed the second embodiment of the traveling wave driven piezoelectric ceramic pump, as Figure 7-8 shown. In this embodiment, the traveling-wave driven fluid piezoelectric pump is connected to the pump body 72 by a pump cover 71 with an inlet port 74 and an outlet port 75. The bottom end of the pump body 72 is bonded with a piezoelectric ceramic ring piece 73. A block 76 is disposed in the groove 721 . It is characterized in that: there are circumferentially distributed grooves 721 on the upper side of the outer circumference of the pump body 72 , the cross section of the groove is rectangular, the three ends of the rectangle rely on the pump body 72 , and the upper end faces rely on the pump cover 71 for sealing. On the lower side of the outer circumference of the pump body 72, a piezoelectric ceramic ring piece 73 is adhered. The inlet port 74 and the outlet port 75 are glued and fixed on the same side of the pump cover 71, and the inle...

Embodiment 3

[0065] The present invention has designed the third embodiment of the traveling wave driven piezoelectric ceramic pump, as Figure 9-10 shown. In this embodiment, the traveling-wave driven fluid piezoelectric pump is connected to the pump body 92 by the pump cover 91 with the inlet port 94 and the outlet port 95, and the bottom end of the pump body 92 is bonded with a piezoelectric ceramic ring piece 93. A block 96 is disposed in the groove 921 . It is characterized in that: there are circumferentially distributed grooves 921 on the upper side of the outer circumference of the pump body 92 , the cross section of the groove is rectangular, the two end faces of the rectangle rely on the pump body 92 , and the other two end faces rely on the pump cover 91 for sealing. A piezoceramic ring sheet 93 is glued to the lower side of the outer circumference of the pump body 92 . The inlet port 94 and the outlet port 95 are glued and fixed on the same side of the pump cover 91, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com