Nano-copper powder and application thereof to preparation of automobile decorative cloth

A technology of nano-copper powder and bivalent copper, applied in the field of nano-copper powder, can solve the problems of unfavorable large-scale industrial application, complex and tedious preparation conditions, restricting application prospects, etc., and achieves good sterilization effect, easy industrialization, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Add 17.05g of copper chloride dihydrate to 50ml of deionized water to prepare a 0.5mol / L solution, then add 0.1g of sodium dodecylbenzenesulfonate to dissolve evenly to obtain a mixed solution.

[0024] The second step: the temperature of the above mixed solution is raised to 60° C. and kept at a constant temperature.

[0025] Step 3: Add 0.15 g of hydrazine hydrate dropwise into the above mixed solution, and stir under a high-speed shear (5000 rpm), and apply ultrasonic waves (ultrasonic power 100 W, ultrasonic frequency 40 kH). After the reaction was carried out for 4 hours, the stirring and ultrasonication were stopped, and the mixture was cooled to room temperature and left to stand.

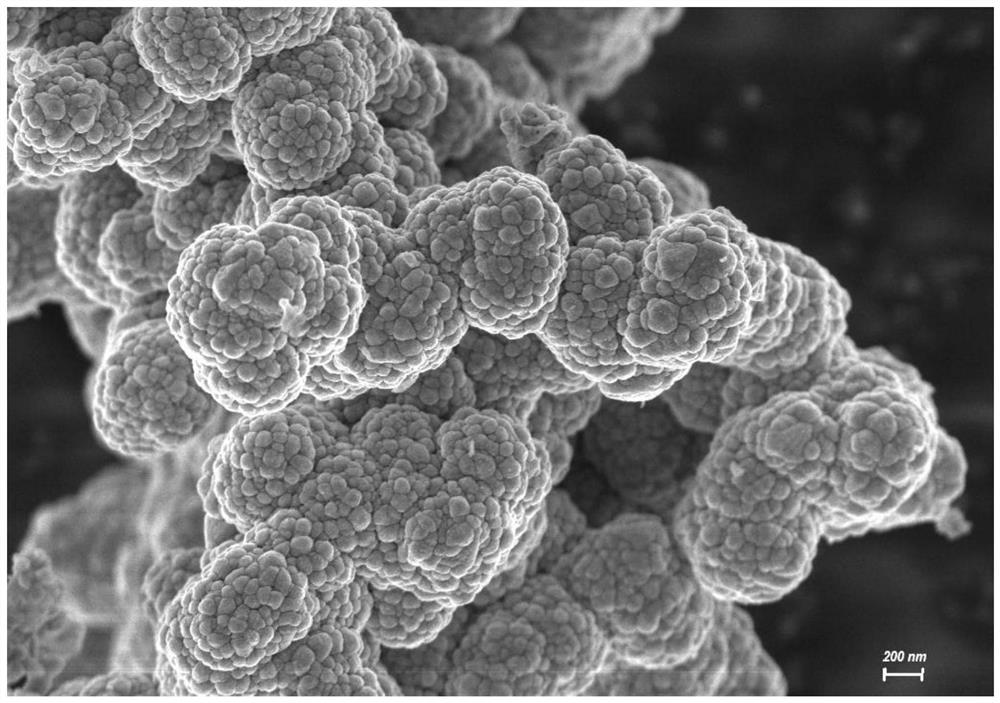

[0026] Step 4: After standing still, the solution is centrifuged through a high-speed centrifuge (10,000 rpm) and washed 3 times with deionized water, and then the nano-copper slurry is dried by a freeze dryer (-80° C.) for 24 hours to obtain nano-copper powder. SEM picture o...

Embodiment 2

[0029] Step 1: Take 1.705g of copper chloride dihydrate and add it to 100ml of deionized water to prepare a 0.1mol / L solution, then add 0.05g of sodium hydroxymethylcellulose to dissolve evenly to obtain a mixed solution.

[0030] Step 2: raise the temperature of the above mixed solution to 80° C. and keep it at a constant temperature.

[0031] Step 3: Add 0.2 g of hydrazine hydrate dropwise into the above mixed solution, and stir under a high-speed shearing machine (5000 rpm), while applying ultrasonic waves (ultrasonic power 100 W, ultrasonic frequency 40 kH). After the reaction was carried out for 10 hours, the stirring and ultrasonication were stopped, and the mixture was cooled to room temperature and allowed to stand.

[0032] Step 4: After standing still, the solution is centrifuged by a high-speed centrifuge (10000 rpm), washed with deionized water for 3 times, and then the nano-copper slurry is dried by a freeze dryer (-80° C.) for 24 hours to obtain nano-copper powde...

Embodiment 3

[0035] Step 1: Add 8.525g of copper chloride dihydrate to 50ml of deionized water to prepare a 0.25mol / L solution, then add 0.05g of sodium dodecylbenzenesulfonate to dissolve evenly to obtain a mixed solution.

[0036] The second step: the temperature of the above mixed solution is raised to 95° C. and kept at a constant temperature.

[0037] Step 3: Add 0.4 g of sodium borohydride dropwise into the above mixed solution, and stir under a high-speed shear (5000 rpm), while applying ultrasonic waves (ultrasonic power 100 W, ultrasonic frequency 40 kH). After the reaction was carried out for 16 hours, the stirring and ultrasonication were stopped, and the mixture was cooled to room temperature and left standing.

[0038] Step 4: After standing still, the solution is centrifuged by a high-speed centrifuge (10000 rpm), washed with deionized water for 3 times, and then the nano-copper slurry is dried by a freeze dryer (-80° C.) for 24 hours to obtain nano-copper powder.

[0039] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com