Alumina supported type cerium oxide powder material preparation method

A technology of ceria and powder materials, which is applied in the field of material processing engineering, can solve problems such as toxic liquid waste, poor dispersion effect, complex influence of precursors and solutions, etc., to improve product reliability, reduce production costs, The effect of good industry prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

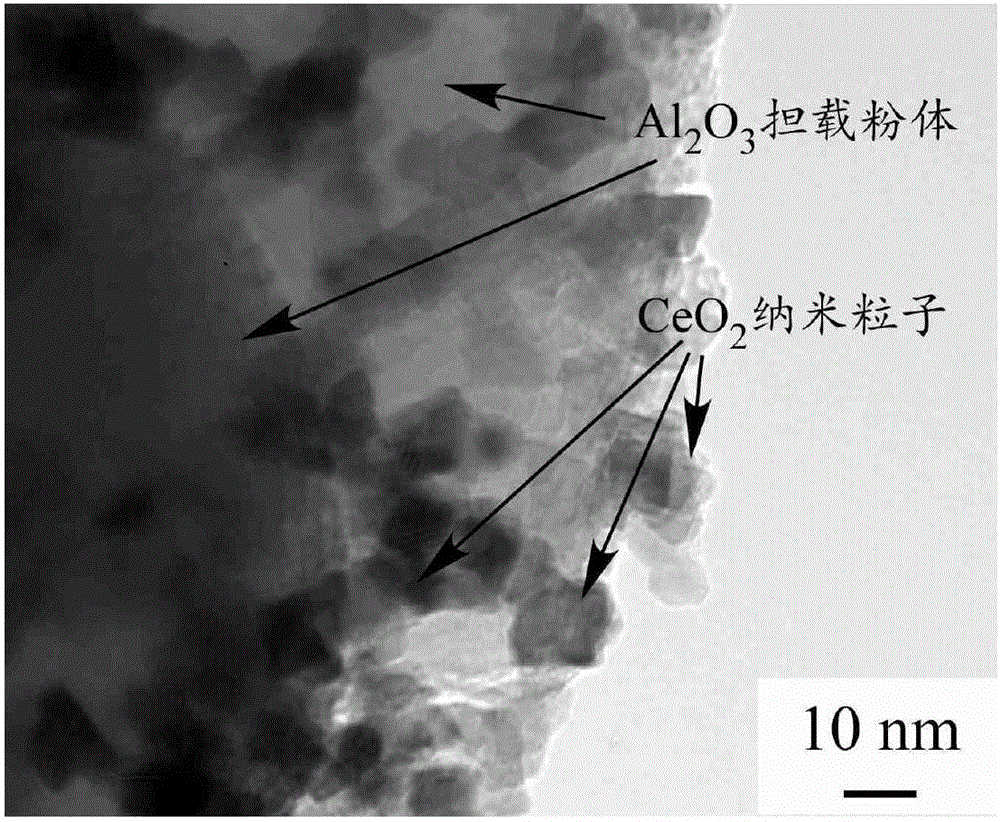

Image

Examples

Embodiment 1

[0024] The invention provides a method for preparing an alumina-supported ceria powder material. The preparation steps are as follows:

[0025] (1) Ce(DPM) 4 As 1g of organic raw material, heated to 250°C in an evaporator;

[0026] (2) 5gAl 2 o 3 Powder (Al 2 o 3 The average particle size of the powder is 100 μm, the purity is not less than 95%) and dried at 80°C for 2 hours, and then the processed Al 2 o 3 The powder is placed in the chemical vapor deposition reaction chamber, vacuumed to 7Pa, preheated at a heating rate of 10°C / min and raised to 500°C;

[0027] (3) feed the mixed gas of oxygen, argon and evaporated raw material in the rotary reactor, the flow of argon gas is 100sccm, the flow of oxygen gas is 10sccm, then adjust the pressure in the reaction chamber, the total pressure is 200Pa, wherein the partial pressure of oxygen is 50Pa. During the coating process, the temperature was 600°C, the reactor speed was 45rpm, and the temperature was kept for 0.5h, so t...

Embodiment 2

[0032]The invention provides a method for preparing an alumina-supported ceria powder material. The preparation steps are as follows:

[0033] (1) Ce(DPM) 4 As organic raw material 3g, heated to 100°C in an evaporator;

[0034] (2) 5gAl 2 o 3 Powder (Al 2 o 3 The average particle size of the powder is 50 μm, and the purity is not less than 95%), which is pretreated by drying at 80°C for 2 hours, and then the processed Al 2 o 3 The powder is placed in the chemical vapor deposition reaction chamber, evacuated to 5Pa, and the temperature is raised to 600°C at a preheating rate of 2°C / min;

[0035] (3) feed the mixed gas of oxygen, argon and evaporated raw material in the rotary reactor, the flow of argon gas is 100sccm, the flow of oxygen gas is 10sccm, then adjust the pressure in the reaction chamber, the total pressure is 500Pa, wherein the partial pressure of oxygen is 100Pa. During the coating process, the temperature was 600 ° C, the reactor speed was 45 rpm, and the...

Embodiment 3

[0040] The invention provides a method for preparing an alumina-supported ceria powder material. The preparation steps are as follows:

[0041] (1) Ce(DPM) 4 As 10g of organic raw material, heated to 100°C in an evaporator;

[0042] (2) 5gAl 2 o 3 Powder (Al 2 o 3 The average particle size of the powder is 10 μm, and the purity is not less than 95%), which is dried at 80°C for 2 hours, passed through a 100-mesh sieve for 3 pretreatments, and then the processed Al 2 o 3 The powder is placed in the chemical vapor deposition reaction chamber, evacuated to 5Pa, preheated and heated at a rate of 5°C / min to 600°C;

[0043] (3) feed the mixed gas of oxygen, argon and evaporated raw material in the rotary reactor, the flow of argon gas is 100sccm, the flow of oxygen gas is 10sccm, then adjust the pressure in the reaction chamber, the total pressure is 1000Pa, wherein the partial pressure of oxygen is 300Pa. During the coating process, the temperature was 800°C, the reactor spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com