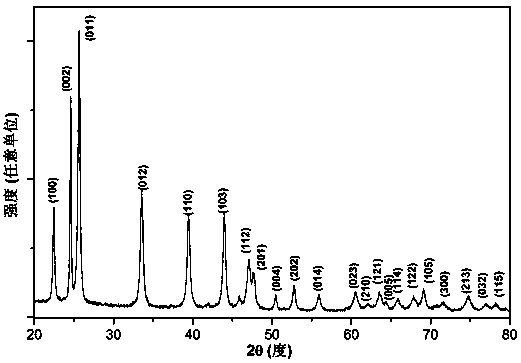

A nanocomposite mg2ge/mg3sb2 thermoelectric material and its preparation method

A thermoelectric material and nano-composite technology, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, nanotechnology, etc., can solve the problems that the preparation process of nano-composite enhanced thermoelectric merit has never been reported, and achieve the preparation process Short period, prevent oxidation of magnesium, increase the effect of phonon scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Use high-purity (99.99%) magnesium particles (Mg), antimony particles (Sb) and germanium particles (Ge) as initial raw materials in a vacuum glove box, according to Mg 2 Ge weight percentage of Mg 2 Ge / Mg 3 Sb 2 1.5% of the composite material is mixed, the total weight is 50g, after weighing, put it into a boron nitride crucible with a lid, and then package the whole crucible into a quartz glass tube, the packaging atmosphere is Ar gas, and the quartz tube is sealed with argon gas The air pressure is 0.2 atmospheres. Put the quartz tube with the crucible into the vertical tube furnace for melting, the melting temperature is 880℃, the heating rate is 90℃ / h, after holding for 2h, it is quenched in 12% normal temperature brine, and then at 580℃ Anneal at the temperature for 24h to obtain a master alloy. Put the prepared master alloy into a quartz tube with a tip size of 0.4mm, heat it to 900-950°C and smelt it into a melt, then spin the melt to obtain a series of ribbon-sha...

Embodiment 2

[0042] Use high-purity (99.99%) magnesium particles (Mg), antimony particles (Sb) and germanium particles (Ge) as initial raw materials in a vacuum glove box, according to Mg 2 Ge weight percentage of Mg 2 Ge / Mg 3 Sb 2 1.0% of the composite material is mixed, the total weight is 50g, after weighing, put it into a boron nitride crucible with a lid, and then package the whole crucible into a quartz glass tube, the packaging atmosphere is Ar gas, and the quartz tube is sealed with argon gas The air pressure is 0.25 atmospheres. Put the quartz tube with the crucible into the vertical tube furnace for melting, the melting temperature is 890℃, the heating rate is 100℃ / h, after keeping it for 3h, it is quenched in brine, and then annealed at 580℃ for 24h to obtain the mother alloy. Put the prepared master alloy into a quartz tube with a tip size of 0.5mm, heat it to 900-950℃ to melt into a melt, and then spin the melt to obtain a series of ribbon-shaped products, the thickness of the ...

Embodiment 3

[0045] Use high-purity (99.99%) magnesium particles (Mg), antimony particles (Sb) and germanium particles (Ge) as initial raw materials in a vacuum glove box, according to Mg 2 Ge weight percentage of Mg 2 Ge / Mg 3 Sb 2 Mix 2.0% of the composite material, the total mass is 50g, after weighing, put it into a boron nitride crucible with a lid, and then package the whole crucible into a quartz glass tube, the packaging atmosphere is Ar gas, and the quartz tube is sealed with argon gas The air pressure is 0.2 atmospheres. Put the quartz tube with the crucible into the vertical tube furnace for melting, the melting temperature is 900℃, the heating rate is 110℃ / h, after keeping it for 3h, it is quenched in brine, and then annealed at 580℃ for 24h to obtain the mother alloy. Put the prepared master alloy into a quartz tube with a sharp nozzle size of 0.6mm, heat it to 900-950℃ to melt into a melt, and then spin the melt to obtain a series of ribbon-shaped products, the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com