Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Excellent low temperature adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt waterproof paint for building and preparation method thereof

InactiveCN101921545AUnique performanceImprove performanceUnspecified rubber coatingsBituminous coatingsChemical industryBituminous waterproofing

The invention relates to an asphalt waterproof paint for a building and a preparation method thereof, belonging to the technical field of chemical industry. The asphalt waterproof paint for a building comprises the following raw materials according to parts by weight: 20-25 parts of plasticizer, 6-8 parts of modifier, 25-30 parts of asphalt, 20-30 parts of filler, 4-6 parts of tackifier, 0.2-0.3 parts of crosslink coupling agent, and 0.3-0.5 parts of dispersing agent. The invention has the advantages of reasonable compound design, good intensity, safety, environmental protection and stable product quality, and is capable of adapting the climatic conditions at high and low temperatures.

Owner:嘉兴市博豪家纺有限公司

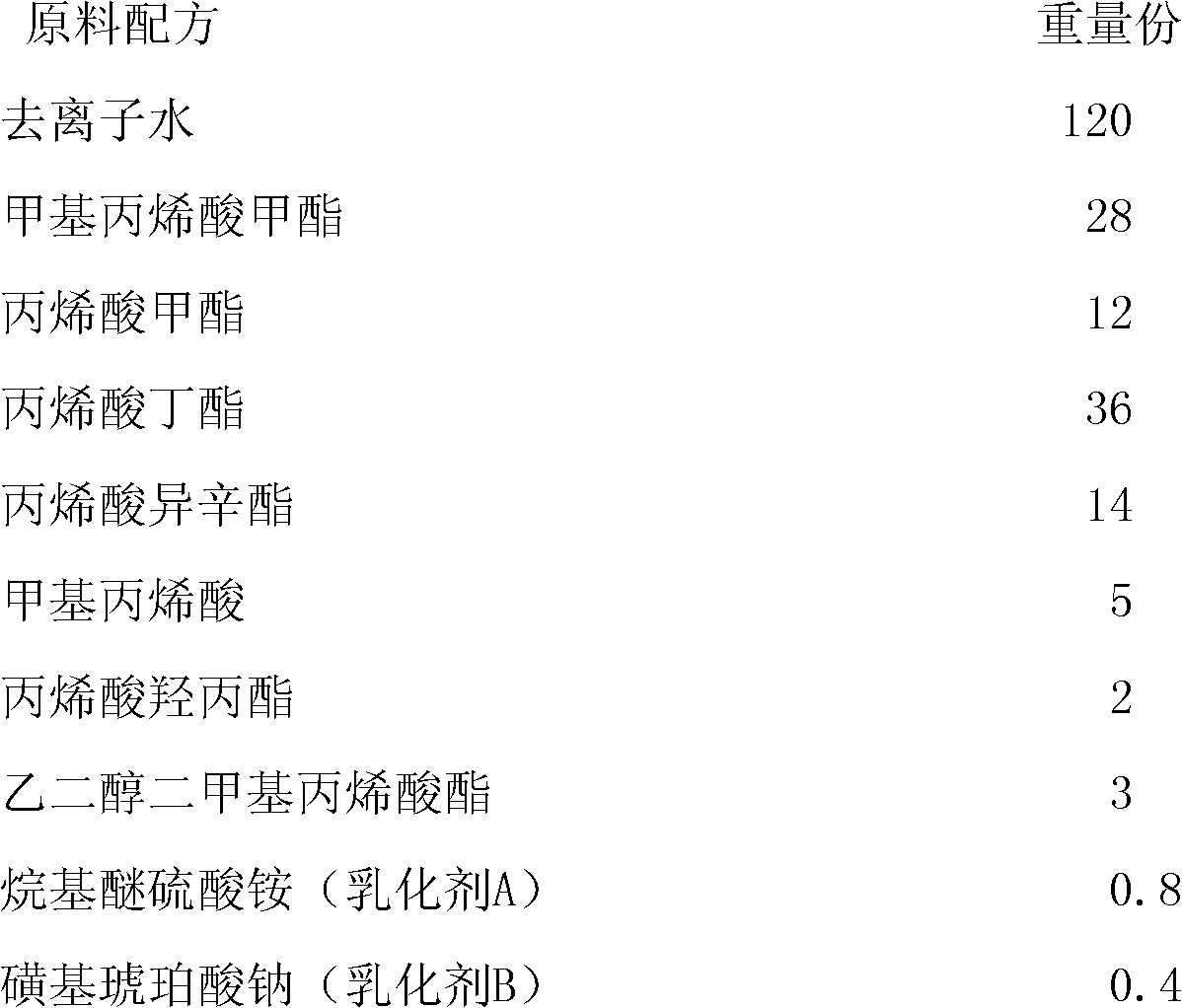

Water-based polyacrylic emulsion laminating adhesive and preparation method thereof

InactiveCN102140320AReduce the amount addedImprove initial tack performanceEster polymer adhesivesWater basedFunctional monomer

The invention discloses a water-based polyacrylic emulsion laminating adhesive and a preparation method thereof, which belong to the field of adhesives. The laminating adhesive with solid content of between 40 percent and 50 percent is prepared from raw materials of monomers, an emulsifier, an initiator, a buffering agent, a pH regulator, a waterborne aid and deionized water by adopting steps of pre-emulsification, seed reaction, polymerization and compounding, wherein the monomers include a hard monomer, a soft monomer and a functional monomer containing -COOH and -OH groups; the emulsifier consists of alkyl ether ammonium sulfate, sulpho sodium succinate and allyloxyl alkyl sodium sulfonate in the ratio of 2:1:(0.4-0.8); and the waterborne aid comprises a waterborne wetting agent, a waterborne defoaming agent and a waterborne preservative. The allyloxyl alkyl sodium sulfonate serving as a reactive emulsifier is introduced into the laminating adhesive, so that the influence of the migration of emulsifier micromolecules onto a paper / plastic interface is reduced, and initial adhesion and bonding strength are enhanced; and the functional monomer containing the -COOH and -OH groups is introduced, so that the bonding strength is enhanced, and the low-temperature adhesive property and ink affinity are improved.

Owner:NANTONG GAOMENG NEW MATERIAL

Polyimide resin composition, adhesive agent and laminate each comprising same, and device

InactiveCN102712755AImprove heat resistanceExcellent low temperature adhesionFinal product manufactureSemiconductor/solid-state device detailsAcid anhydrideSilicone

A polyimide resin composition containing a polyimide produced by fusing a diamine component comprising an aromatic diamine (A) represented by general formula (1-1) or the like, a silicone diamine (B) represented by general formula (2) and an aliphatic diamine (C) represented by general formula (3) to an acid anhydride component comprising a specific aromatic tetracarboxylic acid dianhydride (D); a laminate produced using the polyimide resin composition; and a device.

Owner:MITSUI CHEM INC

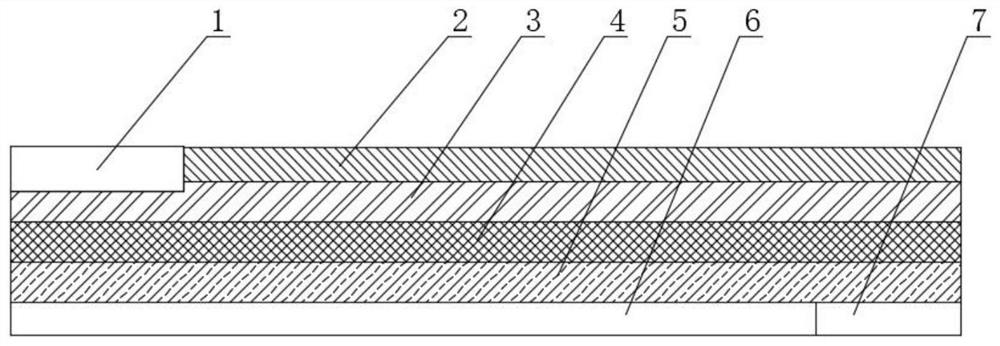

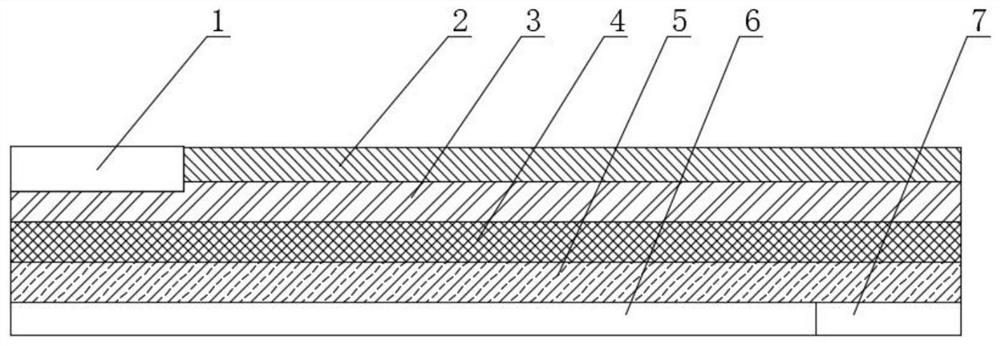

Super strong cross laminated film self-adhesive waterproof coiled material and preparation process thereof

ActiveCN111805994AImprove physical performanceHigh tensile strengthNon-macromolecular adhesive additivesSynthetic resin layered productsPolymer scienceAdhesive

The invention relates to a super strong cross laminated film self-adhesive waterproof coiled material which sequentially comprises an isolation protection layer, a non-asphalt-based self-adhesive layer, a strong cross laminated film, an asphalt self-adhesive layer and a PE isolation film from top to bottom, one side of the upper surface of the coiled material is a lap joint edge, and the other side of the lower surface of the coiled material is also provided with a lap joint edge. The bonding performance of the waterproof coiled material provided by the invention and post-cast concrete is better than that of an asphalt-based coiled material; the waterproof coiled material can be better bonded with a main body structure (namely a pre-laid reverse-bonding coiled material), the strong cross laminated film in the middle of the coiled material has good ductility, the coiled material can still be well bonded with the main body structure when a base layer slightly sinks or the main body structure slightly deforms, the coiled material cannot be separated, and a good waterproof effect can be achieved.

Owner:TIANJIN JOABOA TECH CO LTD

Expansible rehumidified adhesive and its preparing method

InactiveCN1966598AExcellent low temperature adhesionHigh bonding strengthAmide/imide polymer adhesivesEster polymer adhesivesAdhesive cementPolymer science

The invention disclosed a kind of inflatable re-wet mastic the ingredient of which is cross-link copolymer (the solid content of the copolymer is 20-50%). The copolymer refers to the cross-link copolymer of non-ion metamer and positive ion metamer, the cross-link copolymer of non-ion metamer and negative ion metamer or the mixture of the two copolymers, the aqueous mediator and the oily mediator. The mastic in the invention has good gluing ability at low temperature; it also has strong initial cohesity, quick moistening back-glue speed; it takes less than 35 seconds to reach strong gluing ability; it has very good stability and expandibility, the volume can be expanded by 25 times so it can compensate the damage because of the coarse surface; it can be used in various aspects such as wall paper, ads, labels, stamps, envelop sealing and so on.

Owner:SOUTH CHINA UNIV OF TECH

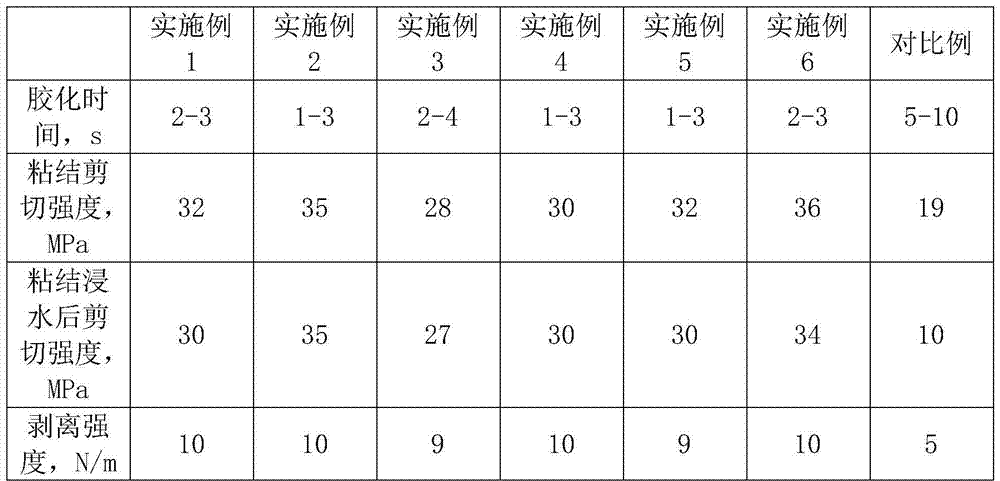

Instant adhesive

InactiveCN102994022AExcellent low temperature adhesionLow priceNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceDistillation

The invention discloses an instant adhesive. The instant adhesive is prepared from the following raw materials: polymethyl methacrylate, ethyl cyanoacetate, 30-35% formaldehyde, piperidine, dichloroethane, a hydroquinone polymerization inhibitor and modified sepiolite. The instant adhesive is prepared by the following steps of: based on parts by weight, mixing the polymethyl methacrylate, the piperidine, the ethyl cyanoacetate and the 35% formaldehyde and then adding the obtained mixture into a reaction kettle to react for 1 hour at 70 DEG C when heated; and then adding the hydroquinone polymerization inhibitor, the modified sepiolite and the dichloroethane for reduced pressure distillation at 180 DEG C. The instant adhesive disclosed by the invention is an adhesive which has single component and is instantly cured on meeting moisture, and is convenient to use, the adhered surface needs no special pretreatment, heating and pressurizing are not necessary, and the adhesive is widely applied to the adhesion and location between plastics, and between the plastic and metal, is water-fast, cannot be combusted, is good in low-temperature adhesion property, and is low in cost.

Owner:ANHUI DONGFANGJINHE PRECISION MACHINERY MFG +1

Anti-stripping cyanoacrylate adhesive and preparation method thereof

ActiveCN105315933AImprove impact resistanceImprove anti-stripping performanceNon-macromolecular adhesive additivesProtein adhesivesEthyl cyanoacrylateGelatin

The invention discloses an anti-stripping cyanoacrylate adhesive. The anti-stripping cyanoacrylate adhesive is prepared from, by weight, 30-50 parts of alpha-ethyl cyanoacrylate, 0.5-4 parts of EVA, 2-5 parts of beta-propiolactone, 0.5-1 part of modified titanium oxide, 8-12 parts of gelatin, 5-10 parts of polyacrylate, 2-8 parts of galactomannan, 3-8 parts of hydroxyethyl cellulose and 1-1.5 parts of coupling agent. The invention further discloses a preparation method of the anti-stripping cyanoacrylate adhesive. The anti-stripping cyanoacrylate adhesive is high in curing speed, good in water resistance, high in impact resistance, large in bonding strength, good in anti-stripping performance, small in use amount, free of toxicity and beneficial to environmental protection.

Owner:ZHEJIANG TIME NEW MATERIAL

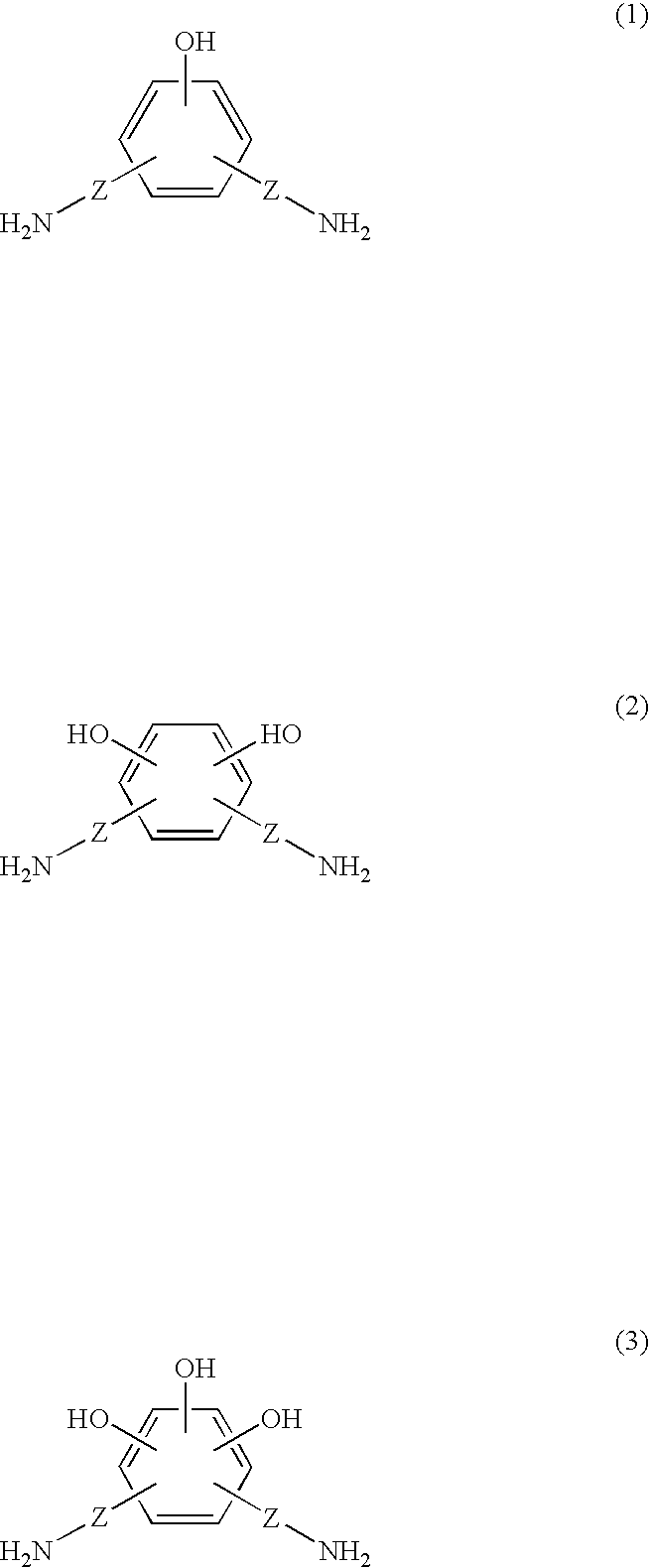

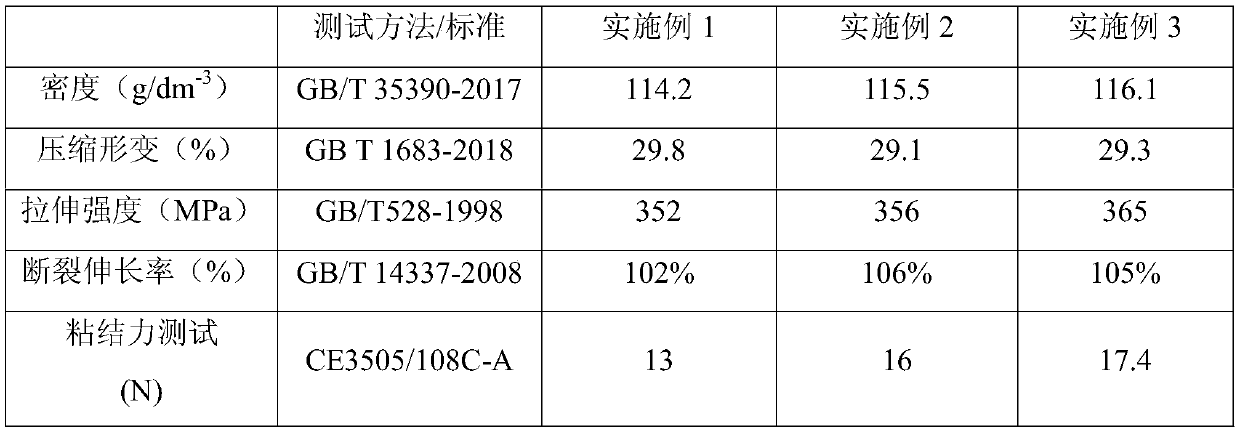

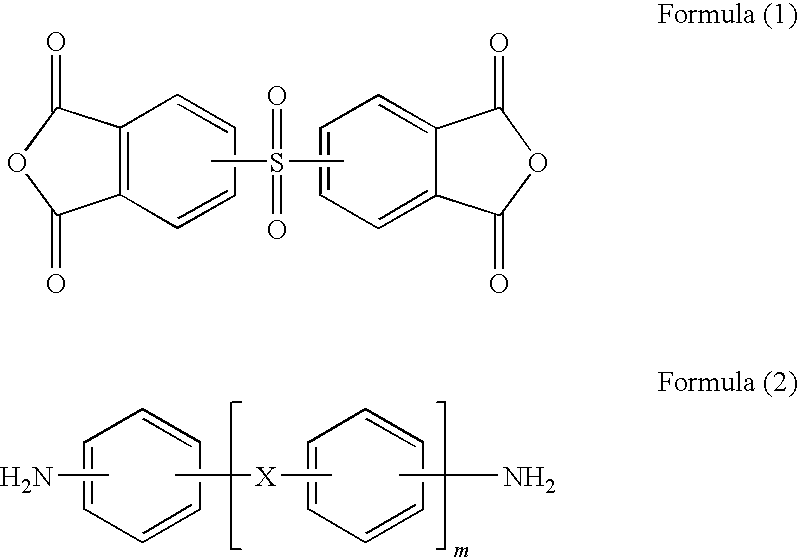

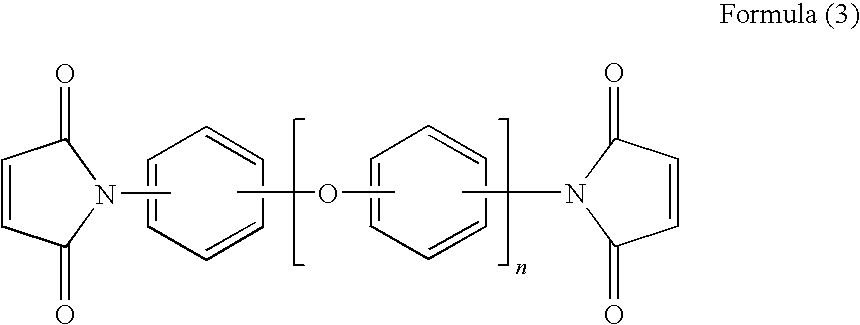

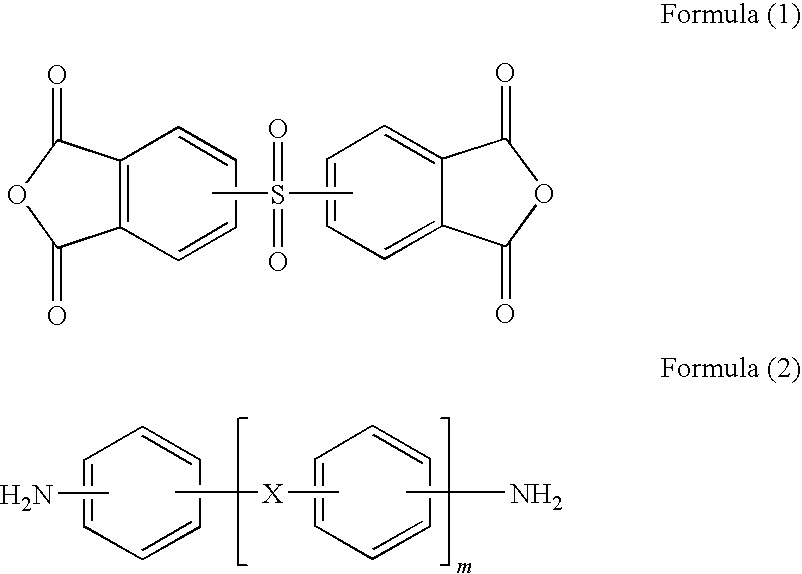

Resin composition and metal laminate plate

InactiveUS20090075103A1Excellent low temperature adhesionEasy to disassembleSynthetic resin layered productsElectrical equipmentDiamineMetal

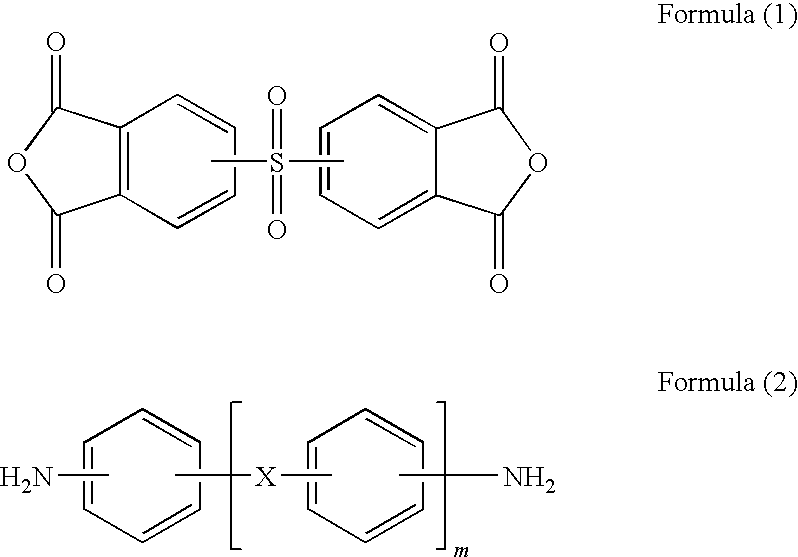

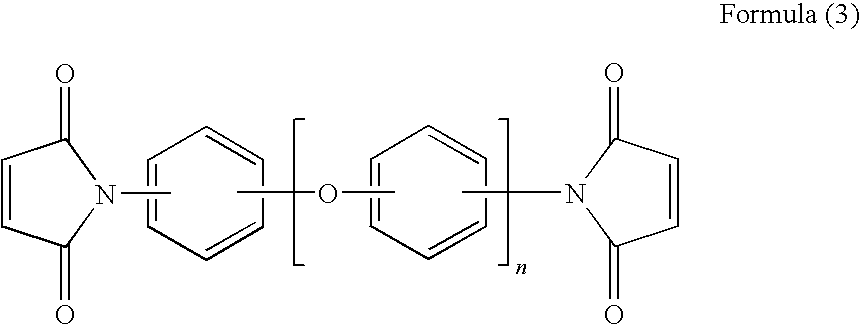

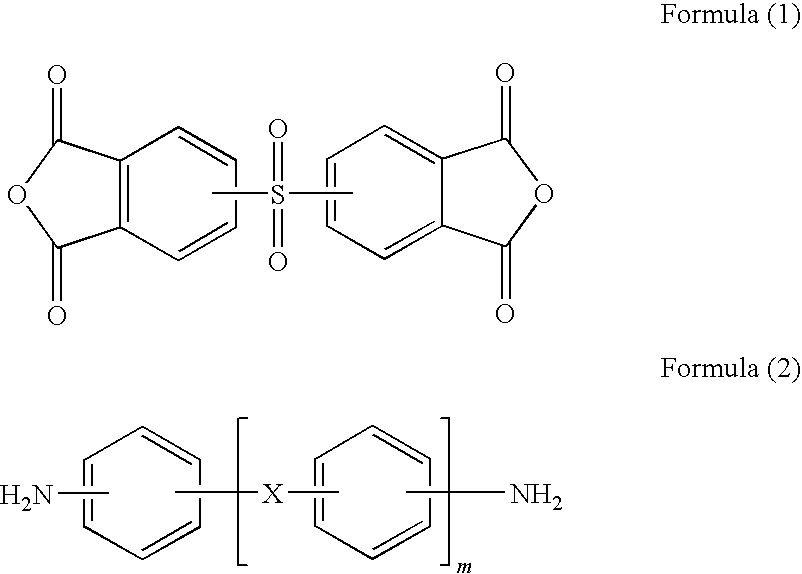

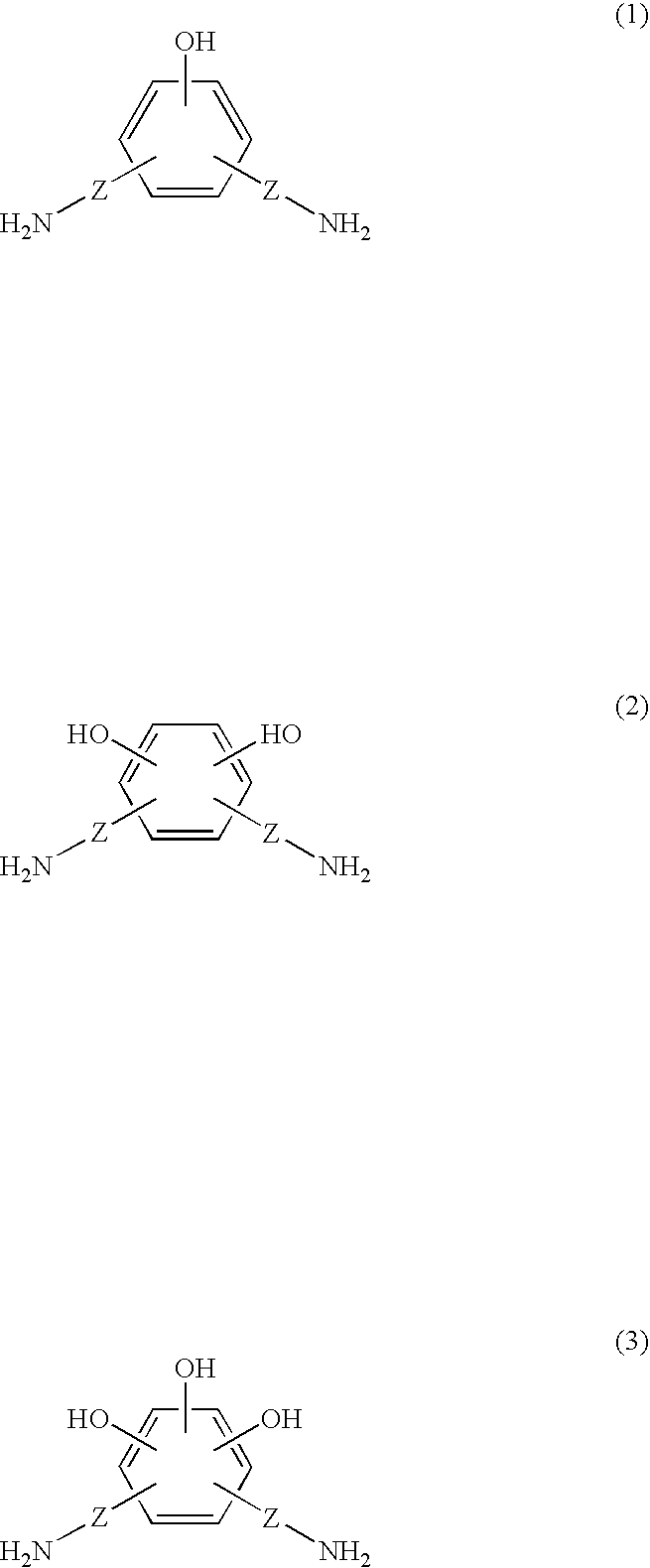

A resin composition comprises a polyimide resin composition or precursor thereof obtained from an acid dianhydride component containing a compound represented by the following Formula (1) and a diamine component containing a diamine compound represented by the following Formula (2), and a bismaleimide compound represented by the following Formula (3),wherein the diamine component contains a diamine compound (a) in which m in the Formula (2) represents an integer of 0 or 1 and a diamine component (b) in which m in the Formula (2) represents an integer of 2 to 6 in a molar ratio (a:b) of from 100:0 to 50:50,wherein, in the Formula (2), when m is 2 or more, each X may be independently the same or different, and represents O, SO2, S, CO, CH2, C(CH3)2, C(CF3)2 or a direct bond,wherein, in the Formula (3), n represents an integer of 0 to 6.

Owner:MITSUI CHEM INC

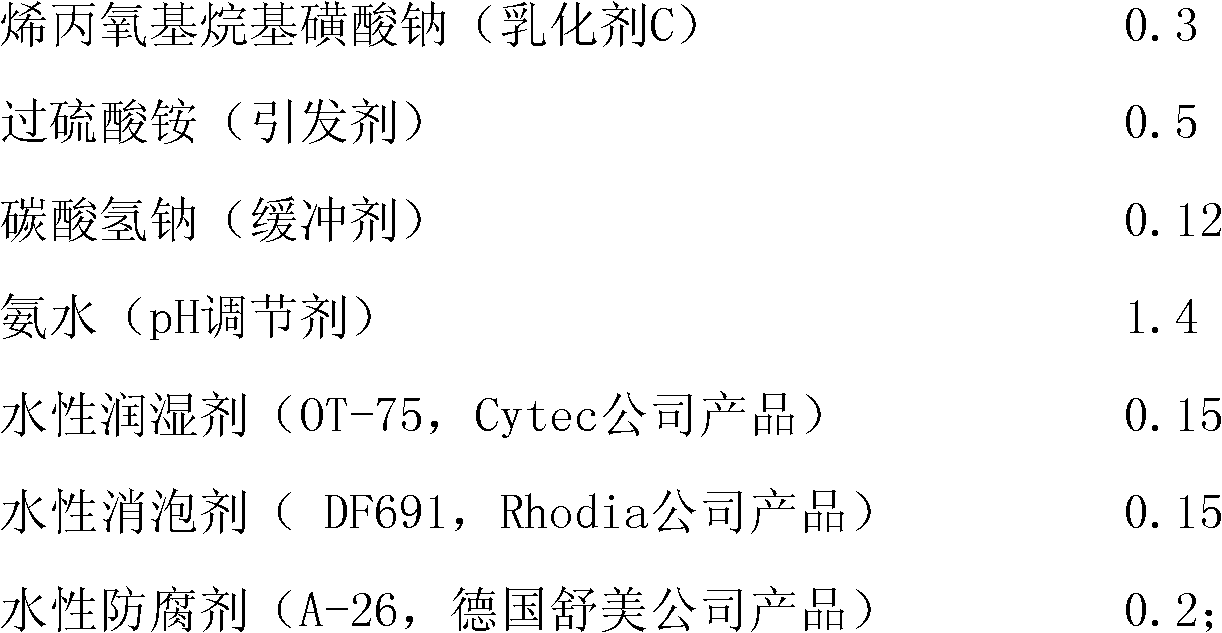

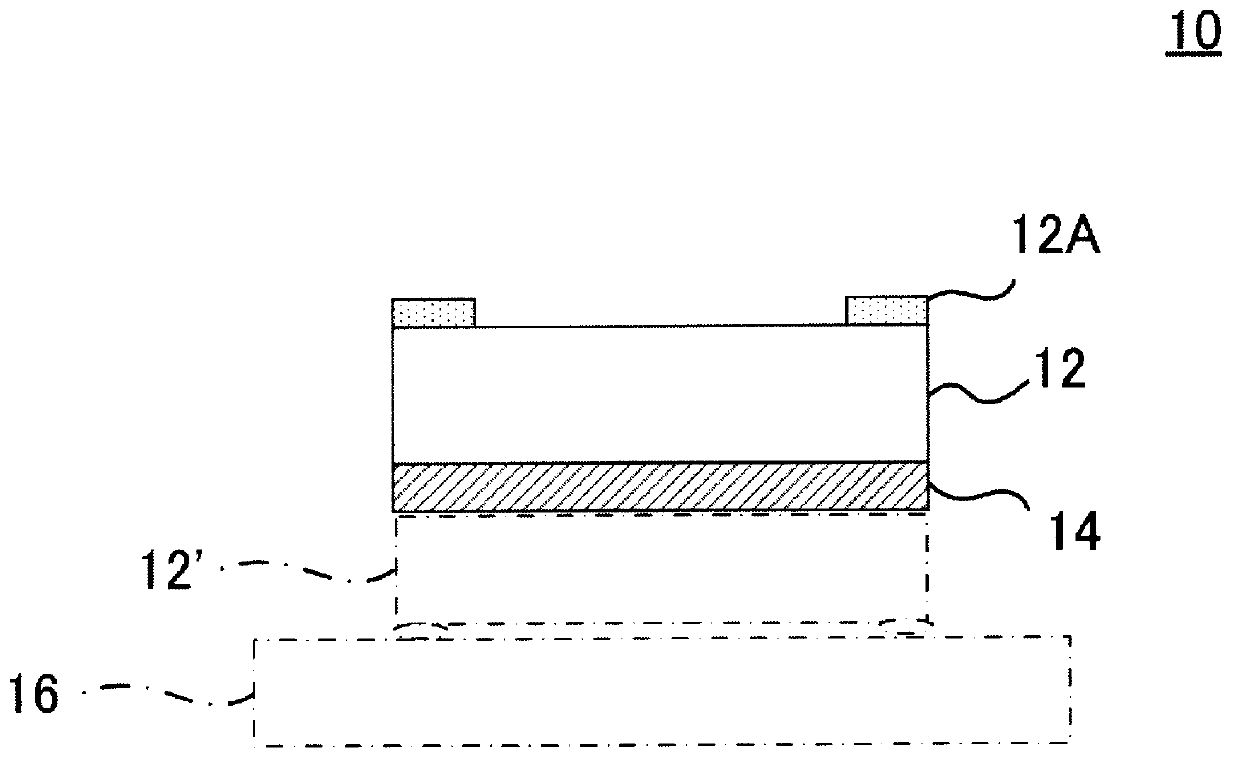

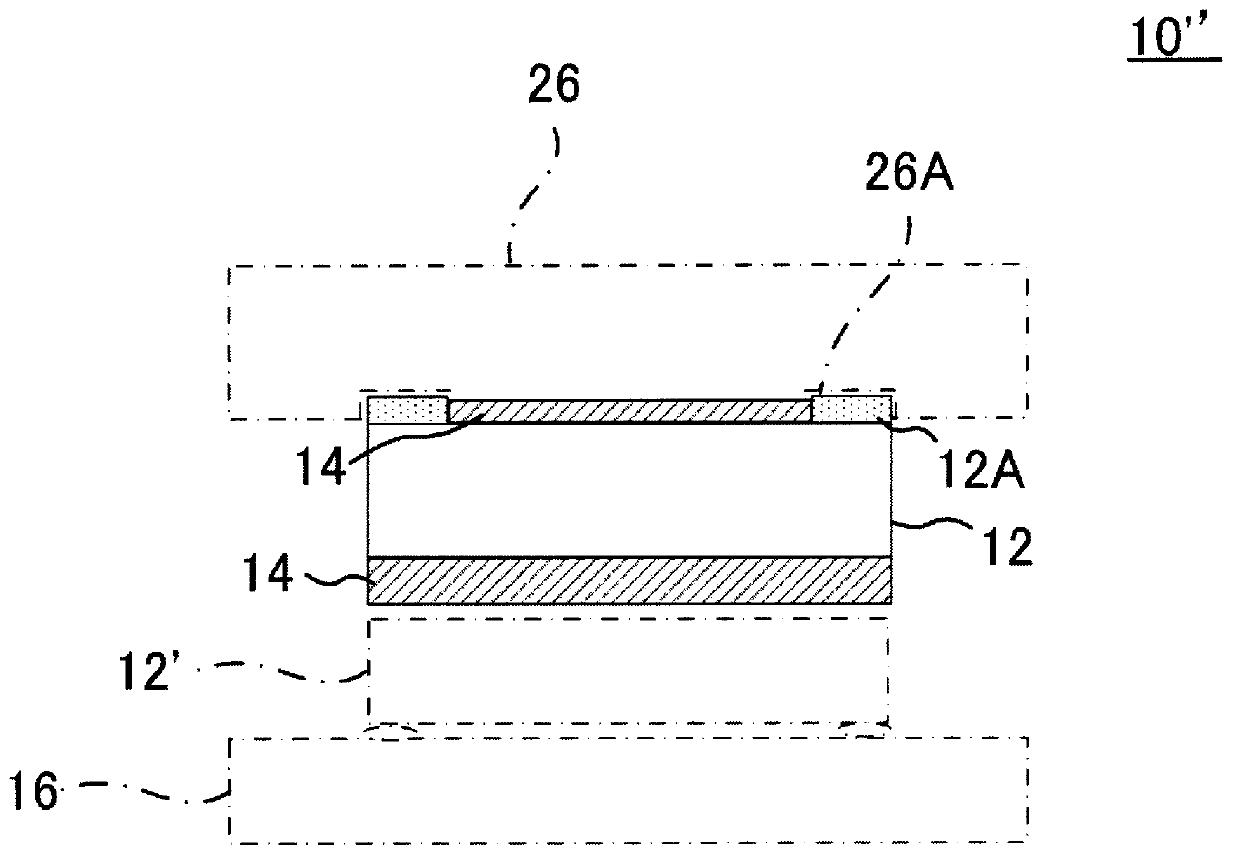

Film adhesive and semiconductor package using the same

InactiveUS20060110595A1Excellent in low-temperature adhesive propertySimple processLayered productsSolid-state devicesShear modulusVitrification

A film adhesive having an adhesive layer (C) mainly containing a thermoplastic polyimide having a glass transition temperature of not more than 100° C. and an adhesive layer (D) having a storage shear modulus of not more than 106 Pa at 50° C. Furthermore, the film adhesive further comprises a base material (A) and an adhesive layer (B). The film adhesive can exhibit excellent low-temperature adhesive property and covering capability functioning as a die bonding adhesive film which can be used in a semiconductor package. In addition, the film adhesive can exhibit excellent low-temperature adhesive property and covering capability which functions both as a die bonding adhesive film and as a dicing tape.

Owner:MITSUI CHEM INC

Instant drying adhesive for plastics

InactiveCN1443822AWater resistantExcellent low temperature adhesionEster polymer adhesivesCellulose acetateAdhesive

The present invention discloses a rapidest adhesive for plastics. It is mainly formed from polymethyl methacrylate resin, dichloromethane, dichloroethane, tetrahydrofuran and acetone. It can be extensively used for instantaneous adhesion bond between plastic self-bodies or mutually them or ABS plastics, PS plastics, HIPS plastics, PMMA plastics, PVC plastics, PC plastics, polysulfones plastics, polyphenyl ether, acetyl cellulose and cellulose propionate. Said adhesive is colourless and trasparent, water-proof, fire-retardant, and is good in low-temp. adhesivity.

Owner:王崇高

Metallurgic refractory brick joint gum type sealer

The invention discloses a metallurgic refractory brick joint gum type sealer, which is composed of the following raw materials in part by weight: 40-50 parts of bauxite clinker powder; 30-40 parts of bonding agent (soft clay); 30-40 parts of high-temperature adhesive; 1-2 parts of cellulose; 1-2 parts of floating agent; 1-2 parts of paper pulp powder and the balance of water. All the raw materials are 80-mesh to 200-mesh fine powders in terms of specification; the preparation method of the gum type sealer comprises the steps: weighing and adding the above raw materials in part by weight into water for being sufficiently mixed, and packaging when slimy mixture is formed. The application finds that, the raw materials of the gum type sealer, which are 80-mesh to 200-mesh fine powders in terms of specification, can meet the demands of sealing different metallurgic refractory brick joints and seams. Based on the raw materials selected and the weight parts thereof in mixture, the purposes of good low-temperature bonding effect, high high-temperature strength and good fire resistance can be achieved. Furthermore, not only the bonding time, which is 2 to 5 hours, is appropriate, but the fluidity bonding degree is satisfactory.

Owner:赵俊淇

Environmental-friendly modified starch / feather protein grafted copolymer composite size, preparation method and application thereof

ActiveCN110820332AExcellent low temperature adhesionReduce surface tensionFibre typesCopolymerMaterials science

The invention provides an environmental-friendly modified starch / feather protein grafted copolymer composite size, a preparation method and application thereof. Waste feather down is taken as a rawmaterial for preparing a feather protein grafted copolymer size, and modified starch is taken as a primary size, particularly, the preparation method includes the steps of firstly, stirring and gelatinizing a modified starch aqueous dispersion into the size at a high temperature, cooling the size as needed, adding the feather protein grafted copolymer aqueous solution which is stirred fully at thesame temperature into the primary size, and stirring fully for a certain time to achieve full compositing, so as to obtain the composite size. The composite size prepared by the method has the advantages that as polar groups of molecular chains of the modified starch and the feather protein grafted copolymer size can be subjected to hydrogen-bond interaction with ester groups on the molecular chains of polylactic acids and can generate Van der Waals' force, and the feather protein grafted copolymer size has low surface tension, low-temperature bonding action of starch to polylactic acid yarnscan be improved greatly, and the composite size is well applicable to low-temperature sizing of polylatic acid warps.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

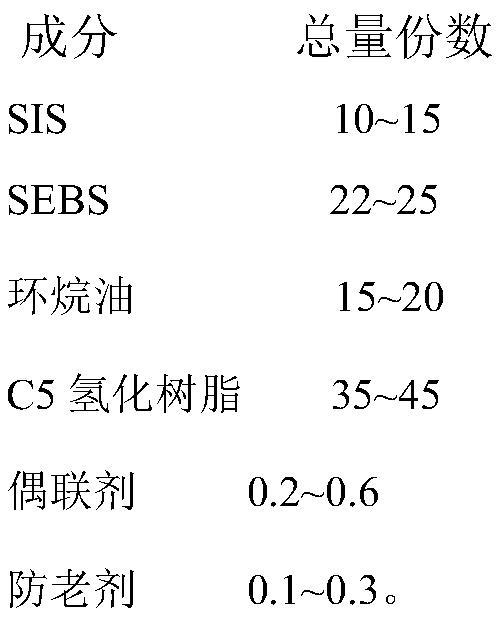

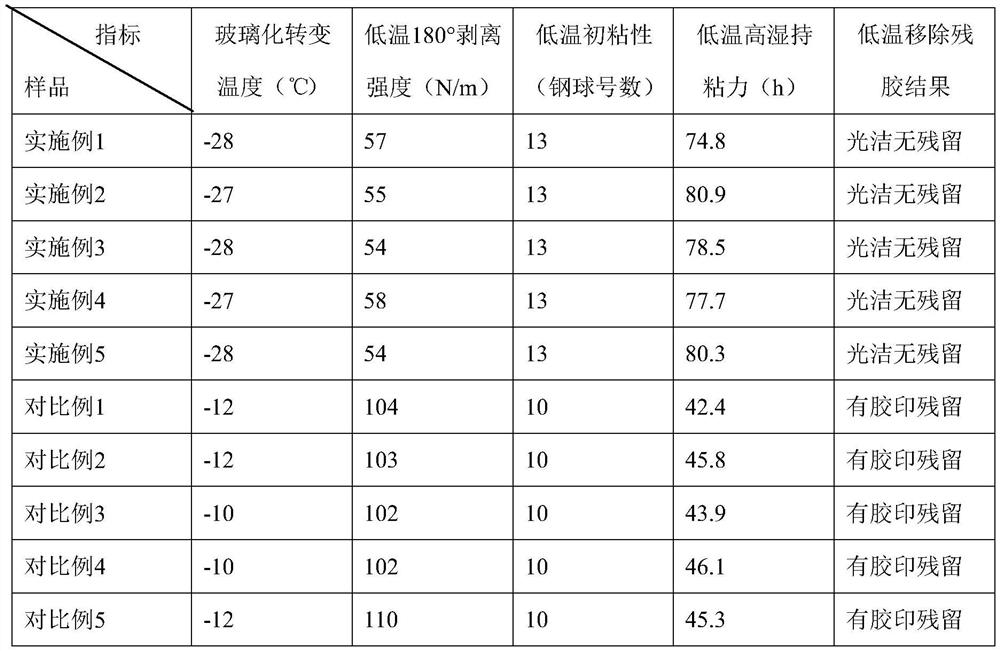

Substrate-free removable rubber-based pressure-sensitive adhesive

InactiveCN112280506ANot easy to precipitateLossless removalNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerAdhesion force

The invention discloses a substrate-free removable rubber pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is prepared from the following raw materials inparts by weight: 20-75 parts of elastomer SIS, 20-60 parts of terpene resin, 1-10 parts of glycerol ester of rosin, 5-40 parts of naphthenic oil, 0.2-1.5 parts of nano silicon dioxide (with the diameter of 20-100nm) and 1-8 parts of an antioxidant. The relative molecular weight of the elastomer SIS is 8 * 10 < 4>-12 * 10 < 4 >, and the S / I block ratio is 20%. The pressure-sensitive adhesive is prepared through adhesive preparation and coating. The pressure-sensitive adhesive is free of base materials, stable in adhesive force, easy to remove at low temperature, free of residual adhesive and free of polluting an attached object.

Owner:ZHONGSHAN TAILI HOUSEHOLD PROD MFG

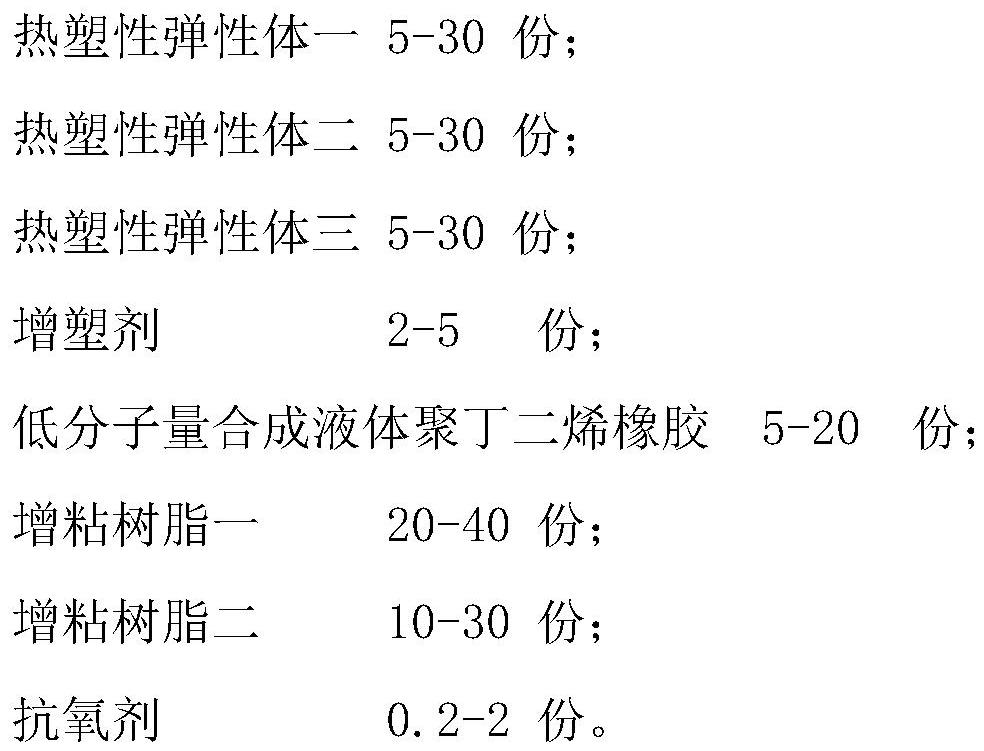

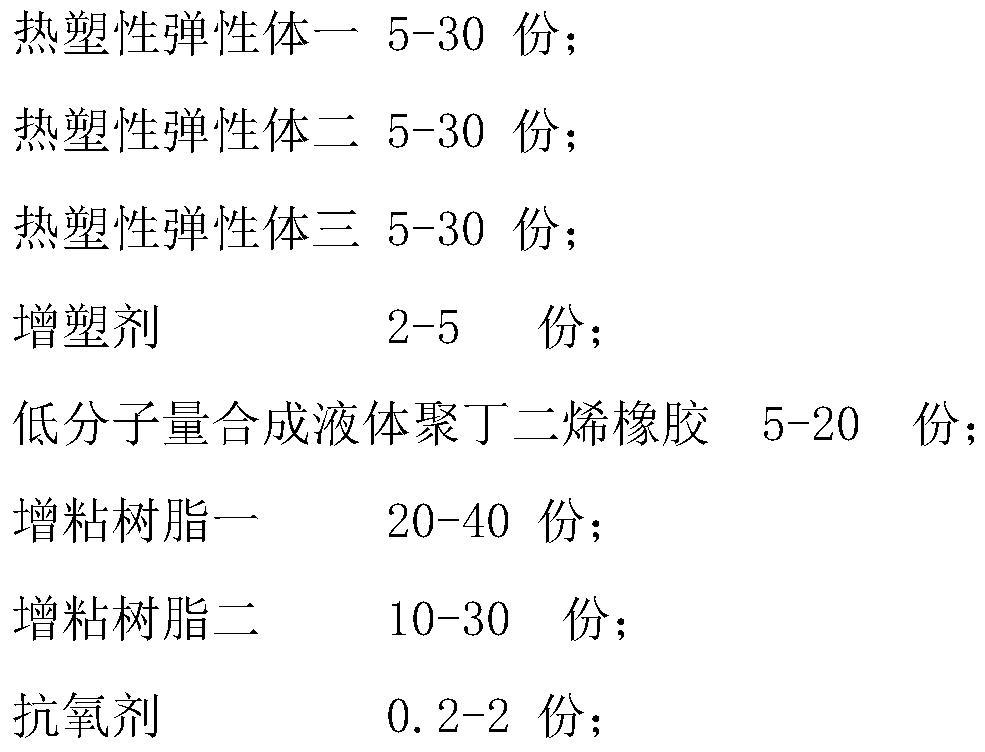

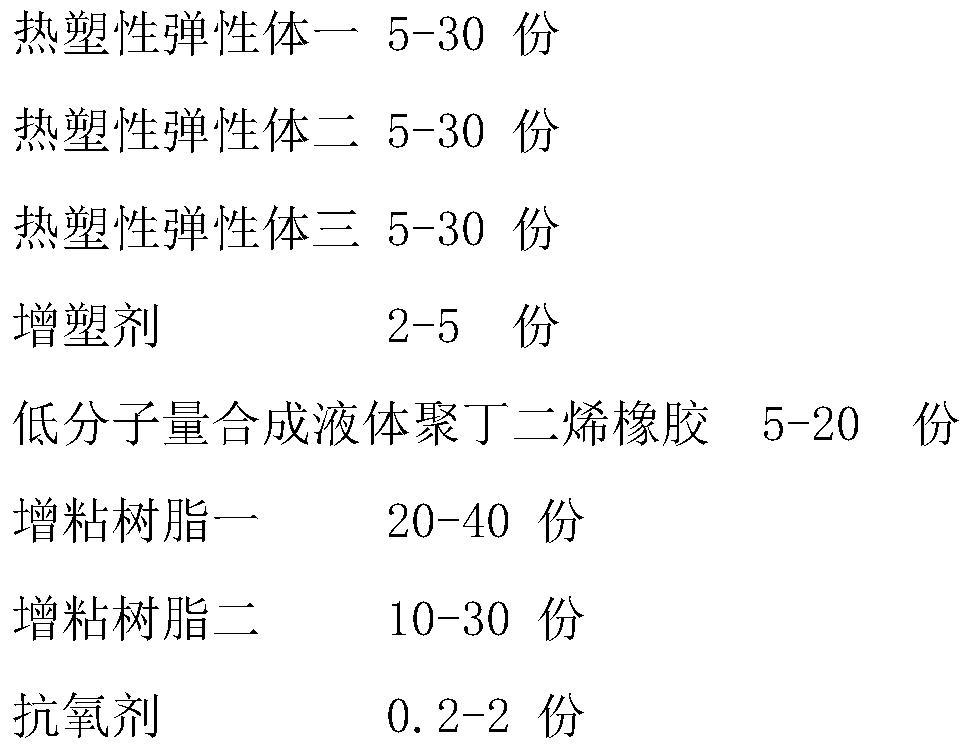

Oil-seepage-resistant, low-temperature-resistant and high-stripping-force hot-melt pressure-sensitive adhesive and preparation method of thereof

InactiveCN111607344AHigh glass transition temperatureLow viscosityMacromolecular adhesive additivesConjugated diene hydrocarbon adhesivesElastomerPolymer science

The invention discloses an oil-seepage-resistant, low-temperature-resistant and high-stripping-force hot-melt pressure-sensitive adhesive and a preparation method thereof. The hot-melt pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 5-30 parts of thermoplastic elastomer I, 5-30 parts of thermoplastic elastomer II, 5-30 parts of thermoplastic elastomer III, 0-5 parts of a plasticizer, 5-20 parts of low molecular weight synthetic liquid polybutadiene rubber, 20 to 40 parts of tackifying resin I, 10 to 30 parts of tackifying resin II, and 0.2 to 2 parts of an antioxidant. According to the oil-seepage-resistant low-temperature-resistant high-stripping-force hot-melt pressure-sensitive adhesive and the preparation method thereof disclosed by the invention, the technical requirements of downstream application on oil seepage resistance and high-stripping-force low temperature resistance are met, and the oil seepage resistance, high stripping forceand low temperature resistance of a hot-melt pressure-sensitive adhesive product are effectively guaranteed.

Owner:浙江金嘉科技有限公司

Film adhesive and semiconductor package using the same

InactiveUS7718258B2Excellent low temperature adhesionCovering capability for unevennessSolid-state devicesSemiconductor/solid-state device manufacturingVitrificationShear modulus

A film adhesive having an adhesive layer (C) mainly containing a thermoplastic polyimide having a glass transition temperature of not more than 100° C. and an adhesive layer (D) having a storage shear modulus of not more than 106 Pa at 50° C. Furthermore, the film adhesive further comprises a base material (A) and an adhesive layer (B). The film adhesive can exhibit excellent low-temperature adhesive property and covering capability functioning as a die bonding adhesive film which can be used in a semiconductor package. In addition, the film adhesive can exhibit excellent low-temperature adhesive property and covering capability which functions both as a die bonding adhesive film and as a dicing tape.

Owner:MITSUI CHEM INC

Manufacturing process of high-adhesion polyurethane automobile instrument panel

The invention belongs to the technical field of polymer materials, and specifically relates to a manufacturing process of a high-adhesion polyurethane automobile instrument panel. The polyurethane automobile instrument panel is manufactured from a material A and a material B, wherein the material A is prepared from polyether polyol, polyester polyol, a catalyst, silicone oil, a chain extender andwater, and the material B is prepared from liquefied MDI and crude MDI. The low-volatility reactive composition materials are selected, the production method is not only environmentally friendly and easy to implement, but also has high bonding performance, and the requirements of middle-and-high end automobile markets for high-cohesion polyurethane automobile instrument panels are met.

Owner:SHANGHAI INST OF TECH

Resin composition and metal laminate plate

InactiveUS8173264B2Excellent low temperature adhesionEasy to disassembleSynthetic resin layered productsElectrical equipmentPolyresinDiamine

A resin composition comprises a polyimide resin composition or precursor thereof obtained from an acid dianhydride component containing a compound represented by the following Formula (1) and a diamine component containing a diamine compound represented by the following Formula (2), and a bismaleimide compound represented by the following Formula (3),wherein the diamine component contains a diamine compound (a) in which m in the Formula (2) represents an integer of 0 or 1 and a diamine component (b) in which m in the Formula (2) represents an integer of 2 to 6 in a molar ratio (a:b) of from 100:0 to 50:50,wherein, in the Formula (2), when m is 2 or more, each X may be independently the same or different, and represents O, SO2, S, CO, CH2, C(CH3)2, C(CF3)2 or a direct bond,wherein, in the Formula (3), n represents an integer of 0 to 6.

Owner:MITSUI CHEM INC

Water-based printing ink composition for gravure printing and method for producing the same

Owner:NANYA PLASTICS CORP

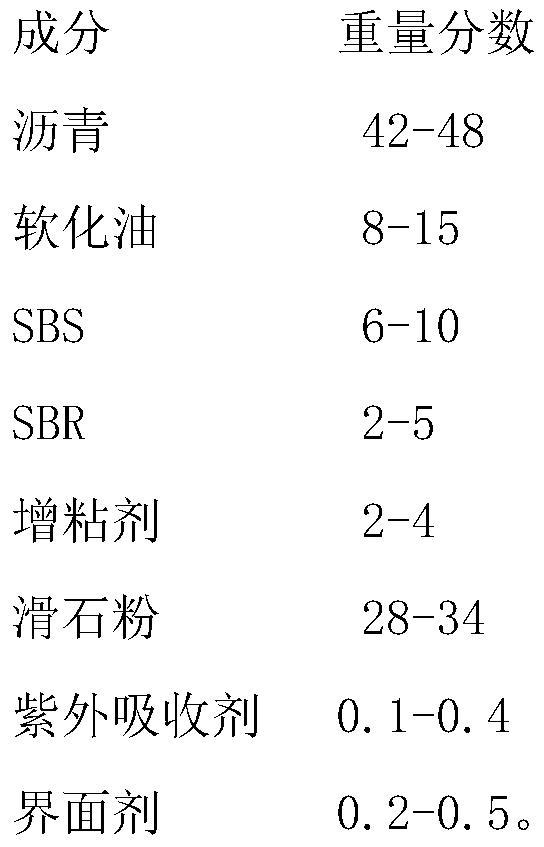

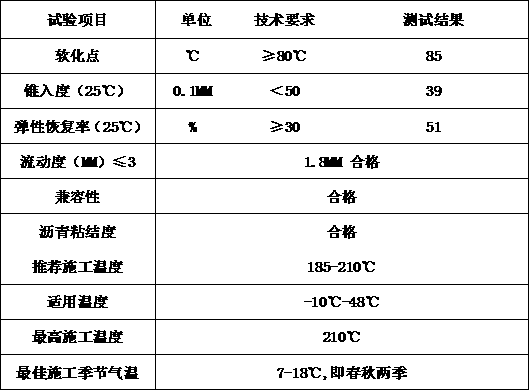

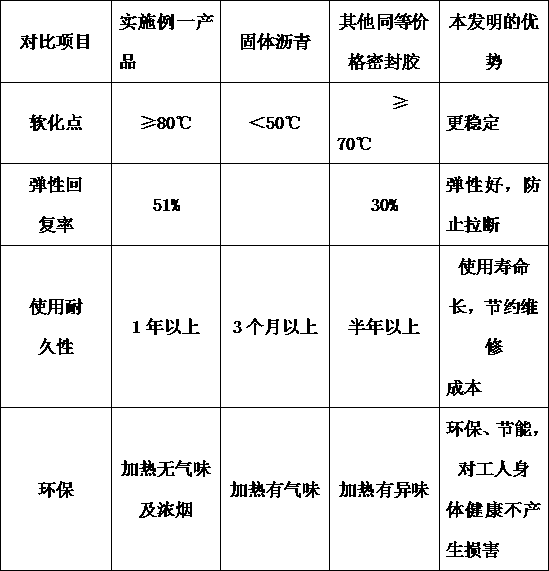

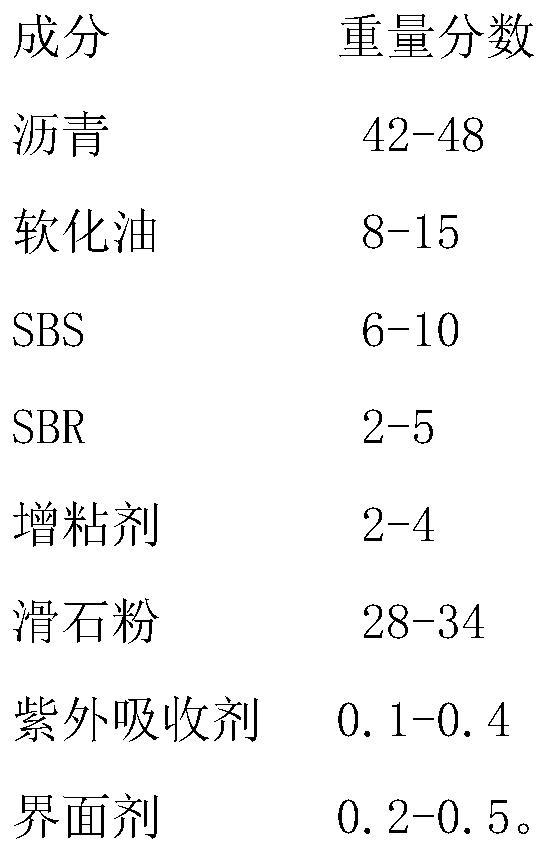

Production and construction technology of a road sealant

ActiveCN105199666BEasy rideTraffic noise is smallNon-macromolecular adhesive additivesBituminous material adhesivesActive agentRoad surface

The invention relates to the technical field of road repair, in particular to production and construction technologies of a road sealant applicable to road crack repair of pavements made of various materials. The road sealant mainly comprises 29% by mass of matrix asphalt, 15% by mass of fine rubber powder, 45% by mass of fossil meal, 0.4% by mass of SBS (styrene butadiene styrene) modified asphalt, 0.4% by mass of butadiene styrene rubber powder, 0.1% by mass of an active agent, 0.1% by mass of a tackifier and 10% by mass of diesel oil. The road sealant has high applicability, can be widely applied to crack pouring repair of asphalt pavements such as asphalt and concrete highways, expressways, high-grade highways, urban highways, airport runways and the like as well as seam sealing repair of cement concrete pavements and can be further applied to expansion joints of bridges or structures; when the construction technology is adopted for construction, the driving feeling on the repaired road is excellent, the traffic noise is small, and various problems that cannot be solved with the traditional technology can be solved by the aid of the excellent sealing performance, waterproofness, high-strength adhesion, high-temperature resistance, good low-temperature adhesion and the like of the road sealant.

Owner:DONGGUAN CHAOYI BUILDING MATERIAL CO LTD

Self-adhesive waterproof membrane material and preparation process of super strong cross-laminated film

ActiveCN111805994BImprove physical performanceHigh tensile strengthNon-macromolecular adhesive additivesSynthetic resin layered productsPolymer scienceAdhesive

The invention relates to a self-adhesive waterproof coiled material of a super-strength cross-lamination film, which comprises an isolation protective layer, a non-asphalt-based self-adhesive layer, a strong cross-lamination film, an asphalt self-adhesive layer and a PE isolation film from top to bottom. There is an overlapping edge on one side of the upper surface of the coiled material, and an overlapping edge is also left on the other side of the lower surface of the coiled material. The waterproof membrane provided by the present invention has better bonding performance with the post-cast concrete than the asphalt-based membrane, and can be better bonded with the main structure (that is, the pre-laid anti-adhesive membrane). The strong cross-laminated membrane in the middle of the membrane has Good ductility, when the base layer subsides or the main structure is slightly deformed, the coil can continue to maintain good adhesion to the main structure without detachment, and it will also have a good waterproof effect.

Owner:TIANJIN JOABOA TECH CO LTD

A kind of anti-peeling instant adhesive and preparation method thereof

InactiveCN105315933BImprove impact resistanceImprove anti-stripping performanceNon-macromolecular adhesive additivesProtein adhesivesEthyl-2-cyanoacrylateGelatin

The invention discloses an anti-stripping cyanoacrylate adhesive. The anti-stripping cyanoacrylate adhesive is prepared from, by weight, 30-50 parts of alpha-ethyl cyanoacrylate, 0.5-4 parts of EVA, 2-5 parts of beta-propiolactone, 0.5-1 part of modified titanium oxide, 8-12 parts of gelatin, 5-10 parts of polyacrylate, 2-8 parts of galactomannan, 3-8 parts of hydroxyethyl cellulose and 1-1.5 parts of coupling agent. The invention further discloses a preparation method of the anti-stripping cyanoacrylate adhesive. The anti-stripping cyanoacrylate adhesive is high in curing speed, good in water resistance, high in impact resistance, large in bonding strength, good in anti-stripping performance, small in use amount, free of toxicity and beneficial to environmental protection.

Owner:ZHEJIANG TIME NEW MATERIAL

Asphalt waterproof paint for building and preparation method thereof

InactiveCN101921545BUnique performanceImprove performanceUnspecified rubber coatingsBituminous coatingsChemical industryBituminous waterproofing

The invention relates to an asphalt waterproof paint for a building and a preparation method thereof, belonging to the technical field of chemical industry. The asphalt waterproof paint for a building comprises the following raw materials according to parts by weight: 20-25 parts of plasticizer, 6-8 parts of modifier, 25-30 parts of asphalt, 20-30 parts of filler, 4-6 parts of tackifier, 0.2-0.3 parts of crosslink coupling agent, and 0.3-0.5 parts of dispersing agent. The invention has the advantages of reasonable compound design, good intensity, safety, environmental protection and stable product quality, and is capable of adapting the climatic conditions at high and low temperatures.

Owner:嘉兴市博豪家纺有限公司

Weather-proof long-life waterproof anti-corrosion flame-retardant integrated coating and preparation method thereof

InactiveCN111205704AThe solution is not self-healingSolve flame retardancyFireproof paintsConjugated diene hydrocarbon coatingsElastomerUltraviolet lights

The invention belongs to the technical field of waterproof anticorrosive coating, and in particular, relates to a weather-proof long-service-life waterproof anti-corrosion flame-retardant integrated coating comprising, by the weight percentage, 20-50% of regenerated dehydrated bio-oil, 5-20% of coal ash, 10-40% of an elastomer, 5-28% of tackifying resin, 2-8% of a wetting agent, 0.5-5% of a modifier, 3-10% of a flame retardant, 0.5-2% of an ultraviolet light absorber, 0.5-2% of an antioxidant and 2-10% of zinc oxide. The invention further discloses a preparation method of the weather-resistantlong-service-life waterproof anti-corrosion flame-retardant integrated coating. The weather-resistant long-service-life waterproof anti-corrosion flame-retardant integrated coating disclosed by the invention has the advantages of ultraviolet resistance, aging resistance, acid, alkali and salt corrosion resistance, flame retardance, strong base layer adhesive force, good low-temperature cohesiveness, good creep self-healing property, low construction energy consumption, safety and environmental protection.

Owner:金华一方金雨伞防水科技有限公司

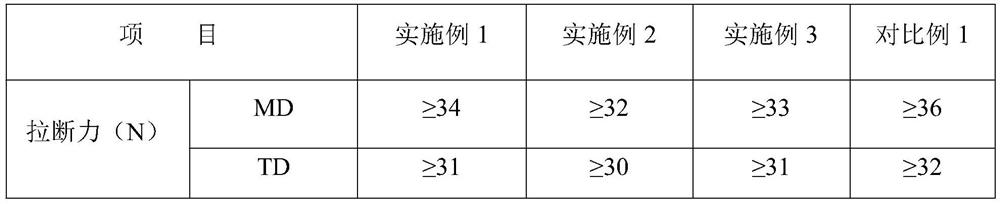

Paper-plastic composite packaging material with high air permeability and preparation method thereof

The invention provides a paper-plastic composite packaging material with high air permeability and a preparation method thereof. The preparation method comprises a film blowing production process, a hot needle micropore process and a hot laminating compounding process;a PE film material with high air permeability is obtained by optimizing a formula of a PE film and performing micropore treatment on the modified PE film; then a conventional adhesive dry compounding mode and a PE particle extrusion compounding mode are avoided, and paper-plastic packaging materials are compounded in a hot laminating manner, so micropores in a modified polyethylene PE film are prevented from being blocked by dry laminating or extrusion laminating; and finally, the PE film material with stable and excellent air permeability is obtained, shows excellent thermal stability, impact resistance, heat sealability and excellent low-temperature adhesive property, is applied to the fields of daily life article packaging, medicine, the clothing industry, electrical elements and the like, and meets the specific requirements of customer markets.

Owner:HUANGSHAN NOVEL

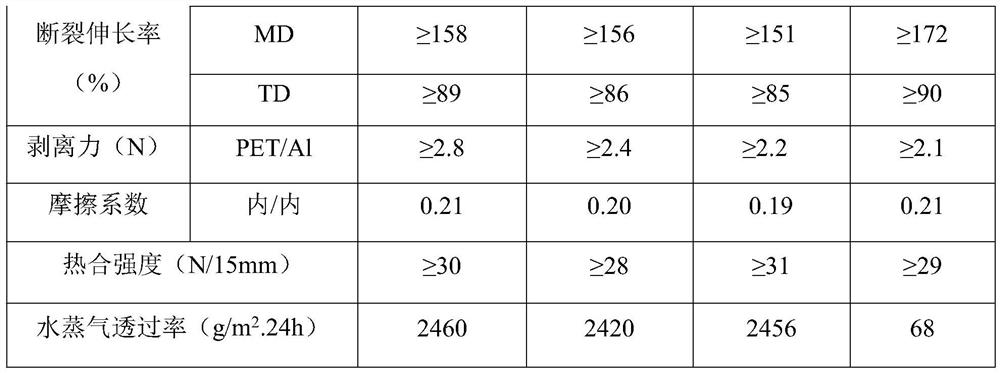

Multilayer film and method for producing same

ActiveCN110719843AWith shape retentionExcellent low temperature adhesionSynthetic resin layered productsDomestic articlesElastomerMultilayer membrane

The present invention addresses the problem of providing: a multilayer film which has excellent handling properties and excellent low-temperature adhesiveness to objects of interest made from variousmaterials and can be used for various decorative molding into three-dimensional shapes, and for which the material and the decoration technique can be selected highly flexibility; and a method for producing the multilayer film. The present invention that can solve the problem is a multilayer film which is composed of a multilayer film composed of an intermediate layer (X) and layers (Y) respectively arranged on both surfaces of the intermediate layer (X), and a decorative layer (Z) closely arranged on the surface of either one of the layers (Y), wherein the intermediate layer (X) is composed of a thermoplastic resin layer having a bending stiffness modulus of 60 to 30000 kPa*mm3, and each of the layers (Y) is made from a thermoplastic polymer composition containing a thermoplastic elastomer (A) that is a block copolymer containing an aromatic vinyl compound block (a1) and a conjugated diene compound block (a2) and a polypropylene resin (B) in an amount of 0 to 50 parts by mass relativeto the amount of the thermoplastic elastomer (A). The present invention is also a method for producing the multilayer film, characterized by comprising bringing the thermoplastic resin layers (Y) that serve as the surface layers and are in a molten state into contact with a roll having a surface made from a hydrophobic resin.

Owner:KURARAY CO LTD

A kind of environment-friendly modified starch/feather protein graft copolymer composite slurry, preparation method and application thereof

ActiveCN110820332BExcellent low temperature adhesionReduce surface tensionFibre typesYarnPolymer science

The invention provides an environment-friendly modified starch / feather protein graft copolymer composite slurry, a preparation method and application thereof. Use waste feather down as raw material to prepare feather protein graft copolymer slurry, and use modified starch as the main slurry. First, the modified starch aqueous dispersion is stirred and gelatinized at high temperature to form a slurry, and then cooled to the required temperature. , add the feather protein graft copolymer aqueous solution which has been fully stirred for a certain period of time at the same temperature as the main slurry, and fully stir for a certain period of time to fully compound to obtain the composite slurry. The composite slurry prepared by the present invention utilizes the modified starch and the polar group of the feather protein graft copolymer slurry molecular chain to hydrogen bond with the ester group on the polylactic acid molecular chain and generate van der Waals force, and with the help of feather protein The low surface tension of the graft copolymer size significantly improves the low-temperature adhesion of starch to polylactic acid yarns, and is very suitable for low-temperature sizing of polylactic acid warp yarns.

Owner:ANHUI POLYTECHNIC UNIV

Tundish coating

InactiveCN111320459AReduce viscosityIncreased flow and thermal insulation propertiesMelt-holding vesselsTundishCorrosion

The invention provides a tundish coating. The tundish coating is prepared from the following raw materials in parts by weight: 80-100 parts of medium-grade sintered magnesia, 7-12 parts of slaked lime, 15-25 parts of glass fibers, 10-20 parts of aluminum powder, 5-12 parts of melamine, 3-10 parts of rosin, 10-15 parts of magnesium sulfate, 20-30 parts of hollow ceramic micro beads and 14-18 partsof aluminum chloride. The raw materials are wide in source, and the obtained tundish coating is long in service life, has a heat preservation performance and corrosion resistance, can further purify molten steel, and is good in low-temperature cohesiveness, high in adhesive force, good in effect and wide in application potential.

Owner:洪江市三兴冶金炉料有限责任公司

Instant drying adhesive for plastics

InactiveCN1195037CWater resistantExcellent low temperature adhesionEster polymer adhesivesCellulose acetateAdhesive

The present invention discloses a rapidest adhesive for plastics. It is mainly formed from polymethyl methacrylate resin, dichloromethane, dichloroethane, tetrahydrofuran and acetone. It can be extensively used for instantaneous adhesion bond between plastic self-bodies or mutually them or ABS plastics, PS plastics, HIPS plastics, PMMA plastics, PVC plastics, PC plastics, polysulfones plastics, polyphenyl ether, acetyl cellulose and cellulose propionate. Said adhesive is colourless and trasparent, water-proof, fire-retardant, and is good in low-temp. adhesivity.

Owner:王崇高

Instant adhesive

InactiveCN102994022BExcellent low temperature adhesionLow priceNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceDistillation

The invention discloses an instant adhesive. The instant adhesive is prepared from the following raw materials: polymethyl methacrylate, ethyl cyanoacetate, 30-35% formaldehyde, piperidine, dichloroethane, a hydroquinone polymerization inhibitor and modified sepiolite. The instant adhesive is prepared by the following steps of: based on parts by weight, mixing the polymethyl methacrylate, the piperidine, the ethyl cyanoacetate and the 35% formaldehyde and then adding the obtained mixture into a reaction kettle to react for 1 hour at 70 DEG C when heated; and then adding the hydroquinone polymerization inhibitor, the modified sepiolite and the dichloroethane for reduced pressure distillation at 180 DEG C. The instant adhesive disclosed by the invention is an adhesive which has single component and is instantly cured on meeting moisture, and is convenient to use, the adhered surface needs no special pretreatment, heating and pressurizing are not necessary, and the adhesive is widely applied to the adhesion and location between plastics, and between the plastic and metal, is water-fast, cannot be combusted, is good in low-temperature adhesion property, and is low in cost.

Owner:ANHUI DONGFANGJINHE PRECISION MACHINERY MFG +1

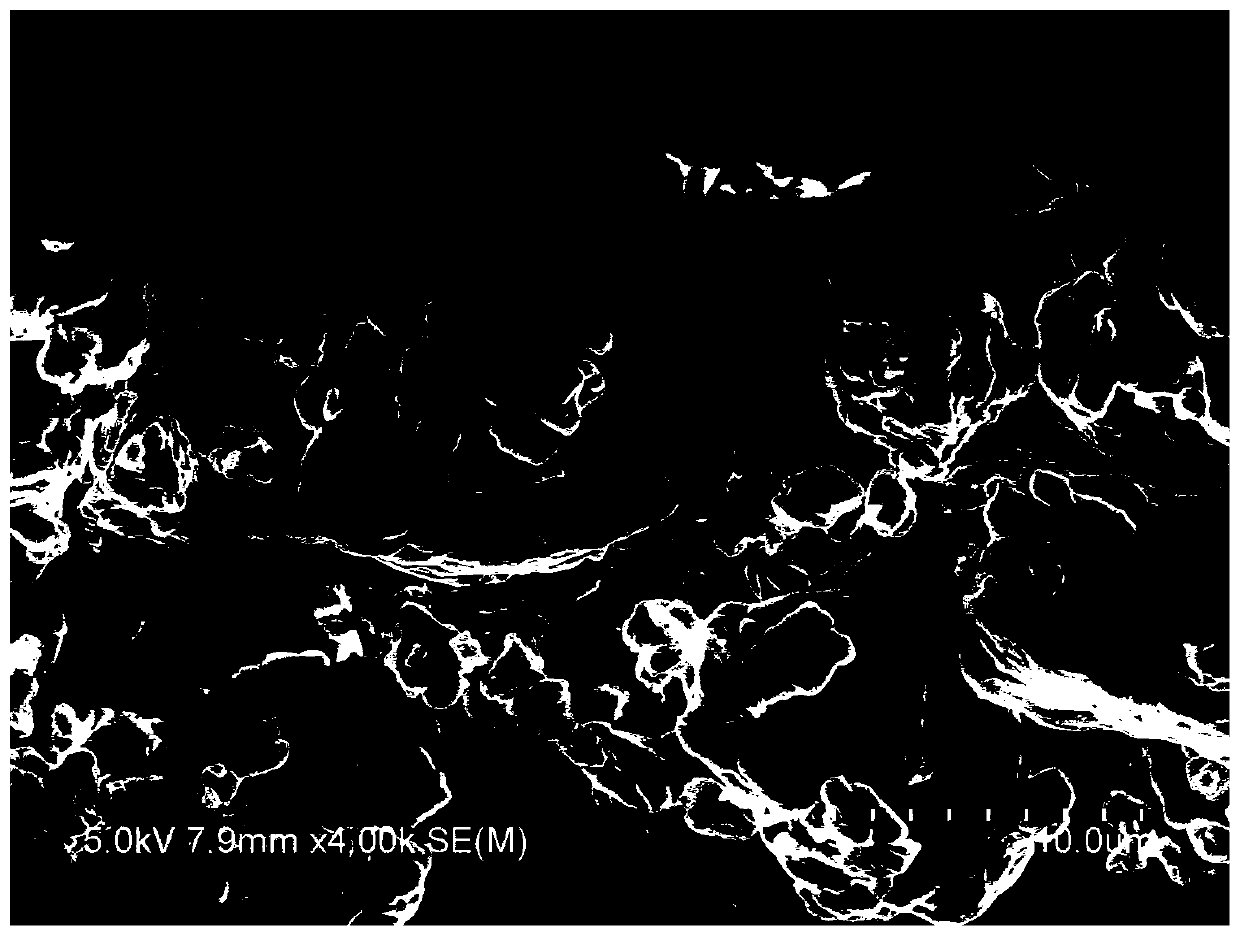

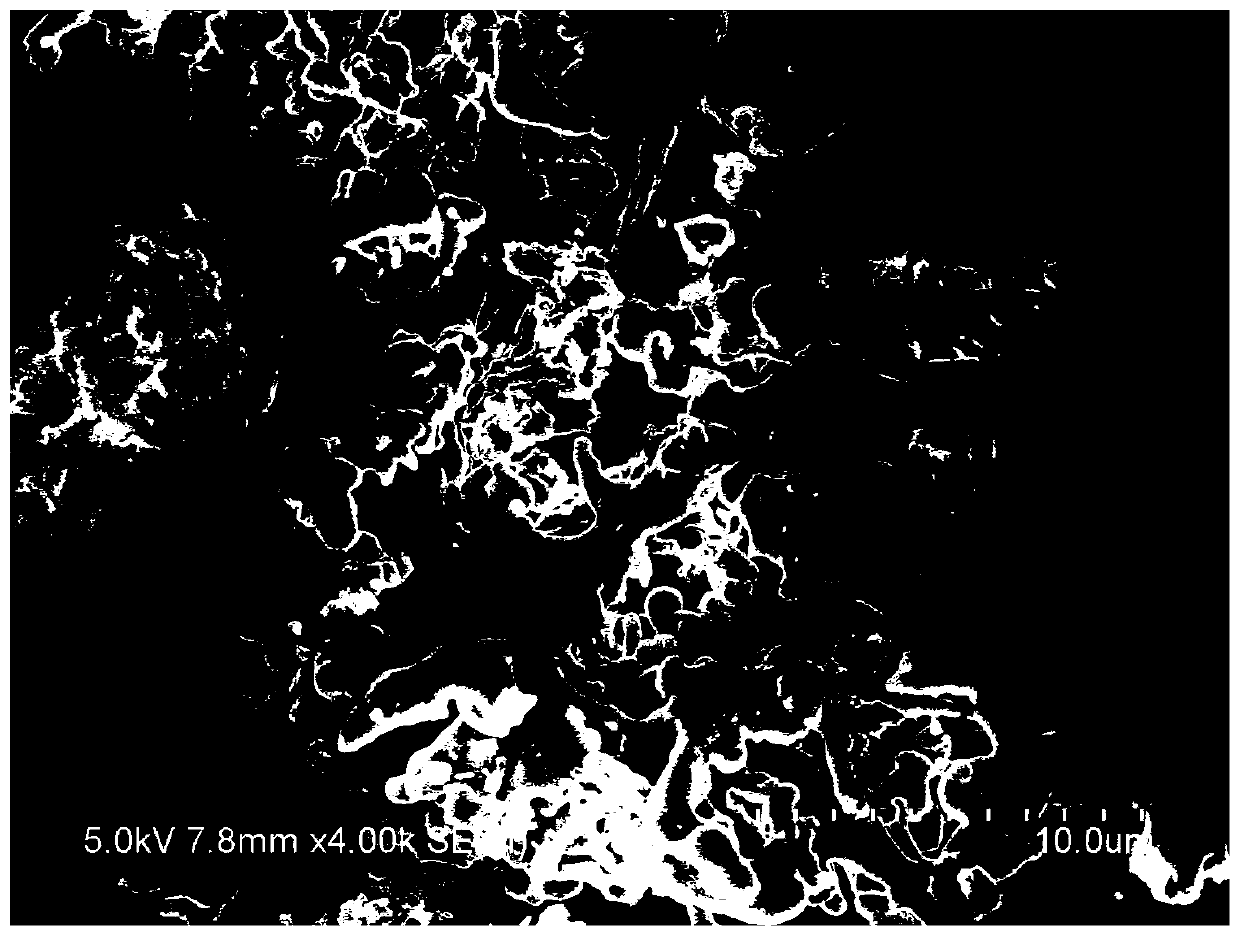

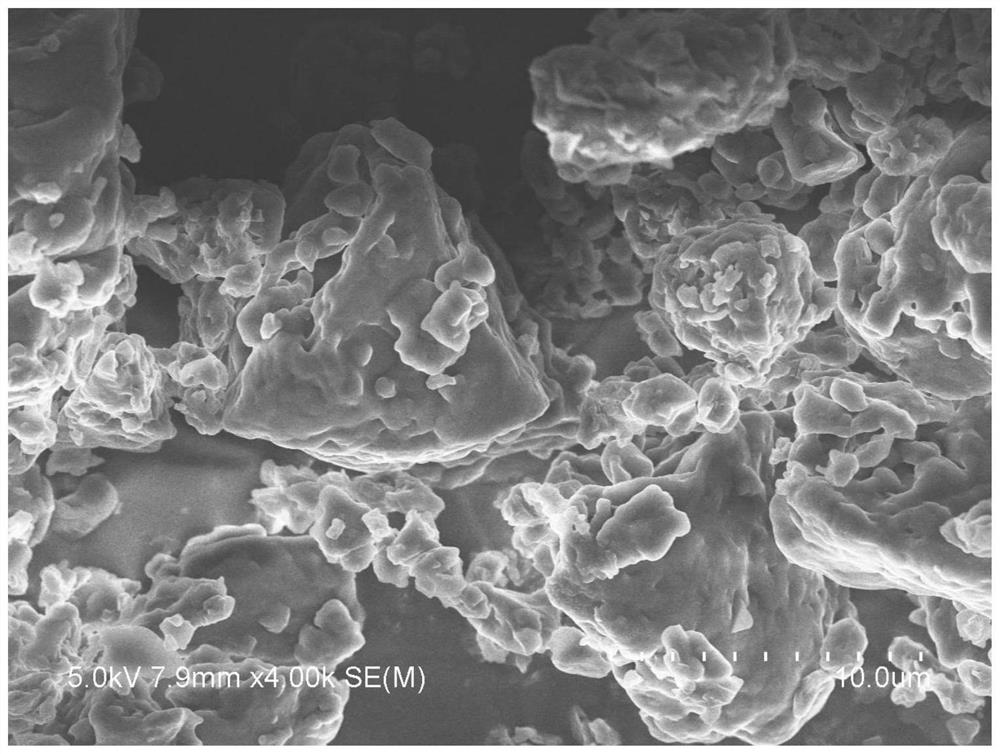

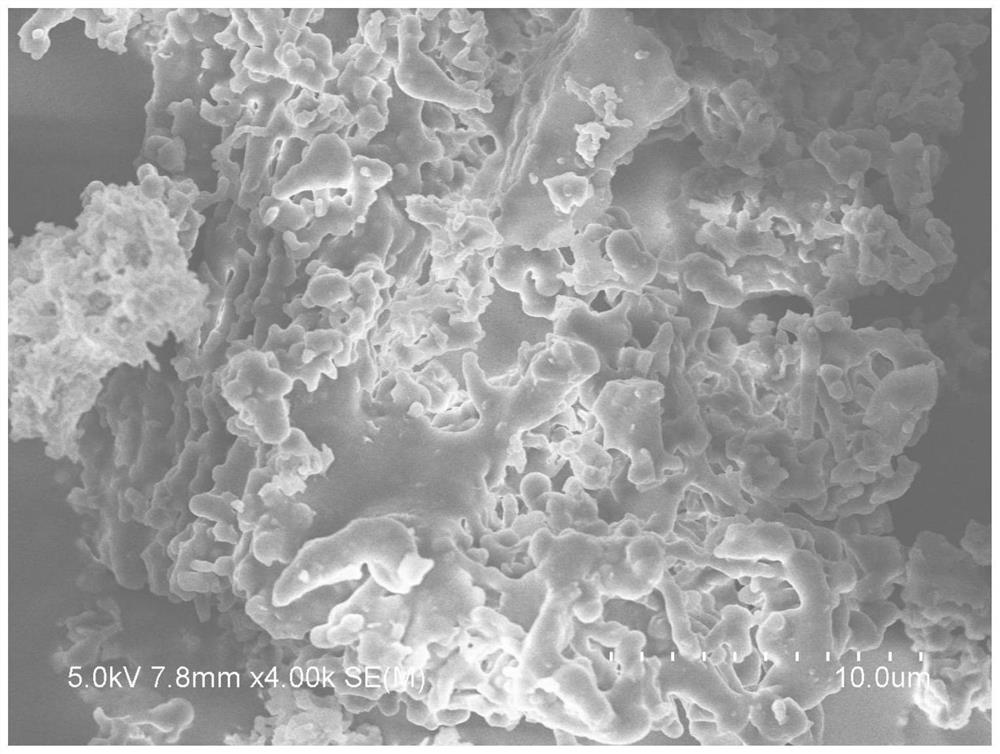

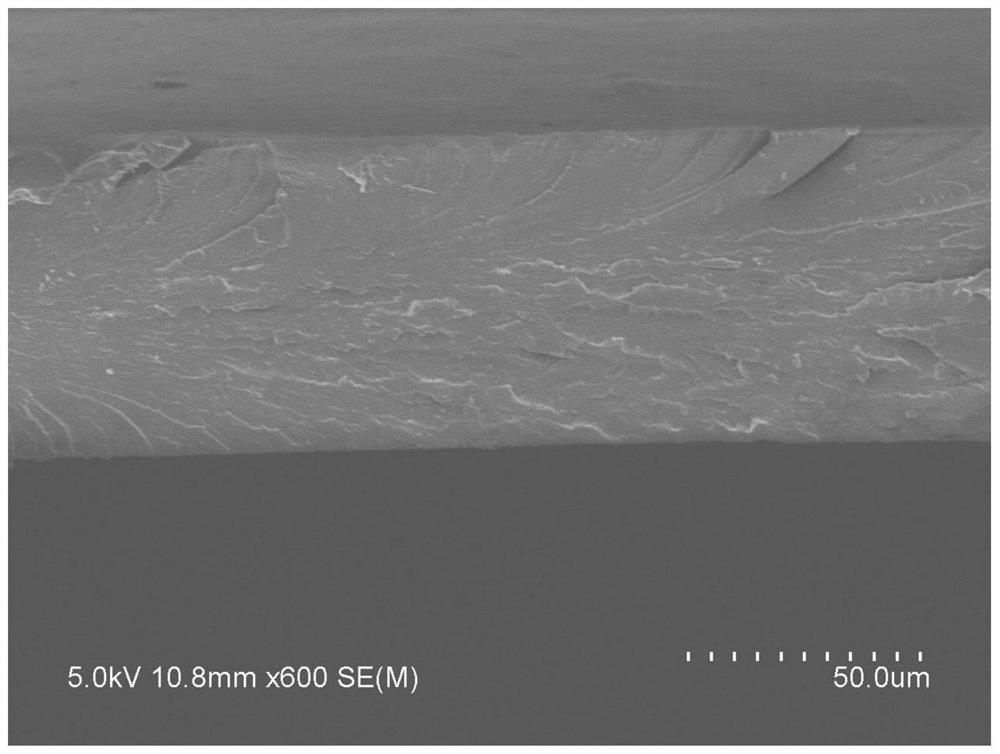

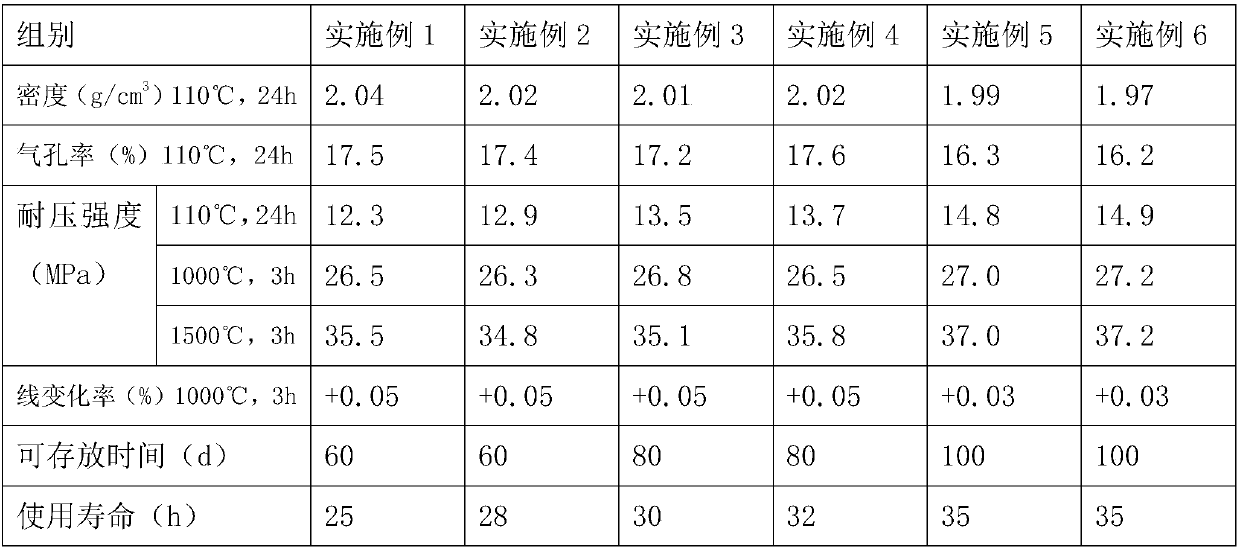

Microporous ceramic, ceramic heating element and preparation method and application thereof

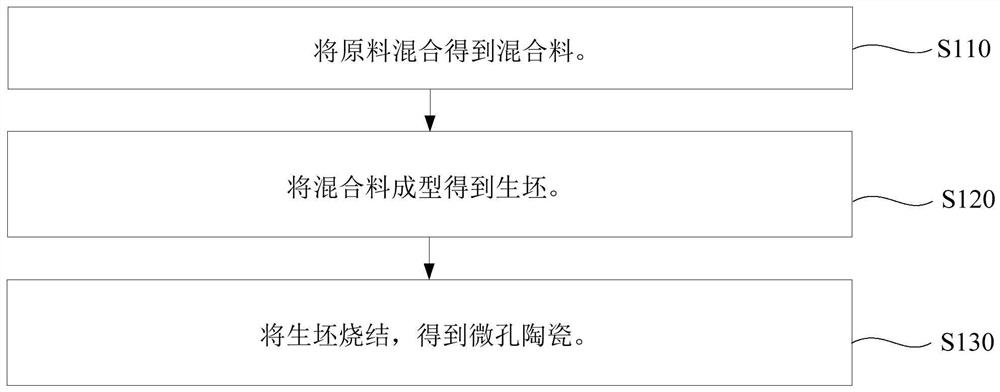

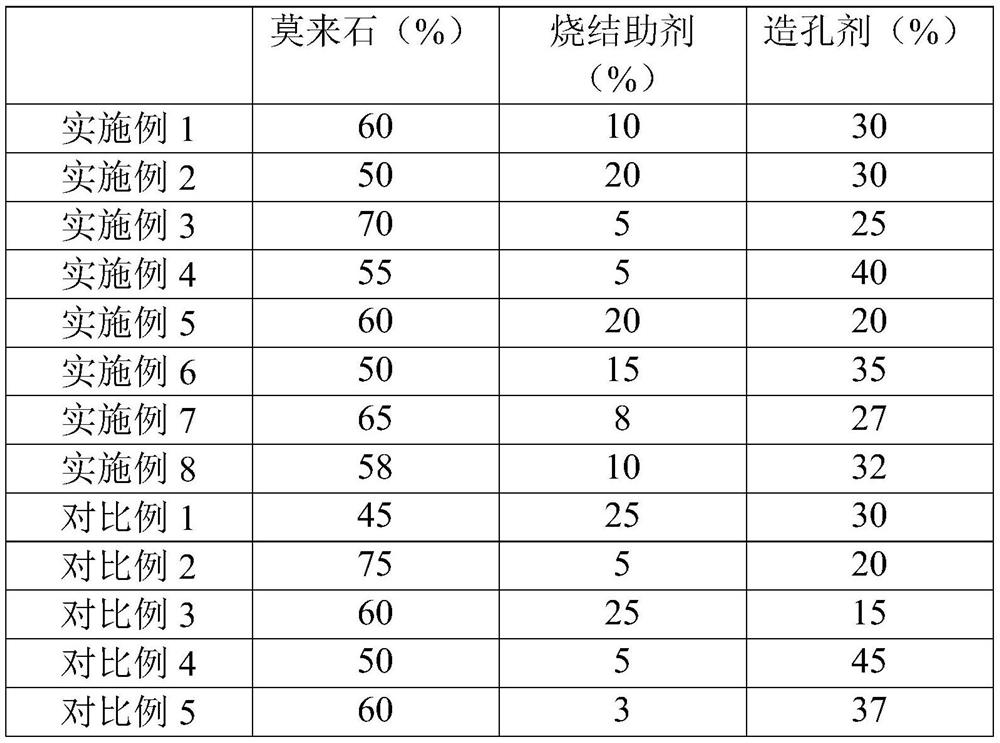

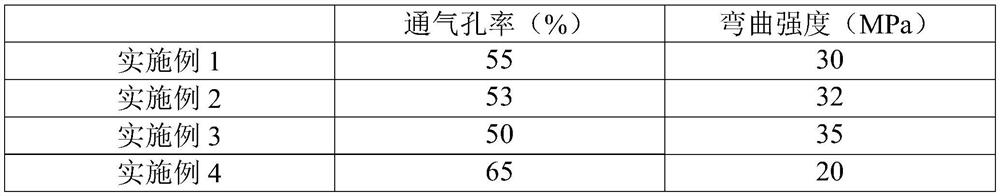

The invention relates to a microporous ceramic, a ceramic heating element and a preparation method and application thereof. The preparation method of the microporous ceramics comprises the following steps: mixing raw materials to obtain a mixture, wherein, in terms of mass percentage, the raw materials include the following components: 50% to 70% of mullite, 5% to 20% % sintering aid and 20% to 40% pore-forming agent, the sintering aid is glass powder with a melting point less than or equal to 500°C, the pore-forming agent is fibrous, and the length of the pore-forming agent is 100 microns to 200 microns, The diameter is 40 microns to 60 microns; molding the mixture to obtain a green body; sintering the green body to obtain microporous ceramics. The microporous ceramics prepared by the above preparation method have both high ventilation porosity and high strength.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com