A kind of anti-peeling instant adhesive and preparation method thereof

An instant adhesive and anti-peeling technology, which is applied in the preparation of animal glue or gelatin, adhesives, grafted polymer adhesives, etc., can solve the problems of high viscosity and large usage, and achieve the improvement of bonding strength and curing Fast speed and good peeling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

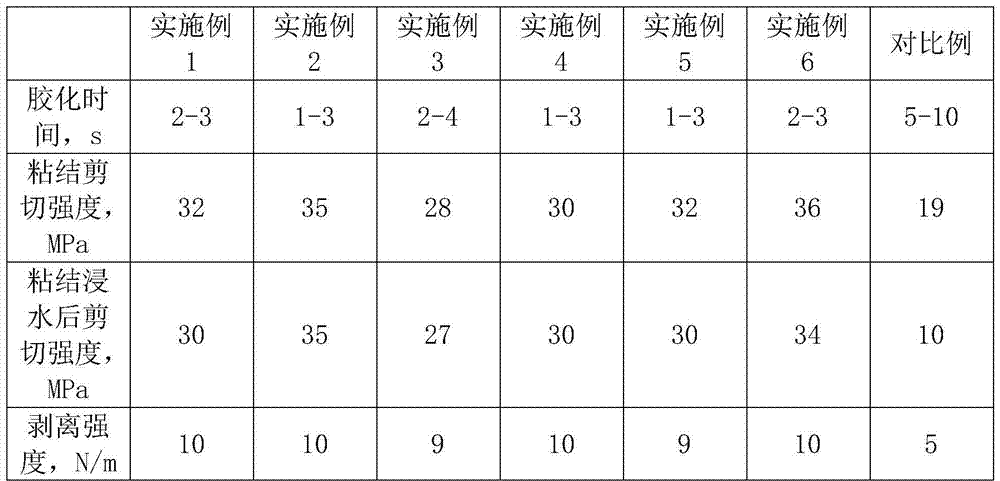

Examples

Embodiment 1

[0034] An anti-peeling instant adhesive, in parts by weight, comprises the following components:

[0035] 30 parts of ethyl α-cyanoacrylate,

[0036] 0.5 parts of EVA, 2 parts of β-propiolactone,

[0037] 0.5 parts of modified titanium oxide, 8 parts of gelatin,

[0038] 5 parts polyacrylate, 2 parts galactomannan,

[0039] 3 parts of hydroxyethyl cellulose, 1 part of coupling agent.

[0040] Its preparation method comprises the following steps:

[0041] (1) Mix and stir α-ethyl cyanoacrylate, EVA, β-propiolactone and polyacrylate evenly, heat and react at 100°C for 1 hour, cool down to 70°C, add galactomannan, hydroxyethyl Base cellulose and coupling agent, heated and melted for 1 hour to obtain a mixed material;

[0042] (2) Add gelatin and modified titanium oxide to the mixed material obtained in step (1), and distill under reduced pressure at 150° C. to obtain an anti-peeling instant adhesive.

Embodiment 2

[0044] An anti-peeling instant adhesive, in parts by weight, comprises the following components:

[0045] 50 parts of ethyl α-cyanoacrylate,

[0046] 4 parts of EVA, 5 parts of β-propiolactone,

[0047] 1 part of modified titanium oxide, 12 parts of gelatin,

[0048] 10 parts of polyacrylate, 8 parts of galactomannan,

[0049] 8 parts of hydroxyethyl cellulose, 1.5 parts of coupling agent.

[0050] Its preparation method comprises the following steps:

[0051] (1) Mix and stir α-ethyl cyanoacrylate, EVA, β-propiolactone and polyacrylate evenly, heat and react at 120°C for 3 hours, cool down to 80°C, add galactomannan, hydroxyethyl Base cellulose and coupling agent, heated and melted for 2 hours to obtain a mixed material;

[0052] (2) Add gelatin and modified titanium oxide to the mixed material obtained in step (1), and distill under reduced pressure at 150-180° C. to obtain an anti-peeling instant adhesive.

Embodiment 3

[0054] An anti-peeling instant adhesive, in parts by weight, comprises the following components:

[0055] 35 parts of ethyl α-cyanoacrylate,

[0056] 1 part of EVA, 2.5 parts of β-propiolactone,

[0057] 0.6 parts of modified titanium oxide, 9 parts of gelatin,

[0058] 6 parts polyacrylate, 3 parts galactomannan,

[0059] 4 parts of hydroxyethyl cellulose, 1.1 parts of coupling agent.

[0060] Its preparation method comprises the following steps:

[0061] (1) Mix and stir α-ethyl cyanoacrylate, EVA, β-propiolactone and polyacrylate evenly, heat and react at 105°C for 1.5h, cool down to 75°C, add galactomannan, hydroxyl Ethyl cellulose and a coupling agent were heated and melted for 1.2 hours to obtain a mixed material;

[0062] (2) Add gelatin and modified titanium oxide to the mixed material obtained in step (1), and distill under reduced pressure at 155° C. to obtain an anti-peeling instant adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com