Multilayer film and method for producing same

A manufacturing method and multi-layer film technology, applied to chemical instruments and methods, coatings, flat products, etc., can solve the problem of decreased adhesion between decorative films and moldings, and achieve excellent low-temperature adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0107] The method for preparing the resin used as the raw material of the above-mentioned resin film is not particularly limited, and any method can be used as long as the above-mentioned components can be uniformly mixed, and the method of mixing by melt-kneading is preferable.

[0108] The decorative layer (Z) can be colored. Examples of the coloring method include: a method in which the resin itself that constitutes the resin film contains a pigment or a dye, thereby coloring the resin itself before film formation; a dyeing method in which the resin film is dipped in a liquid in which a dye is dispersed and colored, etc. , but is not limited to these methods.

[0109] The decorative layer (Z) can be printed. Designs and colors such as patterns, characters, and graphics are given by printing. The pattern can be a colored pattern or an achromatic pattern. In order to prevent discoloration of the printed layer, printing may be performed on the side in contact with the therm...

Embodiment

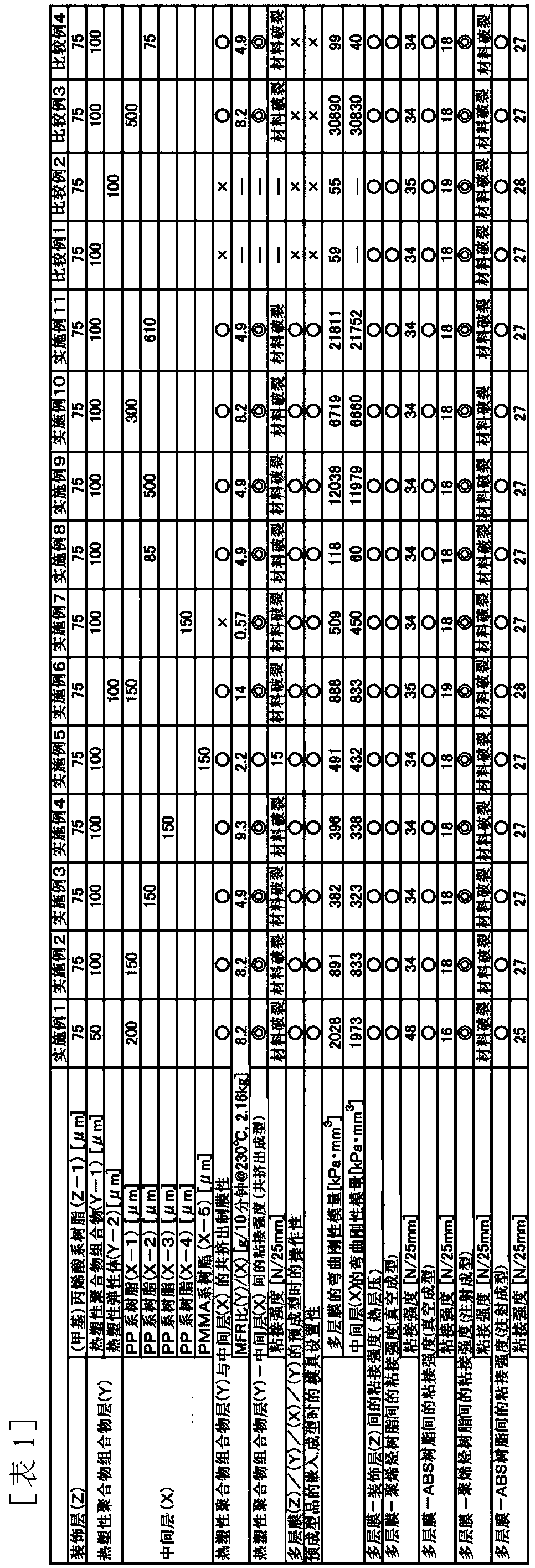

[0129] Hereinafter, although an Example etc. demonstrate this invention in more detail, this invention is not limited to these Examples at all. Preparation of test samples and measurement or evaluation of various physical properties in Examples and Comparative Examples were performed as follows, and the results are summarized in the table.

[0130] Each component used in this Example and a comparative example is as follows.

[0131] [multilayer film]

[0132]

[0133] As the intermediate layer (X), the following resins were used.

[0134] ・Polypropylene-based resin (X-1) Polypropylene-based resin CALP-E4361-1 (with talc, melting point = 125°C, heat of fusion = 404mJ, crystallinity = 27 (as a value in the polypropylene matrix), MFR =0.9g / 10min, tensile modulus of elasticity at 23°C E=2960000kPa)

[0135] · Polypropylene-based resin (X-2) polypropylene-based resin Novatec EG7FTB (polypropylene-ethylene random copolymer, melting point = 149°C, heat of fusion = 437mJ, crystal...

Synthetic example 1

[0205] [Thermoplastic Elastomer (A-1)]

[0206] 64 L of cyclohexane as a solvent, 0.20 L of sec-butyllithium (10% by mass cyclohexane solution) as an initiator, and 0.3 L of tetrahydrofuran as an organic Lewis base were charged into the pressure-resistant container after nitrogen substitution and drying. After the temperature was raised to 50° C., 2.3 L of styrene was added and polymerized for 3 hours, then 23 L of isoprene was added and polymerized for 4 hours, and 2.3 L of styrene was further added and polymerized for 3 hours. The obtained reaction solution was poured into 80 L of methanol, and the precipitated solid was filtered off and dried at 50° C. for 20 hours to obtain a triblock copolymer composed of polystyrene-polyisoprene-polystyrene. Next, 10 kg of a triblock copolymer composed of polystyrene-polyisoprene-polystyrene was dissolved in 200 L of cyclohexane, and palladium carbon ( Palladium supported amount: 5% by mass), the reaction was carried out for 10 hours u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com